Log in

Search

Latest topics

» How's the weather?by HalfaDave Today at 12:02 pm

» Cox .35 and .40 in Nürnberg Toy Fair

by Levent Suberk Today at 11:57 am

» Wen Mac .049 - Conditioning.

by MauricioB Today at 11:39 am

» music vids.. some of your favorites

by HalfaDave Today at 11:23 am

» Enya .09 II Questions

by Surfer_kris Today at 10:59 am

» Jim Walker Firebaby

by rsv1cox Today at 8:27 am

» Draco Goes Flying, But Misses the Eclipse

by HalfaDave Yesterday at 9:59 pm

» A prototype Cox Reed-valve marine engine

by davidll1984 Yesterday at 9:15 pm

» Happy 53rd birthday Mauricio!!!

by MauricioB Yesterday at 11:47 am

» Testers Sprite engine swap

by Greenman38633 Yesterday at 10:57 am

» UV Restore of Yellowed Decals

by Levent Suberk Yesterday at 8:59 am

» 22mm 2-blade nylon marine prop and solid-shaft drive

by roddie Yesterday at 6:46 am

Cox Engine of The Month

experimental reed-valve test 5-5-18

Page 2 of 3

Page 2 of 3 •  1, 2, 3

1, 2, 3

Re: experimental reed-valve test 5-5-18

Re: experimental reed-valve test 5-5-18

NEW222 wrote:Great video. Sounds like it was running good, especially for reverse... The one fun part of Cox engines without starter springs! Anyways, glad the reed ran good for you. Also, the props do hold out good too. Cheap as well. Do you have a model or part number of the props you used, as they look different from the ones I have. Mine are the 'Bullnose' variety in I believe 5045. Could not see a 5030. Might order a set or two for myself. Thanks.

Chancey, The prop was a DAL #5040 (5d x 4p). I corrected the original post to reflect that info. Sorry for the mix-up..

Re: experimental reed-valve test 5-5-18

Re: experimental reed-valve test 5-5-18

I'll be testing more homemade reed designs/shapes, but figured I'd show ya'll what I found when removing the 1st test-reed.

The "matte-side" of this .008" plastic was a .001" coating (paint/silk-screen) which wear's-off in short-order of running in an engine. The base-material is crystal-clear.. and measures .007"

I hope that the coating's breaking-down doesn't foul the coil-element in the glow-head.

The "matte-side" of this .008" plastic was a .001" coating (paint/silk-screen) which wear's-off in short-order of running in an engine. The base-material is crystal-clear.. and measures .007"

I hope that the coating's breaking-down doesn't foul the coil-element in the glow-head.

Re: experimental reed-valve test 5-5-18

Re: experimental reed-valve test 5-5-18

I will be bench testing two more different homemade reeds, cut from the same .008" plastic-sheet material. Today's weather is a bit harsh though. Yesterday was sunny/high-60's F. Today is overcast/40's..

One of the reeds is similar to the original Cox star-shaped reed.. and will be tested in the same engine.

I'll admit; I should be re-testing the first reed with engine running in the proper rotation. I'd assume the rpm's to be less than Andras Balogh noted with his audio-tach. I will assure correct rotation via using either a starter-spring or my electric-starter for future testing.

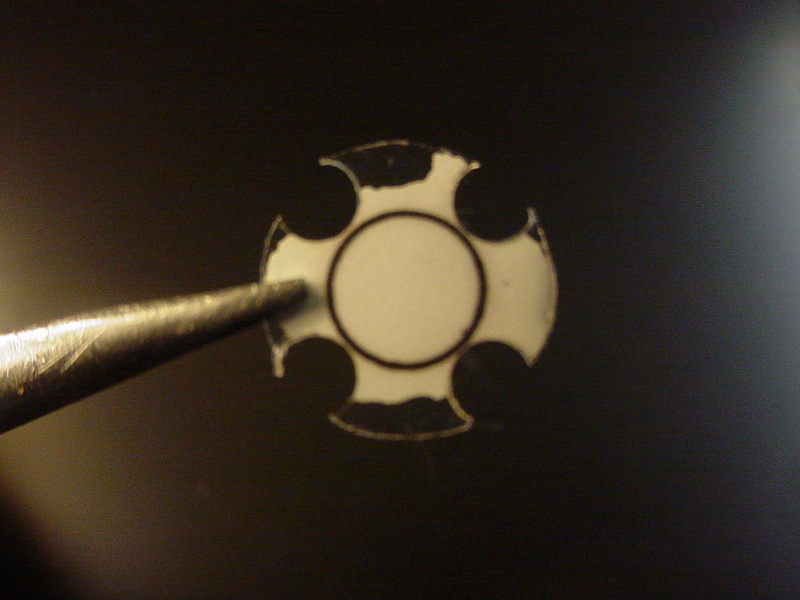

Here's what the 2nd test-reed looks like. The radii were cut using a standard 1/4" hole-punch.

As you can see; it's far from perfect.. but I'm hoping to prove that a perfect/symmetrical shape isn't needed.

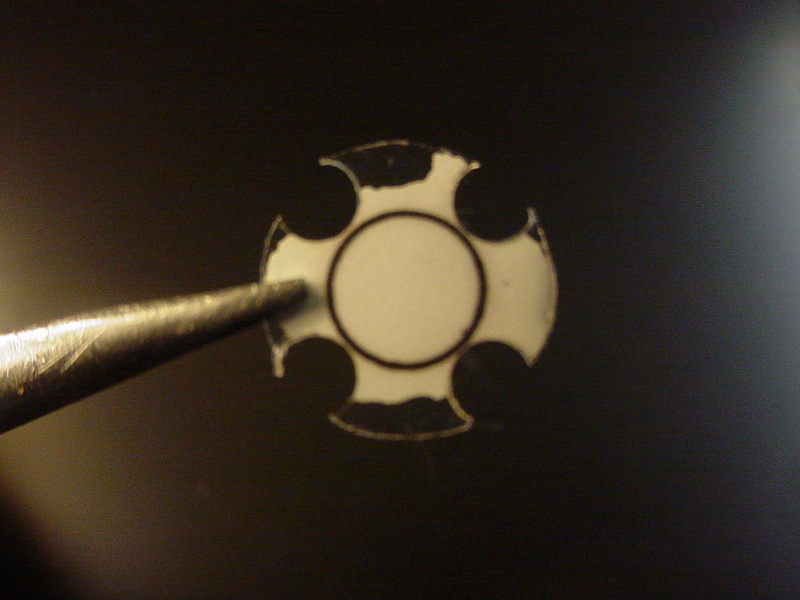

I'll be testing a 3rd reed which is a combination of the 1st and 2nd in the way of its shape. It has two different-size radii; 180 degrees opposed. (see below)

The radii were cut using 1/8" and 1/4" hole-punches. This is a different engine.. although identically-configured. Not a very scientific approach to measuring performance between the different reed-types.. but I have two objectives. One is finding out if these reeds function.. and the other is preparing twin-engines to run reliably for my C/L P-38.

One of the reeds is similar to the original Cox star-shaped reed.. and will be tested in the same engine.

I'll admit; I should be re-testing the first reed with engine running in the proper rotation. I'd assume the rpm's to be less than Andras Balogh noted with his audio-tach. I will assure correct rotation via using either a starter-spring or my electric-starter for future testing.

Here's what the 2nd test-reed looks like. The radii were cut using a standard 1/4" hole-punch.

As you can see; it's far from perfect.. but I'm hoping to prove that a perfect/symmetrical shape isn't needed.

I'll be testing a 3rd reed which is a combination of the 1st and 2nd in the way of its shape. It has two different-size radii; 180 degrees opposed. (see below)

The radii were cut using 1/8" and 1/4" hole-punches. This is a different engine.. although identically-configured. Not a very scientific approach to measuring performance between the different reed-types.. but I have two objectives. One is finding out if these reeds function.. and the other is preparing twin-engines to run reliably for my C/L P-38.

Re: experimental reed-valve test 5-5-18

Re: experimental reed-valve test 5-5-18

Cool. I will Bee watching for the results whenever the weather cooperates for you.

NEW222- Top Poster

- Posts : 3892

Join date : 2011-08-13

Age : 45

Location : oakbank, mb

Re: experimental reed-valve test 5-5-18

Re: experimental reed-valve test 5-5-18

NEW222 wrote:Cool. I will Bee watching for the results whenever the weather cooperates for you.

Thanks Chancey! Yesterday would have been well-spent burning some glow-fuel. The weather was perfect for just about anything model related outdoors. I chose to do some needed safety-maintenance on my wife's car.. which was more important.

I could have sprayed a few coats of paint.. but didn't get set up for it. The model-engine work was completed later-on in the afternoon/evening.

Tonight I'll see if I have the parts to install right and left-hand starter-springs to the engines. I know that I have the parts.. but I want to see if I have a left-hand "zero-drag" spring. I don't think I do. I'm not even sure that Cox made one. If they did; it could have been fitted to a PT-19/Flight-Trainer's product engine.. prior to the "cam-style" design being used. The Stock propeller for the PT-19 was a 6" x 2" "L/H" propeller.. at least in the final years of production.

Re: experimental reed-valve test 5-5-18

Re: experimental reed-valve test 5-5-18

Hey there roddie. Look what I found for you while playing around online...

https://coxengines.ca/338-cox-.049-snap-starter-spring-lh-oem.html

https://coxengines.ca/338-cox-.049-snap-starter-spring-lh-oem.html

NEW222- Top Poster

- Posts : 3892

Join date : 2011-08-13

Age : 45

Location : oakbank, mb

Re: experimental reed-valve test 5-5-18

Re: experimental reed-valve test 5-5-18

NEW222 wrote:Hey there roddie. Look what I found for you while playing around online...

https://coxengines.ca/338-cox-.049-snap-starter-spring-lh-oem.html

Thanks Chancey!! That's great! I'll have to put a bundle-order together to make the shipping worth it.

Re: experimental reed-valve test 5-5-18

Re: experimental reed-valve test 5-5-18

Roddie, Do you know if anyone has tried using copper sheet to make replacement reeds? Seems like there’s been trials of Mylar, stainless steel, CD disks etc. why can’t we just “stamp” out some OEM shaped reeds out of this stuff:

https://basiccopper.com/samplerpacks.html

Check out their videos on different thickness sheets:

https://www.youtube.com/watch?v=ANdAoWOTGL4

https://basiccopper.com/samplerpacks.html

Check out their videos on different thickness sheets:

https://www.youtube.com/watch?v=ANdAoWOTGL4

Last edited by Marleysky on Mon Apr 16, 2018 11:53 am; edited 1 time in total (Reason for editing : Video)

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 71

Location : Grand Rapids, MI

Re: experimental reed-valve test 5-5-18

Re: experimental reed-valve test 5-5-18

Marleysky wrote:Roddie, Do you know if anyone has tried using copper sheet to make replacement reeds? Seems like there’s been trials of Mylar, stainless steel, CD disks etc. why can’t we just “stamp” out some OEM shaped reeds out of this stuff:

https://basiccopper.com/samplerpacks.html

Check out their videos on different thickness sheets:

https://www.youtube.com/watch?v=ANdAoWOTGL4

Rene, The Copper that Cox used to make their reeds I believe was Beryllium-copper (BeCu or CuBe).. also known as "spring-copper". The copper shown in your web-link is annealed.. and too soft for making a reed. The other materials you mentioned are suitable.. because they can flex and recoil (like a spring).. which is imperative for a reed to function in this type of design. The Cox Beryllium-copper "star-shaped" reed is .001" thick. If it was thicker.. it probably wouldn't flex enough (too rigid) to function.

Below is a web-link to a supplier of BeCu;

http://www.ejbmetals.com/master.php?PAGE_ID=36

twin-engine run

twin-engine run

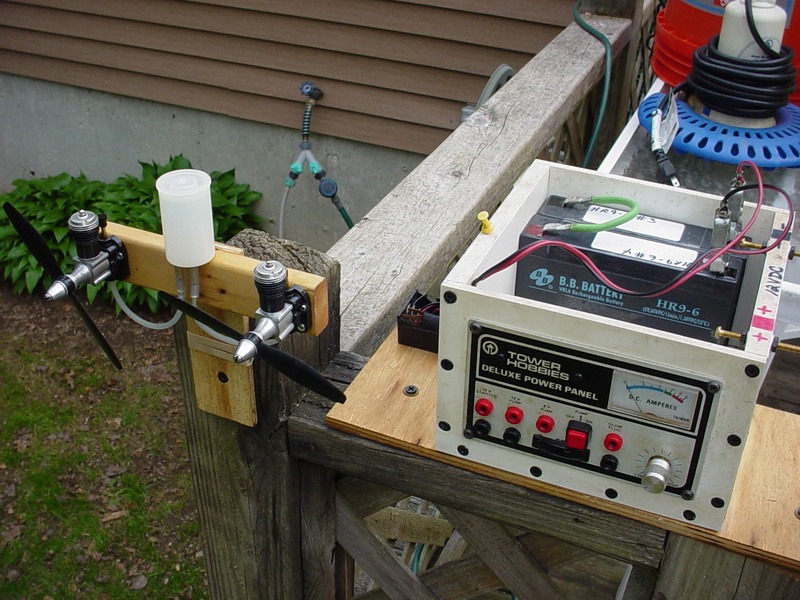

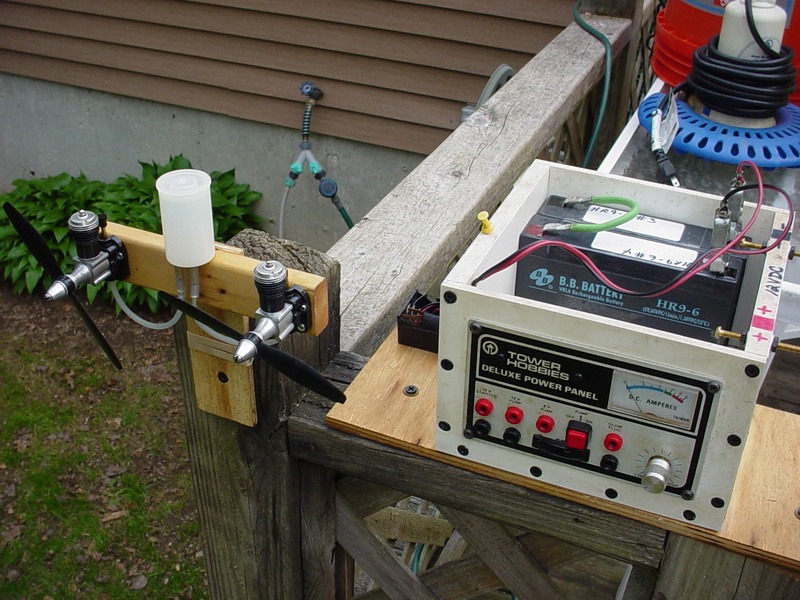

This video was shot at 9:00 this morning.. after Roddie pulled an all-nighter.. Both engines have homemade reeds. The engine on the "right" has a star-shaped reed that is similar to the OEM type. It seems to run a lot smoother than the other engine. It also is running a "DAL" brand #5040 (5"d. x 4"p.) left-hand propeller. The engine on the left is running a DAL 5040 right-hand propeller.. and a reed that has two different radii. My electric starter seems to work well, since I rebuilt it.

Re: experimental reed-valve test 5-5-18

Re: experimental reed-valve test 5-5-18

What a nice run Roddie..how about your neighbors do they enjoy theCo(x)ncert?

balogh- Top Poster

Posts : 4740

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Re: experimental reed-valve test 5-5-18

Re: experimental reed-valve test 5-5-18

roddie wrote:

Below is a web-link to a supplier of BeCu;

http://www.ejbmetals.com/master.php?PAGE_ID=36

There looks to be quite a few variations in the product. Not sure which would be the right one, although it would appear (from my short look) that they don't do .001". Also, it looks pretty expensive

although that is their bulk price.

although that is their bulk price.Rod.

Oldenginerod- Top Poster

- Posts : 3969

Join date : 2012-06-15

Age : 61

Location : Drouin, Victoria

Re: experimental reed-valve test 5-5-18

Re: experimental reed-valve test 5-5-18

balogh wrote:What a nice run Roddie..how about your neighbors do they enjoy theCo(x)ncert?

I made sure that I waited until 9:00am before running the engines. No one has complained yet. The area where I run the engines is directly behind our house. Being situated on a "circle-drive" the neighboring houses don't have a direct "line of sight" to my test-area.. therefor the engine-noise is not direct either.

Running them for 5+ minutes is pushing my luck though..

Re: experimental reed-valve test 5-5-18

Re: experimental reed-valve test 5-5-18

Great video. Had me running for cover as it sounded like a huge swarm of Bees coming for me!  You could definately hear the difference in the two reeds. I think those will be making that P-38 a quick little plane.

You could definately hear the difference in the two reeds. I think those will be making that P-38 a quick little plane.

NEW222- Top Poster

- Posts : 3892

Join date : 2011-08-13

Age : 45

Location : oakbank, mb

Re: experimental reed-valve test 5-5-18

Re: experimental reed-valve test 5-5-18

Great video Roddie! To my untrained ears they sounded like they were “in sync” with each other. I suspose you’d have to use a tachometer to verify their exact RPMs. I like how you stood behind the running engines and dusted yourself with Cox 049 colone or “ode de nitro”. Now, I can’t wait for a flight video!!

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 71

Location : Grand Rapids, MI

Re: experimental reed-valve test 5-5-18

Re: experimental reed-valve test 5-5-18

Thanks guys. I was in rare-form.. I'm not usually that animated/fidgety. The dual-feed tank worked pretty well.. but I decided to make some needed changes. I'll create a thread for that.

Re: experimental reed-valve test 5-5-18

Re: experimental reed-valve test 5-5-18

Good Fun Man !! that was entertaining to say the least . Thank You for taking the time to do and post !

If it were me i would run the same reed configuration in both engines and they cut off about the same time is a +

If it were me i would run the same reed configuration in both engines and they cut off about the same time is a +

If it were me i would run the same reed configuration in both engines and they cut off about the same time is a +

If it were me i would run the same reed configuration in both engines and they cut off about the same time is a +

getback- Top Poster

Posts : 10097

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: experimental reed-valve test 5-5-18

Re: experimental reed-valve test 5-5-18

getback wrote:Good Fun Man !! that was entertaining to say the least . Thank You for taking the time to do and post !

If it were me i would run the same reed configuration in both engines and they cut off about the same time is a +

Yup, it was fun. The engine with the homemade/star-shaped reed (the R/H engine in the vid..) ran really steady. If I cut another reed like that.. which runs as good; I may go that route. Using a single tank with a "dual-feed" was interesting. The L/H feed-line was slightly longer.. or else both engines might have shut-off at exactly the same time.

more testing..

more testing..

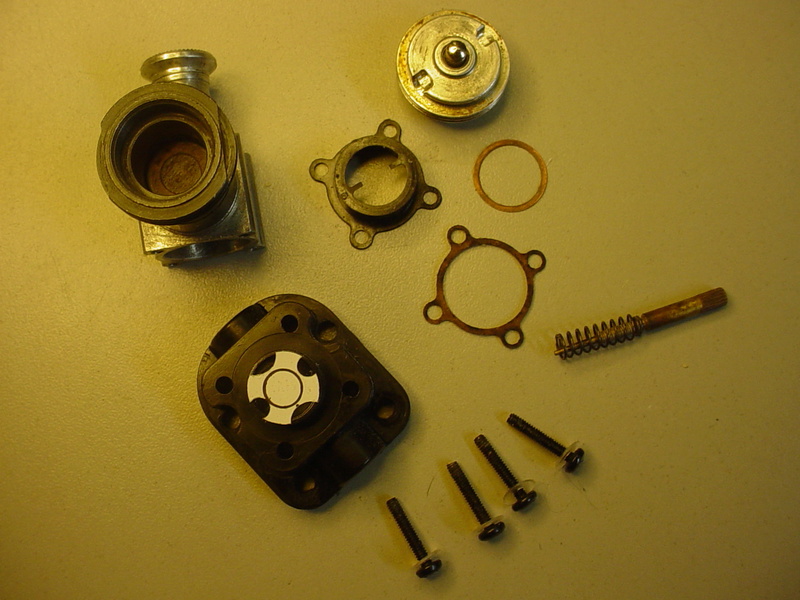

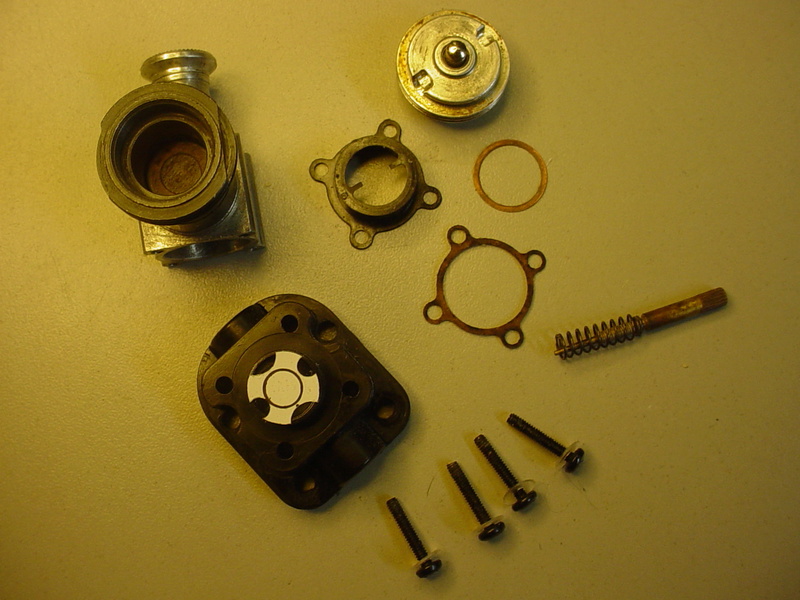

Hi folks.. I've been trying to configure two stock Cox .049 reed-valve "product engines" for my C/L 26" span/sheet-wing P-38 Lightning.

Here's some "stills" that I shot before the video.

I shot and uploaded a vid to "youtube" this afternoon. Don't watch it.. unless you have absolutely nothing else better to do.. Actually.. there's some "pearls" in there.. BUT.. from 08:00:00 thru 08:45:00 I had to fetch a glowhead-wrench..

Actually.. there's some "pearls" in there.. BUT.. from 08:00:00 thru 08:45:00 I had to fetch a glowhead-wrench..

I wanted to do a "cold-start" video... of the engines.. and that's what I did.

https://www.youtube.com/watch?v=VYvo7P48oYI&feature=youtu.be

I suspect an air-leak in the NVA of the L/H engine... but I'm wide-open to suggestions..

Here's some "stills" that I shot before the video.

I shot and uploaded a vid to "youtube" this afternoon. Don't watch it.. unless you have absolutely nothing else better to do..

I wanted to do a "cold-start" video... of the engines.. and that's what I did.

https://www.youtube.com/watch?v=VYvo7P48oYI&feature=youtu.be

I suspect an air-leak in the NVA of the L/H engine... but I'm wide-open to suggestions..

Re: experimental reed-valve test 5-5-18

Re: experimental reed-valve test 5-5-18

Cool Test Facility !!!!!

Kim- Top Poster

Posts : 8519

Join date : 2011-09-06

Location : South East Missouri

Re: experimental reed-valve test 5-5-18

Re: experimental reed-valve test 5-5-18

Now I know why the Medallion is my favorite Cox engine.

ticomareado- Account Under Review

- Posts : 1089

Join date : 2013-10-03

Location : NC

Re: experimental reed-valve test 5-5-18

Re: experimental reed-valve test 5-5-18

I would trade out glow plugs. I’ve had plugs that work perfectly fine on one engine not work on another.

Are those fine thread needles? If yes I would run those suckers in bladder pressure.

Are those fine thread needles? If yes I would run those suckers in bladder pressure.

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 56

Location : Colorado

Re: experimental reed-valve test 5-5-18

Re: experimental reed-valve test 5-5-18

It looks like you may have a reed problem on the right-hand engine (as seen from the front)?

It seem to give lots of blow-back to the tank, or you have a very unbalanced prop on it perhaps. Looking at the fuel inside the tank there was no problem with the left-hand engine running alone, only when the right-hand was running (alone or with both engines running).

It seem to give lots of blow-back to the tank, or you have a very unbalanced prop on it perhaps. Looking at the fuel inside the tank there was no problem with the left-hand engine running alone, only when the right-hand was running (alone or with both engines running).

Surfer_kris- Diamond Member

- Posts : 1902

Join date : 2010-11-20

Location : Sweden

Re: experimental reed-valve test 5-5-18

Re: experimental reed-valve test 5-5-18

JPvelo wrote:I would trade out glow plugs. I’ve had plugs that work perfectly fine on one engine not work on another.

Are those fine thread needles? If yes I would run those suckers in bladder pressure.

They're just standard 80tpi needles Jim. They could both use the silicone tubing-seal treatment. I'll try a different glowhead. Thanks for the tip.

Re: experimental reed-valve test 5-5-18

Re: experimental reed-valve test 5-5-18

Surfer_kris wrote:It looks like you may have a reed problem on the right-hand engine (as seen from the front)?

It seem to give lots of blow-back to the tank, or you have a very unbalanced prop on it perhaps. Looking at the fuel inside the tank there was no problem with the left-hand engine running alone, only when the right-hand was running (alone or with both engines running).

I think it's the prop Kris.. I didn't check the balance on the props.

Page 2 of 3 •  1, 2, 3

1, 2, 3

Similar topics

Similar topics» Pee Wee .020 Reed Valve

» Reed Valve

» Reed Valve Material

» Ace Cox Reed Valve Throttle

» Venturi Size .049

» Reed Valve

» Reed Valve Material

» Ace Cox Reed Valve Throttle

» Venturi Size .049

Page 2 of 3

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules