Log in

Search

Latest topics

» music vids.. some of your favoritesby Oldenginerod Today at 1:59 am

» Draco Goes Flying, But Misses the Eclipse

by HalfaDave Yesterday at 9:59 pm

» A prototype Cox Reed-valve marine engine

by davidll1984 Yesterday at 9:15 pm

» Enya .09 II Questions

by Surfer_kris Yesterday at 2:45 pm

» Wen Mac .049 - Conditioning.

by MauricioB Yesterday at 12:21 pm

» Happy 53rd birthday Mauricio!!!

by MauricioB Yesterday at 11:47 am

» Jim Walker Firebaby

by rdw777 Yesterday at 11:22 am

» Testers Sprite engine swap

by Greenman38633 Yesterday at 10:57 am

» UV Restore of Yellowed Decals

by Levent Suberk Yesterday at 8:59 am

» 22mm 2-blade nylon marine prop and solid-shaft drive

by roddie Yesterday at 6:46 am

» Post edit??

by roddie Yesterday at 5:33 am

» Original Super Power fuel formula?

by HalfaDave Wed Apr 17, 2024 7:28 pm

Cox Engine of The Month

Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Page 1 of 2

Page 1 of 2 • 1, 2

Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Flying Saucer Repairs - "Gravity Resistant Flying Machine"

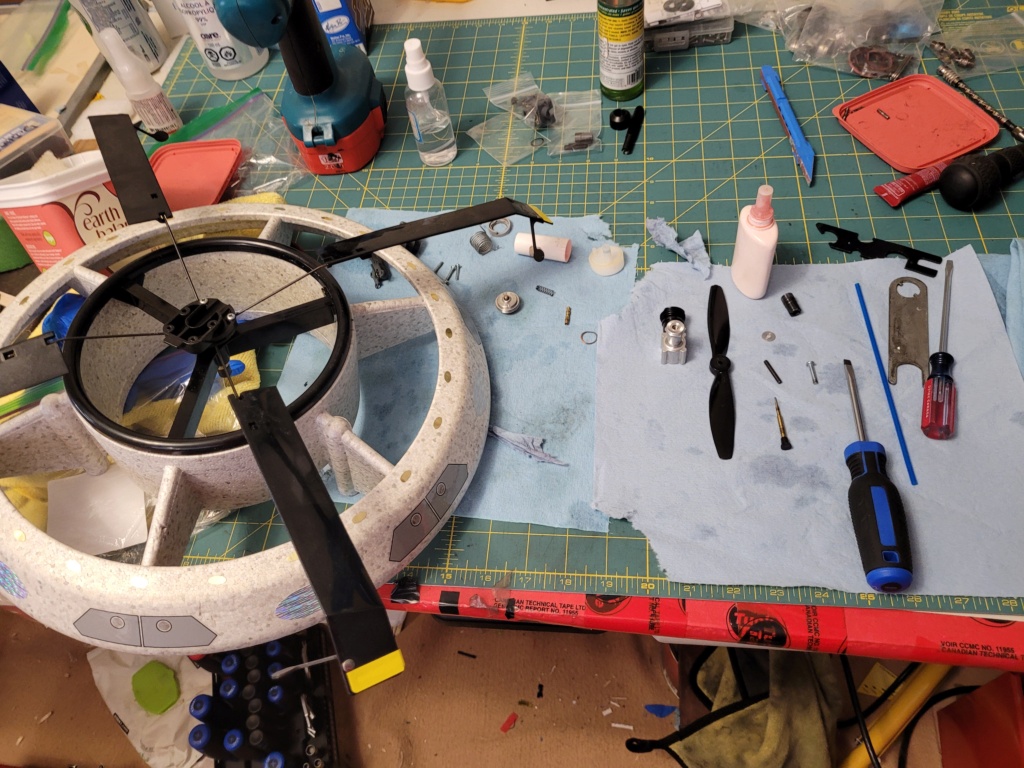

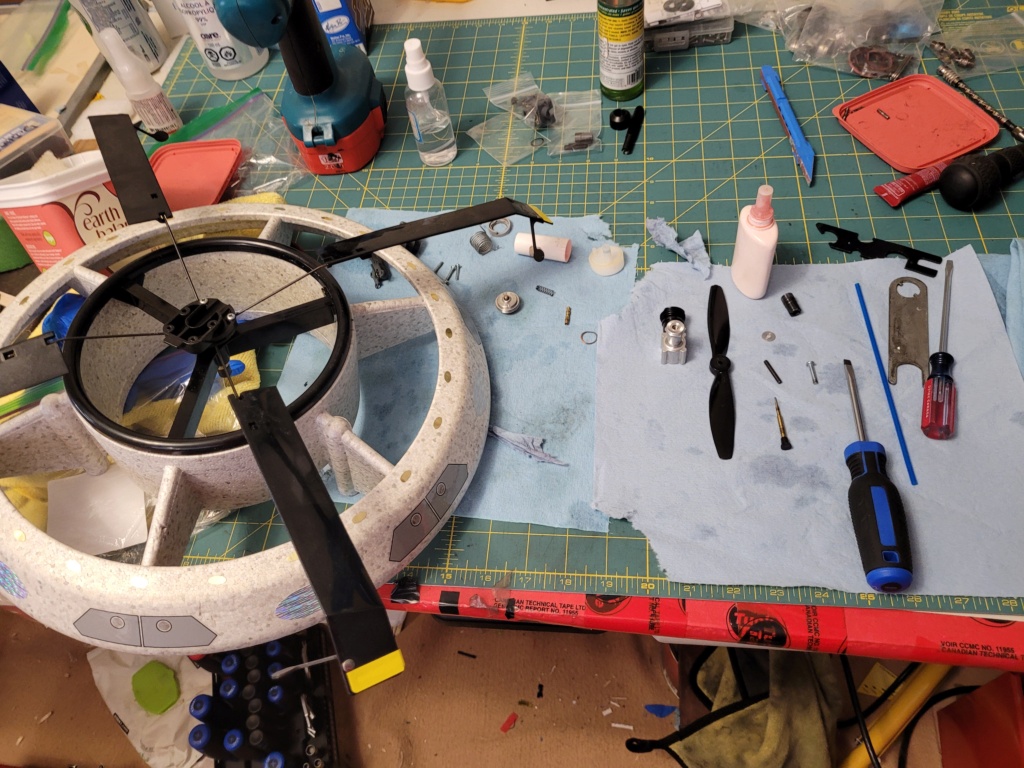

Hi Everyone, almost have a fun little project wrapped up. Thought I'd share.

Here's repair list;

missing the bushings for the helicopter blade main axle assembly.

engine back plate had a crack through the venturi opening, needed ball and socket reset

engine gummed and had wd40 or something nasty sparyed in it.

I made new split bushing from a wood dowel. I made a fixture that I could us in the drill press then turn the dowel down to the correct diameter. Once to dimension, I inserted a razer blade in the drill chuck and sliced the dowel bushing in half. Worked amazingly. Same approach for the spacer. Wood glued and held on with heat shrink tubing.

Now the saucer body is good to go. Ultrasonic cleaned the engine. Rest ball socket. Now to decide which backplate style to use. I have the classic horse shoe or the one with the choke. Then all that's left is bolt er up and go fly it with the kids

Here's repair list;

missing the bushings for the helicopter blade main axle assembly.

engine back plate had a crack through the venturi opening, needed ball and socket reset

engine gummed and had wd40 or something nasty sparyed in it.

I made new split bushing from a wood dowel. I made a fixture that I could us in the drill press then turn the dowel down to the correct diameter. Once to dimension, I inserted a razer blade in the drill chuck and sliced the dowel bushing in half. Worked amazingly. Same approach for the spacer. Wood glued and held on with heat shrink tubing.

Now the saucer body is good to go. Ultrasonic cleaned the engine. Rest ball socket. Now to decide which backplate style to use. I have the classic horse shoe or the one with the choke. Then all that's left is bolt er up and go fly it with the kids

Last edited by layback209 on Mon Mar 21, 2022 3:08 pm; edited 2 times in total

layback209- Gold Member

- Posts : 280

Join date : 2017-10-13

Age : 38

Location : Okotoks

layback209- Gold Member

- Posts : 280

Join date : 2017-10-13

Age : 38

Location : Okotoks

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Good job. I like it.

And "engine gummed with WD40." Yes, nasty stuff. It never gets near any of my engines.

And "engine gummed with WD40." Yes, nasty stuff. It never gets near any of my engines.

rsv1cox- Top Poster

Posts : 10518

Join date : 2014-08-18

Location : West Virginia

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Thanks, got it all together and ready to test. So turns out every one of those choke style back plates is cracked where the spray bar is inserted. Even the 2 new ones I bought from cox international were cracked.  So I motosealed it all together, hope for the best. If it works it works. From now on its only non chock style backplate. Engine has amazing compression. 2 head shims installed. Probably needs more run in.

So I motosealed it all together, hope for the best. If it works it works. From now on its only non chock style backplate. Engine has amazing compression. 2 head shims installed. Probably needs more run in.

Hope to have a flight report soon.

So I motosealed it all together, hope for the best. If it works it works. From now on its only non chock style backplate. Engine has amazing compression. 2 head shims installed. Probably needs more run in.

So I motosealed it all together, hope for the best. If it works it works. From now on its only non chock style backplate. Engine has amazing compression. 2 head shims installed. Probably needs more run in. Hope to have a flight report soon.

layback209- Gold Member

- Posts : 280

Join date : 2017-10-13

Age : 38

Location : Okotoks

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

The original "290" engines, the "postage stamp" back (engines and replacements for the RTF's) were molded out of DuPont Delrin, which was almost indestructible. My 290's from the early 1970's are as good now as they were then, IMO. It appears that the earlier horseshoe backs were also made of the same material. The latest plastic of the horseshoe backs is of a different plastic, appears brittle. Since the stocks could be as old as 25 years, it is possible that the plastic became age hardened. I attempted to remove the NVA to repair a Testors McCoy Rotomatic engine from a new horseshoe back I bought a couple years ago, and it cracked.

(A common practice before was to remove the NVA and drill out the venturi to allow more air to pass, increasing the engine's power. With the back cracking would make this maneuver impractical.)

Seems that since this is a common occurrence, may be if someone in the community could make either a metal or plastic collar band that would wedge the crack shut and hold it firm, (say 0.001" undersized for tight fit) might be a good way. I don't know if the choke tube is sufficient along with cracked edge sealed with sealant to help salvage the situation.

(A common practice before was to remove the NVA and drill out the venturi to allow more air to pass, increasing the engine's power. With the back cracking would make this maneuver impractical.)

Seems that since this is a common occurrence, may be if someone in the community could make either a metal or plastic collar band that would wedge the crack shut and hold it firm, (say 0.001" undersized for tight fit) might be a good way. I don't know if the choke tube is sufficient along with cracked edge sealed with sealant to help salvage the situation.

GallopingGhostler- Top Poster

Posts : 5278

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Someone here already fixed this crack in the horseshoe backplate using a coper tube or aluminium one Not sure cant rember  cool flying saucer i never se one of those

cool flying saucer i never se one of those

cool flying saucer i never se one of those

cool flying saucer i never se one of those

davidll1984- Diamond Member

- Posts : 2283

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Cool deal I like the way you made your own bushing and spacers to fit , Good luck on the flights with the Kids!!

getback- Top Poster

Posts : 10095

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

I like the idea of the tube/ring to close the cracks. Thanks. I remember reading about that on here for TD venturi bodies. I gotta get that old metal lathe going

to bad about the quality issues over the years.

to bad about the quality issues over the years.

See if the janky fix will holds up enough, my goal was to seal the airleaks. The choke does cover the venturi nicely. Now thinking about how that engine will be freewheeling around the tank will probably apply a load the spray bar, cracked area. I do have a non choke backplate I can bolt on, might be a good idea to bring it to the field.

Here's the fixture I came up with to hold the dowel bushing for "machining." I new there was no chance I could drill the hole dead center. So I drilled the hole first, incerted the fixture with a drop of ca. Then held the rod with the drill press chuck to turn it. That way I could use a file and square off the drill press table to "true" it up, file to dimensions. According to my caliper I got it with in .1 mm good enough.

good enough.

to bad about the quality issues over the years.

to bad about the quality issues over the years. See if the janky fix will holds up enough, my goal was to seal the airleaks. The choke does cover the venturi nicely. Now thinking about how that engine will be freewheeling around the tank will probably apply a load the spray bar, cracked area. I do have a non choke backplate I can bolt on, might be a good idea to bring it to the field.

Here's the fixture I came up with to hold the dowel bushing for "machining." I new there was no chance I could drill the hole dead center. So I drilled the hole first, incerted the fixture with a drop of ca. Then held the rod with the drill press chuck to turn it. That way I could use a file and square off the drill press table to "true" it up, file to dimensions. According to my caliper I got it with in .1 mm

layback209- Gold Member

- Posts : 280

Join date : 2017-10-13

Age : 38

Location : Okotoks

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

If you wanted or needed actual dimensions of the missing bearing, I can get those for you off of my UFO.

NEW222- Top Poster

- Posts : 3892

Join date : 2011-08-13

Age : 45

Location : oakbank, mb

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Flew the saucer today! It was a big hit with the kids. Had a few issues starting it, no fuel draw. Put it to the side for a bit then tried again and it was good to go. My guess is the read was sticking a bit or something.

It's so darn cool. It even sounds like a alien ufo. And kinda hovers around. This model needed to be run at near peak to fly properly, I thought wet 2 cycle would be good but not enough. Fun morning and all. Lots of flights, the engine should be near broken in now, and looks like my janky fix is working so far.

Thanks NEW222 appreciate the offer. Illreach out if I need to make some more.

It's so darn cool. It even sounds like a alien ufo. And kinda hovers around. This model needed to be run at near peak to fly properly, I thought wet 2 cycle would be good but not enough. Fun morning and all. Lots of flights, the engine should be near broken in now, and looks like my janky fix is working so far.

Thanks NEW222 appreciate the offer. Illreach out if I need to make some more.

layback209- Gold Member

- Posts : 280

Join date : 2017-10-13

Age : 38

Location : Okotoks

Levent Suberk- Diamond Member

- Posts : 2197

Join date : 2017-12-24

Location : Türkiye

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Cool Man I bet the kids were all in to it  , Never seen one but seem to bee cool for the time period .

, Never seen one but seem to bee cool for the time period .

getback- Top Poster

Posts : 10095

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

To fix cracked venturi you can try different round ballpoint pen barrels for a snug fit on venturi. A piece of ballpoint pen barrel is enough to fix it. Sanding inside of pen barrel piece with rolled sandpaper can bring it to snug fit size. I didn't try yet, but I think that it works.

Levent Suberk- Diamond Member

- Posts : 2197

Join date : 2017-12-24

Location : Türkiye

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Levent Suberk wrote:Surestart backplate fix:

https://www.coxengineforum.com/t14591-surestart-engines-with-cracked-backplate-housings?highlight=Surestart+crackMauricioB wrote:I have seen that problem on gray plates. Therefore a while ago I made this solution. You can even make it long and also place an air valve if it is of your interest. The aluminum alloy tube is the permanent and definitive solution to this problem that comes from the source.

and if you want you can place an additional air valve

Mauricio came up with a deluxe fix, plus enhanced it with a choke style throttle. Back in the mid 1970's, I worked a year in the shop of Research Corp. of the University of Hawaii's Geophysics Department. As a student help at minimum wage (cheap student labor), I helped Bert, a german immigrant watch maker, who as their machinist made parts for the UH Geo's ocean bottom seismometer project, having access to very nice Bridgeport milling machines and lathes under Bert's helpful eyes. Then they found I could do electronics, soldered components onto custom printed circuit boards for the seismometer instrumentation package.

A bit of a pragmatic practical realist

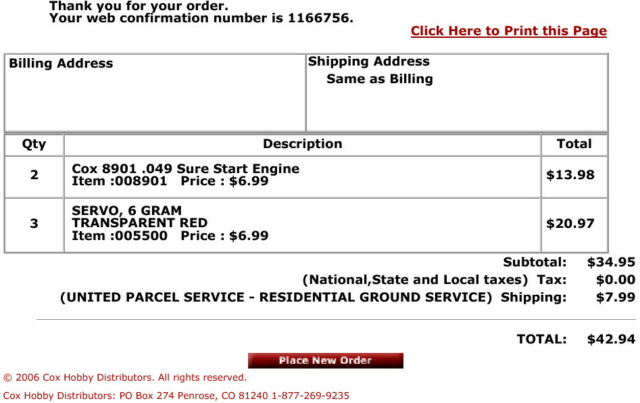

, at this later stage in retirement, affording a $500 miniature modeling lathe/mill might be quite a stretch to repair a $7 engine from the Cox Surplus Sales outlet (April 12, 2008).

, at this later stage in retirement, affording a $500 miniature modeling lathe/mill might be quite a stretch to repair a $7 engine from the Cox Surplus Sales outlet (April 12, 2008).

But again, I am flabbergasted

Levent Suberk wrote:To fix cracked venturi you can try different round ballpoint pen barrels for a snug fit on venturi. A piece of ballpoint pen barrel is enough to fix it. Sanding inside of pen barrel piece with rolled sandpaper can bring it to snug fit size. I didn't try yet, but I think that it works.

Levent, that is a good bit of practical thinking on an inexpensive solution to the gray horseshoe cracked venturi problem.

Brainstorming (a lost art these days

GallopingGhostler- Top Poster

Posts : 5278

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Ballpoint pen handles are made from polystyrene or polypropylene as like as Bic ballpoint pens. Because they are seamless they are very resistant to crack. Aluminum is better perhaps. Need to try

Levent Suberk- Diamond Member

- Posts : 2197

Join date : 2017-12-24

Location : Türkiye

layback209- Gold Member

- Posts : 280

Join date : 2017-10-13

Age : 38

Location : Okotoks

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Hi everyone thought I'd share a flight video. This thing is a hoot. After a quick field repair as the power pack started to separate from the foam we got about 6 flights in beforewe got winded out. My kids had fun launching it too. My oldest took a great video of the UFO saucing action

.

.

layback209- Gold Member

- Posts : 280

Join date : 2017-10-13

Age : 38

Location : Okotoks

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Cool Flight ! I bet the kids and You enjoyed the flights , It was very good the way it floated around before blasting into the sky .

getback- Top Poster

Posts : 10095

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

getback wrote:Cool Flight ! I bet the kids and You enjoyed the flights , It was very good the way it floated around before blasting into the sky .

Thanks getback, we sure did. We did get it to hover right above our heads for 1 whole tank but could not repeat it. I think the cooler morning air was the trick for that tune. It's really neat how the saucer appears to spin opposite the helicopter blades, if it's dead calm it makes gental circles or a helical pattern. We will have to fly the apache chopper next

layback209- Gold Member

- Posts : 280

Join date : 2017-10-13

Age : 38

Location : Okotoks

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

and thanks for the inspiration, just bought one off FB marketplace. I always wanted one, now I gotta restor it.

cstatman- Platinum Member

Posts : 533

Join date : 2021-02-17

Age : 59

Location : San Jose, CA

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

received the UFO .. cleaned it up, took it out last weekend. Motor starts and runs STRONG. UFO does not even hover, just kinda, flops to the ground. I tried spinning, flinging, etc. nothing>

took it home and cleaned it up

NOW! thank you RSV-Bob, the addiction is kicking in.

I disemboweled and am rebuilding the box. Who knew you could use an iron on cardboard to flatten it? Or packing tape, linen tape, new cellophane, etc. etc.

the box was pretty worn, but it will be an okay display

then I will try to figure out the stickers on the UFO. I am not sure if I should leave them on, or remove and try to replicate...

took it home and cleaned it up

NOW! thank you RSV-Bob, the addiction is kicking in.

I disemboweled and am rebuilding the box. Who knew you could use an iron on cardboard to flatten it? Or packing tape, linen tape, new cellophane, etc. etc.

the box was pretty worn, but it will be an okay display

then I will try to figure out the stickers on the UFO. I am not sure if I should leave them on, or remove and try to replicate...

cstatman- Platinum Member

Posts : 533

Join date : 2021-02-17

Age : 59

Location : San Jose, CA

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Yours is interesting Charles, because it uses propeller thrust to fly whereas the other saucers use helicopter blades turned by the torque of the engine with propeller.

Appears to be insufficient thrust from the prop. Could it be that the prop being used is too mild, and needs to be further pitched, like a 5x4 or 5x5 versus a 5x3? Will a 6" prop fit without touching the sides? Generally, a 6x3 prop provides the best thrust within the peak power band of the engine.

The reedies are torque engines, and I gather that Cox's original prop was better sized and pitched for more thrust.

Appears to be insufficient thrust from the prop. Could it be that the prop being used is too mild, and needs to be further pitched, like a 5x4 or 5x5 versus a 5x3? Will a 6" prop fit without touching the sides? Generally, a 6x3 prop provides the best thrust within the peak power band of the engine.

The reedies are torque engines, and I gather that Cox's original prop was better sized and pitched for more thrust.

GallopingGhostler- Top Poster

Posts : 5278

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

rsv1cox- Top Poster

Posts : 10518

Join date : 2014-08-18

Location : West Virginia

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

cstatman wrote:and thanks for the inspiration, just bought one off FB marketplace. I always wanted one, now I gotta restor it.

Wow thats so cool!!! Nice snag glad your having some fun with it and putting it work.

Mine started flipping over and crashing, I think it got tweaked too much from the heavey flying and hastily performed repairs. Probably got 60 flights out of it. I think the thrust is no longer centered appropriately.

layback209- Gold Member

- Posts : 280

Join date : 2017-10-13

Age : 38

Location : Okotoks

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

Re: Flying Saucer Repairs - "Gravity Resistant Flying Machine"

i think the prop may be a good place to start. I dont know if its stock, and more thrust may help

I got it all cleaned up, and the box is now a box again. but I realize it will never be close to perfect, so I got it all together, and now need to decide "keep trying to fly it" or "put it on the museum shelf of oddities"

I am also looking for me Free Light!

I got it all cleaned up, and the box is now a box again. but I realize it will never be close to perfect, so I got it all together, and now need to decide "keep trying to fly it" or "put it on the museum shelf of oddities"

I am also looking for me Free Light!

cstatman- Platinum Member

Posts : 533

Join date : 2021-02-17

Age : 59

Location : San Jose, CA

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Building tip: CA cement and eye irritation

» Repairs Bits and Pieces

» Zoomslot Saucer

» CG Centre of Gravity

» What is the most oil and nitro resistant covering?

» Repairs Bits and Pieces

» Zoomslot Saucer

» CG Centre of Gravity

» What is the most oil and nitro resistant covering?

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules