Log in

Search

Latest topics

» music vids.. some of your favoritesby Oldenginerod Today at 1:59 am

» Draco Goes Flying, But Misses the Eclipse

by HalfaDave Yesterday at 9:59 pm

» A prototype Cox Reed-valve marine engine

by davidll1984 Yesterday at 9:15 pm

» Enya .09 II Questions

by Surfer_kris Yesterday at 2:45 pm

» Wen Mac .049 - Conditioning.

by MauricioB Yesterday at 12:21 pm

» Happy 53rd birthday Mauricio!!!

by MauricioB Yesterday at 11:47 am

» Jim Walker Firebaby

by rdw777 Yesterday at 11:22 am

» Testers Sprite engine swap

by Greenman38633 Yesterday at 10:57 am

» UV Restore of Yellowed Decals

by Levent Suberk Yesterday at 8:59 am

» 22mm 2-blade nylon marine prop and solid-shaft drive

by roddie Yesterday at 6:46 am

» Post edit??

by roddie Yesterday at 5:33 am

» Original Super Power fuel formula?

by HalfaDave Wed Apr 17, 2024 7:28 pm

Cox Engine of The Month

Small Precision Washers

Page 1 of 1

Small Precision Washers

Small Precision Washers

It's always nice to have a washer that fits good. I use 1/16" music-wire a lot on my small models. Finding a washer that fit's this wire snug is important to me.. because I often use the spring-style retainers on l/g wire to hold the wheels on.. plus I'm a modeler with OCD.

These washers are made by Hob-Bits.. and were "once" a common hobby-shop item.

These fit perfectly.. and are of a thickness that makes them act as a bushing too. When I use 1/16" music-wire to make pushrods.. I can make an "L"-bend and use the washer/retainer to attain a nice-fitting link.

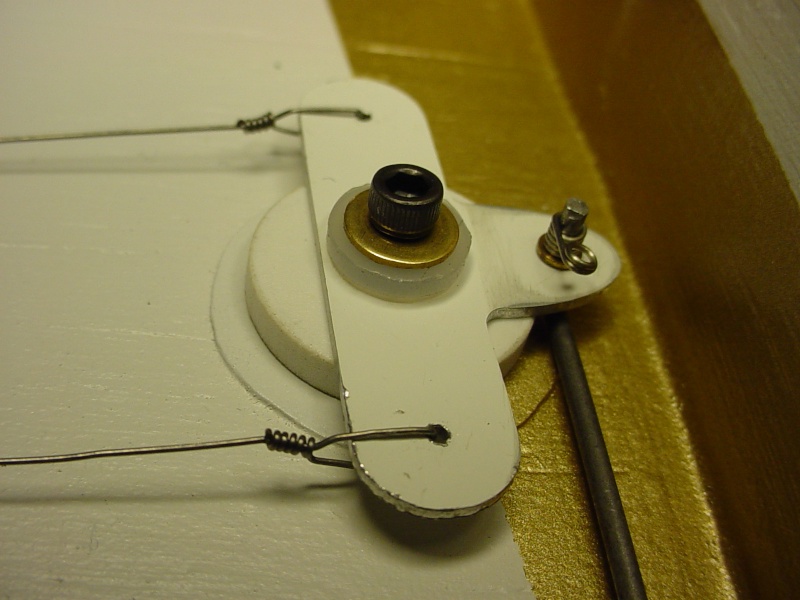

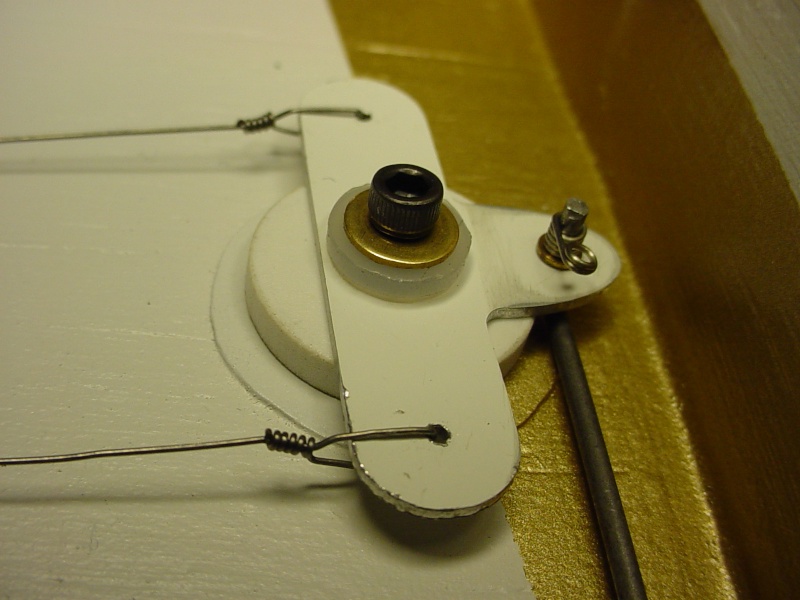

This bell-crank link is 1/16" music-wire with the above-referenced washer and a Goldberg-style 1/2A spring-collar.

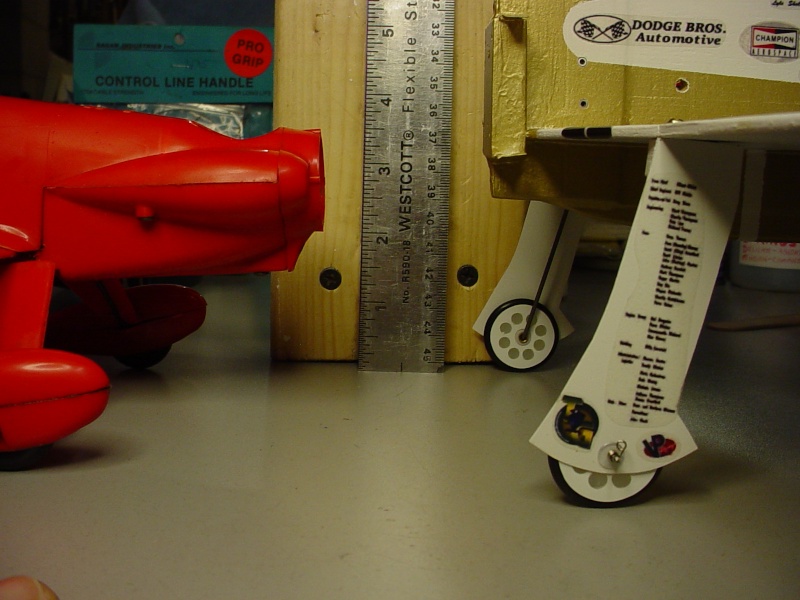

And how about nice smooth-rolling little wheels? Bushing your axles/hubs can make a difference in whether your model noses-over on both R.O.G take-offs and landings on pavement.

Here's what was on my Cox PT-19 Flight Trainer..

and here's the upgrade..

These washers are made by Hob-Bits.. and were "once" a common hobby-shop item.

These fit perfectly.. and are of a thickness that makes them act as a bushing too. When I use 1/16" music-wire to make pushrods.. I can make an "L"-bend and use the washer/retainer to attain a nice-fitting link.

This bell-crank link is 1/16" music-wire with the above-referenced washer and a Goldberg-style 1/2A spring-collar.

And how about nice smooth-rolling little wheels? Bushing your axles/hubs can make a difference in whether your model noses-over on both R.O.G take-offs and landings on pavement.

Here's what was on my Cox PT-19 Flight Trainer..

and here's the upgrade..

Re: Small Precision Washers

Re: Small Precision Washers

I got a bag of tiny washers for some straight razors I repinned. Good thought on what to do with them as I have about 90 left over.

http://www.microfasteners.com/home.php?cat=646

Phil

http://www.microfasteners.com/home.php?cat=646

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

which ones?

which ones?

pkrankow wrote:I got a bag of tiny washers for some straight razors I repinned. Good thought on what to do with them as I have about 90 left over.

http://www.microfasteners.com/home.php?cat=646

Phil

Phil: which ones? the link is to a page that shows choices.

#0 flat washers #0 wide flat washers copper #1 S/S copper plated washers

happydad

happydad- Rest In Peace

- Posts : 1592

Join date : 2012-05-28

Age : 78

Location : Escondido, CA

Re: Small Precision Washers

Re: Small Precision Washers

I have the brass washers in #0, not sure which exact ones as I did the razor project several years ago now.

Phil

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Can we chart these?

Can we chart these?

If we could get a chart indicating which washer to use with each diameter wire that we typically use (1/16", 3/32", etc.), that would be so awesome!

BTW, do they still make those Goldberg LG spring fasteners in different sizes?

BTW, do they still make those Goldberg LG spring fasteners in different sizes?

VUgearhead- Gold Member

- Posts : 155

Join date : 2013-07-02

Age : 56

Location : Boynton Beach, FL

Re: Small Precision Washers

Re: Small Precision Washers

Discussions like this always remind me how much I LOVE the metric system

You know, 2mm washer for 2mm wire and so on. Not to mention fuel mixing calculations

You know, 2mm washer for 2mm wire and so on. Not to mention fuel mixing calculations

KariFS- Diamond Member

- Posts : 2000

Join date : 2014-10-10

Age : 52

Re: Small Precision Washers

Re: Small Precision Washers

VUgearhead wrote:If we could get a chart indicating which washer to use with each diameter wire that we typically use (1/16", 3/32", etc.), that would be so awesome!

BTW, do they still make those Goldberg LG spring fasteners in different sizes?

Sig Mfg. discontinued them unfortunately. There's a chance that Cox International might have found some in that large shipment of hobby-goods they acquired a few weeks ago. Bernie and Theresa are probably still busy cataloguing all of it.

The spring-fasteners can be hand-wound from .015" music-wire though. Just wind it (tightly) around a short post (secured in a vice or chuck).. slightly smaller than the diameter you need the retainer for. Example; use a 3/64" (.047") music-wire winding-post.. for a 1/16" (.062") wire retainer or a 1/16" winding-post for 5/64" (.078").. etc. After removing your "spring" from the winding post, grab a sandwich-bag and side-cutters. Hold the coil inside the bag and cut the length you need. The bag will help from losing the small part when it shears-off.. and is also added protection for your eyes. (always wear safety-glasses when working with music-wire) Form the "tang-loop" by holding the coil with pointed tweezers on a wood-block.. and bend 1 (one) end-coil open with a knife blade. Finish-bend 180 degrees using needle-nose pliers. This "tang" is what takes the pressure off the coil when installing (twisting-on/off).. regardless of whether the coil was made l/h or r/h.

But wait.. there's more..! Since this is a thread on small precision washers.. I had planned on explaining how to make some from plastic-sheet. No.. there not "steel/machine" washers.. but they're great for spacers.. hubcaps.. and they don't rust. Save a flat piece of clear-plastic packaging (you know.. the kind you have to cut open w/scissors to get your stuff out..) Drill a row of holes with the appropriate size drill.. along one edge.. and space them apart at least 1/4". Use the "eye" of a hand-type paper-punch to center the hole, and punch it out. I had to remove the chip-collector on mine, to expose the eye. You'll have a 1/4" O.D.. on all your washers.. but being able to custom-bore the I.D. to size is a nice option.. especially if you have #drills.

These hubcaps were made with the paper-punch method.

Similar topics

Similar topics» making thin washers

» Homemade Washers

» Cox International wish list

» Precision Throttle Control for .Cox 049 Medallion

» New England local Precision Aerobatics

» Homemade Washers

» Cox International wish list

» Precision Throttle Control for .Cox 049 Medallion

» New England local Precision Aerobatics

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules