Log in

Search

Latest topics

» WenMac 049 - Glow Plug & Head Gasket replacements?by Ken Cook Today at 3:17 pm

» audio-tach anyone?

by roddie Today at 2:58 pm

» A choke-tube with velocity-stack configured Bee

by roddie Today at 2:54 pm

» Jim Walkers FireBee - This is going to be fun

by rsv1cox Today at 2:43 pm

» 12 string guitar suggestions

by 1/2A Nut Today at 1:58 pm

» Nostalgia alert, my 1959 Corvette revisited

by Admin Today at 1:11 pm

» Hawk had breakfast and then took a bath

by rsv1cox Today at 10:26 am

» Prop Rod - resto to a runner

by rsv1cox Today at 7:32 am

» Jim Walker Firebaby

by rdw777 Yesterday at 4:58 pm

» Prayers for my Wife Please

by akjgardner Yesterday at 10:28 am

» Cox prop rod

by Wiggy Fri May 17, 2024 4:30 pm

» "Red Neck" .049 elec. starter

by getback Fri May 17, 2024 7:19 am

My recent disaster

Page 1 of 2

Page 1 of 2 • 1, 2

My recent disaster

My recent disaster

I haven't been contributing much recently following a very simple event. The motor on my tiny milling machine went bang!

There I was - machine running - milling a crankcase for a 049 Cox hybrid and the motor went bang with a very large flash. It blew the house fuse and took out the power to the house. A simple flick of a switch and power was back.

Unfortunately - the motor took out the speed controller and the motherboard on my PC. Very expensive!!!

It took me a while to find a replacement Mini ITX motherboard with a parallel port and I couldn't match the original. PCs don't have parallel ports any more!

After many, many hours rebuilding I discover that the motherboard doesn't like Windows XP and there are no USB drivers that match.

However, I decided to check the operation - plugged the parallel port into my controller and it blew my new motherboard! The controller had blown as well.

So - I have built a new controller, another motherboard - this time I have gone to Windows 7 64 bit. The controller now has opto couplers which should reduce the chance of blow back and I have put together a Smoothstepper between the PC and the controller. This no longer uses the PC parallel port but has an Ethernet cable plugged into it and converts the signals to parallel.

This has taken hours and hours. Microsoft no longer support XP, PCs no longer have parallel ports, Mach3 (my controller software) only works with parallel ports and 32bit, new motherboards are designed around Windows 8 or Windows 7 64 bit. I tried Windows 7 32 bit and that didn't work either.

Building and rebuilding has driven me nuts! I now have to retune all my equipment. I am still a few hours away from being operational.

I hadn't realised how much I would miss something. Even though I had backups of the PC they (although I could restore files, settings and the software) proved useless without the original style motherboard. I was forced to upgrade.

There I was - machine running - milling a crankcase for a 049 Cox hybrid and the motor went bang with a very large flash. It blew the house fuse and took out the power to the house. A simple flick of a switch and power was back.

Unfortunately - the motor took out the speed controller and the motherboard on my PC. Very expensive!!!

It took me a while to find a replacement Mini ITX motherboard with a parallel port and I couldn't match the original. PCs don't have parallel ports any more!

After many, many hours rebuilding I discover that the motherboard doesn't like Windows XP and there are no USB drivers that match.

However, I decided to check the operation - plugged the parallel port into my controller and it blew my new motherboard! The controller had blown as well.

So - I have built a new controller, another motherboard - this time I have gone to Windows 7 64 bit. The controller now has opto couplers which should reduce the chance of blow back and I have put together a Smoothstepper between the PC and the controller. This no longer uses the PC parallel port but has an Ethernet cable plugged into it and converts the signals to parallel.

This has taken hours and hours. Microsoft no longer support XP, PCs no longer have parallel ports, Mach3 (my controller software) only works with parallel ports and 32bit, new motherboards are designed around Windows 8 or Windows 7 64 bit. I tried Windows 7 32 bit and that didn't work either.

Building and rebuilding has driven me nuts! I now have to retune all my equipment. I am still a few hours away from being operational.

I hadn't realised how much I would miss something. Even though I had backups of the PC they (although I could restore files, settings and the software) proved useless without the original style motherboard. I was forced to upgrade.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 69

Location : England

Re: My recent disaster

Re: My recent disaster

That really stinks Ian. Sounds like a huge PITA. Best of luck to you, I bet you'll be up and running in no time!

Ron

Ron

Cribbs74- Moderator

Posts : 11899

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: My recent disaster

Re: My recent disaster

I had noticed you'd been a little scarce lately. Someone was mentioning they were surprised you hadn't chipped into one thread about a 1/2A stunter plan.

You remind me how glad I am I don't rely on knowing how to work on computers anymore. About all I remember how to do is turn it on and run a weekly backup. I made a big fat notebook over the years to remind me what do do if it goes blooey. It's titled "In Case of Crash." I've been running Win7-32 since the day it was released some distant October ago. Was it 2009, seems longer. The first mostly stable Windows program ever. Hard to believe we kept gobbling up Microsoft crap like it was candy. Now, if the house catches fire, I'll just grab my Rocketfish drive and run, this week's airplane pictures bedamned!

Glad you're getting back in action Ian.

Rusty

You remind me how glad I am I don't rely on knowing how to work on computers anymore. About all I remember how to do is turn it on and run a weekly backup. I made a big fat notebook over the years to remind me what do do if it goes blooey. It's titled "In Case of Crash." I've been running Win7-32 since the day it was released some distant October ago. Was it 2009, seems longer. The first mostly stable Windows program ever. Hard to believe we kept gobbling up Microsoft crap like it was candy. Now, if the house catches fire, I'll just grab my Rocketfish drive and run, this week's airplane pictures bedamned!

Glad you're getting back in action Ian.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My recent disaster

Re: My recent disaster

Hey Ian,

Sorry to hear about your computer dilemma.

If the software isn't working in Win7 32 bit you can try running it in Compatibility mode.

Also, have you tried a PCI LPT Port card?

Shawn

Sorry to hear about your computer dilemma.

If the software isn't working in Win7 32 bit you can try running it in Compatibility mode.

Also, have you tried a PCI LPT Port card?

Shawn

sdjjadk- Platinum Member

- Posts : 640

Join date : 2012-04-07

Location : Southern Maryland

Re: My recent disaster

Re: My recent disaster

Ian , Good too hear from you old man,,,, Sorry to hear all that crap is giveing you a bunch of BS . Sounds like you have gotten it straightened out

So what the heck were ya turning the crank down for anyway!! I know s$$t about computers..... Rusty are you on the pipe AGAIN ! Getback:D

So what the heck were ya turning the crank down for anyway!! I know s$$t about computers..... Rusty are you on the pipe AGAIN ! Getback:D

getback- Top Poster

Posts : 10168

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: My recent disaster

Re: My recent disaster

Man... sorry that happened Ian. Computers are awesome.. until they crash. I have two Windows machines running XP. My digital music recording software/hardware won't work with anything newer.

This is a major pain for you now... but once you get the new system all synched-up.. you'll be better off... and also protected against the damage caused from a back-feed dead-short. The only thing I can equate with what happened in your case.. is a lightning-strike. I've often considered isolating my sensitive electronics completely by using inverters with deep cycle batteries.. especially if I need to boot-up when there's the threat of a thunder storm.

I'm curious about the Cox .049 crankcase.. could it be that your milling a new case to accept a front bearing for the crankshaft?

This is a major pain for you now... but once you get the new system all synched-up.. you'll be better off... and also protected against the damage caused from a back-feed dead-short. The only thing I can equate with what happened in your case.. is a lightning-strike. I've often considered isolating my sensitive electronics completely by using inverters with deep cycle batteries.. especially if I need to boot-up when there's the threat of a thunder storm.

I'm curious about the Cox .049 crankcase.. could it be that your milling a new case to accept a front bearing for the crankshaft?

Re: My recent disaster

Re: My recent disaster

sdjjadk wrote:Hey Ian,

Sorry to hear about your computer dilemma.

If the software isn't working in Win7 32 bit you can try running it in Compatibility mode.

Also, have you tried a PCI LPT Port card?

Shawn

Some of my reasoning is long and involved but the prime software I run to control my machines is Mach3. It will run under Windows 7 32 bit with a parallel port but ............ now here it gets a little iffy ........ new motherboards are geared to 64 bit. There are no drivers available for 32 bit software - Microsofts current release is Windows 8.1. So you can install Win & but find there are no drivers available for the USB ports on the motherboard! No USB means I cannot easily transfer files, deploy USB keyboard or mouse and. more importantly for me, I use a USB

Shuttlepro for manually controlling the machine axes.

Matching operating system and motherboard is a problem.

The case I use is Mini ITX. It has a small motherboard and only one PCIx expansion slot (This is not the standard PCI port) . I use Mini ITX because it is fan less and small. It reduces the chance of swarf being drawn into the PC. So I have my own imposed limitations.

The largest dilemma is that the board blew in the first place. I had not realised how sensitive they are and there is no protection for any form of spiking through a parallel port.

It was also particularly galling that I had two other PCs - and XP laptop and a Win Vista laptop that were incapable of driving my CNC controller (no parallel port).

So I had a choice of deploying a Smoothstepper - Ethernet or USB. I chose Ethernet because you can use a longer cable between the PC and the Smothstepper. The Ethernet Smoothstepper also emulates three parallel ports! It provides another blowout defense for the mother board.

I can now control my equipment with all three machines - both laptops and the newly built PC.

It is not so much the cost of a motherboard but the time it takes to rebuild and my hobby down time that follows!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 69

Location : England

Re: My recent disaster

Re: My recent disaster

roddie wrote:Man... sorry that happened Ian. Computers are awesome.. until they crash. I have two Windows machines running XP. My digital music recording software/hardware won't work with anything newer.

This is a major pain for you now... but once you get the new system all synched-up.. you'll be better off... and also protected against the damage caused from a back-feed dead-short. The only thing I can equate with what happened in your case.. is a lightning-strike. I've often considered isolating my sensitive electronics completely by using inverters with deep cycle batteries.. especially if I need to boot-up when there's the threat of a thunder storm.

I'm curious about the Cox .049 crankcase.. could it be that your milling a new case to accept a front bearing for the crankshaft?

Roddie - I am sure you are aware that XP is dead in the water and no longer supported by Microsoft. I set up Windows XP emulation under Windows 7 64 bit and it only worked to a point. Again you still need Windows XP drivers to match the motherboard.

For reasons mentioned above - I went for the "upgrade" route but an alternative was scooping up cheap pre owned equipment. There will be a time though when something will happen and XP will become unusable. Microsoft will not provide a fix.

For a few of us - hardware is not the investment. It is software! It is not just the cost of the software but the time taken to learn and use it. Nothing these days seems to be backwards or forwards compatible.

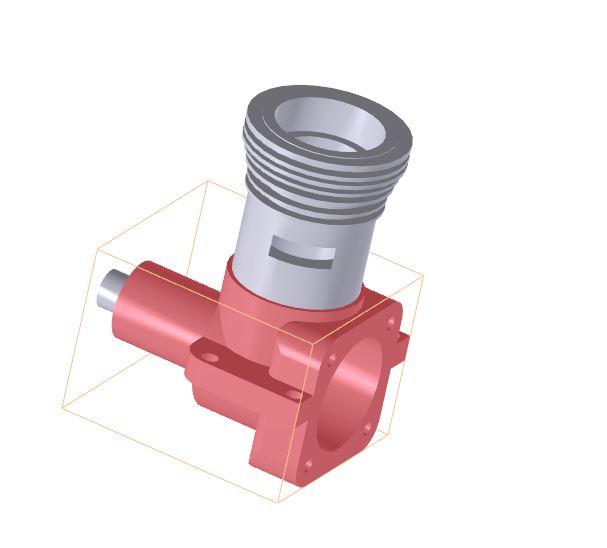

The crankcase I am milling will not have a bearing (yet! I have not located bearings that fit the 049 bee crankshaft). I have printed this part with the intention of producing castings but decided to machine it. It will be easy to modify it for bearings.

I was in usual mode. I saw your mounts for the postage stamp backplates and thought I would take that a stage further and modify one of my designs.

A beam mounted crankcase for a postage stamp backplate!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 69

Location : England

Re: My recent disaster

Re: My recent disaster

On the pipe! If I was, I couldn't talk about it here.getback wrote: ..... Rusty are you on the pipe AGAIN ! Getback:D

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My recent disaster

Re: My recent disaster

RknRusty wrote:On the pipe! If I was, I couldn't talk about it here.getback wrote: ..... Rusty are you on the pipe AGAIN ! Getback:D

Why not?

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 69

Location : England

Re: My recent disaster

Re: My recent disaster

Hi Ian, I hope you're back up and running. I really like your crankcase design!! I'm ashamed to say; that I've never removed a crankshaft from a cox engine... so I don't know what it's O.D. measures at the nose.. I agree that a bearing that size would be tough to find.. even if one existed. Machining the case to accept it.. might also compromise the strength of the stock case in that area. Do you suppose that the case could be bored/reamed to accept an "oilite" bushing to support the crank? This could possibly be done on a drill-press.. and might be an option for repairing old "egged-out" cases??

Your thoughts?

Your thoughts?

Re: My recent disaster

Re: My recent disaster

I'll poke my nose in, if I may, Roddie.roddie wrote: Do you suppose that the case could be bored/reamed to accept an "oilite" bushing to support the crank? This could possibly be done on a drill-press.. and might be an option for repairing old "egged-out" cases??

Your thoughts?

I bought this case and heat treated crank from

KustomKraftmanship in the early 80's.

Bob

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Re: My recent disaster

Re: My recent disaster

Not quite up and running but not far away now.

I have restored quite a few crankcases - can't bear to thow anything away. So I have the tools to bore, ream and install a brass or phospor bronze bearing and bore and ream that for a crankshaft. The crankshaft is not a standard drill size but I had a "worn" and resharpened reamer that does the job.

Here is an example

I have restored quite a few crankcases - can't bear to thow anything away. So I have the tools to bore, ream and install a brass or phospor bronze bearing and bore and ream that for a crankshaft. The crankshaft is not a standard drill size but I had a "worn" and resharpened reamer that does the job.

Here is an example

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 69

Location : England

Re: My recent disaster

Re: My recent disaster

Ian, looking at your beam mount case design, I

wonder how casting it with glass resin (ala the Testors

pipe bomb) would work. Of course that would probably

intail threaded inserts for the case screws and cylinder,

besides the crank bushing. Lots of work, I'm sure.

Never mind.

Bob

Bob

wonder how casting it with glass resin (ala the Testors

pipe bomb) would work. Of course that would probably

intail threaded inserts for the case screws and cylinder,

besides the crank bushing. Lots of work, I'm sure.

Never mind.

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Re: My recent disaster

Re: My recent disaster

ian1954 wrote:RknRusty wrote:On the pipe! If I was, I couldn't talk about it here.getback wrote: ..... Rusty are you on the pipe AGAIN ! Getback:D

Why not?

xBvqYmmvhDY

Oh That pipe. Not the Peace pipe. Lol I think I'd be safer on the latter.

Okay now i'm off to read the rest of the posts in the thread. They look interesting.

Rusty

Edit: It was interesting. You have great ideas and do nice work too.[/quote]

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My recent disaster

Re: My recent disaster

dckrsn wrote:I'll poke my nose in, if I may, Roddie.roddie wrote: Do you suppose that the case could be bored/reamed to accept an "oilite" bushing to support the crank? This could possibly be done on a drill-press.. and might be an option for repairing old "egged-out" cases??

Your thoughts?

I bought this case and heat treated crank from

KustomKraftmanship in the early 80's.

Bob

Yes Bob.. that's what I'm talking about.. (nice piece BTW..) Did KK install a rear bushing as well? Have you ever measured the Cox .049 crank's O.D.? I'm curious as to what it is. Ian states that it's not a standard drill size... and I don't understand why that would be.

Ian.. is that dieselized Bee really wiggling??

Re: My recent disaster

Re: My recent disaster

Roddie, I'll check for the bushing and measure

some cranks tomorrow.

Bob

Bob

some cranks tomorrow.

Bob

Bob

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Re: My recent disaster

Re: My recent disaster

I would find it extremely difficult next to impossible to drill and bush a case using a drill press accurately. I've bushed these cases myself . I have a fixture which not only holds case in the jaws, but it also prevents the bushing from protruding into the rear of the case too far. This prevents the bearing from requiring machining on the inside. There would be no guarantee that your drilling the case square as your just following a existing bore which itself could be off due to wear or incorrectly drilled from the start. If one of the angles of the drill bit is even slightly ground from the correct angle, the drill walks. Once the bushing is installed, a reamer is the best choice due to accuracy and consistency . I used a boring bar which took what seemed forever due to the light passes required to prevent the boring bar from flexing due to being so narrow to fit inside. A reamer was purchased later. While there are many different grades of brass it wouldn't be my choice of bearing material as it isn't ever considered a material to be used for such. This of course is just my experience. Ken

Ken Cook- Top Poster

- Posts : 5491

Join date : 2012-03-27

Location : pennsylvania

Re: My recent disaster

Re: My recent disaster

dckrsn wrote:Roddie, I'll check for the bushing and measure

some cranks tomorrow.Bob

I'd appreciate that Bob.. Thank you.

Ken, yea.. you've got some good points there. I'm sure it's not as easy as I thought. I'd like to buy a small precision machine for home use someday. Ian has made some suggestions to me. I had gotten my "feet wet" in metalwork; the last 3-4 years.. but didn't know enough to earn decent pay. As far as "training" goes... the two companies I'd worked for, didn't want to invest the time in me.

Re: My recent disaster

Re: My recent disaster

Ken Cook wrote:I would find it extremely difficult next to impossible to drill and bush a case using a drill press accurately. I've bushed these cases myself . I have a fixture which not only holds case in the jaws, but it also prevents the bushing from protruding into the rear of the case too far. This prevents the bearing from requiring machining on the inside. There would be no guarantee that your drilling the case square as your just following a existing bore which itself could be off due to wear or incorrectly drilled from the start. If one of the angles of the drill bit is even slightly ground from the correct angle, the drill walks. Once the bushing is installed, a reamer is the best choice due to accuracy and consistency . I used a boring bar which took what seemed forever due to the light passes required to prevent the boring bar from flexing due to being so narrow to fit inside. A reamer was purchased later. While there are many different grades of brass it wouldn't be my choice of bearing material as it isn't ever considered a material to be used for such. This of course is just my experience. Ken

"Brass" is an alloy and there are many variations. There are quite a few "Brasses" that aren't suitable for machining but quite a few are.

Brass C464 (Naval Brass) is used extensively in marine construction due to its high corrosion resistance to seawater It is known for its good strength, good rigidity/hardness and resistance to wear, fatigue, galling and stress cracking. Also recognized for superior tensile strength, higher yield strength, good elongation, excellent thermal conductivity, good capacity for being cold worked, excellent capacity for being hot formed and excellent soldering and brazing.

Typical Applications: Bushings, Fasteners, Light Bearings, Marine Hardware, Plumbing Fittings, Propeller Shafts, Screw Machine Parts, Seawater Valve Systems, Water Boiler Systems, Welding Rod Bearings .

Here is one you wouldn't use

Brass C260 has been produced as a combination of copper and zinc, it has the highest ductility in the yellow brass series. It is an attractive material with a smooth, yellow brass finish and it can have a polished or brushed (satin) finish. C260 Brass can be used in corrosive enviroments. C260 Brass forms a thin protective patina ( layer ),which, unlike steel and iron, will not rust when exposed to the atmosphere. It has excellent cold workability and is used extensively in the automotive industry, also in the manufacturing of plumbing, hardware, and ammunition components.

Typical Applications:

Air instruments and machines, heat exchangers, pump cylinders, wire screens, pumps, liners, power cylinders, Odometer contacts, heater cores, thermostats, electrical connectors, radiator cores, radiator tube, radiator tanks, Snaps, planters, fireplace screens, etched articles, bird cages, coinage, chain links, pen/pencil, lamps, inserts and clips, syringe parts, watch parts, costume jewelry, buttons, shells – electrical sockets in the automotive industry, also in the manufacturing of plumbing, hardware, and ammunition components. pressure conveyer systems, sound proofing equipment, springs, chain, bead chain

"White Metal" is also easy to form - low meting point and easy to machine

% Sn % Sb % Cu % Pb Applications

93 3.5 3.5 - Light and medium IC engine big end bearings

86 10.5 3.5 - Light and medium IC engine main bearings

80 11 3.0 6 General purpose heavy bearings (lead increases plasticity)

60 10 28.5 1.5 Heavy duty marine engine bearings, electrical machines

40 10 1.5 48.5 Low cost, general purpose, medium duty bearings

Phosphor bronze is excellent but difficult to machine - it is a drill grabber!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 69

Location : England

Re: My recent disaster

Re: My recent disaster

roddie wrote:

Ian.. is that dieselized Bee really wiggling??What was the purpose of grooving the nose of the case? Is that an 8 x 4 prop on that engine? The "wiggly" Bee seemed to run much faster than the Tee Dee.. Is this because of the bearings you installed in it? Are the same props being run on both engines in the vid? (sorry for all these questions..

)

Both props are 7x5. The Bee did wiggle! The mounting was loose.

The TD diesel is an excellent runner and faster than the Bee but I was running it in. A very rich mixture and throttle restriction.

The aim of the bushing was to repair an otherwise useless crankcase. I am not sure that bushing would make a big difference in performance.

The grooving was primarily decoration but the raised portions are concentric to the bore and allowed me to reverse the crankcase and fit it to a collet chuck. The I could confidently machine the inside of the bearing.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 69

Location : England

getback- Top Poster

Posts : 10168

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: My recent disaster

Re: My recent disaster

Roddoe,just got home from work and measured 3 random Bee cranks.roddie wrote:dckrsn wrote:Roddie, I'll check for the bushing and measure

some cranks tomorrow.Bob

I'd appreciate that Bob.. Thank you.

Ken, yea.. you've got some good points there. I'm sure it's not as easy as I thought. I'd like to buy a small precision machine for home use someday. Ian has made some suggestions to me. I had gotten my "feet wet" in metalwork; the last 3-4 years.. but didn't know enough to earn decent pay. As far as "training" goes... the two companies I'd worked for, didn't want to invest the time in me.

.2190in-7/32in.

As for the bushed case, the bushing only extends about 1/4" back from the nose.

I didn't know that. Impossible for me to photograph with my camera.

Bob

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Re: My recent disaster

Re: My recent disaster

I have one of those KK cases and the bushing stops just short of all the way into the crankcase, there is a grove in the bushing about 1/4" back from the nose like maybe the bushing is two pieces.

No oil grove.

No oil grove.

crankbndr- Top Poster

- Posts : 3073

Join date : 2011-12-10

Location : Homestead FL

Re: My recent disaster

Re: My recent disaster

dckrsn wrote:

Roddoe,just got home from work and measured 3 random Bee cranks.

.2190in-7/32in.

As for the bushed case, the bushing only extends about 1/4" back from the nose.

I didn't know that. Impossible for me to photograph with my camera.

Bob

Unfortunately, 7/32 is .21875. that is a tight fit.

A tight fit is fine for pressing in a bushing.

The next size up is a Number 2 drill - .2210 a very loose fit.

I have just been a checked my maching notes and I use a 5.5 mm drill followed by a 15/64 reamer. 15/64 = .2344 but this has been re sharpened twice and is now .21905. The drill and the reamer are used with plenty of cutting fluid. With cutting fluid the hole probly ends up at .21915.

The drill is pecked - constantly withdrawn to remove swarf.

The hole to be reamed with a machine reamer must be drilled or bored to within 0.012 inch of the finished size so that the machine reamer will only have to remove the cutter bit marks. The reamer should be withdrawn from the hole carefully, turning it in the same direction as when reaming. Never turn a reamer backwards.

There are hand reamers and machine reamers. Never use a hand reamer under power! Must be turned slowly and be within 0.005 inch of the required finished size.

I bush a Bee crankcase the full length but can see nothing wrong with just covering the bearing surface on the crankshaft. Less weight!

I am not sure that the oil groove is necessary.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 69

Location : England

Page 1 of 2 • 1, 2

Similar topics

Similar topics» How's the weather?

» Recipe for disaster!

» Keil Kraft Silver Hurricane Restoration

» Recent kit build…

» AMA membership

» Recipe for disaster!

» Keil Kraft Silver Hurricane Restoration

» Recent kit build…

» AMA membership

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules