Log in

Search

Latest topics

» Fox .35 Modifications by GallopingGhostler Today at 3:58 pm

» Jim Walkers FireBee - This is going to be fun

by rsv1cox Today at 3:56 pm

» Happy Anzac Day!

by GallopingGhostler Today at 12:44 pm

» Revivng Some Childhood Classics

by rsv1cox Today at 7:17 am

» Introducing our Cox .049 TD Engines

by getback Today at 6:20 am

» Project Cox .049 r/c & Citabrian Champion

by getback Today at 6:17 am

» Roddie's flat-bottomed boat..

by Levent Suberk Today at 12:23 am

» Cox powered jet-pump for model Sprint Boat

by roddie Yesterday at 10:25 pm

» Micro Draco Gets to Fly on a Beautiful Morning.

by rdw777 Yesterday at 8:15 pm

» Jim Walker Firebaby

by rdw777 Yesterday at 8:06 pm

» Hydro-bat by Vic Smeed: engine probs

by GallopingGhostler Yesterday at 5:12 pm

» Roddie-Rigger.. a 2005 original design

by roddie Yesterday at 3:39 pm

Cox Engine of The Month

Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Page 5 of 31

Page 5 of 31 •  1, 2, 3, 4, 5, 6 ... 18 ... 31

1, 2, 3, 4, 5, 6 ... 18 ... 31

THE UPDATED THESIS

THE UPDATED THESIS

http://www.steven-stanley-bayes.com/Cox%20.049%20SureStart%20Diesel.doc

I AM ALLOWED TO POST LINKS AND HERE IS THE LINK TO THE THESIS, AS I HAVE PROMISSED, WHICH HAS BEEN REPOSTED BY OTHERS, SOME OF THEM HAVE CREATED A MIRROR ON OTHER SITES, BUT THE MIRRORS ARE UNLIKELY TO UPDATE THE THESIS AND I CONSTANTLY UPDATE THE THESIS. This is the version as of now.

Except the new pictures with explanations which have been inserted at the beginning of the " chapter " called " The Crankcase ", all other updates are positioned in the last pages in a special " chapter " called " Corrections and Additions to the Document " or alike. MOST OR ALL OF THESE CORRECTIONS AND ADDITIONS HAVE BEEN MADE BECAUSE OF THE RESPONSES I HAVE RECEIVED ON THIS FORUM, SOME OF THEM, DIRECTLY COPIED AND PASTED, FOR WHICH I AM THANKFUL TO THE PEOPLE WHO HAVE PROVIDED THIS EXTREMELY USEFUL INFORMATION. I have expressed special thanks in other posts.

I AM ALLOWED TO POST LINKS AND HERE IS THE LINK TO THE THESIS, AS I HAVE PROMISSED, WHICH HAS BEEN REPOSTED BY OTHERS, SOME OF THEM HAVE CREATED A MIRROR ON OTHER SITES, BUT THE MIRRORS ARE UNLIKELY TO UPDATE THE THESIS AND I CONSTANTLY UPDATE THE THESIS. This is the version as of now.

Except the new pictures with explanations which have been inserted at the beginning of the " chapter " called " The Crankcase ", all other updates are positioned in the last pages in a special " chapter " called " Corrections and Additions to the Document " or alike. MOST OR ALL OF THESE CORRECTIONS AND ADDITIONS HAVE BEEN MADE BECAUSE OF THE RESPONSES I HAVE RECEIVED ON THIS FORUM, SOME OF THEM, DIRECTLY COPIED AND PASTED, FOR WHICH I AM THANKFUL TO THE PEOPLE WHO HAVE PROVIDED THIS EXTREMELY USEFUL INFORMATION. I have expressed special thanks in other posts.

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

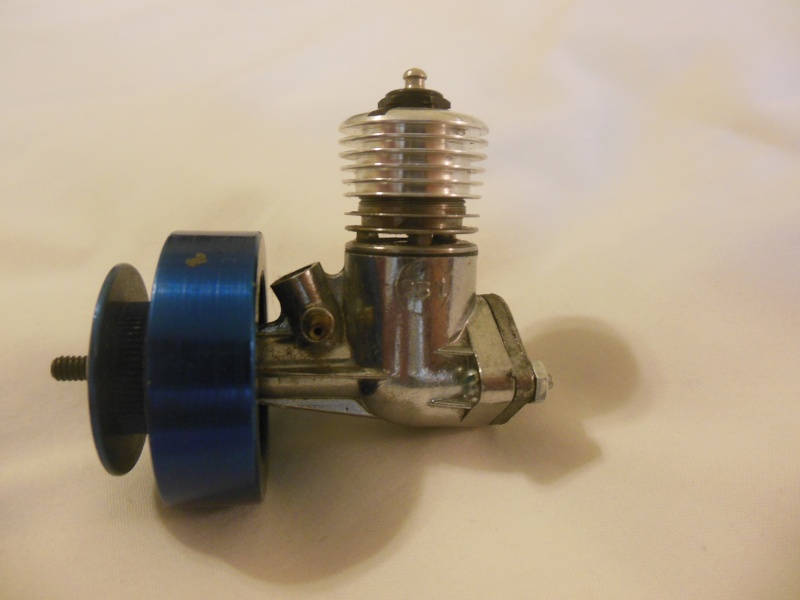

that is no flywheel that is just a counter balance

it is so that the engine does not kills itself

normaly the prob acts as the flywheel but now with a dynamo attatched the flywheel is gone

and so the engine cant run as smoot

you want slow rpm then you need a big flywheel to store inertia

with you did with a fan and those rings in it

and yea it makes it wear quicker if your ballance is off

my dummas boat (powered by a cox medalion) has a flywheel just to make the inertia bigger for running on water

and my kyosho 049 (also powered by a cox ) also has a flywheel

and this is for some more inertia on the steet

it is so that the engine does not kills itself

normaly the prob acts as the flywheel but now with a dynamo attatched the flywheel is gone

and so the engine cant run as smoot

you want slow rpm then you need a big flywheel to store inertia

with you did with a fan and those rings in it

and yea it makes it wear quicker if your ballance is off

my dummas boat (powered by a cox medalion) has a flywheel just to make the inertia bigger for running on water

and my kyosho 049 (also powered by a cox ) also has a flywheel

and this is for some more inertia on the steet

robot797- Platinum Member

- Posts : 749

Join date : 2013-07-28

Age : 33

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 69

Location : England

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

robot797 wrote:that is no flywheel that is just a counter balance

it is so that the engine does not kills itself

normaly the prob acts as the flywheel but now with a dynamo attatched the flywheel is gone

and so the engine cant run as smoot

you want slow rpm then you need a big flywheel to store inertia

with you did with a fan and those rings in it

and yea it makes it wear quicker if your ballance is off

my dummas boat (powered by a cox medalion) has a flywheel just to make the inertia bigger for running on water

and my kyosho 049 (also powered by a cox ) also has a flywheel

and this is for some more inertia on the steet

Thank you for this information. I am happy you have done so with your yacht and am very happy to get this information from a person who have had a great deal of experience in this specific topic.

I have been considering a flywheel effect and, for now, I have decided against. I also think the dynamo may get some inertia into the system, although I do not think this inertia would be extremely high.

However, in the future, I may consider a flywheel strongly and may experiment with one. For sure, I will remember and take your advise and experience.

I am happy you have been using Cox for marine applications. I have read someone build a car with a Cox engine. I agree with you, in these applications, low RPM performance may come handy.

I apologise for the misunderstanding : I call a flywheel anything which " stores " inertia based on the eccentric principle of non symmetrical weight ( like the crankshaft " counterweight " as you have expressed ). I call " flywheel effect " everything which brings inertia to the system, such as symmetrical weights.

Thanks for your reply which I will remember.

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Thanks. Looks OK.

Not related to you, I saw a German generator which had a pulley for pull start which I do not think was a flywheel but extremely light Aluminium starter pulley.

I am happy to see your design. As I have replied to the previous responder on the flywheel, for now, I am happy with the system as is which, I think, brings a good response at low RPM. In case I decide to experiment more with flywheels and effects of this sort, I will remember your post as well as the post of the previous replier.

Thank you.

I am also happy to see your excellent design of the flywheel.

For now, I am even afraid to put light Aluminium pulleys to avoid extra weight and use plastic pulleys. I may be forced to use the Aluminium ones in case I am unable to keep the belt.

And I will remember your advise should I need a flywheel in the future.

LOW RPM WITHOUT A FLYWHEEL OR A FLYWHEEL EFFECT

LOW RPM WITHOUT A FLYWHEEL OR A FLYWHEEL EFFECT

For obvious reasons, this reply does not apply to the people who replied with an interesting topic of flywheels but to all other who have expressed response on low RPM. I had written this reply on Word for Windows before I received the flywheel replies.

Here is the post :

A lot of people have concentrated their energy on replying on the power of the engine at low RPM. I have received opposite responses. Some say this engine is powerful at low RPM. Others say not.

I thank all for these responses, although, as I have requested in the reply with subject “ THE HELP I NEED “, this is not the main topic I need help with. I mainly need help with the SETTINGS AND FUEL for a better performance at low RPM. Settings are the positions of the main three controls : air valve ( throttle ), fuel needle valve and compression. Settings are not tunings. One can mistake tunings with changes to the engine to better perform at this condition which is not what I ask for because, for now, I use only Cox original parts and nothing else.

I have not had A LOT OF experience with this engine, yet, I have had experiences with many general purpose engines with internal combustion.

I am sure I will not achieve the maximal power output at low RPM which is not the goal.

I will be able to find more when I assemble and run the generator although the findings will not be very accurate because I will rely on the unknown power / RPM function of the dynamo to measure the electrical power output of the hole system ( to multiply DC current by DC voltage by reading the ampermeter and the voltmeter ).

However :

I have visually examined the output of the engine at low RPM and, from what I can see, this looks high.

I have also done a simple “ test “ by mistake : I put a hand on the TOP of the propeller path while the engine was working at low RPM. The hand got cut by the TOP of the propeller blades and blood flew all over. The engine did not blink. Decreased the RPM slightly and then increased again for less than a second.

Thus, based on the visual examination with a heavy 8 inch dual blade propeller as well as on the mentioned “ test “, I agree with whoever said “ These engines pack a punch at low RPM “.

I do not need much more help on this issue and prefer you all to concentrate on the main issues listed in the reply with a subject “ The Help I Need “.

Please, do concentrate on the main topics I need help with : SETTINGS AND FUEL. I have read what the documentations on this subject say BUT I want to read from you all.

I will again post a copy of the post with a subject : “ The Help I Need “ for clarification.

I have not been teaching anyone anything as I am not the one to teach. I have been simply replaying to all post because I think not to reply is offensive or impolite. In case this is the other way around, just say so and I will stop answering to every post.

I DO NEED HELP WITH THE ENGINE. I have clearly been saying what help.

1. HELP WITH THIS ENGINE AND ALTERNATIVE FUELS SUCH AS BIODIESEL. Any information for fuel with standard products and without Ether is welcome ( IN CASE THIS IS POSSIBLE, because, as some say, this may not be possible with this engine ). I thanked the post from the UK which showed an engine running on such a fuel. I may try after the project is assembled and run on standard fuel.

2. HELP WITH THIS ENGINE AND STANDARD FUEL :

2.1 WHAT KIND OF STANDARD FUEL CAN I USE. WHAT ARE THE COMPONENTS? WHAT ARE THE PERCENTAGES OF THE COMPONENTS. I have thanked Ken for the information of medicinal Kerosene as well as First Pressed Castor Oil. Also for Cetane Booster : Amil or Isopropyl Nitrate and not EthylExyl Nitrate. I cannot find these but I am thankful I will know what to look for and get should these become available here.

2.2 WHAT ARE THE START UP SETTINGS FOR A GIVEN FUEL : How much is the air valve ( throttle open )? How much is the fuel needle valve ( throttle ) open. How much is the compression screw open. How many ( very approximately ) spring starts would I need to do before the engine starts.

2.3 WHAT ARE THE SETTINGS AFTER START UP? To what extend do I have to tighten up the compression screw after start as well as the air valve ( throttle ) and the needle valve? How many seconds or minutes do I have to react and readjust these?

2.4 WHAT ARE THE SETTINGS FOR A NORMAL RUN? What is the fuel needle valve setting? What is the compression screw setting? Obviously, the air valve ( throttle ) is used from almost fully closed or fully closed to fully open.

2.5 WHAT PERCENTAGES OF THE STANDARD FUEL OR WHAT FUEL DO YOU THINK IS THE BEST FOR GETTING MORE POWER AT LOW RPM?

2.6 WHAT DO YOU THINK OF METHANOL BASED FUEL AS OPPOSED TO KEROSENE BASED FUEL?

2.7 I do not expect an answer to this question but this is the most important question : Where can I get these and other fuel components or fuels in Ottawa, Ontario, Canada? Again : I DO NOT EXPECT AN ANSWER.

3. Does anyone know of a clever way to get inexpensive Ether and or Methanol? University Supply Places, Medical Supply, Hobby Supply, Model Airplane Clubs, Racing, Truck Stops, Truckers Helping Truckers, Diesel Car Enthusiast Groups, Paint Shops, Private Airfields?

4. ENGINE RELIABILITY AND LONGEVITY AFTER A LONG CONTINUOUS ( OR APPROXIMATELY CONTINUOUS ) WORK AT ANY RPM, EVEN HIGHEST. How much do you run your engines. When you go out to fly, do you run your engines for 6 or 8 hours, tank load after tank load. How often do you go for a fly session? Do you go almost every Saturday and Sunday? Do you do competition where you have to train almost the whole week and or month? Do you abuse your engines a lot in order to perform stunts. Without keeping a log book : approximately : how long? Have your engines ever broken? What? How long after new?

5. PISTON RESETTING : How often do you do piston resetting when engine new and how often when run. I thank this responder who said the piston was only reset once when the engine was acquired ( second hand ) and than run for years under heavy abuse ( purchased for $3 ) without a problem. What are your experiences?

6. Do you know other tricks for a better start up, other than priming. What is your input on priming? Do you warm your cylinders with a blow torch? Do you keep your engines in your cars just before start up in the freeze? What is the most freezing weather you have started a diesel in? What will happen in case the engine is kept at minus 10ºC for a long while? Will the engine start? What other temperatures have you started your engines in?

7. HOW DO YOU ADJUST THE SETTINGS AS WELL AS THE FUEL PERCENTAGES IN FREEZING WEATHER AS WELL AS IN HOT?

8. WHAT IS THE TINIEST PROPELLER TO USE FOR LOW RPM? CAN I USE, SAY, A 3.5 INCH PROPELLER? HOW MANY BLADES? Remember, I do not use the propeller for flying but as a fan.

To summarise : THE HELP I NEED THE MOST HAS BEEN LISTED HERE AND BEFORE. Any help with the engine is welcome even this which says of alternative cranks. Third party carburetor prices and availability welcome for future. Taking care of the engine is also welcome.

Special thanks to :

The poster of the post on reliability of the engine and longevity.

The poster from the UK of the alternative diesel fuel with percentages and components.

The posters who have commented on low RPM : positive and negative, all.

Ken from the UK who clarified the best products to make the best Kerosene based fuel and displayed the bottles with labels to do so.

The poster who commented on the bidirectionality of the engine which was corrected in the thesis.

The posters who have posted other micro generators for a good reference.

Please, be kind posters. REFLECT ON THE ENGINE AND FUEL. Try to refrain from commercial viability or any business advices as well as electrical and electronics or, in case you must, try to be as quick on these as possible and as long as possible on the engine and fuel and other listed questions. Also, please, try to skip long comments on things which I will easily be able to find out and there is no much room for a mistake, for example : I will soon hear how loud the engine with a muffler is and will post a video. No need to post long comments on what I can hear. However, in case you would like to comment on how to improve these, you are more than welcome. In this example, in case you say how to reduce the noise ( with fuel or more muffler or the two thereof ) you are welcome.

Here is the post :

A lot of people have concentrated their energy on replying on the power of the engine at low RPM. I have received opposite responses. Some say this engine is powerful at low RPM. Others say not.

I thank all for these responses, although, as I have requested in the reply with subject “ THE HELP I NEED “, this is not the main topic I need help with. I mainly need help with the SETTINGS AND FUEL for a better performance at low RPM. Settings are the positions of the main three controls : air valve ( throttle ), fuel needle valve and compression. Settings are not tunings. One can mistake tunings with changes to the engine to better perform at this condition which is not what I ask for because, for now, I use only Cox original parts and nothing else.

I have not had A LOT OF experience with this engine, yet, I have had experiences with many general purpose engines with internal combustion.

I am sure I will not achieve the maximal power output at low RPM which is not the goal.

I will be able to find more when I assemble and run the generator although the findings will not be very accurate because I will rely on the unknown power / RPM function of the dynamo to measure the electrical power output of the hole system ( to multiply DC current by DC voltage by reading the ampermeter and the voltmeter ).

However :

I have visually examined the output of the engine at low RPM and, from what I can see, this looks high.

I have also done a simple “ test “ by mistake : I put a hand on the TOP of the propeller path while the engine was working at low RPM. The hand got cut by the TOP of the propeller blades and blood flew all over. The engine did not blink. Decreased the RPM slightly and then increased again for less than a second.

Thus, based on the visual examination with a heavy 8 inch dual blade propeller as well as on the mentioned “ test “, I agree with whoever said “ These engines pack a punch at low RPM “.

I do not need much more help on this issue and prefer you all to concentrate on the main issues listed in the reply with a subject “ The Help I Need “.

Please, do concentrate on the main topics I need help with : SETTINGS AND FUEL. I have read what the documentations on this subject say BUT I want to read from you all.

I will again post a copy of the post with a subject : “ The Help I Need “ for clarification.

I have not been teaching anyone anything as I am not the one to teach. I have been simply replaying to all post because I think not to reply is offensive or impolite. In case this is the other way around, just say so and I will stop answering to every post.

I DO NEED HELP WITH THE ENGINE. I have clearly been saying what help.

1. HELP WITH THIS ENGINE AND ALTERNATIVE FUELS SUCH AS BIODIESEL. Any information for fuel with standard products and without Ether is welcome ( IN CASE THIS IS POSSIBLE, because, as some say, this may not be possible with this engine ). I thanked the post from the UK which showed an engine running on such a fuel. I may try after the project is assembled and run on standard fuel.

2. HELP WITH THIS ENGINE AND STANDARD FUEL :

2.1 WHAT KIND OF STANDARD FUEL CAN I USE. WHAT ARE THE COMPONENTS? WHAT ARE THE PERCENTAGES OF THE COMPONENTS. I have thanked Ken for the information of medicinal Kerosene as well as First Pressed Castor Oil. Also for Cetane Booster : Amil or Isopropyl Nitrate and not EthylExyl Nitrate. I cannot find these but I am thankful I will know what to look for and get should these become available here.

2.2 WHAT ARE THE START UP SETTINGS FOR A GIVEN FUEL : How much is the air valve ( throttle open )? How much is the fuel needle valve ( throttle ) open. How much is the compression screw open. How many ( very approximately ) spring starts would I need to do before the engine starts.

2.3 WHAT ARE THE SETTINGS AFTER START UP? To what extend do I have to tighten up the compression screw after start as well as the air valve ( throttle ) and the needle valve? How many seconds or minutes do I have to react and readjust these?

2.4 WHAT ARE THE SETTINGS FOR A NORMAL RUN? What is the fuel needle valve setting? What is the compression screw setting? Obviously, the air valve ( throttle ) is used from almost fully closed or fully closed to fully open.

2.5 WHAT PERCENTAGES OF THE STANDARD FUEL OR WHAT FUEL DO YOU THINK IS THE BEST FOR GETTING MORE POWER AT LOW RPM?

2.6 WHAT DO YOU THINK OF METHANOL BASED FUEL AS OPPOSED TO KEROSENE BASED FUEL?

2.7 I do not expect an answer to this question but this is the most important question : Where can I get these and other fuel components or fuels in Ottawa, Ontario, Canada? Again : I DO NOT EXPECT AN ANSWER.

3. Does anyone know of a clever way to get inexpensive Ether and or Methanol? University Supply Places, Medical Supply, Hobby Supply, Model Airplane Clubs, Racing, Truck Stops, Truckers Helping Truckers, Diesel Car Enthusiast Groups, Paint Shops, Private Airfields?

4. ENGINE RELIABILITY AND LONGEVITY AFTER A LONG CONTINUOUS ( OR APPROXIMATELY CONTINUOUS ) WORK AT ANY RPM, EVEN HIGHEST. How much do you run your engines. When you go out to fly, do you run your engines for 6 or 8 hours, tank load after tank load. How often do you go for a fly session? Do you go almost every Saturday and Sunday? Do you do competition where you have to train almost the whole week and or month? Do you abuse your engines a lot in order to perform stunts. Without keeping a log book : approximately : how long? Have your engines ever broken? What? How long after new?

5. PISTON RESETTING : How often do you do piston resetting when engine new and how often when run. I thank this responder who said the piston was only reset once when the engine was acquired ( second hand ) and than run for years under heavy abuse ( purchased for $3 ) without a problem. What are your experiences?

6. Do you know other tricks for a better start up, other than priming. What is your input on priming? Do you warm your cylinders with a blow torch? Do you keep your engines in your cars just before start up in the freeze? What is the most freezing weather you have started a diesel in? What will happen in case the engine is kept at minus 10ºC for a long while? Will the engine start? What other temperatures have you started your engines in?

7. HOW DO YOU ADJUST THE SETTINGS AS WELL AS THE FUEL PERCENTAGES IN FREEZING WEATHER AS WELL AS IN HOT?

8. WHAT IS THE TINIEST PROPELLER TO USE FOR LOW RPM? CAN I USE, SAY, A 3.5 INCH PROPELLER? HOW MANY BLADES? Remember, I do not use the propeller for flying but as a fan.

To summarise : THE HELP I NEED THE MOST HAS BEEN LISTED HERE AND BEFORE. Any help with the engine is welcome even this which says of alternative cranks. Third party carburetor prices and availability welcome for future. Taking care of the engine is also welcome.

Special thanks to :

The poster of the post on reliability of the engine and longevity.

The poster from the UK of the alternative diesel fuel with percentages and components.

The posters who have commented on low RPM : positive and negative, all.

Ken from the UK who clarified the best products to make the best Kerosene based fuel and displayed the bottles with labels to do so.

The poster who commented on the bidirectionality of the engine which was corrected in the thesis.

The posters who have posted other micro generators for a good reference.

Please, be kind posters. REFLECT ON THE ENGINE AND FUEL. Try to refrain from commercial viability or any business advices as well as electrical and electronics or, in case you must, try to be as quick on these as possible and as long as possible on the engine and fuel and other listed questions. Also, please, try to skip long comments on things which I will easily be able to find out and there is no much room for a mistake, for example : I will soon hear how loud the engine with a muffler is and will post a video. No need to post long comments on what I can hear. However, in case you would like to comment on how to improve these, you are more than welcome. In this example, in case you say how to reduce the noise ( with fuel or more muffler or the two thereof ) you are welcome.

Status Report

Status Report

Many have been interested in why I am not building the project now.

I am currently waiting to receive mail from Cox with some parts.

The mail takes 1 week. I have been waiting for more than a week and a half. Nothing.

I will reassemble the engine after I receive the parts and improve the stand.

Then, I will be able to make a video and pictures. I hope the video provides some basic visual information and a possibility for a very basic, non scientific, evaluation.

Until then, I will attempt to respond to all replies. I will try to do so thereafter too.

I am currently waiting to receive mail from Cox with some parts.

The mail takes 1 week. I have been waiting for more than a week and a half. Nothing.

I will reassemble the engine after I receive the parts and improve the stand.

Then, I will be able to make a video and pictures. I hope the video provides some basic visual information and a possibility for a very basic, non scientific, evaluation.

Until then, I will attempt to respond to all replies. I will try to do so thereafter too.

LOW RPM POWER WITHOUT ANY FLYWHEEL AND FLYWHEEL EFFECT

LOW RPM POWER WITHOUT ANY FLYWHEEL AND FLYWHEEL EFFECT

StevenStanleyBayes wrote:For obvious reasons, this reply does not apply to the people who replied with an interesting topic of flywheels but to all other who have expressed response on low RPM. I had written this reply on Word for Windows before I received the flywheel replies.

Here is the post :

A lot of people have concentrated their energy on replying on the power of the engine at low RPM. I have received opposite responses. Some say this engine is powerful at low RPM. Others say not.

I thank all for these responses, although, as I have requested in the reply with subject “ THE HELP I NEED “, this is not the main topic I need help with. I mainly need help with the SETTINGS AND FUEL for a better performance at low RPM. Settings are the positions of the main three controls : air valve ( throttle ), fuel needle valve and compression. Settings are not tunings. One can mistake tunings with changes to the engine to better perform at this condition which is not what I ask for because, for now, I use only Cox original parts and nothing else.

I have not had A LOT OF experience with this engine, yet, I have had experiences with many general purpose engines with internal combustion.

I am sure I will not achieve the maximal power output at low RPM which is not the goal.

I will be able to find more when I assemble and run the generator although the findings will not be very accurate because I will rely on the unknown power / RPM function of the dynamo to measure the electrical power output of the hole system ( to multiply DC current by DC voltage by reading the ampermeter and the voltmeter ).

However :

I have visually examined the output of the engine at low RPM and, from what I can see, this looks high.

I have also done a simple “ test “ by mistake : I put a hand on the TOP of the propeller path while the engine was working at low RPM. The hand got cut by the TOP of the propeller blades and blood flew all over. The engine did not blink. Decreased the RPM slightly and then increased again for less than a second.

Thus, based on the visual examination with a heavy 8 inch dual blade propeller as well as on the mentioned “ test “, I agree with whoever said “ These engines pack a punch at low RPM “.

I do not need much more help on this issue and prefer you all to concentrate on the main issues listed in the reply with a subject “ The Help I Need “.

Please, do concentrate on the main topics I need help with : SETTINGS AND FUEL. I have read what the documentations on this subject say BUT I want to read from you all.

I will again post a copy of the post with a subject : “ The Help I Need “ for clarification.

I have not been teaching anyone anything as I am not the one to teach. I have been simply replaying to all post because I think not to reply is offensive or impolite. In case this is the other way around, just say so and I will stop answering to every post.

I DO NEED HELP WITH THE ENGINE. I have clearly been saying what help.

1. HELP WITH THIS ENGINE AND ALTERNATIVE FUELS SUCH AS BIODIESEL. Any information for fuel with standard products and without Ether is welcome ( IN CASE THIS IS POSSIBLE, because, as some say, this may not be possible with this engine ). I thanked the post from the UK which showed an engine running on such a fuel. I may try after the project is assembled and run on standard fuel.

2. HELP WITH THIS ENGINE AND STANDARD FUEL :

2.1 WHAT KIND OF STANDARD FUEL CAN I USE. WHAT ARE THE COMPONENTS? WHAT ARE THE PERCENTAGES OF THE COMPONENTS. I have thanked Ken for the information of medicinal Kerosene as well as First Pressed Castor Oil. Also for Cetane Booster : Amil or Isopropyl Nitrate and not EthylExyl Nitrate. I cannot find these but I am thankful I will know what to look for and get should these become available here.

2.2 WHAT ARE THE START UP SETTINGS FOR A GIVEN FUEL : How much is the air valve ( throttle open )? How much is the fuel needle valve ( throttle ) open. How much is the compression screw open. How many ( very approximately ) spring starts would I need to do before the engine starts.

2.3 WHAT ARE THE SETTINGS AFTER START UP? To what extend do I have to tighten up the compression screw after start as well as the air valve ( throttle ) and the needle valve? How many seconds or minutes do I have to react and readjust these?

2.4 WHAT ARE THE SETTINGS FOR A NORMAL RUN? What is the fuel needle valve setting? What is the compression screw setting? Obviously, the air valve ( throttle ) is used from almost fully closed or fully closed to fully open.

2.5 WHAT PERCENTAGES OF THE STANDARD FUEL OR WHAT FUEL DO YOU THINK IS THE BEST FOR GETTING MORE POWER AT LOW RPM?

2.6 WHAT DO YOU THINK OF METHANOL BASED FUEL AS OPPOSED TO KEROSENE BASED FUEL?

2.7 I do not expect an answer to this question but this is the most important question : Where can I get these and other fuel components or fuels in Ottawa, Ontario, Canada? Again : I DO NOT EXPECT AN ANSWER.

3. Does anyone know of a clever way to get inexpensive Ether and or Methanol? University Supply Places, Medical Supply, Hobby Supply, Model Airplane Clubs, Racing, Truck Stops, Truckers Helping Truckers, Diesel Car Enthusiast Groups, Paint Shops, Private Airfields?

4. ENGINE RELIABILITY AND LONGEVITY AFTER A LONG CONTINUOUS ( OR APPROXIMATELY CONTINUOUS ) WORK AT ANY RPM, EVEN HIGHEST. How much do you run your engines. When you go out to fly, do you run your engines for 6 or 8 hours, tank load after tank load. How often do you go for a fly session? Do you go almost every Saturday and Sunday? Do you do competition where you have to train almost the whole week and or month? Do you abuse your engines a lot in order to perform stunts. Without keeping a log book : approximately : how long? Have your engines ever broken? What? How long after new?

5. PISTON RESETTING : How often do you do piston resetting when engine new and how often when run. I thank this responder who said the piston was only reset once when the engine was acquired ( second hand ) and than run for years under heavy abuse ( purchased for $3 ) without a problem. What are your experiences?

6. Do you know other tricks for a better start up, other than priming. What is your input on priming? Do you warm your cylinders with a blow torch? Do you keep your engines in your cars just before start up in the freeze? What is the most freezing weather you have started a diesel in? What will happen in case the engine is kept at minus 10ºC for a long while? Will the engine start? What other temperatures have you started your engines in?

7. HOW DO YOU ADJUST THE SETTINGS AS WELL AS THE FUEL PERCENTAGES IN FREEZING WEATHER AS WELL AS IN HOT?

8. WHAT IS THE TINIEST PROPELLER TO USE FOR LOW RPM? CAN I USE, SAY, A 3.5 INCH PROPELLER? HOW MANY BLADES? Remember, I do not use the propeller for flying but as a fan.

To summarise : THE HELP I NEED THE MOST HAS BEEN LISTED HERE AND BEFORE. Any help with the engine is welcome even this which says of alternative cranks. Third party carburetor prices and availability welcome for future. Taking care of the engine is also welcome.

Special thanks to :

The poster of the post on reliability of the engine and longevity.

The poster from the UK of the alternative diesel fuel with percentages and components.

The posters who have commented on low RPM : positive and negative, all.

Ken from the UK who clarified the best products to make the best Kerosene based fuel and displayed the bottles with labels to do so.

The poster who commented on the bidirectionality of the engine which was corrected in the thesis.

The posters who have posted other micro generators for a good reference.

Please, be kind posters. REFLECT ON THE ENGINE AND FUEL. Try to refrain from commercial viability or any business advices as well as electrical and electronics or, in case you must, try to be as quick on these as possible and as long as possible on the engine and fuel and other listed questions. Also, please, try to skip long comments on things which I will easily be able to find out and there is no much room for a mistake, for example : I will soon hear how loud the engine with a muffler is and will post a video. No need to post long comments on what I can hear. However, in case you would like to comment on how to improve these, you are more than welcome. In this example, in case you say how to reduce the noise ( with fuel or more muffler or the two thereof ) you are welcome.

The same good low RPM power performance applies for a 3.5 inch triple blade propeller without weights.

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

I don't know if you're aware of this but they do make a device called a tachometer which can be used to measure the RPM of a engine, without you having to mistakenly test it by sticking your hand into the arch of a moving propeller?It will work on a two or three bladed prop.There is also a company called Davis Diesel that makes products you could use to run and maintain your .049 surestart.

P-40 Warhawk- Moderate Poster

- Posts : 27

Join date : 2012-03-28

Age : 66

Location : Bowie,Maryland

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

P-40 Warhawk wrote:I don't know if you're aware of this but they do make a device called a tachometer which can be used to measure the RPM of a engine, without you having to mistakenly test it by sticking your hand into the arch of a moving propeller?It will work on a two or three bladed prop.There is also a company called Davis Diesel that makes products you could use to run and maintain your .049 surestart.

And you can order fuel from Ed Carlson.

http://carlsonengineimports.net

Good luck.

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 56

Location : Colorado

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

P-40 Warhawk wrote:I don't know if you're aware of this but they do make a device called a tachometer which can be used to measure the RPM of a engine, without you having to mistakenly test it by sticking your hand into the arch of a moving propeller?It will work on a two or three bladed prop.There is also a company called Davis Diesel that makes products you could use to run and maintain your .049 surestart.

Thank you for the information.

I have not stuck the hand to measure anything I DID THIS BY MISTAKE.

I am not happy to purchase a tachometer although I may do so from AliExpress : http://www.aliexpress.com/item/100-original-New-G-T-Power-Model-Profession-RC-Motor-Tachometer-free-shipping/1984747364.html for $15 to $16.

I would use a guitar tuner to measure the frequency of the sound the engine makes. Because the engine has one combustion per one full cycle, the frequency of the engine is equal to the measured frequency of the generated sound ( noise ). 1Hz is one cycle per second. Multiplied by 60 would give the RPM. The lowest audible sound is 20Hz which is 1200 RPM. The problem is I am not sure the guitar tuner, although fully chromatic ( can measure anything throughout the frequency range and not only what a guitar string is supposed to be ) would go this low because there are not very many instruments which would go down to 20Hz. However, measuring the whole audible range is easy, so, I would not be surprised in case the manufacturer of the guitar tuner did so. Corg C1 ( http://www.korg.com/us/products/tuners/ca_1/ ) goes to the note C1 which is 32.70Hz = 1962 RPM ~ 2000 RPM.

Your information in regards to Davies Diesel is very consistent with what others say. Everyone on the forum seems to be happy with this company. However, their prices are very high and so is their postage. Most importantly, Davis Diesel CANNOT ship to Canada because of the law which says no flammable materials are allowed to be shipped or received by mail regardless on how they are packed.

In case I ever hear of a shop which sells Davis Diesel in Ottawa, Ontario, Canada, I will be one of the first to try. The hobby shop here does not sell any diesel product.

I AM VERY MUCH INTERESTED IN THE SETTINGS ( AIR VALVE ( THROTTLE ), FUEL NEEDLE VALVE, COMPRESSION ) OF THIS OR ANY OTHER ENGINE WITH ANY FUEL INCLUDING DAVIS DIESEL : START UP SETTINGS ( WHEN YOU START THE ENGINE ) AND RUNNING SETTINGS ( WHEN YOU RUN THE ENGINE NORMALLY ).

In case you would like to share this information, I will be happy.

Thanks again.

Last edited by StevenStanleyBayes on Thu Feb 26, 2015 10:09 pm; edited 1 time in total

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

JPvelo wrote:P-40 Warhawk wrote:I don't know if you're aware of this but they do make a device called a tachometer which can be used to measure the RPM of a engine, without you having to mistakenly test it by sticking your hand into the arch of a moving propeller?It will work on a two or three bladed prop.There is also a company called Davis Diesel that makes products you could use to run and maintain your .049 surestart.

And you can order fuel from Ed Carlson.

http://carlsonengineimports.net

Good luck.

Thanks again. This is the type of information which really helps and not the mumbo jumbo we have been doing here ( with some exceptions ).

Again, this company is in US. Does not work here. Cannot ship here. Even company in Canada cannot. The only way is to walk in the shop and get.

Thesis Update

Thesis Update

http://www.steven-stanley-bayes.com/Cox%20.049%20SureStart%20Diesel.doc

The last chapter of the thesis has been updated at the sub chapter called " Fuel " with the information on the biodiesel from the UK and Davis Diesel for US readers.

The last chapter of the thesis has been updated at the sub chapter called " Fuel " with the information on the biodiesel from the UK and Davis Diesel for US readers.

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

I must admit that "Steven Stanley Bayes" is entertaining, if not amusing, but don't you think it's time he gave his keyboard a rest? Same questions, same answers - over and over.

Steven Stanley Bayes, you've been told all the answers from the blokes who know. It's about time to move on to your next forum of choice and wear out their good will.

Steven Stanley Bayes, you've been told all the answers from the blokes who know. It's about time to move on to your next forum of choice and wear out their good will.

dinsdale- Account Deactivated by Owner

- Posts : 317

Join date : 2012-02-22

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Maybe when his piston arrives he can move on from the theoretical to the applied part of this project.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

StevenStanleyBayes wrote:

I AM VERY MUCH INTERESTED IN THE SETTINGS ( AIR VALVE ( THROTTLE ), FUEL NEEDLE VALVE, COMPRESSION ) OF THIS OR ANY OTHER ENGINE WITH ANY FUEL INCLUDING DAVIS DIESEL : START UP SETTINGS ( WHEN YOU START THE ENGINE ) AND RUNNING SETTINGS ( WHEN YOU RUN THE ENGINE NORMALLY ).

The air valve can be in any position you like, it has the same function as could start choke on regular engines. So you could either use it as a cold start choke to enricher the fuel to air ratio, or you use the main needle to do it. No one can tell you what these values should be as it is all up to you how you run the engine.

Fuel ratio, compression setting, fuel formula and engine load are all related. So this is something that every owner has to find out for themselves. There are also large machining differences from one engine to another, so again you can only find the settings for each individual engine by running it.

In general you would use a higher compression setting to start the engine when it is cold. Once up to running temperature you can then back of the compression. On a hot engine you can instead reduce the compression setting a little for the start, and once the engine runs you go back to the running settings.

Once running you you need to tune on both the compression setting and the fuel ratio to find the optimum settings. These are then usually reproducible for the same fuel blend and similar weather conditions, but usually one world always give them a quick check to adjust for changes in the weather and/or the fuel etc.

Surfer_kris- Diamond Member

- Posts : 1905

Join date : 2010-11-20

Location : Sweden

Status Report

Status Report

The mail from Cox has arrived after nearly 2 business weeks since mailed.

The engine has been almost fully reassembled with a Cox muffler. The engine has been mounted on the metallic part of the stand ( half of an Aluminium enclosure, usually used for electronics ) and the wood for the pedestal of the Aluminium enclosure is in house and has been measured, ready to be cut and mounted.

The Cox starter spring has yet not been attached. Although possible to be mounted over the muffler without any modification, I am afraid the spring may come out. I am thinking of a possibility to tie the C shaped attachment of the spring to the cylinder with a Copper wire to ensure the spring would not come out of the muffler but I am not sure whether this would work. I am reluctant to remodel the spring as this would make the spring loose some tension or be slightly displaced of normal position.

I will hopefully continue with the assembly and the stand support tomorrow. I had to watch " Mayday " and " Close Encounters ". Sorry.

The piston rod of the new piston has a slight tolerance when moved up and down against the piston. I think this tolerance is bigger than 1 to 3 thousandths of an inch as advertised by Cox. I will try to remember the slack between the piston and the piston rod for evaluation when resetting may be necessary and how much.

Although I have a new cylinder too, I have decided to use the old one which is broken in. Still, I would not work the engine at high RPM for a while to make sure the new piston is broken in too.

Everything seems to be OK. This would be the first start with a muffler ( except one which I did with Ether only as a fuel for a test and breaking in where, at very low compression and air valve ( throttle ) fully open and, I think, the fuel needle valve was either fully or almost fully open too where the engine started and run for a while ( a few seconds ) until the fuel burned on Ether and Castor Oil only ), so, please, wish the attempt all of the luck you can.

The engine has been almost fully reassembled with a Cox muffler. The engine has been mounted on the metallic part of the stand ( half of an Aluminium enclosure, usually used for electronics ) and the wood for the pedestal of the Aluminium enclosure is in house and has been measured, ready to be cut and mounted.

The Cox starter spring has yet not been attached. Although possible to be mounted over the muffler without any modification, I am afraid the spring may come out. I am thinking of a possibility to tie the C shaped attachment of the spring to the cylinder with a Copper wire to ensure the spring would not come out of the muffler but I am not sure whether this would work. I am reluctant to remodel the spring as this would make the spring loose some tension or be slightly displaced of normal position.

I will hopefully continue with the assembly and the stand support tomorrow. I had to watch " Mayday " and " Close Encounters ". Sorry.

The piston rod of the new piston has a slight tolerance when moved up and down against the piston. I think this tolerance is bigger than 1 to 3 thousandths of an inch as advertised by Cox. I will try to remember the slack between the piston and the piston rod for evaluation when resetting may be necessary and how much.

Although I have a new cylinder too, I have decided to use the old one which is broken in. Still, I would not work the engine at high RPM for a while to make sure the new piston is broken in too.

Everything seems to be OK. This would be the first start with a muffler ( except one which I did with Ether only as a fuel for a test and breaking in where, at very low compression and air valve ( throttle ) fully open and, I think, the fuel needle valve was either fully or almost fully open too where the engine started and run for a while ( a few seconds ) until the fuel burned on Ether and Castor Oil only ), so, please, wish the attempt all of the luck you can.

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Yes. This is the same link. This is the crankshaft used for Cox .049 Diesel. Thanks.

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

RknRusty wrote:Maybe when his piston arrives he can move on from the theoretical to the applied part of this project.

Rusty

I can hardly wait to make the wooden support to the stand and try the first start and run with a muffler and standard fuel.

Thanks.

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

dinsdale wrote:I must admit that "Steven Stanley Bayes" is entertaining, if not amusing, but don't you think it's time he gave his keyboard a rest? Same questions, same answers - over and over.

Steven Stanley Bayes, you've been told all the answers from the blokes who know. It's about time to move on to your next forum of choice and wear out their good will.

Thanks. Yet, I have not had many inputs on : Start and Run Settings, Fuels and Alternative Fuels. This is what I have wanted the most from this forum. Thanks for all of the response, though.

Last edited by StevenStanleyBayes on Sat Feb 28, 2015 12:18 am; edited 1 time in total

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Surfer_kris wrote:StevenStanleyBayes wrote:

I AM VERY MUCH INTERESTED IN THE SETTINGS ( AIR VALVE ( THROTTLE ), FUEL NEEDLE VALVE, COMPRESSION ) OF THIS OR ANY OTHER ENGINE WITH ANY FUEL INCLUDING DAVIS DIESEL : START UP SETTINGS ( WHEN YOU START THE ENGINE ) AND RUNNING SETTINGS ( WHEN YOU RUN THE ENGINE NORMALLY ).

The air valve can be in any position you like, it has the same function as could start choke on regular engines. So you could either use it as a cold start choke to enricher the fuel to air ratio, or you use the main needle to do it. No one can tell you what these values should be as it is all up to you how you run the engine.

Fuel ratio, compression setting, fuel formula and engine load are all related. So this is something that every owner has to find out for themselves. There are also large machining differences from one engine to another, so again you can only find the settings for each individual engine by running it.

In general you would use a higher compression setting to start the engine when it is cold. Once up to running temperature you can then back of the compression. On a hot engine you can instead reduce the compression setting a little for the start, and once the engine runs you go back to the running settings.

Once running you you need to tune on both the compression setting and the fuel ratio to find the optimum settings. These are then usually reproducible for the same fuel blend and similar weather conditions, but usually one world always give them a quick check to adjust for changes in the weather and/or the fuel etc.

THIS IS WHAT I CALL A HELPFUL TOPIC OF A RESPONSE. THANKS.

I have tried to use the fuel needle valve for start up enrichment as you and some of the Cox distributed documentation ( McQueen ) says. I have not been able to do so. Looks like everyone else in the world can and only I cannot. Hence the cry for help with the settings and not only. Unless the compression is very low, the engine would not be able to sustain the too open settings and jump to high RPM, although, OTHER PEOPLE DO SO AND SHOW SO. Again, you are right, yet, I am unable to do so and I do not know why. Too low compression, though does not ignite the Ether. I fully agree these depend on the fuel. I have used 39% Ether, 34% Kerosene, 24% Castor Oil, 3% Cetane Booster. Too advanced. When I position fuel needle valve to 5 turns open and air valve to fully open to enrich the mixture and compression to around one eighth open, the engine starts and stops in a few turns. I tried with lower compression, I think, but I tried so many things so I may have forgotten. These settings bring fuel and this is still something I am happy with.

Thus, I have used your other suggestion for all more closed as I have described. Worked OK. However, never tried with muffler. Hence I want to have many inputs. I want to also be able to start the engine in many different ways ( settings ) to have many back up start up scenarios. This is why I have cried for help and I have received a very good input from you. In case you start OK with open enrichment, therefore, either I do something totally wrong or the fuel is very different than yours.

I will remember your input and keep trying.

Initially, I thought exactly like you ( the normal way ) : start with higher compression and then decrease and many people on YouTube do so and works perfectly. I have found, however, in the case I am in, the other way around is what happens. Cox also say so. With the Cox published fuel : 40% Ether, 35% Kerosene, 25% Castor Oil, and the closed settings for enrichment, I start at lower compression ( one eighth or around unscrewed compression screw ) and then have a few seconds to slightly close the compression screw, otherwise, the engine may stop.

I am happy, however, you have managed to do what is standard to do. I do this with the other fuel with Cetane Booster.

The very main reason for crying out loud for help with starter settings is because, unlike you, I have an incredibly strict restrains on the settings and, looks like, I am the only one. After a lot of blood, sweat and ether, I have only been able to start the engine with these settings and nothing else and I have tried a lot, although, I admit, not as much with a starter spring because I have been stupid to think I can start the engine with a drill or hand cranking the propeller.

Anyway, for your comments and suggestions and help : This is the only way I can start the engine so far :

Method : Spring Start

Muffler : No

Temperature of Engine : Room ( 25C )

Temperature of Fuel : Around Room ( 25C )

Usual Number of Spring Starts to Start at Settings : 4

Fuel : 39% John Deere 80% Ether Starter Fluid, 34% Kerosene from the Camping Section of a big store, 24% Castor Oil from Cox, 3% Cetane Booster : 2 EthylExyl Nitrate & Xelone

Settings :

Compression Screw : around one eighth open ( the most closed compression screw to allow one or two more spins when spring started ( the propeller rotates freely ) )

Air Valve ( Throttle ) : one eighth open only

Fuel Needle valve : three and a quarter turns open from fully closed

These have been very consistent BUT, I REPEAT, THESE HAVE BEEN THE ONLY SETTINGS I HAVE BEEN ABLE TO START THE ENGINE WITH.

All of you seem to start the engine with any settings, even open. One of the Cox distributed documents, written by Mr. McQueen suggests open enrichment as well as you. I SEEM TO BE THE ONLY ONE WITH THIS PROBLEM. Obviously, I may be doing something wrong.

YOU ARE PROBABLY THE FIRST PERSON ON THE FORUM TO TALK SETTINGS. THANK YOU! I STRONGLY BEG YOU TO CONTINUE, PLEASE, AS WELL AS I ASK ALL TO GET INTO THIS DICUSSION.

THANKS!

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

I don't know diesel operation so can't help with settings. But don't worry too much about a little slop at the ball and socket. Even with the right reset tool, it takes a practiced and deft touch to tighten it without mushrooming the crown. I've mushroomed a few and usually avoid doing it unless I'm going to be running hard and hot at high RPMs. If you feel you must reset one, it helps if you use the same hammer every time so you know just how much to hit it. Also you need an anvil like the small one on most vise clamps as your support for the tool. I use a vise bolted to a disk brake rotor and placed on my concrete floor so there is zero cushion to absorb the impact. A wood table may not always suffice. But again, I'd recommend avoiding that until you get the rest ironed out. It shouldn't affect the engine's performance, and at operating temperature, it's probably tighter than what you feel when it's cold.

It usually needs reset only once in its life after break-in because the metal gets work hardened, but high RPMs are usually what loosens them in a glow fuel engine. A little slop is okay. The eventual castor varnish may tighten it some too. It builds up during rich break-in runs more than lean fast runs. With our modern 50/50 castor/synthetic glow fuel, we don't get as much buildup as with pure castor. With the synthetic in the blend, it tends to attain a beneficial coating of varnish and level off there. Our diesel guys may have some different ideas about the subject, so we'll see if they toss in any helpful tips.

Rusty

It usually needs reset only once in its life after break-in because the metal gets work hardened, but high RPMs are usually what loosens them in a glow fuel engine. A little slop is okay. The eventual castor varnish may tighten it some too. It builds up during rich break-in runs more than lean fast runs. With our modern 50/50 castor/synthetic glow fuel, we don't get as much buildup as with pure castor. With the synthetic in the blend, it tends to attain a beneficial coating of varnish and level off there. Our diesel guys may have some different ideas about the subject, so we'll see if they toss in any helpful tips.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

RknRusty wrote:I don't know diesel operation so can't help with settings. But don't worry too much about a little slop at the ball and socket. Even with the right reset tool, it takes a practiced and deft touch to tighten it without mushrooming the crown. I've mushroomed a few and usually avoid doing it unless I'm going to be running hard and hot at high RPMs. If you feel you must reset one, it helps if you use the same hammer every time so you know just how much to hit it. Also you need an anvil like the small one on most vise clamps as your support for the tool. I use a vise bolted to a disk brake rotor and placed on my concrete floor so there is zero cushion to absorb the impact. A wood table may not always suffice. But again, I'd recommend avoiding that until you get the rest ironed out. It shouldn't affect the engine's performance, and at operating temperature, it's probably tighter than what you feel when it's cold.

It usually needs reset only once in its life after break-in because the metal gets work hardened, but high RPMs are usually what loosens them in a glow fuel engine. A little slop is okay. The eventual castor varnish may tighten it some too. It builds up during rich break-in runs more than lean fast runs. With our modern 50/50 castor/synthetic glow fuel, we don't get as much buildup as with pure castor. With the synthetic in the blend, it tends to attain a beneficial coating of varnish and level off there. Our diesel guys may have some different ideas about the subject, so we'll see if they toss in any helpful tips.

Rusty

Thanks a lot. This is very helpful. I will try not to reset the piston unless the slack is much higher than the original. This was not the case before and I paid for fixing what was not broken. Good I learned your post.

Thanks.

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

StevenStanleyBayes wrote:Surfer_kris wrote:StevenStanleyBayes wrote:

I AM VERY MUCH INTERESTED IN THE SETTINGS ( AIR VALVE ( THROTTLE ), FUEL NEEDLE VALVE, COMPRESSION ) OF THIS OR ANY OTHER ENGINE WITH ANY FUEL INCLUDING DAVIS DIESEL : START UP SETTINGS ( WHEN YOU START THE ENGINE ) AND RUNNING SETTINGS ( WHEN YOU RUN THE ENGINE NORMALLY ).

The air valve can be in any position you like, it has the same function as could start choke on regular engines. So you could either use it as a cold start choke to enricher the fuel to air ratio, or you use the main needle to do it. No one can tell you what these values should be as it is all up to you how you run the engine.

Fuel ratio, compression setting, fuel formula and engine load are all related. So this is something that every owner has to find out for themselves. There are also large machining differences from one engine to another, so again you can only find the settings for each individual engine by running it.

In general you would use a higher compression setting to start the engine when it is cold. Once up to running temperature you can then back of the compression. On a hot engine you can instead reduce the compression setting a little for the start, and once the engine runs you go back to the running settings.

Once running you you need to tune on both the compression setting and the fuel ratio to find the optimum settings. These are then usually reproducible for the same fuel blend and similar weather conditions, but usually one world always give them a quick check to adjust for changes in the weather and/or the fuel etc.

Also, please, note the fuel has much more advanced ignition than other people's fuels as this contains 40% Ether. I can only the open valve enrichment start scenario would work with less advanced ignition fuels. One of the documents, also distributed by Cox, suggests 20% Ether which would probably also give more powerful combustion at the expense of the temperature. I am afraid to try this fuel for now. I will also be afraid to try this fuel after break in. I may try in the future when I overcome the psychological barrier I now have not to try new things for a while from now on.

I presume you run Davis Diesel. Do they provide the ingredients and the percentages and can you or anyone post them here.

THANKS A LOT FOR YOUR HELP. MEANS A LOT.

THIS IS WHAT I CALL A HELPFUL TOPIC OF A RESPONSE. THANKS.

I have tried to use the fuel needle valve for start up enrichment as you and some of the Cox distributed documentation ( McQueen ) says. I have not been able to do so. Looks like everyone else in the world can and only I cannot. Hence the cry for help with the settings and not only. Unless the compression is very low, the engine would not be able to sustain the too open settings and jump to high RPM, although, OTHER PEOPLE DO SO AND SHOW SO. Again, you are right, yet, I am unable to do so and I do not know why. Too low compression, though does not ignite the Ether. I fully agree these depend on the fuel. I have used 39% Ether, 34% Kerosene, 24% Castor Oil, 3% Cetane Booster. Too advanced. When I position fuel needle valve to 5 turns open and air valve to fully open to enrich the mixture and compression to around one eighth open, the engine starts and stops in a few turns. I tried with lower compression, I think, but I tried so many things so I may have forgotten. These settings bring fuel and this is still something I am happy with.

Thus, I have used your other suggestion for all more closed as I have described. Worked OK. However, never tried with muffler. Hence I want to have many inputs. I want to also be able to start the engine in many different ways ( settings ) to have many back up start up scenarios. This is why I have cried for help and I have received a very good input from you. In case you start OK with open enrichment, therefore, either I do something totally wrong or the fuel is very different than yours.

I will remember your input and keep trying.

Initially, I thought exactly like you ( the normal way ) : start with higher compression and then decrease and many people on YouTube do so and works perfectly. I have found, however, in the case I am in, the other way around is what happens. Cox also say so. With the Cox published fuel : 40% Ether, 35% Kerosene, 25% Castor Oil, and the closed settings for enrichment, I start at lower compression ( one eighth or around unscrewed compression screw ) and then have a few seconds to slightly close the compression screw, otherwise, the engine may stop.

I am happy, however, you have managed to do what is standard to do. I do this with the other fuel with Cetane Booster.

The very main reason for crying out loud for help with starter settings is because, unlike you, I have an incredibly strict restrains on the settings and, looks like, I am the only one. After a lot of blood, sweat and ether, I have only been able to start the engine with these settings and nothing else and I have tried a lot, although, I admit, not as much with a starter spring because I have been stupid to think I can start the engine with a drill or hand cranking the propeller.

Anyway, for your comments and suggestions and help : This is the only way I can start the engine so far :

Method : Spring Start

Muffler : No

Temperature of Engine : Room ( 25C )

Temperature of Fuel : Around Room ( 25C )

Usual Number of Spring Starts to Start at Settings : 4

Fuel : 39% John Deere 80% Ether Starter Fluid, 34% Kerosene from the Camping Section of a big store, 24% Castor Oil from Cox, 3% Cetane Booster : 2 EthylExyl Nitrate & Xelone

Settings :

Compression Screw : around one eighth open ( the most closed compression screw to allow one or two more spins when spring started ( the propeller rotates freely ) )

Air Valve ( Throttle ) : one eighth open only

Fuel Needle valve : three and a quarter turns open from fully closed

These have been very consistent BUT, I REPEAT, THESE HAVE BEEN THE ONLY SETTINGS I HAVE BEEN ABLE TO START THE ENGINE WITH.

All of you seem to start the engine with any settings, even open. One of the Cox distributed documents, written by Mr. McQueen suggests open enrichment as well as you. I SEEM TO BE THE ONLY ONE WITH THIS PROBLEM. Obviously, I may be doing something wrong.

YOU ARE PROBABLY THE FIRST PERSON ON THE FORUM TO TALK SETTINGS. THANK YOU! I STRONGLY BEG YOU TO CONTINUE, PLEASE, AS WELL AS I ASK ALL TO GET INTO THIS DICUSSION.

THANKS!

Page 5 of 31 •  1, 2, 3, 4, 5, 6 ... 18 ... 31

1, 2, 3, 4, 5, 6 ... 18 ... 31

Similar topics

Similar topics» car engine diesel??? (aka generator V3)

» RC Cars Cox 0.49 (Cox Stocker Kyosho f1,beetle) Killer Bee Backplate New Video!

» Norvel Handi-Start Micro Electric Starter

» 3.5 cc diesel needs needle valve

» little generator

» RC Cars Cox 0.49 (Cox Stocker Kyosho f1,beetle) Killer Bee Backplate New Video!

» Norvel Handi-Start Micro Electric Starter

» 3.5 cc diesel needs needle valve

» little generator

Page 5 of 31

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules