Log in

Search

Latest topics

» Stealth SB-Xby Admin Yesterday at 8:28 pm

» ST .35 STUNT / VOODOO / ZERO POINT ZERO NITRO

by TD ABUSER Yesterday at 7:45 pm

» SUPERTIGER .15 PROJECT

by TD ABUSER Yesterday at 7:42 pm

» For sale -- Cox Custom Carburetors for Tee Dee engines

by sosam117 Yesterday at 5:23 pm

» WHERE ARE YOU BUYING YOUR FUEL AND GLOW PLUGS...?

by TD ABUSER Yesterday at 4:35 pm

» Waiting for Engines from Ken Enya

by sosam117 Yesterday at 4:33 pm

» Unusual Cox 049 cylinder - Need help identifying

by anm2 Yesterday at 4:12 pm

» Jim Walker Bonanza etc.

by rsv1cox Yesterday at 2:57 pm

» What's the Best Reed for Cox Reed Valve Engines.

by roddie Yesterday at 1:37 pm

» Fuel choice

by 1975 control line guy Fri Aug 30, 2024 4:01 pm

» "Fall S.M.A.L.L." Video 3.

by GallopingGhostler Fri Aug 30, 2024 2:37 pm

» Gifted Fox

by Ken Cook Fri Aug 30, 2024 11:12 am

Cox Engine of The Month

August-2024

balogh's

"Cox TD09 R/C Beast of Burden featuring Kamtechnik head and DIY metallic fuel nipple"

PAST WINNERS

balogh's

"Cox TD09 R/C Beast of Burden featuring Kamtechnik head and DIY metallic fuel nipple"

PAST WINNERS

Tee Dee .09 rebuild.. and run!

Page 1 of 8

Page 1 of 8 • 1, 2, 3, 4, 5, 6, 7, 8

Tee Dee .09 rebuild.. and run!

Tee Dee .09 rebuild.. and run!

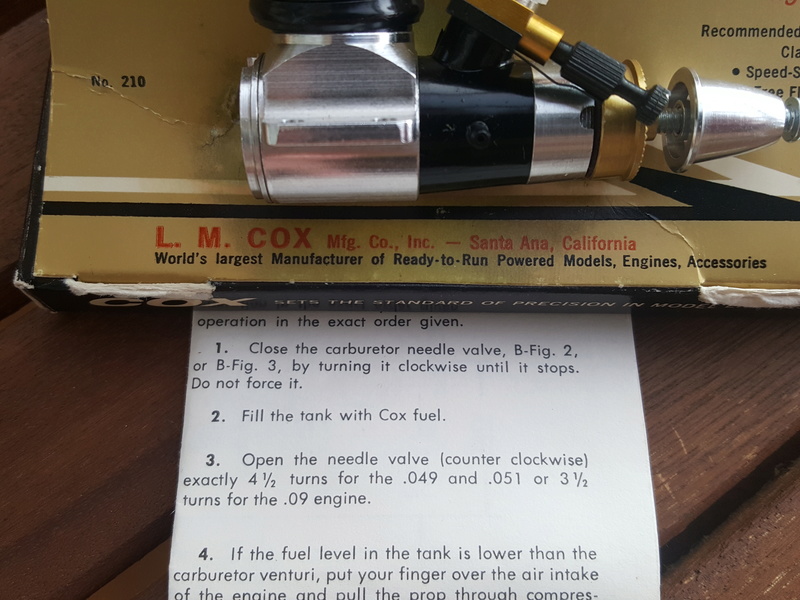

I've never run a Tee Dee. This .09 was "given" to me a few months ago by a fella who was having a model-airplane "yard-sale". He's a large-scale RC guy.. and C/L glow-engines didn't interest him at all. He was liquidating the estate of a deceased fellow-modeler.. and gave me a boxful of C/L engines.. including this Cox Tee Dee .09 .

With the R/M fly-a-thon approaching.. and my S-5 "Jr." needing an engine.. I thought I'd see if I can get the engine running.

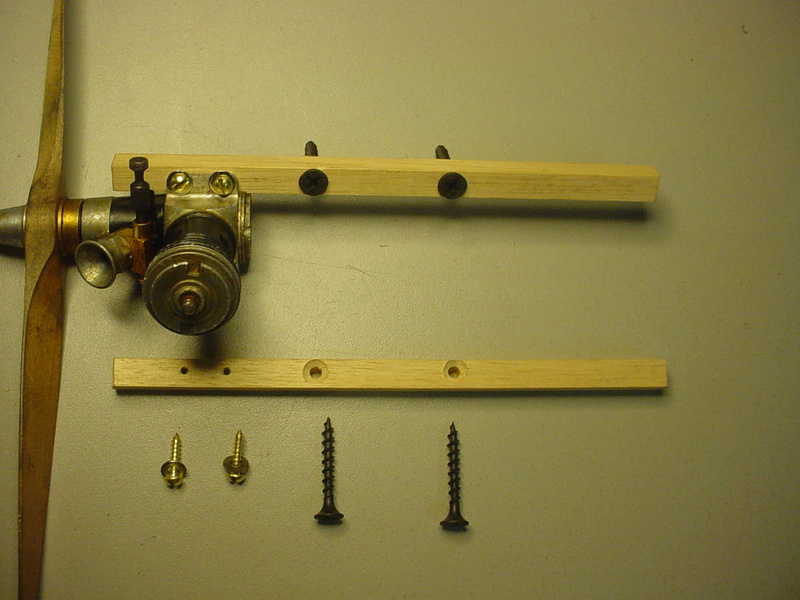

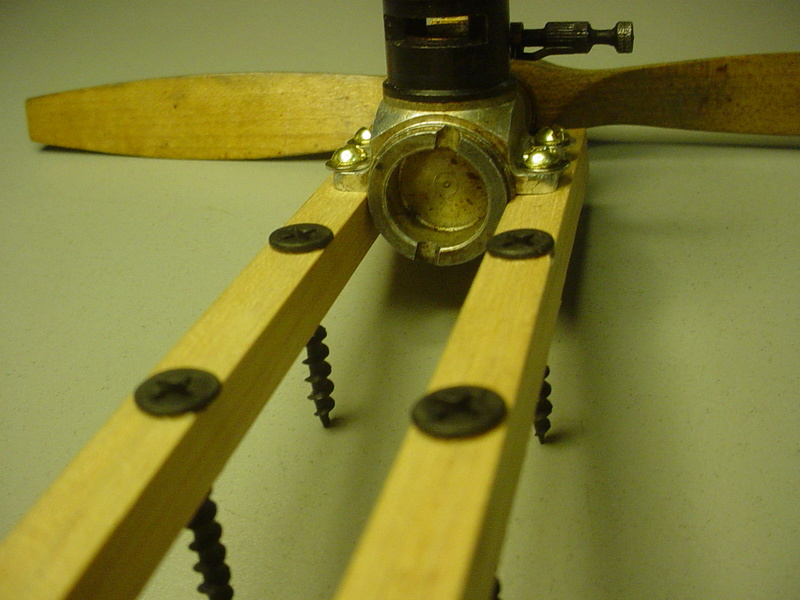

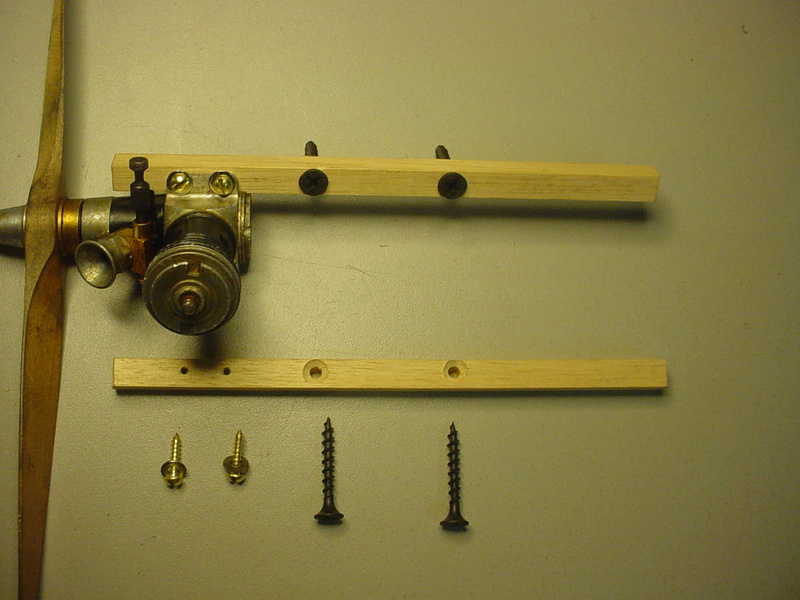

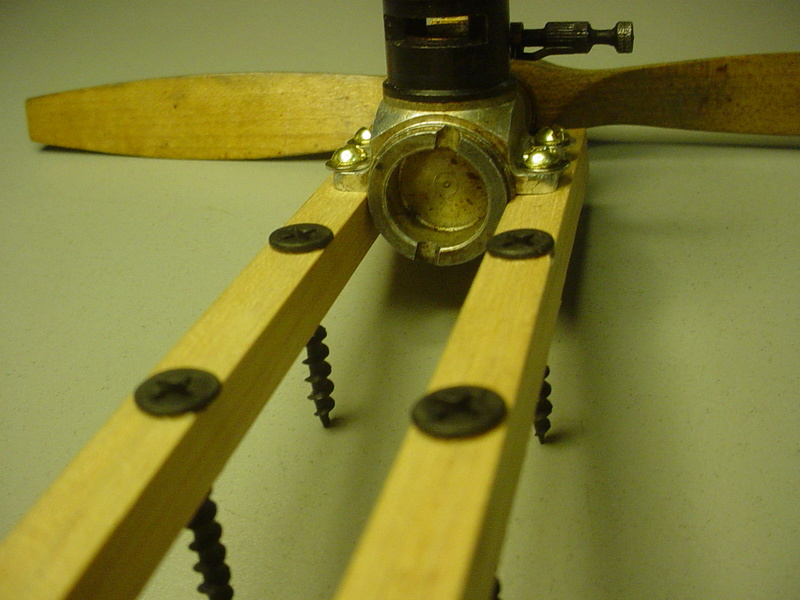

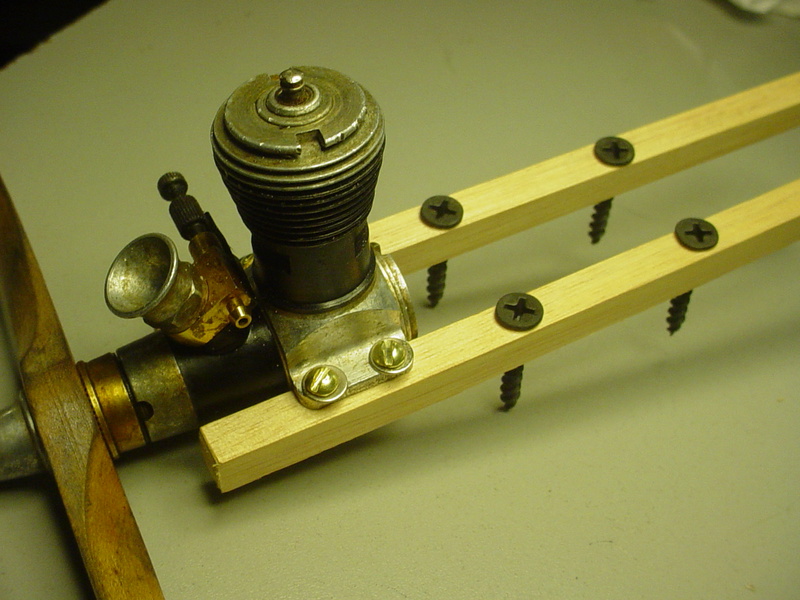

I wanted to make a decent bench-mount.. so I checked my hardwood square-stock to see what I had. I found a 12" length of 5/16" (.312") square-stock.. and cut it in half. This seemed like the ultimate beam-stock for this engine. I marked the engines mounts using an awl.. and drilled holes to accept wood-screws with flat-washers. I had some 4-40 blind-nuts.. but my machine-screws wouldn't thread-into them... wtf.... so I went with wood-screws into pre-drilled pilot-holes.. and then drilled through-holes for mounting the beams to my 2 x 4 deck-railing with drywall-screws.

wtf.... so I went with wood-screws into pre-drilled pilot-holes.. and then drilled through-holes for mounting the beams to my 2 x 4 deck-railing with drywall-screws.

Tomorrow will be the test...... I don't have any wrenches for the engine.. so I don't know the internal-condition.. or if the glow-head lights. We're just going to "wing-it" with some SIG champion "25".. and see what happens. There's a "Zinger" 8 x 4 woody mounted on the engine currently. I received it with a nylon "Tornado" 8 x 4... I have some old 7" diameter wooden-props.. but their pitches are quite high for this engine.. and their hub-holes are bored for a 1/4" crank-shaft.. (possibly speed-engine props..) The Cox Tee Dee .09 uses a 6-32 prop-screw by comparison.

I'll see if I can get a tach-reading if the engine starts and runs.

With the R/M fly-a-thon approaching.. and my S-5 "Jr." needing an engine.. I thought I'd see if I can get the engine running.

I wanted to make a decent bench-mount.. so I checked my hardwood square-stock to see what I had. I found a 12" length of 5/16" (.312") square-stock.. and cut it in half. This seemed like the ultimate beam-stock for this engine. I marked the engines mounts using an awl.. and drilled holes to accept wood-screws with flat-washers. I had some 4-40 blind-nuts.. but my machine-screws wouldn't thread-into them...

Tomorrow will be the test...... I don't have any wrenches for the engine.. so I don't know the internal-condition.. or if the glow-head lights. We're just going to "wing-it" with some SIG champion "25".. and see what happens. There's a "Zinger" 8 x 4 woody mounted on the engine currently. I received it with a nylon "Tornado" 8 x 4... I have some old 7" diameter wooden-props.. but their pitches are quite high for this engine.. and their hub-holes are bored for a 1/4" crank-shaft.. (possibly speed-engine props..) The Cox Tee Dee .09 uses a 6-32 prop-screw by comparison.

I'll see if I can get a tach-reading if the engine starts and runs.

Last edited by roddie on Sun Oct 22, 2017 5:15 pm; edited 6 times in total

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Crap! Forgot about the wrench.... I am headed to South Dakota tomorrow, but shoot me a text later in the week please so I don't keep forgetting.

Cribbs74- Moderator

Posts : 11906

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Roddie - - dON'T know if you are counting or not, but you only have to get 7 More posts to break 5000 !! !!

Cake and Ice Cream at Your House!!

Cake and Ice Cream at Your House!!

Cake and Ice Cream at Your House!!

Cake and Ice Cream at Your House!!

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 71

Location : Grand Rapids, MI

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Hey Roddie, I'm keeping an eye on the pace of your Tee Dee 09! What fuel will you use?

MauricioB- Top Poster

- Posts : 3657

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

MauricioB wrote:Hey Roddie, I'm keeping an eye on the pace of your Tee Dee 09! What fuel will you use?

Hi Mauricio! I will use the Sig "Champion" 25 (25% nitro). I use it in all of my Cox engines.

This will be my first attempt at running a Tee Dee.. so I will need to pay more attention to the fuel-tank "height" for a proper suction-feed. I figure I'll start out slightly "low" (feed in relation to spray-bar) and prime the line by choking the venturi. I haven't run many front rotary-valve engines.. and the last time was probably 15 years ago!

This engine's cylinder doesn't have sub-port induction. It was pointed-out to me that it doesn't have a high-compression glow-head either. Now I'm wondering if it might possibly have a Medallion cylinder..

I thought that all Tee Dee cylinders had SPI.

I thought that all Tee Dee cylinders had SPI.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

roddie wrote:MauricioB wrote:Hey Roddie, I'm keeping an eye on the pace of your Tee Dee 09! What fuel will you use?

Hi Mauricio! I will use the Sig "Champion" 25 (25% nitro). I use it in all of my Cox engines.

This will be my first attempt at running a Tee Dee.. so I will need to pay more attention to the fuel-tank "height" for a proper suction-feed. I figure I'll start out slightly "low" (feed in relation to spray-bar) and prime the line by choking the venturi. I haven't run many front rotary-valve engines.. and the last time was probably 15 years ago!

This engine's cylinder doesn't have sub-port induction. It was pointed-out to me that it doesn't have a high-compression glow-head either. Now I'm wondering if it might possibly have a Medallion cylinder..I thought that all Tee Dee cylinders had SPI.

All right, Roddie.

Keep in mind that if it was a long time ago and it was dirty, it is important to make sure that the perpendicular holes of the air intake, which if I remember correctly are three, are free, that is to say that they are not covered by castor bean. Otherwise, if they get clogged the engine will not suck fuel or if any of the three is plugged, will not suck fuel properly, do you understand Roddie?

MauricioB- Top Poster

- Posts : 3657

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Roddie

All my TD09 engines are of SPI design but I assume the R/C version just like the 050 may have had non-SPI to allow use of a muffler.

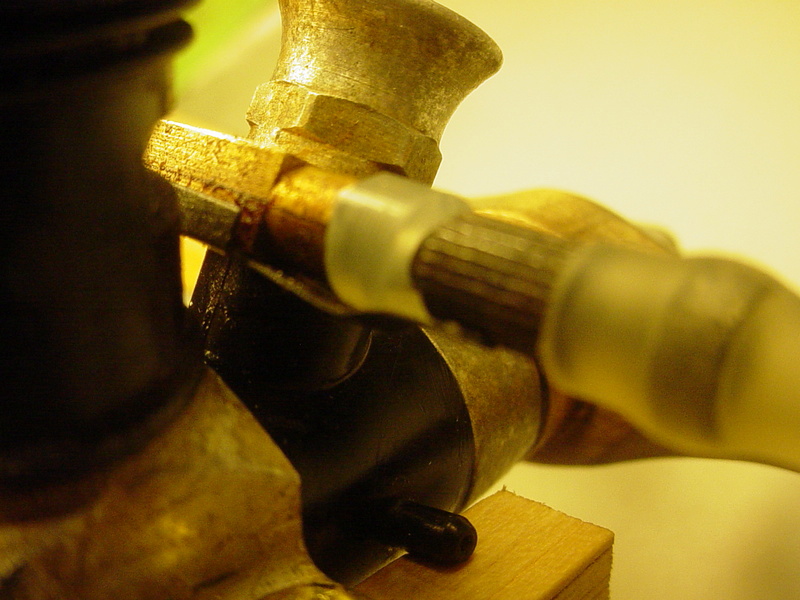

I never had a suction problem with TD-s providing the tank bottom is not too low nor the fuel line is too long. You may want to slip a silicone tube on the NV stem and pull it over on the carb to prevent air leakage along the threads that in an old engine may not be airtight any longer.

With the silicone tube in place the nv will also stay safely set where you leave it so you can also omit the nv spring from the carb assy

All my TD09 engines are of SPI design but I assume the R/C version just like the 050 may have had non-SPI to allow use of a muffler.

I never had a suction problem with TD-s providing the tank bottom is not too low nor the fuel line is too long. You may want to slip a silicone tube on the NV stem and pull it over on the carb to prevent air leakage along the threads that in an old engine may not be airtight any longer.

With the silicone tube in place the nv will also stay safely set where you leave it so you can also omit the nv spring from the carb assy

Last edited by balogh on Sun Aug 20, 2017 11:18 am; edited 2 times in total

balogh- Top Poster

Posts : 4852

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Roddie

Given the wood beams are easy to crack along their length starting out where the wood screws are you may want to balance the prop very well to minimize vibration. This 09 engine is generating much more power than the 049 class engines ....get ready for a surprise....and if it gets loose because of vibration then next the thing to break loose will be the hell...

Given the wood beams are easy to crack along their length starting out where the wood screws are you may want to balance the prop very well to minimize vibration. This 09 engine is generating much more power than the 049 class engines ....get ready for a surprise....and if it gets loose because of vibration then next the thing to break loose will be the hell...

balogh- Top Poster

Posts : 4852

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

MauricioB wrote:

All right, Roddie.

Keep in mind that if it was a long time ago and it was dirty, it is important to make sure that the perpendicular holes of the air intake, which if I remember correctly are three, are free, that is to say that they are not covered by castor bean. Otherwise, if they get clogged the engine will not suck fuel or if any of the three is plugged, will not suck fuel properly, do you understand Roddie?

If you mean the spray-bar.. then yes.. and thank you Mauricio. I have a rubber fuel-"bulb" that I can use to power-flush the NVA with fuel or solvent. A quick air-pressure only test reveals that there is flow being regulated by the needle. I closed the needle and evacuated the air from the bulb before connecting the line.. then I opened the needle, which caused the bulb to expand back into shape. Then I squeezed the bulb to observe the "hissing-sound" of air-flow through the NVA. I have some old glow-fuel that I will use for a liquid-flush before I try to start the engine. Thanks again! You may have saved me some grief..

Andras, Thanks for the tips! I tried to sleeve-seal the needle.. but the spring-tab will not permit the tubing to ride-up onto the housing. There's minimal clearance there.. and the wall-thickness of the silicone tubing is too thick.. causing the tab to bend-away from the knob on the needle.

I did however install a 2" long piece of silicone-tubing over the needle's knob as an extension.. so that I don't catch a blade to the knuckle when tuning.

Incidentally; how many turns open (avg.) should there be to get me in the ball-park for starting the engine?

Incidentally; how many turns open (avg.) should there be to get me in the ball-park for starting the engine?

Regarding the mount.. the beam-stock is dense hardwood.. (not bass or poplar).. I had bought the package of "Forster-brand" assorted-size 12" length square hardwood-dowels many years ago.. and they make for ideal beam-mounts in sizes of 3/16", 1/4", 5/16", 3/8" and 1/2".

I pre-drilled pilot-holes for the screws holding-down the engine. The screws are long enough that they protrude slightly through the bottom of the beams.. and are quite snug. I needed to install them using a small slotted insert-bit, fitted to a larger drive-handle. There's no indication of the beams splitting.. or else I wouldn't chance using the mount. I will check/balance the prop as a safety-measure.

balogh- Top Poster

Posts : 4852

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

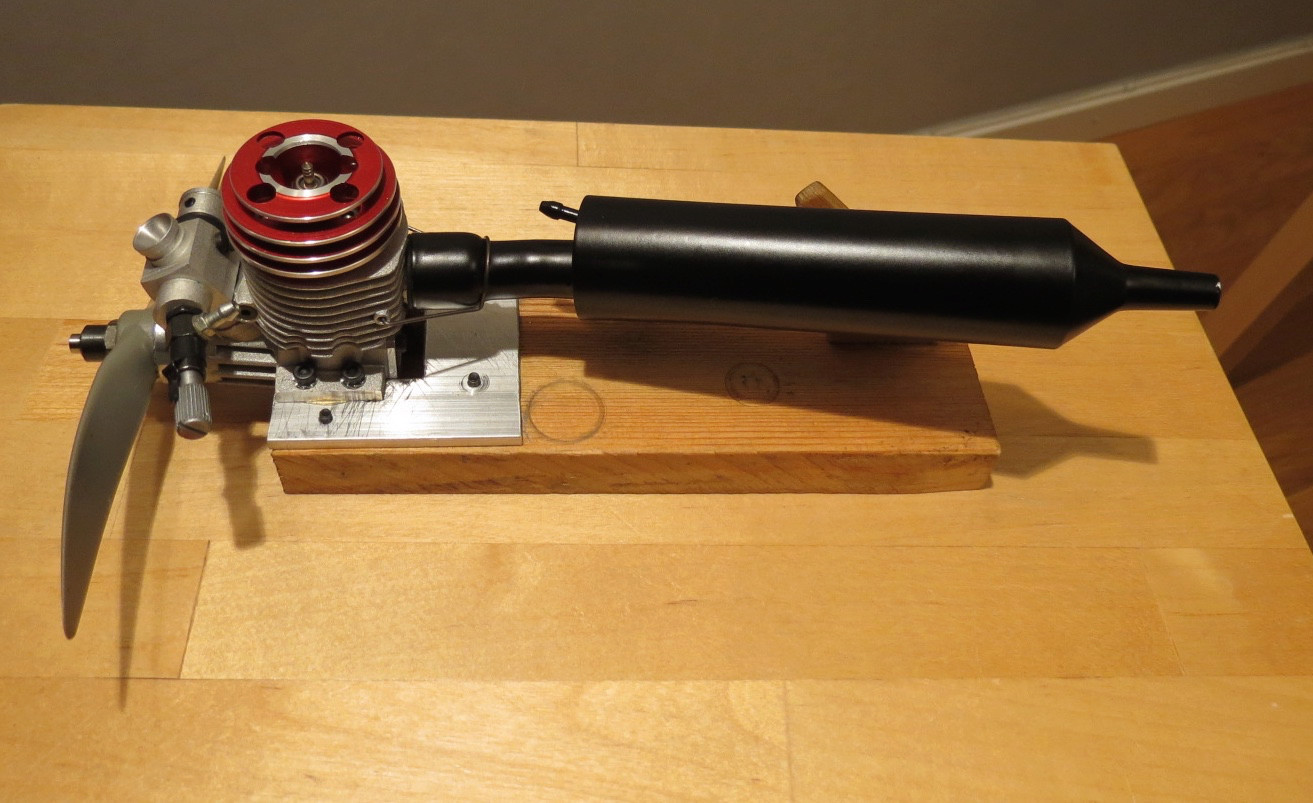

Those wooden sticks are a little too long, be careful so that you don't break of the plastic nipple on the crankcase (the one on the righthand side, used for timed pressure to the tank).

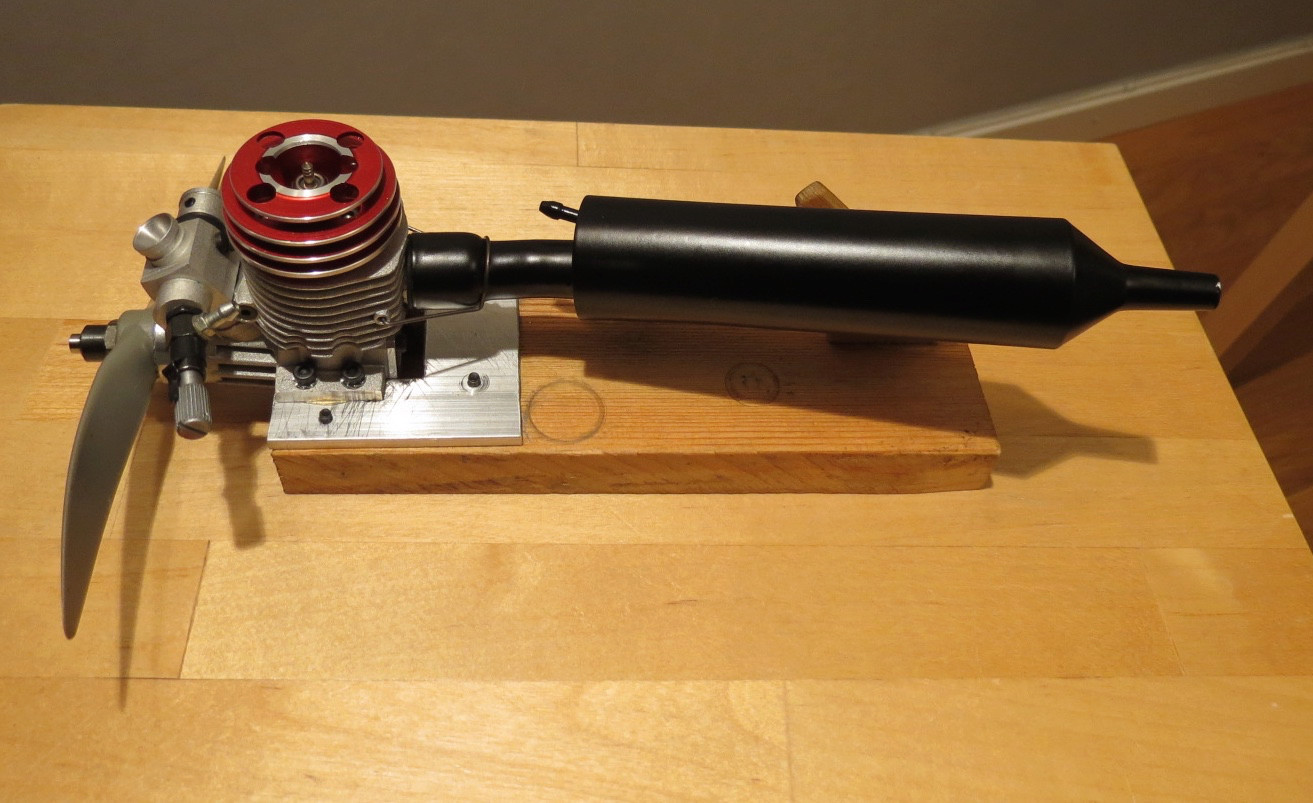

I think it is much better to use an aluminium plate under the engine mounting tabs, just like you would on a plane, there is always a little give in the wood (even from hard wood) and the screws will get loose.

Directly on wood can work on .049 engines, but for anything larger I use something like this (here a .12 picco engine);

I think it is much better to use an aluminium plate under the engine mounting tabs, just like you would on a plane, there is always a little give in the wood (even from hard wood) and the screws will get loose.

Directly on wood can work on .049 engines, but for anything larger I use something like this (here a .12 picco engine);

Surfer_kris- Diamond Member

- Posts : 1909

Join date : 2010-11-20

Location : Sweden

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

roddie wrote:MauricioB wrote:

If you mean the spray-bar.. then yes.. and thank you Mauricio. I have a rubber fuel-"bulb" that I can use to power-flush the NVA with fuel or solvent. A quick air-pressure only test reveals that there is flow being regulated by the needle. I closed the needle and evacuated the air from the bulb before connecting the line.. then I opened the needle, which caused the bulb to expand back into shape. Then I squeezed the bulb to observe the "hissing-sound" of air-flow through the NVA. I have some old glow-fuel that I will use for a liquid-flush before I try to start the engine. Thanks again! You may have saved me some grief..

Roddie,

Mauricio is right in saying the venturi needs also to be checked for unblocked fuel flow. The golden carb "spray bar" allows the metered fuel to flow into an annulus space around the neck of the aluminum venturi where 3 tiny holes, 120 degrees apart, lead the fuel radially into the aluminum venturi. This split fuel dosage ensures a much better atomization in all TD engines of the fuel than the single fuel opening on the spraybar of COX reedies. This is probably one ingredient to the superb performance of TD-s.

All 3 holes need to be clean without any gunk clogging the fuel flow otherwise the engine will not perform as designed. If you block the venturi air channel at one end with your finger and force some fuel with a syringe through the other end, all 3 holes should be seen sprinkling the fuel radially out.

balogh- Top Poster

Posts : 4852

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Just to illuminate... UNLESS the Crank Case has been drilled for the crank case pressure ( here you need the nipple) the only bad thing breaking the nipple off MIGHT cause is an air leak between the plastic carb and the crank case body.

And is easy to fix with drop of J&B glue---- if broken flush

I regularly cut them off all my TeeDees

BUT in my case, I cut with a very short stubb and then soldering iron melt the hole closed

WHY?...cus when they do break off, it is hard to diagnose the air leak

I am a little surprised MECOA still molds them the same as Cox... more diameter and a barb would not add enough weight to make a difference... Timed crank case pressure is fun to play with grin

And is easy to fix with drop of J&B glue---- if broken flush

I regularly cut them off all my TeeDees

BUT in my case, I cut with a very short stubb and then soldering iron melt the hole closed

WHY?...cus when they do break off, it is hard to diagnose the air leak

I am a little surprised MECOA still molds them the same as Cox... more diameter and a barb would not add enough weight to make a difference... Timed crank case pressure is fun to play with grin

fredvon4- Top Poster

Posts : 4007

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Oh good heavens.... just put some fuel in it and fire it off already

Don't think I have seen so many posts about starting an engine.

Have fun with it! Better yet put it on a plane run a tank and then go FLY!

Don't think I have seen so many posts about starting an engine.

Have fun with it! Better yet put it on a plane run a tank and then go FLY!

Cribbs74- Moderator

Posts : 11906

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

I also have an aversion to using wood screws for engine mounting....in fact even for .049s

Nothing wrong with the wood chosen IMO but coarse pitch wood screws loosen at an alarming rate with (any) vibration

at least (very least) use 2-56 bolts, washers and nuts...Better!!! use 4-40 cap screws and also washers and nuts under the beams

This TeeDee .09 is NOT your 5x3 rubber ducky spinning Baby Bee

first prime and brief RAAAAAAPPPPPP!!! you are gonna lean back away and out loud say...OH CRAP!

video with sound for first prime off burn please

Nothing wrong with the wood chosen IMO but coarse pitch wood screws loosen at an alarming rate with (any) vibration

at least (very least) use 2-56 bolts, washers and nuts...Better!!! use 4-40 cap screws and also washers and nuts under the beams

This TeeDee .09 is NOT your 5x3 rubber ducky spinning Baby Bee

first prime and brief RAAAAAAPPPPPP!!! you are gonna lean back away and out loud say...OH CRAP!

video with sound for first prime off burn please

fredvon4- Top Poster

Posts : 4007

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

opening up a can of worms..

opening up a can of worms..

Thanks Andras, I'll go with 3.75 turns-open to start. I'd rather not remove the spring-tab having very little experience with Tee Dees. If I experience erratic-needling, I'll explore that option.

My prop had a very-slightly heavy-blade.. so I applied a brushing of correction-fluid to the light-blade.. and feather-sanded it out until both blades were level in the "Roddie redneck-balancer". The "hub" must be out-of-balance.. because the prop stops horizontally in the same position every-time when rotated. I don't know how to remedy this.. although I've read that there is a fix for it. Maybe it's no big deal.

Regarding the 3-hole spray-bar; I'm going to have to "assume"..

Phred.. I hear your warning regarding the wood-screws. I'll keep a close eye on them. If the engine fly's-off and hits the side of the house.. I'll pour a glass of peppermint schnapps.. and toast you!

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Look in the exhaust port. 2 bypass TD one bypass Medallion.

Cribbs74- Moderator

Posts : 11906

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Agree with Ron... enough pontificating... fire the danged thing  up and make smoke already!

up and make smoke already!

up and make smoke already!

up and make smoke already!

fredvon4- Top Poster

Posts : 4007

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Had to run some errands.. but just flushed the NVA with my fuel-bulb and some well-aged Sig Champion 25 fuel. The "mount" is now mounted to the deck-railing. Video-camera is charged.. and I'm gathering my support-gear.

All this hype.. and the plug will probably be dead..

All this hype.. and the plug will probably be dead..

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Get er done!

Cribbs74- Moderator

Posts : 11906

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

fredvon4 wrote:Agree with Ron... enough pontificating... fire the danged thingup and make smoke already!

WELL? We are waiting............ I'm the one who always fears the worst. Hope you didn't get bit on the fingers and can't type...I'm worried now...

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 71

Location : Grand Rapids, MI

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

If I know Roddie, he's still doing mathematical equations on a giant chalk board.

Just kidding buddy

Just kidding buddy

Cribbs74- Moderator

Posts : 11906

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

A day in the life of watching for Roddie to post a run report.

J/K... the same could be said of me and my quick builds.

Btw, I did finish the P-40 today. Even put decals on it. Instructions said it should take me 5 hours. Mike said he did his in 4. I think mine took a month.

J/K... the same could be said of me and my quick builds.

Btw, I did finish the P-40 today. Even put decals on it. Instructions said it should take me 5 hours. Mike said he did his in 4. I think mine took a month.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

I'm ok guys.. sorry not to report back yesterday. While I was typing my last post, I wasn't feeling well. I'd done some yardwork earlier and I guess the heat got to me. (That's happened to me more than once this season..)

BTW.. there's two bypass-ports in the cylinder.

BTW.. there's two bypass-ports in the cylinder.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

TD.09 BLAST COMING AT US !!

TD.09 BLAST COMING AT US !!

getback- Top Poster

Posts : 10326

Join date : 2013-01-18

Age : 67

Location : julian , NC

Page 1 of 8 • 1, 2, 3, 4, 5, 6, 7, 8

Similar topics

Similar topics» Cox Tee Dee .049 Rebuild ...

» Ez Bee rebuild

» TD rebuild .049

» Barn find rebuild, meet the screaming phoenix

» Tee Dee Engine rebuild

» Ez Bee rebuild

» TD rebuild .049

» Barn find rebuild, meet the screaming phoenix

» Tee Dee Engine rebuild

Page 1 of 8

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules