Log in

Search

Latest topics

» Stealth SB-Xby Admin Today at 8:28 pm

» ST .35 STUNT / VOODOO / ZERO POINT ZERO NITRO

by TD ABUSER Today at 7:45 pm

» SUPERTIGER .15 PROJECT

by TD ABUSER Today at 7:42 pm

» For sale -- Cox Custom Carburetors for Tee Dee engines

by sosam117 Today at 5:23 pm

» WHERE ARE YOU BUYING YOUR FUEL AND GLOW PLUGS...?

by TD ABUSER Today at 4:35 pm

» Waiting for Engines from Ken Enya

by sosam117 Today at 4:33 pm

» Unusual Cox 049 cylinder - Need help identifying

by anm2 Today at 4:12 pm

» Jim Walker Bonanza etc.

by rsv1cox Today at 2:57 pm

» What's the Best Reed for Cox Reed Valve Engines.

by roddie Today at 1:37 pm

» Fuel choice

by 1975 control line guy Yesterday at 4:01 pm

» "Fall S.M.A.L.L." Video 3.

by GallopingGhostler Yesterday at 2:37 pm

» Gifted Fox

by Ken Cook Yesterday at 11:12 am

Cox Engine of The Month

August-2024

balogh's

"Cox TD09 R/C Beast of Burden featuring Kamtechnik head and DIY metallic fuel nipple"

PAST WINNERS

balogh's

"Cox TD09 R/C Beast of Burden featuring Kamtechnik head and DIY metallic fuel nipple"

PAST WINNERS

Driveplate Assembly Bracket

Page 1 of 1

Driveplate Assembly Bracket

Driveplate Assembly Bracket

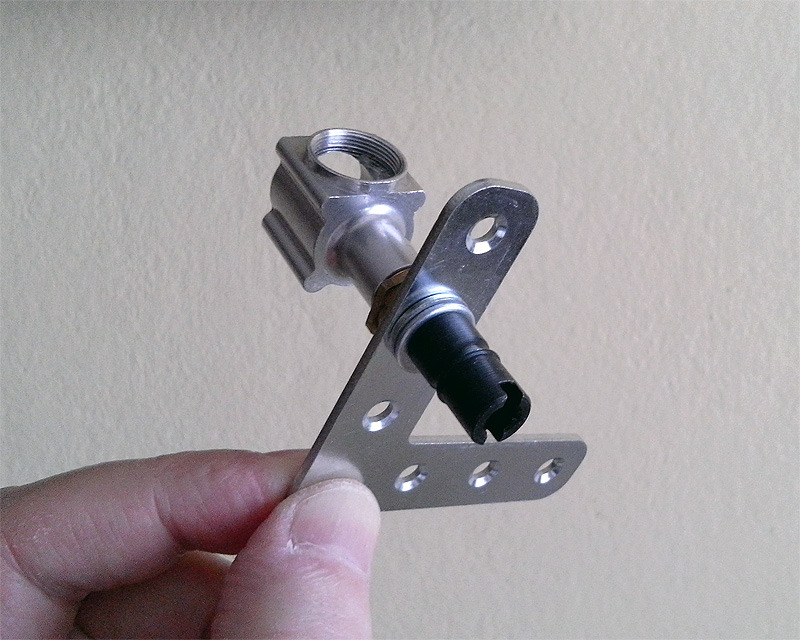

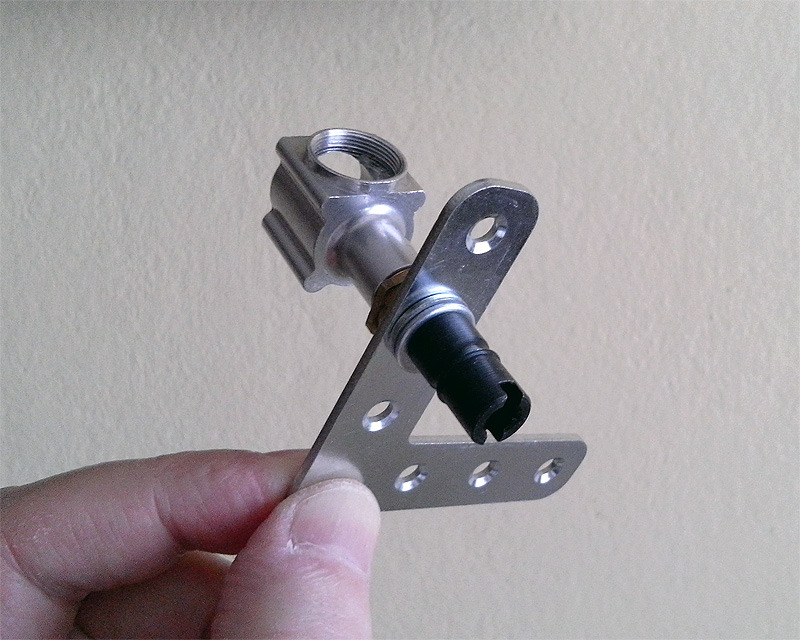

I found that driveplate can wobble if I use a propeller to assemble it, because the front and back hub surfaces of some propellers are not parallel with each other.

I use a metal flat corner brace for this purpose. Both surfaces of these corner braces are parallel. I cut a washer from thin plastic sheet and sanded both sides, then open a hole with a paper punch. I place this thin plastic washer in front of driveplate to avoid flattening knurled surface. Two pieces of electrical tape can also be used for this purpose. Then I place corner brace and two washers. Flat corner brace can also be attached in a vise.

I use a metal flat corner brace for this purpose. Both surfaces of these corner braces are parallel. I cut a washer from thin plastic sheet and sanded both sides, then open a hole with a paper punch. I place this thin plastic washer in front of driveplate to avoid flattening knurled surface. Two pieces of electrical tape can also be used for this purpose. Then I place corner brace and two washers. Flat corner brace can also be attached in a vise.

Levent Suberk- Diamond Member

- Posts : 2233

Join date : 2017-12-24

Location : Türkiye

balogh- Top Poster

Posts : 4852

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Re: Driveplate Assembly Bracket

Re: Driveplate Assembly Bracket

I always thought there must be a better way, than using a prop.

Thanks Levent!

Bob

Thanks Levent!

Bob

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Re: Driveplate Assembly Bracket

Re: Driveplate Assembly Bracket

That is a great idea, as I too have had that problem when using a propeller to install the driveplate.

NEW222- Top Poster

- Posts : 3895

Join date : 2011-08-13

Age : 45

Location : oakbank, mb

getback- Top Poster

Posts : 10326

Join date : 2013-01-18

Age : 67

Location : julian , NC

Similar topics

Similar topics» Mounting bracket for cars

» Crankcase dis-assembly and assembly

» WTB: Medallion .049 Driveplate

» Modeling COX engines with 3D Printer

» Killer bee driveplate.

» Crankcase dis-assembly and assembly

» WTB: Medallion .049 Driveplate

» Modeling COX engines with 3D Printer

» Killer bee driveplate.

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules