Log in

Search

Latest topics

» Stealth SB-Xby Admin Yesterday at 8:28 pm

» ST .35 STUNT / VOODOO / ZERO POINT ZERO NITRO

by TD ABUSER Yesterday at 7:45 pm

» SUPERTIGER .15 PROJECT

by TD ABUSER Yesterday at 7:42 pm

» For sale -- Cox Custom Carburetors for Tee Dee engines

by sosam117 Yesterday at 5:23 pm

» WHERE ARE YOU BUYING YOUR FUEL AND GLOW PLUGS...?

by TD ABUSER Yesterday at 4:35 pm

» Waiting for Engines from Ken Enya

by sosam117 Yesterday at 4:33 pm

» Unusual Cox 049 cylinder - Need help identifying

by anm2 Yesterday at 4:12 pm

» Jim Walker Bonanza etc.

by rsv1cox Yesterday at 2:57 pm

» What's the Best Reed for Cox Reed Valve Engines.

by roddie Yesterday at 1:37 pm

» Fuel choice

by 1975 control line guy Fri Aug 30, 2024 4:01 pm

» "Fall S.M.A.L.L." Video 3.

by GallopingGhostler Fri Aug 30, 2024 2:37 pm

» Gifted Fox

by Ken Cook Fri Aug 30, 2024 11:12 am

Cox Engine of The Month

August-2024

balogh's

"Cox TD09 R/C Beast of Burden featuring Kamtechnik head and DIY metallic fuel nipple"

PAST WINNERS

balogh's

"Cox TD09 R/C Beast of Burden featuring Kamtechnik head and DIY metallic fuel nipple"

PAST WINNERS

Cox .010 application question

Page 1 of 1

Cox .010 application question

Cox .010 application question

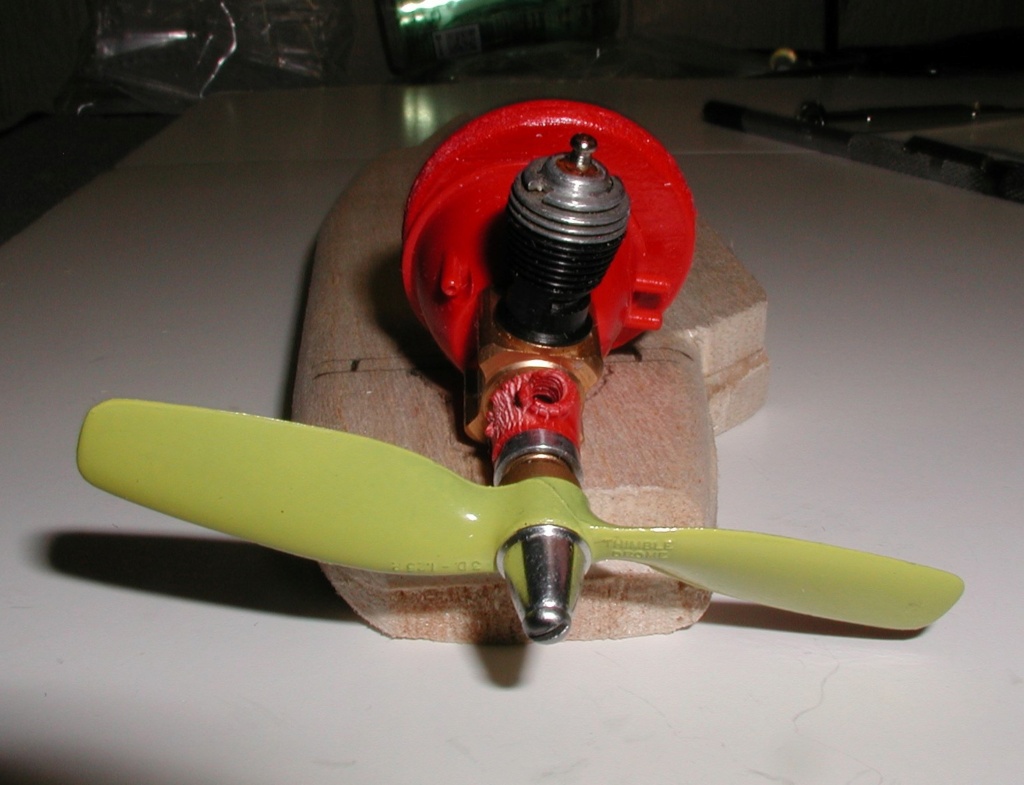

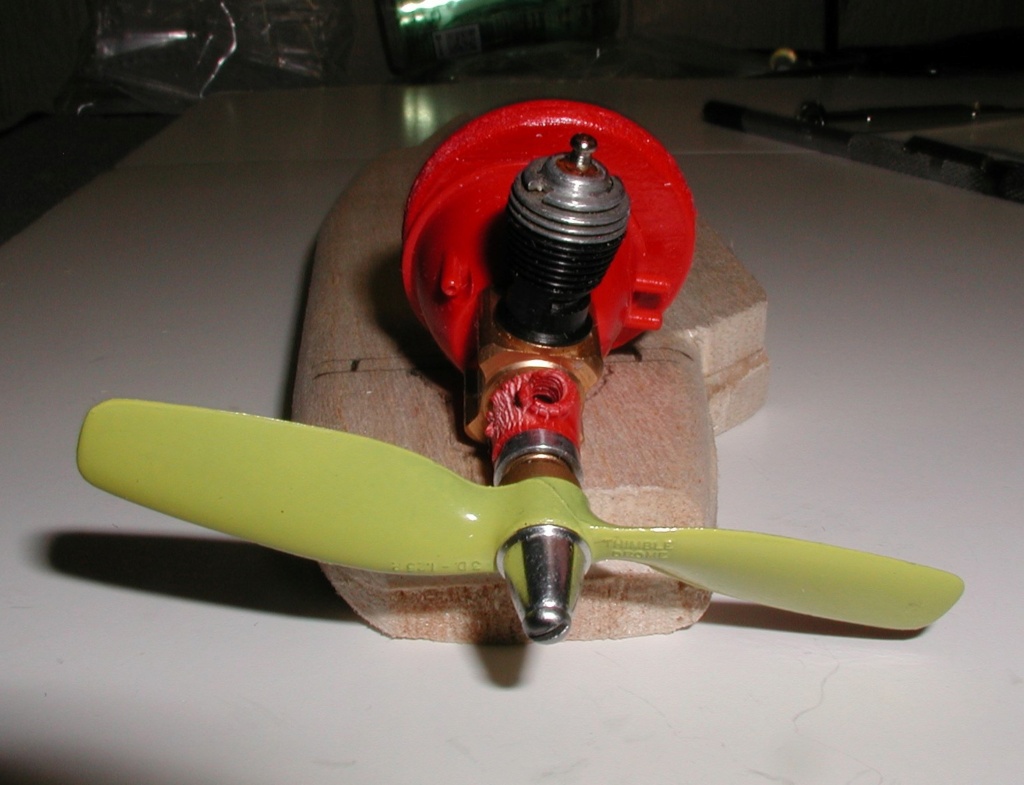

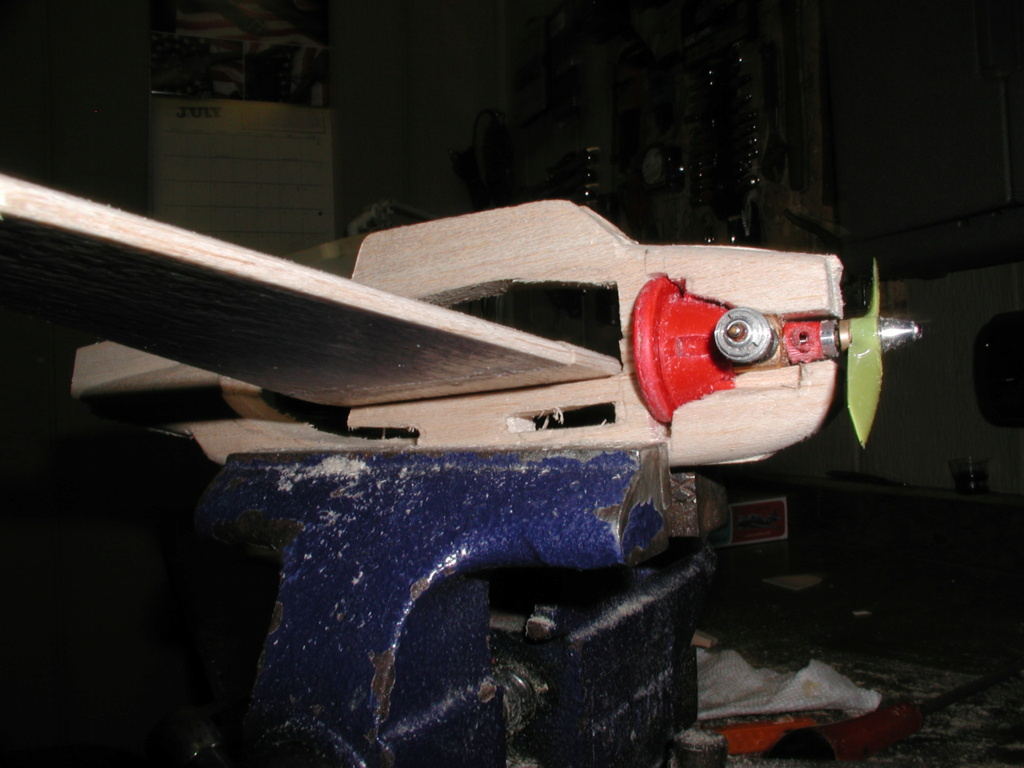

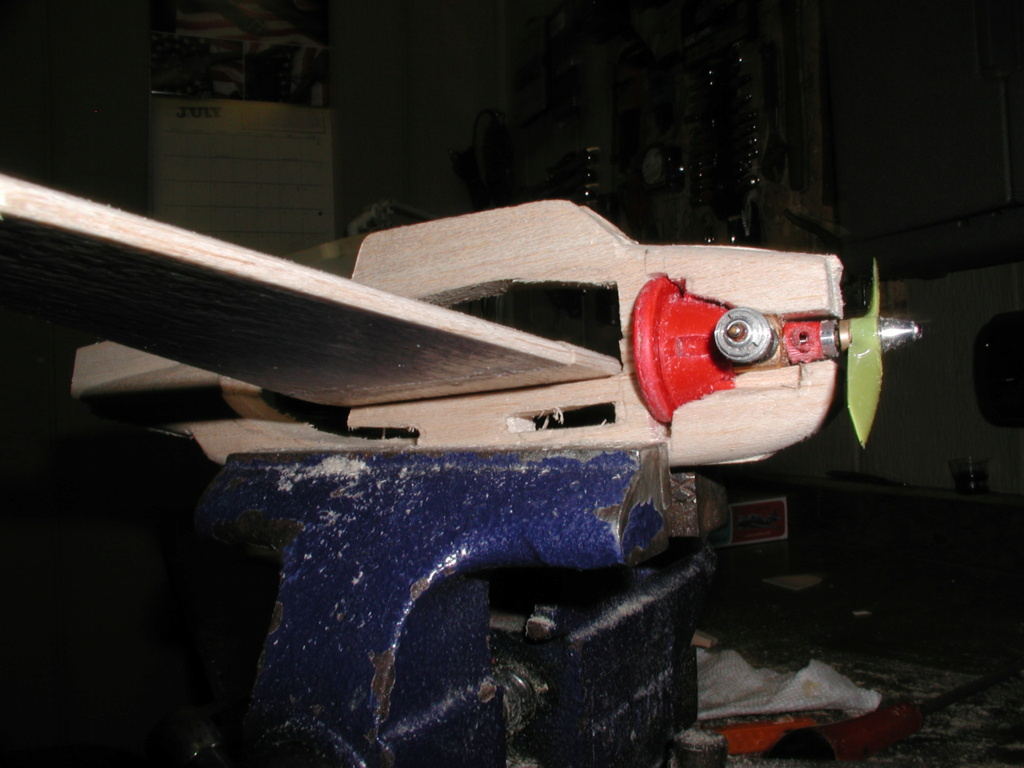

Mauricio, Andras, Coxaddic, anyone. Will this work in this configuration - 90 degrees out? Before I cut balsa, I would like to know. I'm not familiar with these little guys. Don't worry about the engine, I just have it tacked together for measurement purposes. and......yes, I know it's a little silly.

Benefits - better balance with the engine outboard, easier to connect glow plug clip, no cylinder sticking up out of the fuselage. But will it prime and run? Fuel pickup is still outboard for C/L operation.

[/url

[/url

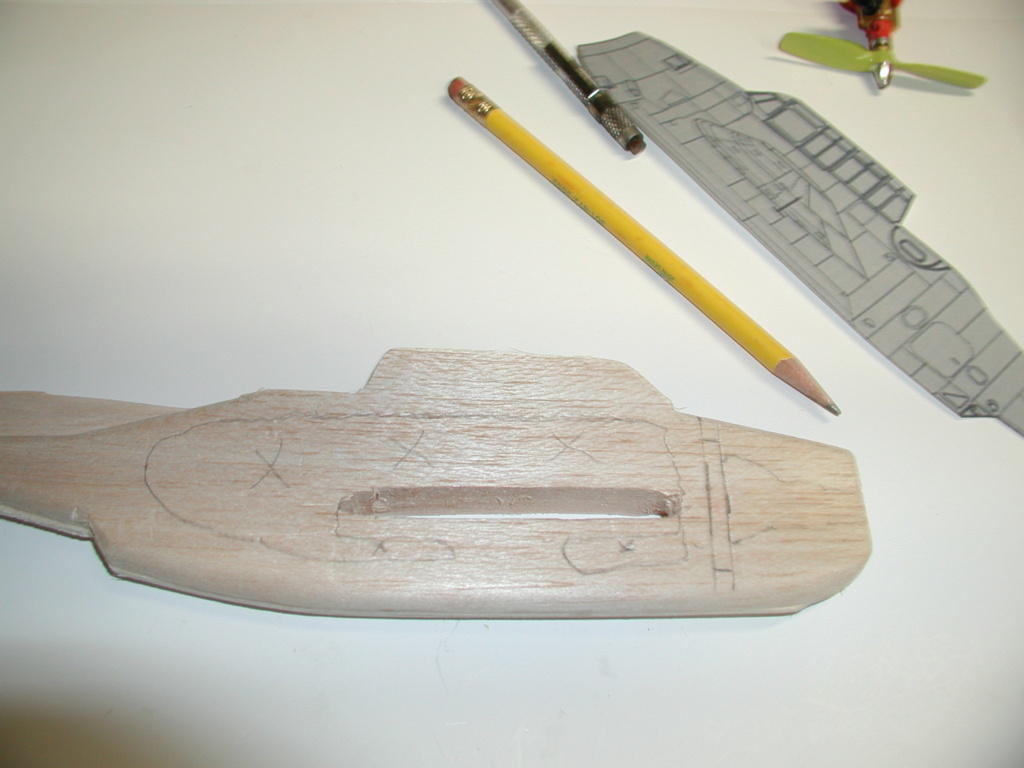

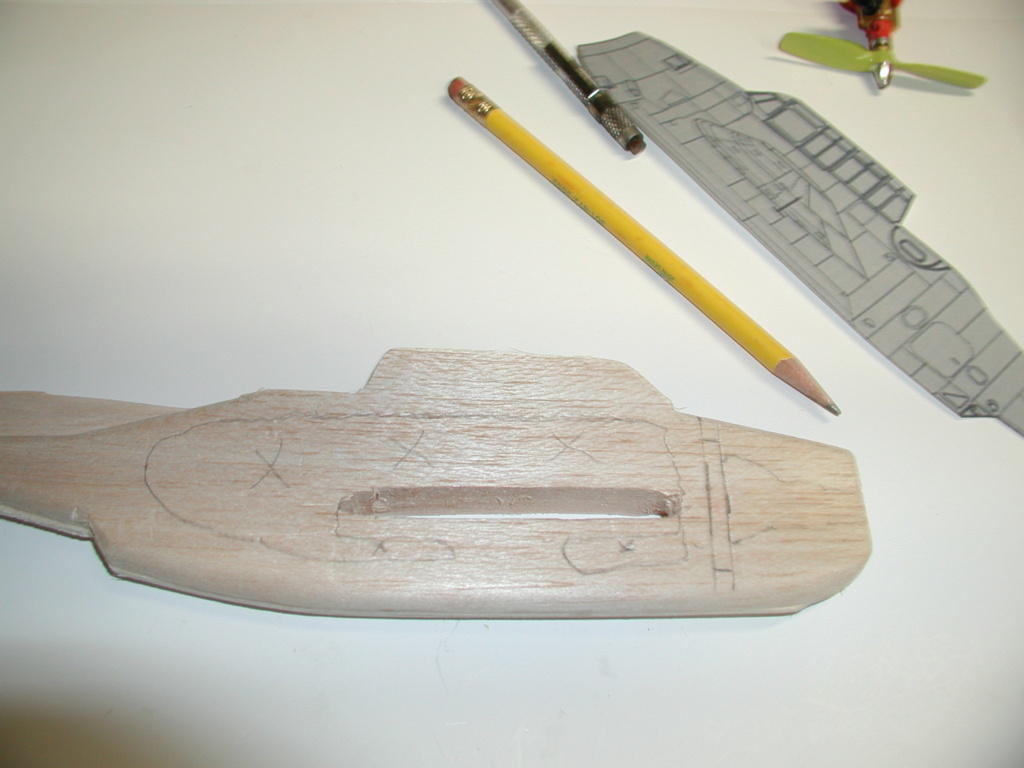

Oh yes, The X'd out balsa will be cut away leaving a stage for the wing to sit on and a backing for the firewall. Then the whole thing covered with 1/16" balsa and blended in.

Benefits - better balance with the engine outboard, easier to connect glow plug clip, no cylinder sticking up out of the fuselage. But will it prime and run? Fuel pickup is still outboard for C/L operation.

[/url

[/url

Oh yes, The X'd out balsa will be cut away leaving a stage for the wing to sit on and a backing for the firewall. Then the whole thing covered with 1/16" balsa and blended in.

rsv1cox- Top Poster

Posts : 10928

Join date : 2014-08-18

Location : West Virginia

Re: Cox .010 application question

Re: Cox .010 application question

Should be fine IMO

706jim- Gold Member

- Posts : 464

Join date : 2013-11-29

Re: Cox .010 application question

Re: Cox .010 application question

Dear friend, the motor will work perfectly at 90 degrees! Go ahead!

There will be a remnant of fuel in the tank due to centrifugal force, but I estimate it will be a small amount, that is, with the sucker placed as seen in the photo, but it will be running long enough to have fun.

There will be a remnant of fuel in the tank due to centrifugal force, but I estimate it will be a small amount, that is, with the sucker placed as seen in the photo, but it will be running long enough to have fun.

MauricioB- Top Poster

- Posts : 3657

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Cox .010 application question

Re: Cox .010 application question

Bob, thanks for addressing this to me too, I second to Mauricio, the 010 will work in any cylinder orientation. The tank mounts on the crankcase with 4 bolts 90 degrees apart, so the tank turns 90 degrees meaning even if the cylinder is sideways, you can keep the tank nipples on the top.

I am looking forward to your next build phases, Bob.

I am looking forward to your next build phases, Bob.

balogh- Top Poster

Posts : 4852

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Re: Cox .010 application question

Re: Cox .010 application question

Thanks guys,

First let me say that this is not intended to be a serious flying control line model airplane. But it will be some sort of flying model (Kim's "lawn dart" or not) as I build all my models that way not but necessarily to be lawn darts. It is just a fun project and something that I have never done before.

That said, cover your eyes..............

Vice make a nice level platform for cutting the wings base. Whole models interior will be filed/sanded smooth, symmetrical and painted with sanding sealer. Exterior will be sheeted with 1/16" balsa and blended in. Paint will be Navy blue on top, off-white on bottom. Canopy, don't know probably the easy way out, bright alluminum Krylon. Engine and backplate will go in last after the model has been completely finished, then the backplate will be epoxied in leaving it for some future generation to chip out. Tubing will provide access to fueling/venting.

Thanks for the comments, gave me courage to cut into this thing. Anyone see problems, let me know now while I can still chuck it in the trash and start over.

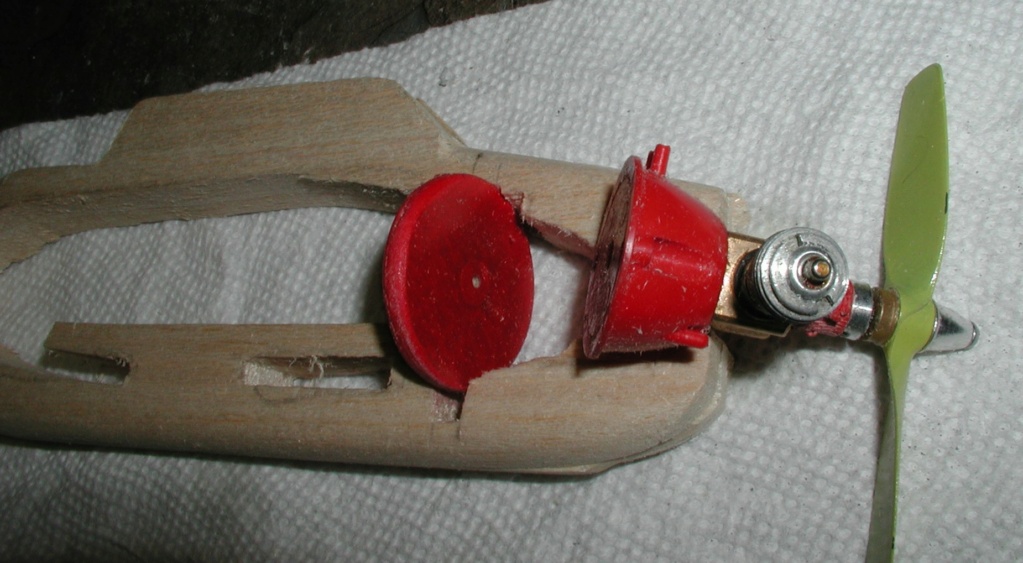

BTW, I'm not wasting those beautiful Cox Int. red cast aluminum tanks and venturi inserts on this engine. Got red plastic ones coming from MECOA.

BTW-2 - I need a glass/plastic ball about one inch in diameter for the rear gunners (Paul Newman) machine gun.

First let me say that this is not intended to be a serious flying control line model airplane. But it will be some sort of flying model (Kim's "lawn dart" or not) as I build all my models that way not but necessarily to be lawn darts. It is just a fun project and something that I have never done before.

That said, cover your eyes..............

Vice make a nice level platform for cutting the wings base. Whole models interior will be filed/sanded smooth, symmetrical and painted with sanding sealer. Exterior will be sheeted with 1/16" balsa and blended in. Paint will be Navy blue on top, off-white on bottom. Canopy, don't know probably the easy way out, bright alluminum Krylon. Engine and backplate will go in last after the model has been completely finished, then the backplate will be epoxied in leaving it for some future generation to chip out. Tubing will provide access to fueling/venting.

Thanks for the comments, gave me courage to cut into this thing. Anyone see problems, let me know now while I can still chuck it in the trash and start over.

BTW, I'm not wasting those beautiful Cox Int. red cast aluminum tanks and venturi inserts on this engine. Got red plastic ones coming from MECOA.

BTW-2 - I need a glass/plastic ball about one inch in diameter for the rear gunners (Paul Newman) machine gun.

rsv1cox- Top Poster

Posts : 10928

Join date : 2014-08-18

Location : West Virginia

Re: Cox .010 application question

Re: Cox .010 application question

Looks good Bob…. I like the blocky-ness of it which is appropriate for this plane…. The fin/rudder treatment works great….. Do you think you could get by with silicone to mount the engine? Looks like the fuse has it trapped well all around…Or maybe a round plate epoxied to the plane and the engine screwed to that?….

rdw777- Diamond Member

Posts : 1520

Join date : 2021-03-11

Location : West Texas

Re: Cox .010 application question

Re: Cox .010 application question

rdw777 wrote:Looks good Bob…. I like the blocky-ness of it which is appropriate for this plane…. The fin/rudder treatment works great….. Do you think you could get by with silicone to mount the engine? Looks like the fuse has it trapped well all around…Or maybe a round plate epoxied to the plane and the engine screwed to that?….

Yes, I like the way the tail "grows" out of the fuselage, unique to this model. I accented the moment in my model.

Silicone, a good idea. I may use it. Dampen vibes. The backplate is an existing luan wheel that I had painted red for one of my other models and never used. It's a perfect fit for this engine, I will just screw it on and slide it in as a unit. Really tight fit, I have to force it in, but it's in great alignment. I will have to drill a hole for the needle and add an extender, it was either the needle sticking up or the cylinder which I did not want.

It will probably stick out on each side, but I may decide to build it in.

So much more detail work to do.

rsv1cox- Top Poster

Posts : 10928

Join date : 2014-08-18

Location : West Virginia

Similar topics

Similar topics» a cheap sport muffler

» hair-pin needle-clip-DIY

» Cox TD 020 question

» .020 with throttle ring - original application was?

» Black Widow generating shavings in non-standard application

» hair-pin needle-clip-DIY

» Cox TD 020 question

» .020 with throttle ring - original application was?

» Black Widow generating shavings in non-standard application

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules