Log in

Search

Latest topics

» Stealth SB-Xby Admin Today at 8:28 pm

» ST .35 STUNT / VOODOO / ZERO POINT ZERO NITRO

by TD ABUSER Today at 7:45 pm

» SUPERTIGER .15 PROJECT

by TD ABUSER Today at 7:42 pm

» For sale -- Cox Custom Carburetors for Tee Dee engines

by sosam117 Today at 5:23 pm

» WHERE ARE YOU BUYING YOUR FUEL AND GLOW PLUGS...?

by TD ABUSER Today at 4:35 pm

» Waiting for Engines from Ken Enya

by sosam117 Today at 4:33 pm

» Unusual Cox 049 cylinder - Need help identifying

by anm2 Today at 4:12 pm

» Jim Walker Bonanza etc.

by rsv1cox Today at 2:57 pm

» What's the Best Reed for Cox Reed Valve Engines.

by roddie Today at 1:37 pm

» Fuel choice

by 1975 control line guy Yesterday at 4:01 pm

» "Fall S.M.A.L.L." Video 3.

by GallopingGhostler Yesterday at 2:37 pm

» Gifted Fox

by Ken Cook Yesterday at 11:12 am

Cox Engine of The Month

August-2024

balogh's

"Cox TD09 R/C Beast of Burden featuring Kamtechnik head and DIY metallic fuel nipple"

PAST WINNERS

balogh's

"Cox TD09 R/C Beast of Burden featuring Kamtechnik head and DIY metallic fuel nipple"

PAST WINNERS

A prototype Cox Reed-valve marine engine

Page 1 of 1

A prototype Cox Reed-valve marine engine

A prototype Cox Reed-valve marine engine

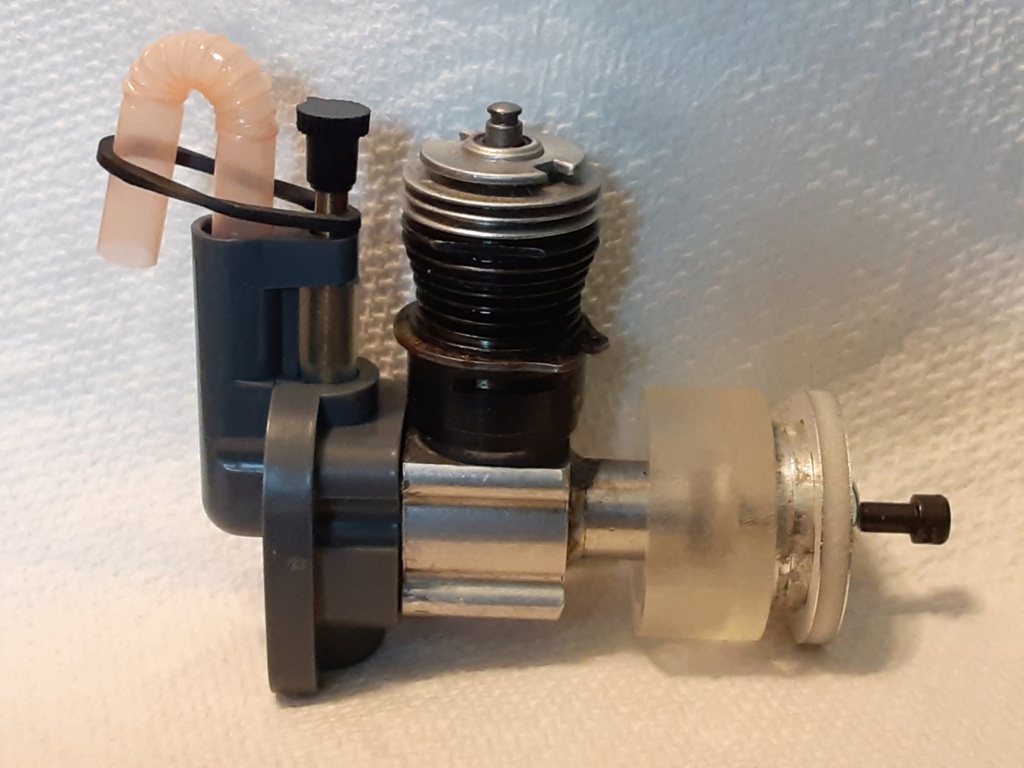

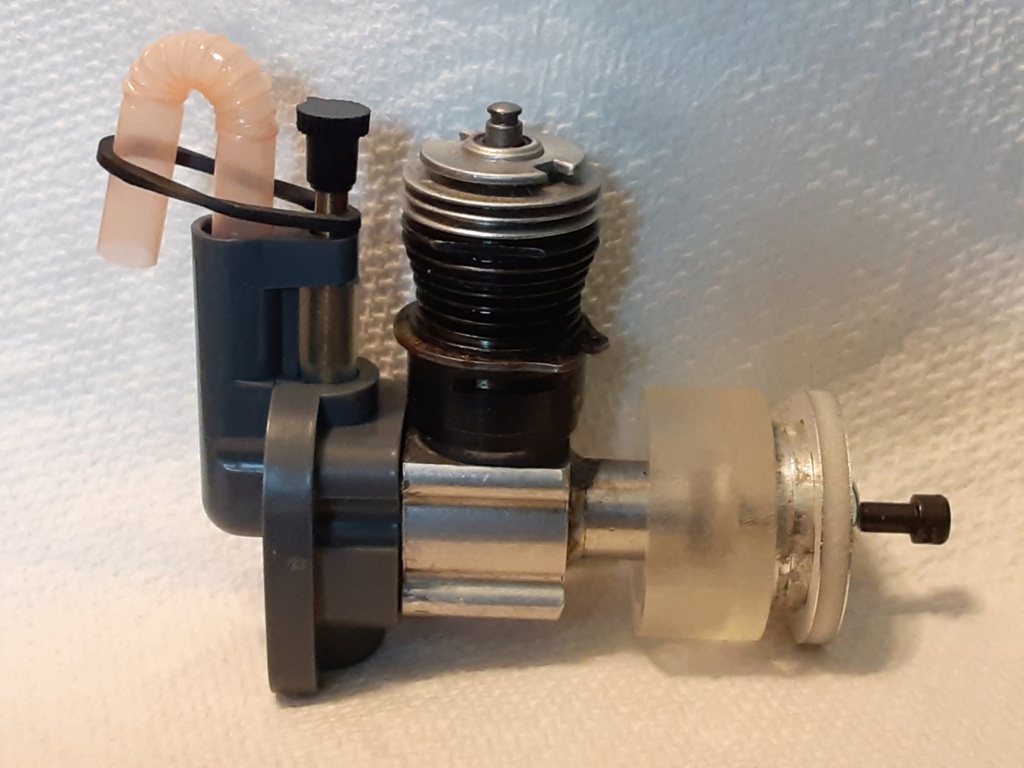

So... I'd been thinking about a different approach to powering a 1/2A glow-engine powered speedboat. I've got the "jet-pump" drive in the works.. with a venturi-throttled Babe Bee engine for input-power. This combo needs to be tested.

A throttle is desired.. and I've been working on a custom exhaust-throttle ring for .049/.051 Cox cylinders. More on that later.....

I knew that I had an OEM/Cox .049 throttle-barrel and matched cylinder that I'd had for decades....... and never set-up. It was now time to try a configuration.

I cleaned/oiled the cylinder and found a random loose piston and crankcase assembly.. installed X2 used head gaskets with a glowhead.. to find really good compression.

I had a plan for the back-end...as well as for the output-shaft.

The back-end would consist of the late horseshoe backplate/choke-tube combination with an added "snorkel" to raise the air-intake a little higher to help keep any bilge-water or spray from entering the venturi.

I put a silicone tube-seal over the needle-shaft.. and I think that it will also help to keep the needle-setting from drifting.

The 4 supplied screws are a good length. You can see that once I tighten them up; there will be ample threads.. but not such a length as to bottom-out in the case holes.

One of my custom flywheels to accept a starting-belt.

I'm looking for an old broken air-conditioner.. to cannibalize for its small diameter copper tubing to make a water-cooling coil for this one.

A throttle is desired.. and I've been working on a custom exhaust-throttle ring for .049/.051 Cox cylinders. More on that later.....

I knew that I had an OEM/Cox .049 throttle-barrel and matched cylinder that I'd had for decades....... and never set-up. It was now time to try a configuration.

I cleaned/oiled the cylinder and found a random loose piston and crankcase assembly.. installed X2 used head gaskets with a glowhead.. to find really good compression.

I had a plan for the back-end...as well as for the output-shaft.

The back-end would consist of the late horseshoe backplate/choke-tube combination with an added "snorkel" to raise the air-intake a little higher to help keep any bilge-water or spray from entering the venturi.

I put a silicone tube-seal over the needle-shaft.. and I think that it will also help to keep the needle-setting from drifting.

The 4 supplied screws are a good length. You can see that once I tighten them up; there will be ample threads.. but not such a length as to bottom-out in the case holes.

One of my custom flywheels to accept a starting-belt.

I'm looking for an old broken air-conditioner.. to cannibalize for its small diameter copper tubing to make a water-cooling coil for this one.

Re: A prototype Cox Reed-valve marine engine

Re: A prototype Cox Reed-valve marine engine

Roddie wrote:I'm looking for an old broken air-conditioner.. to cannibalize for its small diameter copper tubing to make a water-cooling coil for this one.

Nice project roddie…. Most small copper tubing in small AC units is considered capillary tubing and the id would be too small to pass much water…. Not sure if you have Hobby Lobby craft stores in your area but those around here carry K&S soft brass tube that bends easily….. If you find some stuff it as full as possible with thin stranded wire like from a lamp cord before bending, Prevents kinking…. A couple of bent pieces I did for a balloon tank….

rdw777- Diamond Member

Posts : 1520

Join date : 2021-03-11

Location : West Texas

Re: A prototype Cox Reed-valve marine engine

Re: A prototype Cox Reed-valve marine engine

rdw777 wrote:

Nice project roddie…. Most small copper tubing in small AC units is considered capillary tubing and the id would be too small to pass much water…. Not sure if you have Hobby Lobby craft stores in your area but those around here carry K&S soft brass tube that bends easily….. If you find some stuff it as full as possible with thin stranded wire like from a lamp cord before bending, Prevents kinking…. A couple of bent pieces I did for a balloon tank….

Thanks for that advice Robert. I actually ordered (Amazon) a small coil of soft copper tubing that has a 1/8" OD and 5/64" (.075") ID. I hope that's a big enough inner diameter for this app.

Re: A prototype Cox Reed-valve marine engine

Re: A prototype Cox Reed-valve marine engine

Hi roddie.

I had a 'similar' GoldenBee setup with some 'Octura 1/2A prop stuff ', I got from the LHS.

Wrapped some 1/8th soft brass KS tube around the head with proper intake/exhaust to water cool it.

Hard part was, string starting it, setting the needle before it over heated.

The only way the water cooling works, is if it moves through the water...

Somehow,

I traded/snagged a busted up front end Cox SandBlaster power plant, and put it in.

(I wonder how many Cox cars have hit curbs ! )

)

The pull start was nice !

The big heatsink allowed me to set a good needle setting.

Full throttle worked good.

As soon as I throttled down, it quit. Something to do with prop/pitch perhaps...

If you don't mind a true story...

This was the first boat I built. And designed. (DeepV with 45deg deadrise )

)

Very fast on paper, fast standing still. 100mph tied to the dock.

Unfortunately, the Heathkit R/C gear of the day,

Ballasted it down to Crusier/Battleship manouverability.

Balsa planked with the latest then, polyester resin.

Cox engine and R/C moved on to other projects.

Here is the fun part,

One of our 'Cox Gang' got some 'Serious Fireworks'...

My boat got a 'Viking Funeral'.

A splash of gasoline in the bilge.

A bunch of cool fireworks, set off by a 3ft tall wick...

Obviously, you had to be there,

No Cox Engines were harmed that day...

Take care,

Have fun,

Dave

I had a 'similar' GoldenBee setup with some 'Octura 1/2A prop stuff ', I got from the LHS.

Wrapped some 1/8th soft brass KS tube around the head with proper intake/exhaust to water cool it.

Hard part was, string starting it, setting the needle before it over heated.

The only way the water cooling works, is if it moves through the water...

Somehow,

I traded/snagged a busted up front end Cox SandBlaster power plant, and put it in.

(I wonder how many Cox cars have hit curbs !

The pull start was nice !

The big heatsink allowed me to set a good needle setting.

Full throttle worked good.

As soon as I throttled down, it quit. Something to do with prop/pitch perhaps...

If you don't mind a true story...

This was the first boat I built. And designed. (DeepV with 45deg deadrise

Very fast on paper, fast standing still. 100mph tied to the dock.

Unfortunately, the Heathkit R/C gear of the day,

Ballasted it down to Crusier/Battleship manouverability.

Balsa planked with the latest then, polyester resin.

Cox engine and R/C moved on to other projects.

Here is the fun part,

One of our 'Cox Gang' got some 'Serious Fireworks'...

My boat got a 'Viking Funeral'.

A splash of gasoline in the bilge.

A bunch of cool fireworks, set off by a 3ft tall wick...

Obviously, you had to be there,

No Cox Engines were harmed that day...

Take care,

Have fun,

Dave

HalfaDave- Platinum Member

- Posts : 609

Join date : 2022-12-06

Location : Oakville, Ontario

Re: A prototype Cox Reed-valve marine engine

Re: A prototype Cox Reed-valve marine engine

HalfaDave wrote:Hi roddie.

I had a 'similar' GoldenBee setup with some 'Octura 1/2A prop stuff ', I got from the LHS.

Wrapped some 1/8th soft brass KS tube around the head with proper intake/exhaust to water cool it.

Hard part was, string starting it, setting the needle before it over heated.

The only way the water cooling works, is if it moves through the water...

Somehow,

I traded/snagged a busted up front end Cox SandBlaster power plant, and put it in.

(I wonder how many Cox cars have hit curbs !)

The pull start was nice !

The big heatsink allowed me to set a good needle setting.

Full throttle worked good.

As soon as I throttled down, it quit. Something to do with prop/pitch perhaps...

If you don't mind a true story...

This was the first boat I built. And designed. (DeepV with 45deg deadrise)

Very fast on paper, fast standing still. 100mph tied to the dock.

Unfortunately, the Heathkit R/C gear of the day,

Ballasted it down to Crusier/Battleship manouverability.

Balsa planked with the latest then, polyester resin.

Cox engine and R/C moved on to other projects.

Here is the fun part,

One of our 'Cox Gang' got some 'Serious Fireworks'...

My boat got a 'Viking Funeral'.

A splash of gasoline in the bilge.

A bunch of cool fireworks, set off by a 3ft tall wick...

Obviously, you had to be there,

No Cox Engines were harmed that day...

Take care,

Have fun,

Dave

Hi Dave, Yea.... this will be my first time trying a self-made water-cooling coil. I haven't run a glow-engine set-up for a marine application either. I am concerned about the engine's top-end overheating before I can get water flowing.. but I'm wondering if the reed-valve engines tend to run a little cooler than their high-performance/high-rpm big brothers? I think that most boat modelers who have run Cox engines in their boats have run the higher-performance Tee Dees. The Cox "Sea Bee" V-hull/shaft-drive model is powered by their .049 reed-valve engine which is not water-cooled.. and most that I've seen do not have the Cox heat sink installed either. The Sea Bee did have that recoil type pull-starter that you mentioned though. I've set my engine up to use a starter-belt via an electric starter.

I enjoyed your "first boat I built" story Dave..

Re: A prototype Cox Reed-valve marine engine

Re: A prototype Cox Reed-valve marine engine

Roddie It would be my pleasure to make you a cooling jacket of course you will have to wait a bit as I have limited time while the working season is starting again for me I work a lot but I still have the project of making some piece for you friends be patient I I will have a part available to resolve this overheating problem. The first prototype that I made is functional but too complicated to manufacture. I have to change the tool. I am waiting for a smaller boring bar.

I really like your turbine idea and I think there is a good chance it will work very well. I almost bought one too but came with the hull I put it in my list of possible model for .049

I really like your turbine idea and I think there is a good chance it will work very well. I almost bought one too but came with the hull I put it in my list of possible model for .049

davidll1984- Diamond Member

- Posts : 2307

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: A prototype Cox Reed-valve marine engine

Re: A prototype Cox Reed-valve marine engine

"Jeffry Wohlt"

https://www.rcraceboat.com/

Will be using his .062 drive line in nylon tube with outer aluminum tub to save weight.

On weds he sent out .062 x 2mm couplings, 2 wire drives with drive dogs and fresh nylon.

I will tap the 2mm out for 5-40 thread.

- see weight mass load on the ball socket:

Goal will be a 30 mph with a TD .051 outrigger hydro based on known field data.

I have a handful of metal props to try this one will be use first to do test laps / trim and

compare to the Picco .05 that unloaded the prop to 39.72k rpm pass in a larger hydro.

27 mph will be about all the Oct. 0924 prop can do if at 33k in a leaner TD size outrigger.

https://www.rcraceboat.com/

Will be using his .062 drive line in nylon tube with outer aluminum tub to save weight.

On weds he sent out .062 x 2mm couplings, 2 wire drives with drive dogs and fresh nylon.

I will tap the 2mm out for 5-40 thread.

- see weight mass load on the ball socket:

Goal will be a 30 mph with a TD .051 outrigger hydro based on known field data.

I have a handful of metal props to try this one will be use first to do test laps / trim and

compare to the Picco .05 that unloaded the prop to 39.72k rpm pass in a larger hydro.

27 mph will be about all the Oct. 0924 prop can do if at 33k in a leaner TD size outrigger.

1/2A Nut- Top Poster

- Posts : 3464

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

O-Ring starter-belt

O-Ring starter-belt

I'll probably try to run this engine/O-Ring starter-belt combo tomorrow.

I increased the diameter of the O-ring from 1/8" to 3/16".

The 1/8" O-ring was slipping and will require a flywheel assy. rebuild to narrow the groove.. but going with a larger diameter O-ring won't bottom-out in either the starter or the engine pulleys.. but also wont stick/snag/jam. The O-ring is basically riding-on-rails. Applying tension grips the idlers positively. It's the way you'd want it to crank your engine.

I made two different water-cooling coils; one of 1/8" Copper.. and one of 1/8" aluminum thin-wall tubings. I'll rig-up a 2L. gravity-feed water bottle with a pinch-off valve for testing.

I increased the diameter of the O-ring from 1/8" to 3/16".

The 1/8" O-ring was slipping and will require a flywheel assy. rebuild to narrow the groove.. but going with a larger diameter O-ring won't bottom-out in either the starter or the engine pulleys.. but also wont stick/snag/jam. The O-ring is basically riding-on-rails. Applying tension grips the idlers positively. It's the way you'd want it to crank your engine.

I made two different water-cooling coils; one of 1/8" Copper.. and one of 1/8" aluminum thin-wall tubings. I'll rig-up a 2L. gravity-feed water bottle with a pinch-off valve for testing.

F4D Phantom II- Gold Member

- Posts : 239

Join date : 2019-04-08

F4D Phantom II- Gold Member

- Posts : 239

Join date : 2019-04-08

1/2A Nut- Top Poster

- Posts : 3464

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: A prototype Cox Reed-valve marine engine

Re: A prototype Cox Reed-valve marine engine

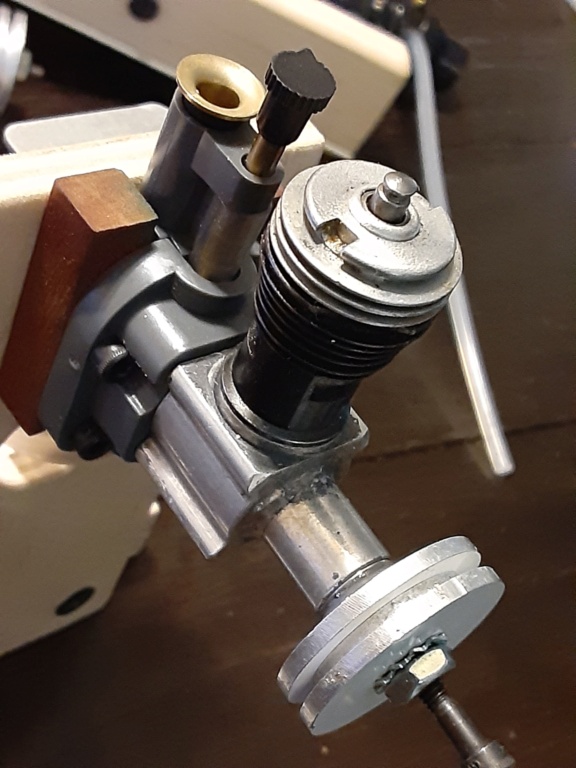

Hello 1/2anut

I had a V groove on my pulley but it was not wide enough to fit the belt so I decided to modify it to test and made a square groove. I will make another pulley with the information that you have posted and will widen the V groove on the flywheel to 3.5 mm also. In my pulley I had installed a one way bearing from a pullstar unit from a model engine and made a stub with a C clip to install in my starter .So as the engine starts the pulley doesn`t load the engine as it freewheels. I just remembered that I had bought a sawing machine belt when I was working on the engine years back and it was a V belt. need to look thru my boxed stuff before I do anything. here are pics.

Juan

I had a V groove on my pulley but it was not wide enough to fit the belt so I decided to modify it to test and made a square groove. I will make another pulley with the information that you have posted and will widen the V groove on the flywheel to 3.5 mm also. In my pulley I had installed a one way bearing from a pullstar unit from a model engine and made a stub with a C clip to install in my starter .So as the engine starts the pulley doesn`t load the engine as it freewheels. I just remembered that I had bought a sawing machine belt when I was working on the engine years back and it was a V belt. need to look thru my boxed stuff before I do anything. here are pics.

Juan

F4D Phantom II- Gold Member

- Posts : 239

Join date : 2019-04-08

Re: A prototype Cox Reed-valve marine engine

Re: A prototype Cox Reed-valve marine engine

Thank you Juan. A toothed-belt would be the ultimate.. but there's the issue of a flywheel to mate with it. You will surely find that weight "adds-up" really quickly in a micro-scale RC model. There's a reason why there aren't more 1/2A glow-powered boats on the water. They're temperamental.

You and Brad touched briefly on flywheel weight/drive-mass. I don't know anything about that.. but I know that it must matter when attempting to get it all to work.

I thought that going with a larger diameter O-ring would be the answer to the belt-slipping issue. but I reexamined the physical properties of the pulley-system that I was using.. and reconfigured my flywheel pulley's width to be narrow enough to keep the O-ring from binding/catching. This required reworking the pulley-system on my elec. starter as well as the one on the engine. I'll be staying with the 1/8" diameter O-ring/belt.

This is the fly-weight/mass of my current drive configuration... for what it's worth..

in grams..

in ounces..

On the weight-scale was my flywheel assembly and drive-coupling(s). I'm putting together a 2mm wire-drive.. but actually more like a solid-shaft configuration.

Re: A prototype Cox Reed-valve marine engine

Re: A prototype Cox Reed-valve marine engine

Hello Roddie

I don`t know much about boats but I`m learning on the job. I don`t know if a light flywheel will work with the cox.049,that is I think that I might need in my case to make one heavier than what I have. I`m placing a carburator and need to make sure the engine work properly at a lower RPM and at full power. So is going to be a trial and error job.

Do you have a Boat for your engine or are you building one ,What is your boat choice for your engine? I will be reading your thread to learn.

Juan

I don`t know much about boats but I`m learning on the job. I don`t know if a light flywheel will work with the cox.049,that is I think that I might need in my case to make one heavier than what I have. I`m placing a carburator and need to make sure the engine work properly at a lower RPM and at full power. So is going to be a trial and error job.

Do you have a Boat for your engine or are you building one ,What is your boat choice for your engine? I will be reading your thread to learn.

Juan

F4D Phantom II- Gold Member

- Posts : 239

Join date : 2019-04-08

Re: A prototype Cox Reed-valve marine engine

Re: A prototype Cox Reed-valve marine engine

What Juan said, and you have got it going on this project. I'm watching.

Bob

Bob

rsv1cox- Top Poster

Posts : 10928

Join date : 2014-08-18

Location : West Virginia

Re: A prototype Cox Reed-valve marine engine

Re: A prototype Cox Reed-valve marine engine

Hello roddie

My sherline lathe doesn`t want to turn on so I took the motor off the lathe and it drives the lathe with a toothed belt with 80 teeth the number on the belt is MB330 and is made in japan. I decided to try it on my starter and it grip real good. The belt is like the ones used in sawing machines. My mother had a Singer electric sawing machine and this belt looks the same. I will have to modify my flywheel by making a wider groove for the belt. I tried it on and the slot needs to be wider.

Juan

My sherline lathe doesn`t want to turn on so I took the motor off the lathe and it drives the lathe with a toothed belt with 80 teeth the number on the belt is MB330 and is made in japan. I decided to try it on my starter and it grip real good. The belt is like the ones used in sawing machines. My mother had a Singer electric sawing machine and this belt looks the same. I will have to modify my flywheel by making a wider groove for the belt. I tried it on and the slot needs to be wider.

Juan

F4D Phantom II- Gold Member

- Posts : 239

Join date : 2019-04-08

Re: A prototype Cox Reed-valve marine engine

Re: A prototype Cox Reed-valve marine engine

F4D Phantom II wrote:Hello Roddie

I don`t know much about boats but I`m learning on the job. I don`t know if a light flywheel will work with the cox.049,that is I think that I might need in my case to make one heavier than what I have. I`m placing a carburator and need to make sure the engine work properly at a lower RPM and at full power. So is going to be a trial and error job.

Do you have a Boat for your engine or are you building one ,What is your boat choice for your engine? I will be reading your thread to learn.

Juan

Hi Juan, Thank you so much for your interest in my marine model project. I don't know much about boats either. I'm literally floating by the seat of my pants..

I have two boat projects that I'm working on.. but one needs to have its drive-system "proven-out". It's a jet-pump drive designed to use a brushed electric 380 series motor. I built a "test-tub" fixture to see how the drive behaves when submerged.. and if the engine will actually run when connected to it.

The other model is a self-designed outrigger hydroplane with a surface-drive that I've actually been spending more time on.

Similar topics

Similar topics» Reed valve engine video clip

» Help! Need Reed valve retainer spring for Cox 010 engine

» New in Box Enya .10 Series #4 engines

» Venturi Size .049

» Reed Valve

» Help! Need Reed valve retainer spring for Cox 010 engine

» New in Box Enya .10 Series #4 engines

» Venturi Size .049

» Reed Valve

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules