Log in

Search

Latest topics

» A choke-tube with velocity-stack configured Beeby roddie Today at 10:48 am

» Hawk had breakfast and then took a bath

by rsv1cox Today at 10:26 am

» Jim Walkers FireBee - This is going to be fun

by getback Today at 9:55 am

» WenMac 049 - Glow Plug & Head Gasket replacements?

by Ken Cook Today at 8:06 am

» Prop Rod - resto to a runner

by rsv1cox Today at 7:32 am

» Jim Walker Firebaby

by rdw777 Yesterday at 4:58 pm

» Nostalgia alert, my 1959 Corvette revisited

by rsv1cox Yesterday at 2:25 pm

» Prayers for my Wife Please

by akjgardner Yesterday at 10:28 am

» Cox prop rod

by Wiggy Fri May 17, 2024 4:30 pm

» "Red Neck" .049 elec. starter

by getback Fri May 17, 2024 7:19 am

» Cox prop rod

by Wiggy Fri May 17, 2024 5:35 am

» Looking For Comet Tri-Pacer

by latole Fri May 17, 2024 3:45 am

So, what's the trick?

Page 1 of 1

So, what's the trick?

So, what's the trick?

I used the search but had no luck in finding an answer.

It was easy to press the crankshaft out of the crankcase on my Tee Dee .010.

My question revolves around on how to properly reattach the prop drive washer onto the crankshaft of a .010. The prop screw is a 2-56 x 5/8" long slotted head. VERY easy to bugger up the slot head when trying to tighten up the screw with propeller attached. I have had no success, for the prop, prop driver and spinner leaves very little room for the 2-56 to screw into the crankshaft. I know it's not easy to align the spline on the crank with the drive plate while trying to hold all the parts together and tighten the 2-56 bolt.

Any suggestions with this teeny tiny engine?

It was easy to press the crankshaft out of the crankcase on my Tee Dee .010.

My question revolves around on how to properly reattach the prop drive washer onto the crankshaft of a .010. The prop screw is a 2-56 x 5/8" long slotted head. VERY easy to bugger up the slot head when trying to tighten up the screw with propeller attached. I have had no success, for the prop, prop driver and spinner leaves very little room for the 2-56 to screw into the crankshaft. I know it's not easy to align the spline on the crank with the drive plate while trying to hold all the parts together and tighten the 2-56 bolt.

Any suggestions with this teeny tiny engine?

DrCox- Gold Member

- Posts : 229

Join date : 2018-07-18

Location : Wisconsin

Re: So, what's the trick?

Re: So, what's the trick?

Don't use the stock prop and screw to re install the drive washer. Source a longer 2-56 allen socket head and place the drive washer aligned on the splines. Put a 2-56 nut on the allen bolt and then place a washer after it. Screw the assembly into the crank and back the nut down onto the drive washer while using a allen wrench to hold the screw. It will press it on and it will firmly stop.

Last edited by Ken Cook on Thu Oct 25, 2018 8:52 pm; edited 1 time in total

Ken Cook- Top Poster

- Posts : 5489

Join date : 2012-03-27

Location : pennsylvania

Re: So, what's the trick?

Re: So, what's the trick?

I double posted, sorry for that

Ken Cook- Top Poster

- Posts : 5489

Join date : 2012-03-27

Location : pennsylvania

Re: So, what's the trick?

Re: So, what's the trick?

Howdy Doc! Welcome to the CEF. Ive never removed or replaced a drive plate on any of my 010 engines. I would highly recommend you follow the instructions given for doing this same thing on the 049 engines. You will need to obtain a 2-56 threaded stud, with 2 washers and a nut to drive the propeller back on and press fit the drive plate back in place. Here’s a lick to Cox Internationals tool to install the 049 prop driver:

You might have to select and inlarge the instructions. :

https://coxengines.ca/assembly-tool-for-cox-.049-engines.html

Oops Ken jumped in before I could type it up. Allen head, good choice!

You might have to select and inlarge the instructions. :

https://coxengines.ca/assembly-tool-for-cox-.049-engines.html

Oops Ken jumped in before I could type it up. Allen head, good choice!

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 71

Location : Grand Rapids, MI

Re: So, what's the trick?

Re: So, what's the trick?

Some great ideas.

Now where to find a 1" long 2-56 socket head bolt. Local Hobby Town just doesn't stock small parts the way hobby shops use to do. Any suggestions?

Thank you gentlemen.

Now where to find a 1" long 2-56 socket head bolt. Local Hobby Town just doesn't stock small parts the way hobby shops use to do. Any suggestions?

Thank you gentlemen.

DrCox- Gold Member

- Posts : 229

Join date : 2018-07-18

Location : Wisconsin

Re: So, what's the trick?

Re: So, what's the trick?

http://brodak.com/2-56-x-1-1-2-mounting-bolt-sets-with-nuts-and-washers.html

Slot head screws, but you can use an exacto blade or other suitable piece of flat sheet metal as a sort of wing nut and get the control you are looking for.

Slot head screws, but you can use an exacto blade or other suitable piece of flat sheet metal as a sort of wing nut and get the control you are looking for.

Dave P.- Gold Member

- Posts : 477

Join date : 2017-07-31

Age : 66

Location : Durham, NC

Re: So, what's the trick?

Re: So, what's the trick?

Dr,

Where are you? I'm sure one of us can "pay it forward."

What's a good screw between friends?

Um, that didn't come out right.

My local home town hardware store stocks the little screws and nuts...I get them there often enough that I have plenty. 7/8" may be the longest I have.

Where are you? I'm sure one of us can "pay it forward."

What's a good screw between friends?

Um, that didn't come out right.

My local home town hardware store stocks the little screws and nuts...I get them there often enough that I have plenty. 7/8" may be the longest I have.

944_Jim- Diamond Member

Posts : 1964

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: So, what's the trick?

Re: So, what's the trick?

Dave P. wrote:http://brodak.com/2-56-x-1-1-2-mounting-bolt-sets-with-nuts-and-washers.html

Slot head screws, but you can use an X-acto blade or other suitable piece of flat sheet metal as a sort of wing nut and get the control you are looking for.

Great site. Thank you Dave for the effort of listing the hotlink.

As an update, I magically found a 2-56 one inch long slotted head in the hobby drawer at home. Followed the advice form Ken Cook and aligned the spline marks from the crankshaft onto the prop drive plate. Dropped a little oil onto the drive plate prior to the alignment. Stuck a plastic pen barrel inside the crankcase to prevent crankshaft rotation. Slowly tightened up the nut onto the drive plate (slowly) and the prop drive plate was pushed onto the crankshaft. Done. No damage. Easy to bugger up.

Really sounds like no big deal, however with my old fat fingers and the tiny parts of the Cox .010, refreshed my memory as to why I avoided the profession of watch repair.

Thank you again gentleman.

DrCox- Gold Member

- Posts : 229

Join date : 2018-07-18

Location : Wisconsin

Re: So, what's the trick?

Re: So, what's the trick?

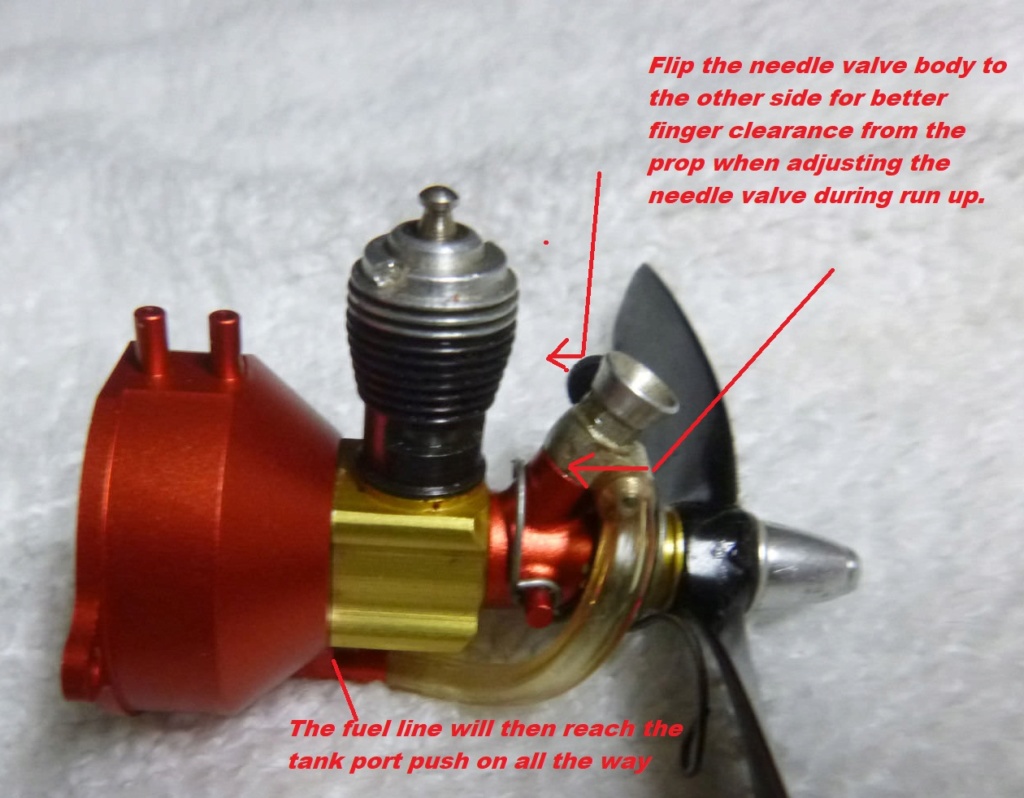

Here was the project. Internal tank cap screws had to be slowly worked in and back out several times with some oil. The tank back was challenging at best to properly seat with the O ring. Personally, I like the appearance.

DrCox- Gold Member

- Posts : 229

Join date : 2018-07-18

Location : Wisconsin

1/2A Nut- Top Poster

- Posts : 3442

Join date : 2013-10-20

Age : 60

Location : Brad in Texas

Similar topics

Similar topics» Trick or Treat

» Whats wrong in this photo?

» Whats inside your Medallion ?

» And the guess whats hiding in there winner is..................................

» whats this gizmo then? Engine mount from toy?

» Whats wrong in this photo?

» Whats inside your Medallion ?

» And the guess whats hiding in there winner is..................................

» whats this gizmo then? Engine mount from toy?

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules