Log in

Search

Latest topics

» Stealth SB-Xby Admin Today at 8:28 pm

» ST .35 STUNT / VOODOO / ZERO POINT ZERO NITRO

by TD ABUSER Today at 7:45 pm

» SUPERTIGER .15 PROJECT

by TD ABUSER Today at 7:42 pm

» For sale -- Cox Custom Carburetors for Tee Dee engines

by sosam117 Today at 5:23 pm

» WHERE ARE YOU BUYING YOUR FUEL AND GLOW PLUGS...?

by TD ABUSER Today at 4:35 pm

» Waiting for Engines from Ken Enya

by sosam117 Today at 4:33 pm

» Unusual Cox 049 cylinder - Need help identifying

by anm2 Today at 4:12 pm

» Jim Walker Bonanza etc.

by rsv1cox Today at 2:57 pm

» What's the Best Reed for Cox Reed Valve Engines.

by roddie Today at 1:37 pm

» Fuel choice

by 1975 control line guy Yesterday at 4:01 pm

» "Fall S.M.A.L.L." Video 3.

by GallopingGhostler Yesterday at 2:37 pm

» Gifted Fox

by Ken Cook Yesterday at 11:12 am

Cox Engine of The Month

August-2024

balogh's

"Cox TD09 R/C Beast of Burden featuring Kamtechnik head and DIY metallic fuel nipple"

PAST WINNERS

balogh's

"Cox TD09 R/C Beast of Burden featuring Kamtechnik head and DIY metallic fuel nipple"

PAST WINNERS

Fine thread NV assembly for a TD

Page 1 of 1

OVERLORD- Diamond Member

- Posts : 1799

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: Fine thread NV assembly for a TD

Re: Fine thread NV assembly for a TD

Interesting, I’ve been contemplating doing something very much like this.

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 56

Location : Colorado

Re: Fine thread NV assembly for a TD

Re: Fine thread NV assembly for a TD

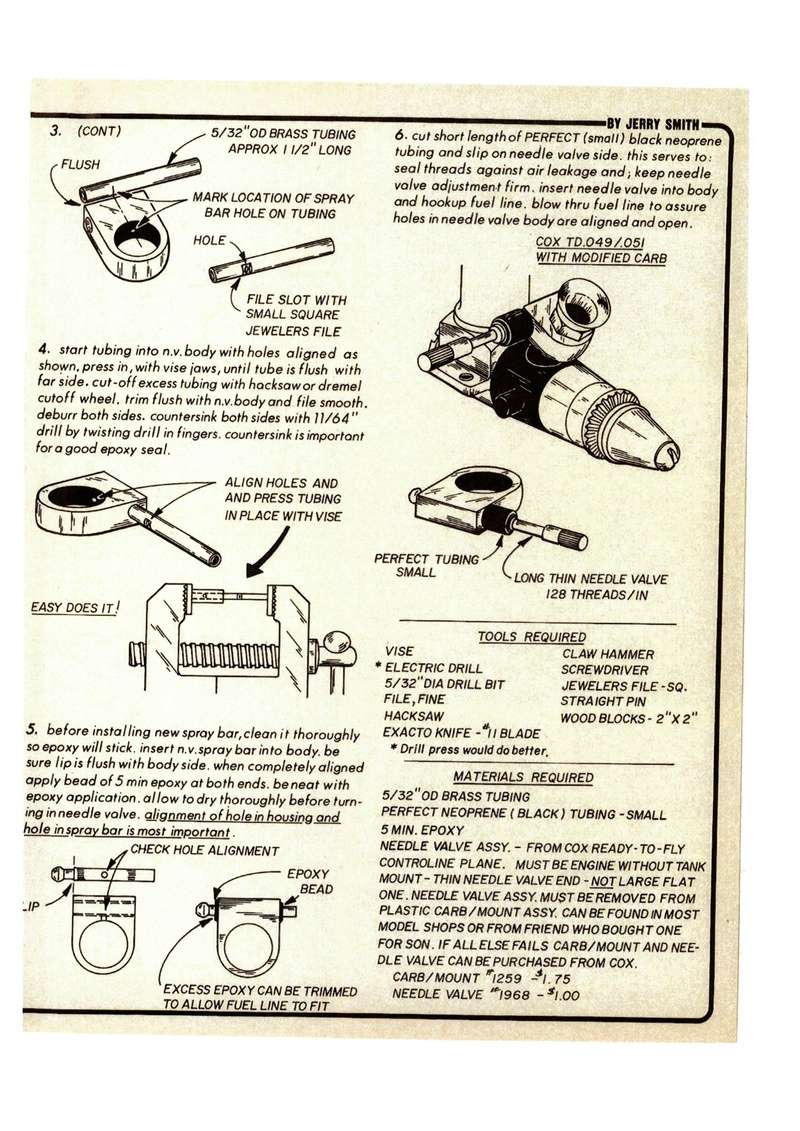

That's what they had to do before Dale Kirn started making and selling the Kirn-Kraft 128 tpi needle valves. And it turned out to be the premium trick for feeding the TD with pressure bladders. Now days they are readily available, but I see they cost more than twice as much since I last bought one for $15 from TexasTimers.com. Now at $35 bucks makes the old DIY method worth while. It's also perfect, and even simpler, for Norvel 1/2A engines. Same size tubing and all I do believe. My old tutorial is out there somewhere, posted here and at RCGroups. I probably learned it from Ken Cook.

Thanks, Lieven. Hope you are doing well these days.

Rusty

Thanks, Lieven. Hope you are doing well these days.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Fine thread NV assembly for a TD

Re: Fine thread NV assembly for a TD

Good stuff Lieven saved it if i need to change one for some reason , and as Rusty said them things have gotten expensive

getback- Top Poster

Posts : 10326

Join date : 2013-01-18

Age : 67

Location : julian , NC

OVERLORD- Diamond Member

- Posts : 1799

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: Fine thread NV assembly for a TD

Re: Fine thread NV assembly for a TD

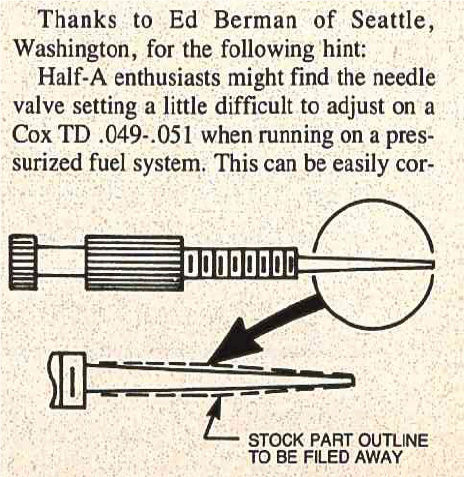

I doubt filing the taper works well because you probably won't have enough thread to screw it in all the way. It may still work for setting mixture, but it probably never close fully. File too much and it may never lean out enough, even with the needle bottom out on the available threads.

gkamysz- Gold Member

- Posts : 397

Join date : 2018-02-22

Location : Chicagoland

Re: Fine thread NV assembly for a TD

Re: Fine thread NV assembly for a TD

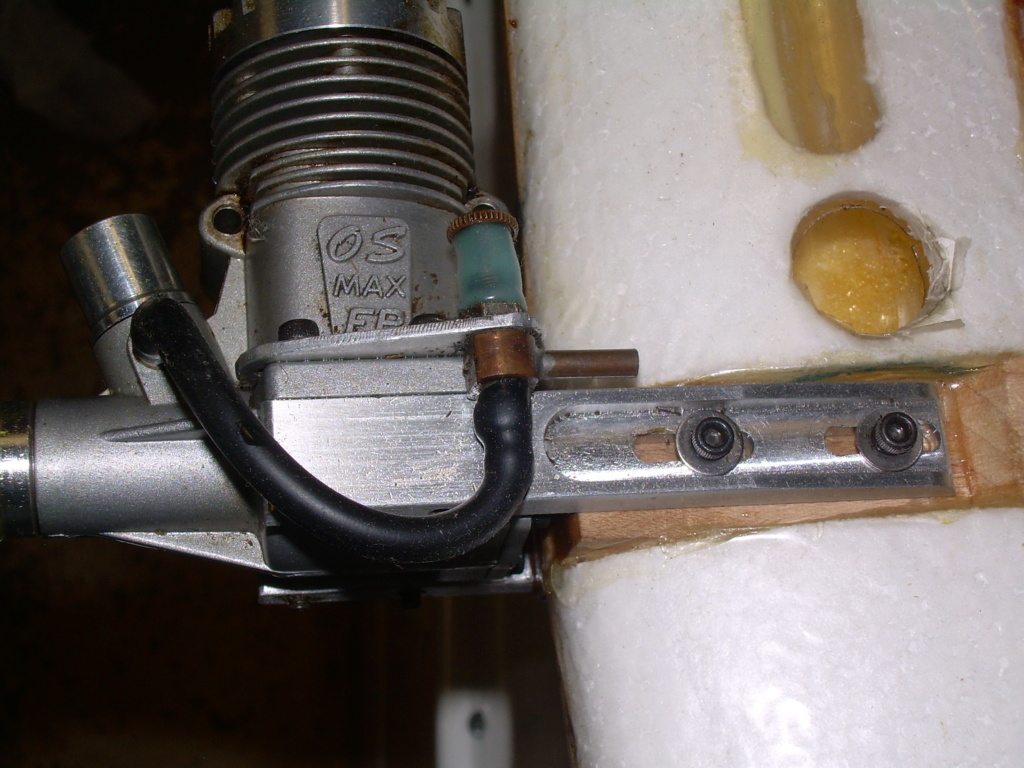

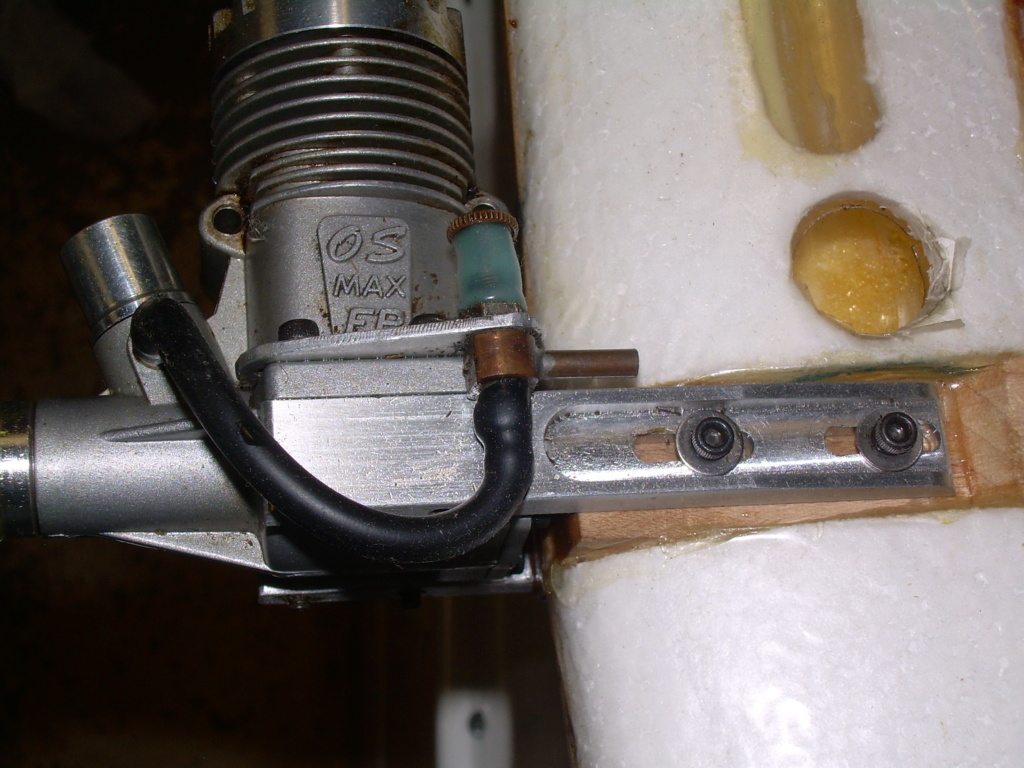

Drilling out the post of a old glow plug to your desired opening can easily yield a simple venturi. The plug will screw right into the carb body. Drill a hole into the side of one of the hex flats and solder a small piece of 1/8" copper and you can use a remote needle setup from pretty much any of the OS r/c engines which will work using pressure.

The stock TD needle still has a fairly coarse thread which regardless of needle taper is going to offer less than desirable results. While it will work, it's going to be very touchy. To compensate for this, you do one or two things which is raise the nitro or run a smaller prop.

Due to lack of camera currently, I can't post a pic. I make a banjo fitting from wheel collars. Remove the set screw from the wheel collar and drill out the hole to 1/8". Solder in a small 1/2" stub of 1/8" tubing. Press a128 TPI needle valve body out of a postage stamp backplate. Prepare the inside of the wheel collar for solder and clean the spraybar by chucking it up in a drill press using some steel wool. DON"T clean around the hole where the fuel exits as this will keep solder from entering into the hole. Solder the spraybar into the wheel collar aligning the spraybar hole with the copper you soldered into the collar. You just need to fabricate a bracket and you now have a 128 thread remote needle valve which didn't cost $40. I made most of my .25 LA engine needle valves this way. This caught the attention of Phil Cartier who took pictures and was featured in Flying Models Combat section some years back. I used the needle valve assemblies from VA engines for this.

The stock TD needle still has a fairly coarse thread which regardless of needle taper is going to offer less than desirable results. While it will work, it's going to be very touchy. To compensate for this, you do one or two things which is raise the nitro or run a smaller prop.

Due to lack of camera currently, I can't post a pic. I make a banjo fitting from wheel collars. Remove the set screw from the wheel collar and drill out the hole to 1/8". Solder in a small 1/2" stub of 1/8" tubing. Press a128 TPI needle valve body out of a postage stamp backplate. Prepare the inside of the wheel collar for solder and clean the spraybar by chucking it up in a drill press using some steel wool. DON"T clean around the hole where the fuel exits as this will keep solder from entering into the hole. Solder the spraybar into the wheel collar aligning the spraybar hole with the copper you soldered into the collar. You just need to fabricate a bracket and you now have a 128 thread remote needle valve which didn't cost $40. I made most of my .25 LA engine needle valves this way. This caught the attention of Phil Cartier who took pictures and was featured in Flying Models Combat section some years back. I used the needle valve assemblies from VA engines for this.

Ken Cook- Top Poster

- Posts : 5573

Join date : 2012-03-27

Location : pennsylvania

Re: Fine thread NV assembly for a TD

Re: Fine thread NV assembly for a TD

Ken, I'm helping a couple of guys on the Stunthgangar video hangout get set up for bladders to fly in the 1/2A Stunt event that Brodak is going to have this June. If you've got a way to post a picture now, I'd love to see it.

I think 1/2A Stunt sounds like loads of fun. I wish I could show up with my new Big Mig powered balsa Hyper Viper. All of my Norvels are retrofitted with fine thread needles from Cox through the venturi.

Thanks,

Rusty

I think 1/2A Stunt sounds like loads of fun. I wish I could show up with my new Big Mig powered balsa Hyper Viper. All of my Norvels are retrofitted with fine thread needles from Cox through the venturi.

Thanks,

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Fine thread NV assembly for a TD

Re: Fine thread NV assembly for a TD

RknRusty wrote:All of my Norvels are retrofitted with fine thread needles from Cox through the venturi.

Thanks,

Rusty

How about pictures and a tutorial. I was thinking about wanting fine needles for my Norvels to run bladder for my Little Legends.

The Student Mark

Never mind, I found it.

The Lazy Mark

batjac- Diamond Member

Posts : 2360

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: Fine thread NV assembly for a TD

Re: Fine thread NV assembly for a TD

Can a fine-thread "Postie" NVA be retrofitted into a Tee Dee or Medallion engine? I ask because I scored a pair of postage-stamp assemblies last year in a consignment-lot at a hobby shop in Sturbridge, (Fiskdale actually) MA. along with a NIP "Kirn-Kraft" fine-thread NVA for Cox Tee Dee .049/.051 engines.

I'm actually assuming that the Kirn-Kraft NVA is a fine-threaded one. After all.. why wouldn't it be? Would Kirn's NVA differ from Kustom Kraftsmanship's (Joe Klauses') offering?

I'm actually assuming that the Kirn-Kraft NVA is a fine-threaded one. After all.. why wouldn't it be? Would Kirn's NVA differ from Kustom Kraftsmanship's (Joe Klauses') offering?

Re: Fine thread NV assembly for a TD

Re: Fine thread NV assembly for a TD

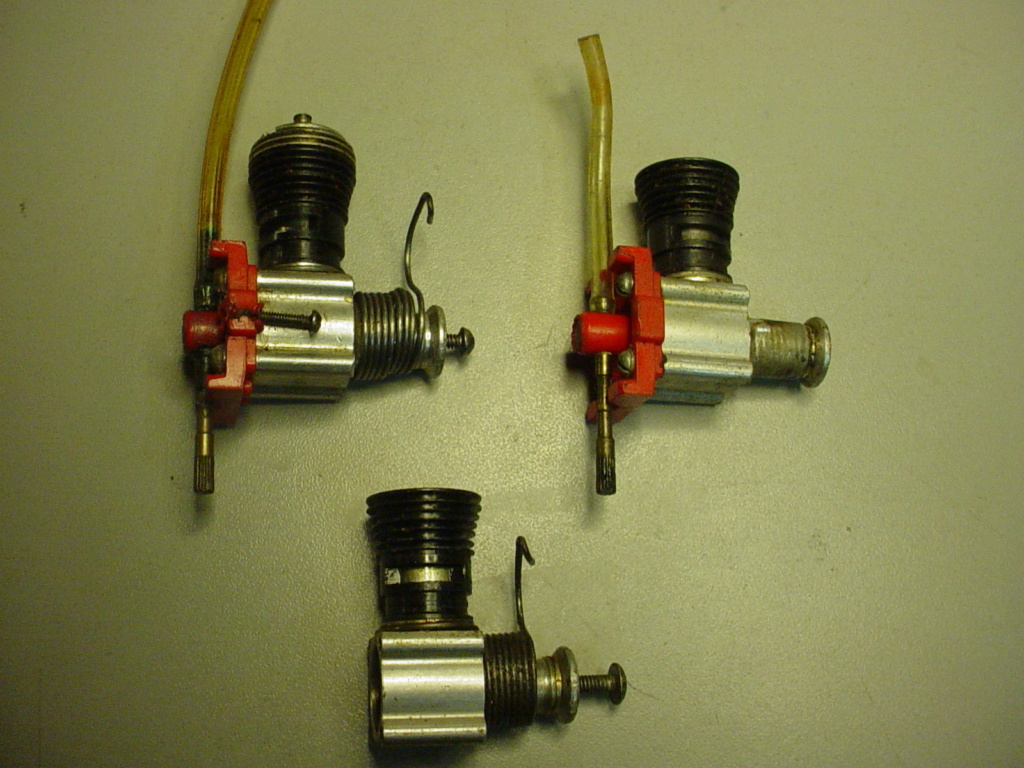

Yes they can be installed and no there's no difference. Here's a way to use your TD assemblies.

This needle valve assembly was made from a VA engine needle assembly, this could be done using a Cox postage stamp spraybar as well. The VA assembly was a through the case assembly with threads on the one side, I used a wheel collar as mentioned above and soldered the spraybar into it. I use these on my .25's but they were originally used on my 1/2A's.

The problem with Norvel cases and similar versions is that they're a bathtub oval. This engine I filled the case with JB weld and drilled it out when dry and tapped it for a Cox TD assembly. I have also used APC broken prop hubs to fill the case, I glue the broken piece into the case and drill and tap it. I have done this to 4 engines. 1/4"-32 tap size for the Cox venturi.

This needle valve assembly was made from a VA engine needle assembly, this could be done using a Cox postage stamp spraybar as well. The VA assembly was a through the case assembly with threads on the one side, I used a wheel collar as mentioned above and soldered the spraybar into it. I use these on my .25's but they were originally used on my 1/2A's.

The problem with Norvel cases and similar versions is that they're a bathtub oval. This engine I filled the case with JB weld and drilled it out when dry and tapped it for a Cox TD assembly. I have also used APC broken prop hubs to fill the case, I glue the broken piece into the case and drill and tap it. I have done this to 4 engines. 1/4"-32 tap size for the Cox venturi.

Ken Cook- Top Poster

- Posts : 5573

Join date : 2012-03-27

Location : pennsylvania

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Fine thread NV assembly for a TD

Re: Fine thread NV assembly for a TD

Ken Cook wrote:

The stock TD needle still has a fairly coarse thread which regardless of needle taper is going to offer less than desirable results.

While it will work, it's going to be very touchy.

My newest TD has a finer thread, and smaller diameter than the #4/40 tpi

in the diagram. Is the newer needle a #2/80 tpi? Is it the same as the needle

valve assembly Ex Engines sells?

Can the newer needle valve assembly still be modified similar the magazine's

instructions?

Bill M.

wmazz- Bronze Member

- Posts : 40

Join date : 2018-12-31

Location : Riverside CA.

Re: Fine thread NV assembly for a TD

Re: Fine thread NV assembly for a TD

Bill, I took one of the new TD needle valve assemblies from EX Models and pressed in a 128 TPI fine needle. Worked the same as my Ace or Texas Timers needle valve assembly.

The Pathfinder Mark

The Pathfinder Mark

batjac- Diamond Member

Posts : 2360

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Michpatriot- Gold Member

- Posts : 157

Join date : 2023-01-12

Re: Fine thread NV assembly for a TD

Re: Fine thread NV assembly for a TD

FYI - there *should* be a fine thread spraybar in the coming months for this, but I need to revamp the tooling a little bit

Re: Fine thread NV assembly for a TD

Re: Fine thread NV assembly for a TD

EXModelEngines wrote:FYI - there *should* be a fine thread spraybar in the coming months for this, but I need to revamp the tooling a little bit

Well that would be great news!!

Michpatriot- Gold Member

- Posts : 157

Join date : 2023-01-12

Similar topics

Similar topics» Older Norvel AME 061 running trouble

» Fine thread NVA for a Norvel

» Fine thread needle valve

» [solved]Sources for fine thread NVA for TD .049

» Cox pee wee fine thread NV and glow heads.

» Fine thread NVA for a Norvel

» Fine thread needle valve

» [solved]Sources for fine thread NVA for TD .049

» Cox pee wee fine thread NV and glow heads.

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules