Log in

Search

Latest topics

» Stealth SB-Xby Admin Yesterday at 8:28 pm

» ST .35 STUNT / VOODOO / ZERO POINT ZERO NITRO

by TD ABUSER Yesterday at 7:45 pm

» SUPERTIGER .15 PROJECT

by TD ABUSER Yesterday at 7:42 pm

» For sale -- Cox Custom Carburetors for Tee Dee engines

by sosam117 Yesterday at 5:23 pm

» WHERE ARE YOU BUYING YOUR FUEL AND GLOW PLUGS...?

by TD ABUSER Yesterday at 4:35 pm

» Waiting for Engines from Ken Enya

by sosam117 Yesterday at 4:33 pm

» Unusual Cox 049 cylinder - Need help identifying

by anm2 Yesterday at 4:12 pm

» Jim Walker Bonanza etc.

by rsv1cox Yesterday at 2:57 pm

» What's the Best Reed for Cox Reed Valve Engines.

by roddie Yesterday at 1:37 pm

» Fuel choice

by 1975 control line guy Fri Aug 30, 2024 4:01 pm

» "Fall S.M.A.L.L." Video 3.

by GallopingGhostler Fri Aug 30, 2024 2:37 pm

» Gifted Fox

by Ken Cook Fri Aug 30, 2024 11:12 am

Cox Engine of The Month

August-2024

balogh's

"Cox TD09 R/C Beast of Burden featuring Kamtechnik head and DIY metallic fuel nipple"

PAST WINNERS

balogh's

"Cox TD09 R/C Beast of Burden featuring Kamtechnik head and DIY metallic fuel nipple"

PAST WINNERS

Piston resetting

Page 1 of 1

Piston resetting

Piston resetting

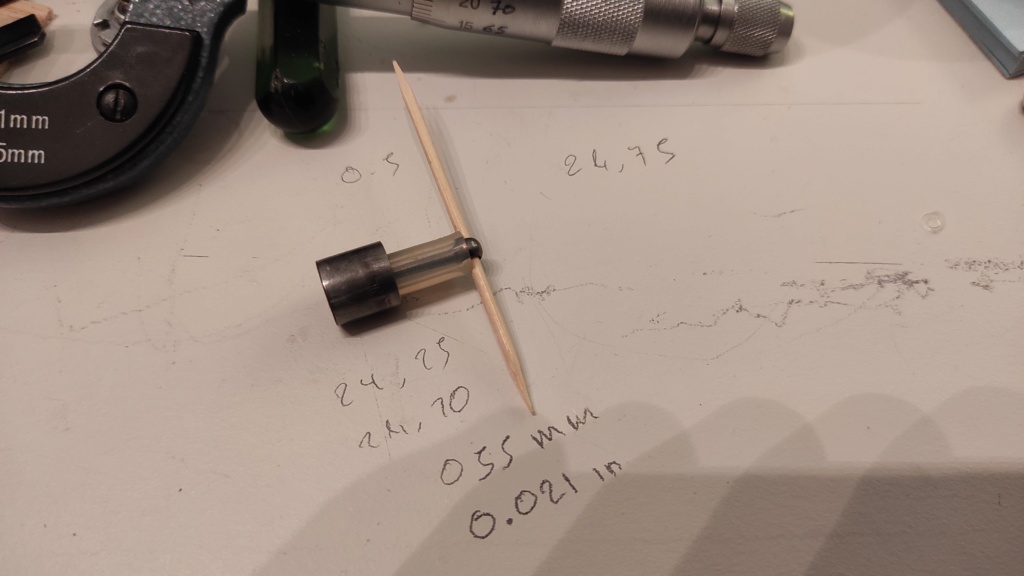

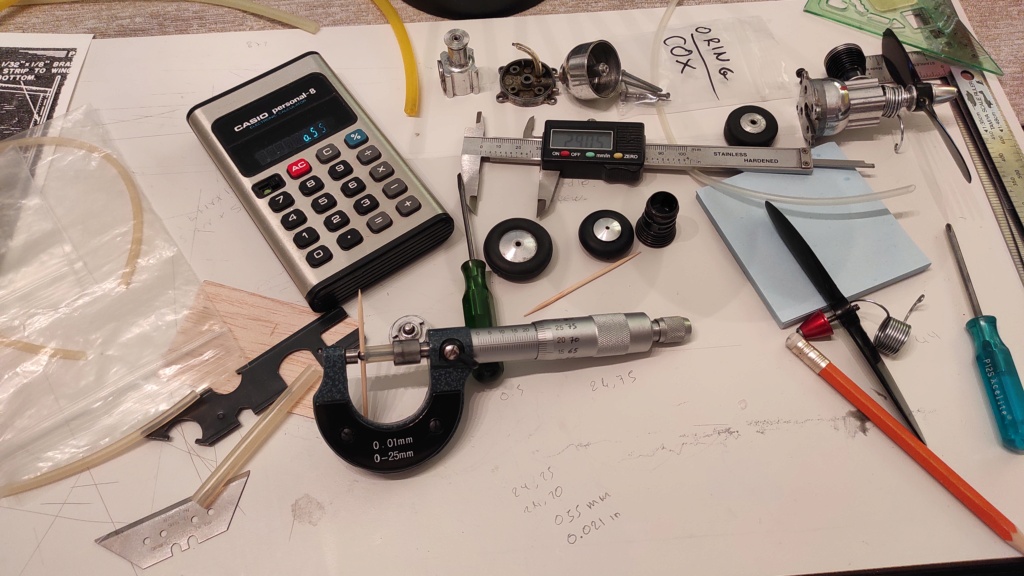

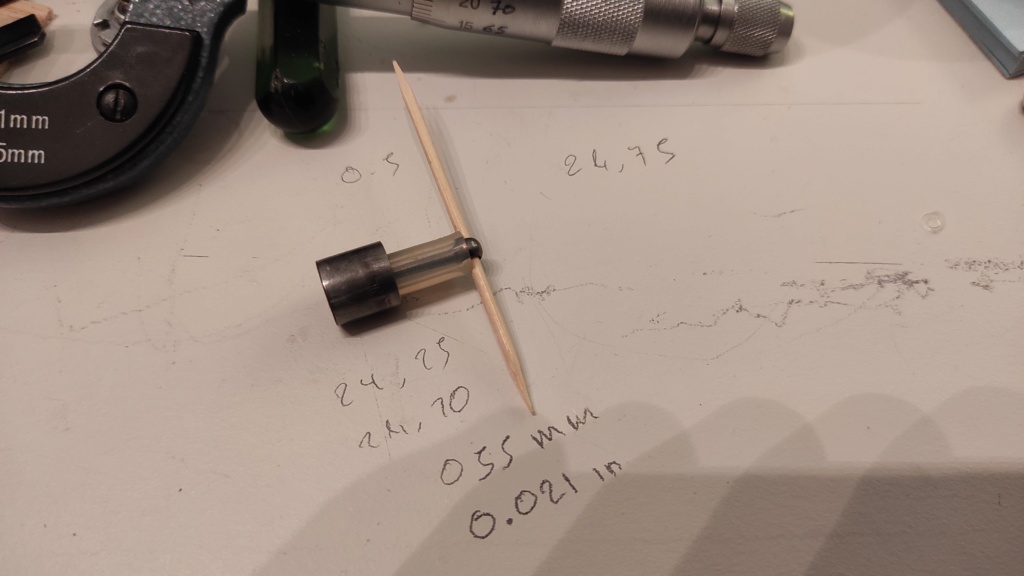

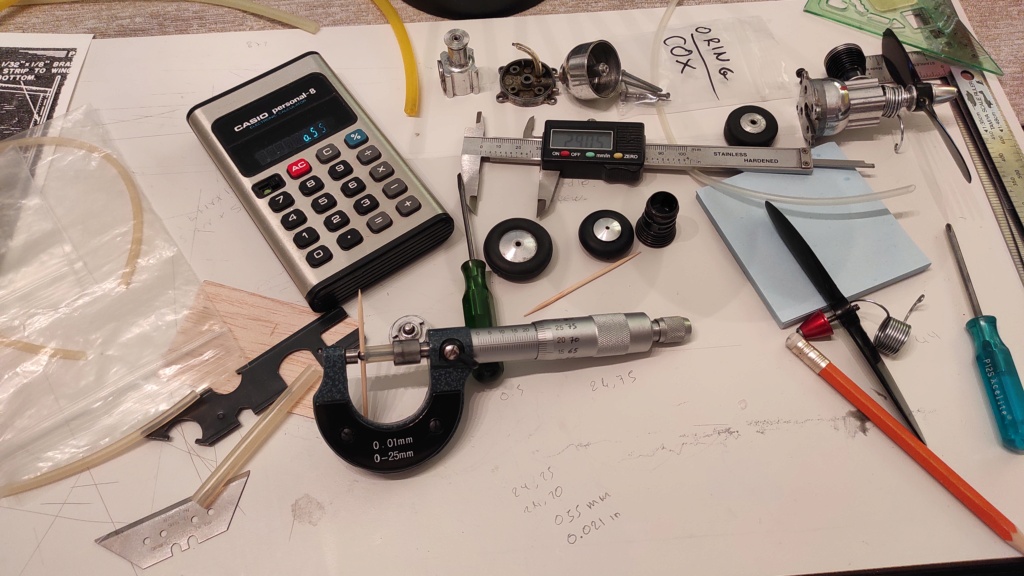

One of my engines has a play and I need to buy a reset tool to make it true again it but I noticed that if you want to speak with numbers it's not very easy to hold this tiny piston and measure it. Things can be very easy with a piece of fuel silicone tube and a toothpic! This way you can keep the Conrod against the piston while at the same time you can compress it with the caliper or with the micrometer. In this case play is 055mm or .021in

Last edited by Gordinir8 on Mon Aug 17, 2020 7:34 am; edited 2 times in total

Gordinir8- Silver Member

- Posts : 70

Join date : 2020-08-05

Age : 49

Re: Piston resetting

Re: Piston resetting

A smart setup! I cannot measure the play though just keep knocking until there remains a hardly tangible one when you pull on the rod. I also spin the rod around to make sure it doesn't stick to the edge of the cup

balogh- Top Poster

Posts : 4852

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Iceberg- Gold Member

- Posts : 382

Join date : 2018-11-03

Location : Suva Fiji Islands

Re: Piston resetting

Re: Piston resetting

.002 is the number that is usually thrown around. Enough for the oil to creep into. To be honest though it isn’t super critical. At least not in my experience. I do resets mostly for longevity and not for performance. I measure play by feel. Some are tight and some are probably just right. After being run they settle out pretty even with each other.

I like the apparatus you made to measure.

I like the apparatus you made to measure.

Cribbs74- Moderator

Posts : 11906

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 71

Location : Grand Rapids, MI

Re: Piston resetting

Re: Piston resetting

By paying subscription I guess but I am not willing to do.

Gordinir8- Silver Member

- Posts : 70

Join date : 2020-08-05

Age : 49

Re: Piston resetting

Re: Piston resetting

Just attach the original image to this forum instead.

Surfer_kris- Diamond Member

- Posts : 1909

Join date : 2010-11-20

Location : Sweden

Re: Piston resetting

Re: Piston resetting

Are you sure? I thought that image has to be host somewhere! Gonna try it thanks.

Gordinir8- Silver Member

- Posts : 70

Join date : 2020-08-05

Age : 49

Re: Piston resetting

Re: Piston resetting

It will technically be hosted on the forum (or another service "servim"?), and everyone will be able to se it here. Just use the "Host"-button with a tiny floppy drive disc on it.

Surfer_kris- Diamond Member

- Posts : 1909

Join date : 2010-11-20

Location : Sweden

Re: Piston resetting

Re: Piston resetting

Hi, I saved your photo and it previews fine for me with Windows Photo Viewer.

I have the Cox .049 reset tool. When I use it, I place the "cup" on a very solid surface. An anvil usually. I like to use a small hammer and tap very lightly on the tool; checking the ball/socket clearance after each tap. Being careful NOT to get heavy-handed; I rotate the tool approx. 120 degrees after each tap.. until the rod will not drop by gravity.. but will move if shaken. If your "setting" feels a little tight.. it might be fine. Some people here have mentioned that they set theirs' on the snug-side.

I'm led to understand that the ball-socket joint need only be reset "once".. as part of a break-in measure. Under normal operation, it shouldn't need resetting again and should hold it's setting due to work-hardening.

Copycat

Copycat

roddie wrote:

Hi, I saved your photo and it previews fine for me with Windows Photo Viewer.

I have the Cox .049 reset tool. When I use it, I place the "cup" on a very solid surface. An anvil usually. I like to use a small hammer and tap very lightly on the tool; checking the ball/socket clearance after each tap. Being careful NOT to get heavy-handed; I rotate the tool approx. 120 degrees after each tap.. until the rod will not drop by gravity.. but will move if shaken. If your "setting" feels a little tight.. it might be fine. Some people here have mentioned that they set theirs' on the snug-side.

I'm led to understand that the ball-socket joint need only be reset "once".. as part of a break-in measure. Under normal operation, it shouldn't need resetting again and should hold it's setting due to work-hardening.

roddie: That is exactly how I do my piston resetting. Always being sure to rotate the tool, and light to medium hits with a ball peen hammer. Anyone remember those?? My dad used those when putting rivets into sheet metal. WW2. He was a single parent before he met my mom.

Happydad

happydad- Rest In Peace

- Posts : 1592

Join date : 2012-05-28

Age : 79

Location : Escondido, CA

Re: Piston resetting

Re: Piston resetting

Thanks for info, this is what I have in mind also. Tool is on its way.

Gordinir8- Silver Member

- Posts : 70

Join date : 2020-08-05

Age : 49

gasface- Moderate Poster

- Posts : 12

Join date : 2020-08-10

Location : NV

Tee Bee- Platinum Member

- Posts : 763

Join date : 2011-08-25

Location : Angleton, TX

Iceberg- Gold Member

- Posts : 382

Join date : 2018-11-03

Location : Suva Fiji Islands

Re: Piston resetting

Re: Piston resetting

Nice looking tool , cool you can just make up one like that , see you have a piston with the oiler hole in the rod boss 3 piece .

getback- Top Poster

Posts : 10326

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Piston resetting

Re: Piston resetting

I've found (based on others) that a smooth hard surface (glass) makes an idea anvil, also lots of light taps. set socket to rotate freely, but no real play. I'd also give it a drop of car oil prior to assembly, once its running the gap will open a little.

Re: Piston resetting

Re: Piston resetting

Cribbs74 wrote:.002 is the number that is usually thrown around. Enough for the oil to creep into. To be honest though it isn’t super critical. At least not in my experience. I do resets mostly for longevity and not for performance. I measure play by feel. Some are tight and some are probably just right. After being run they settle out pretty even with each other.

I like the apparatus you made to measure.

yep, about the only time it becomes an issue is high RPM and/or tight piston fit.

Similar topics

Similar topics» What causes a piston head to mushroom when you reset the piston rod?

» Cox TeeDee .09 piston resetting tool

» Resetting Queen Bee piston?

» Cox Piston/Rod Ball Socket Resetting

» Wanted: Cox .15 piston, or piston/cylinder - FOUND!

» Cox TeeDee .09 piston resetting tool

» Resetting Queen Bee piston?

» Cox Piston/Rod Ball Socket Resetting

» Wanted: Cox .15 piston, or piston/cylinder - FOUND!

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules