Log in

Search

Latest topics

» Older ignition booksby lla Today at 4:17 pm

» Fox .35 Modifications

by Onelife Today at 3:54 pm

» Jim Walkers FireBee - This is going to be fun

by rsv1cox Today at 3:33 pm

» *Cox Engine of The Month* Submit your pictures! -May 2024-

by getback Today at 10:23 am

» S1 Ringmaster

by Onelife Today at 8:40 am

» Speed plane - Crispy but not too crispy

by rsv1cox Today at 7:54 am

» O&R 23 & Brown Jr

by getback Today at 7:47 am

» Introducing our Cox .049 TD Engines

by MauricioB Today at 2:31 am

» Jim Walker Firebaby

by rdw777 Yesterday at 4:16 pm

» Hemostat clamp/smooth-jaws

by roddie Yesterday at 3:48 pm

» Black Widow Run time

by Ken Cook Yesterday at 3:44 pm

» 1:64 scale Diecast (Hot Wheels)

by roddie Yesterday at 3:33 pm

Cox Engine of The Month

Got this great Enya .06-II Series #1 from Ebay -- So I thought?

Page 1 of 1

Got this great Enya .06-II Series #1 from Ebay -- So I thought?

Got this great Enya .06-II Series #1 from Ebay -- So I thought?

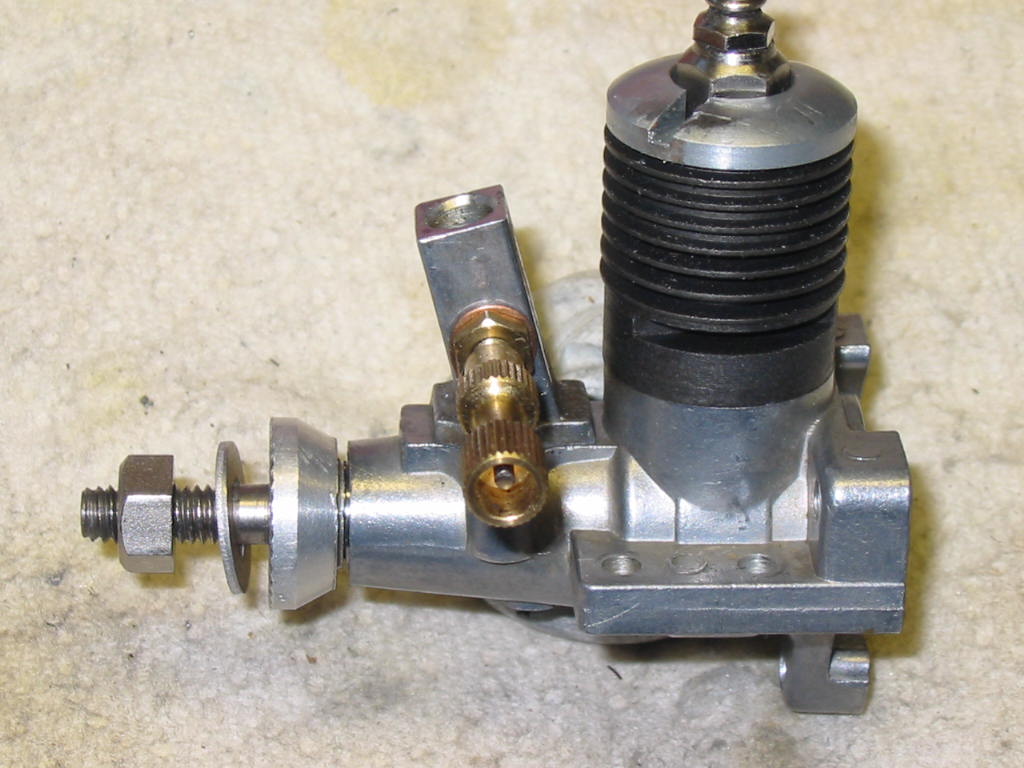

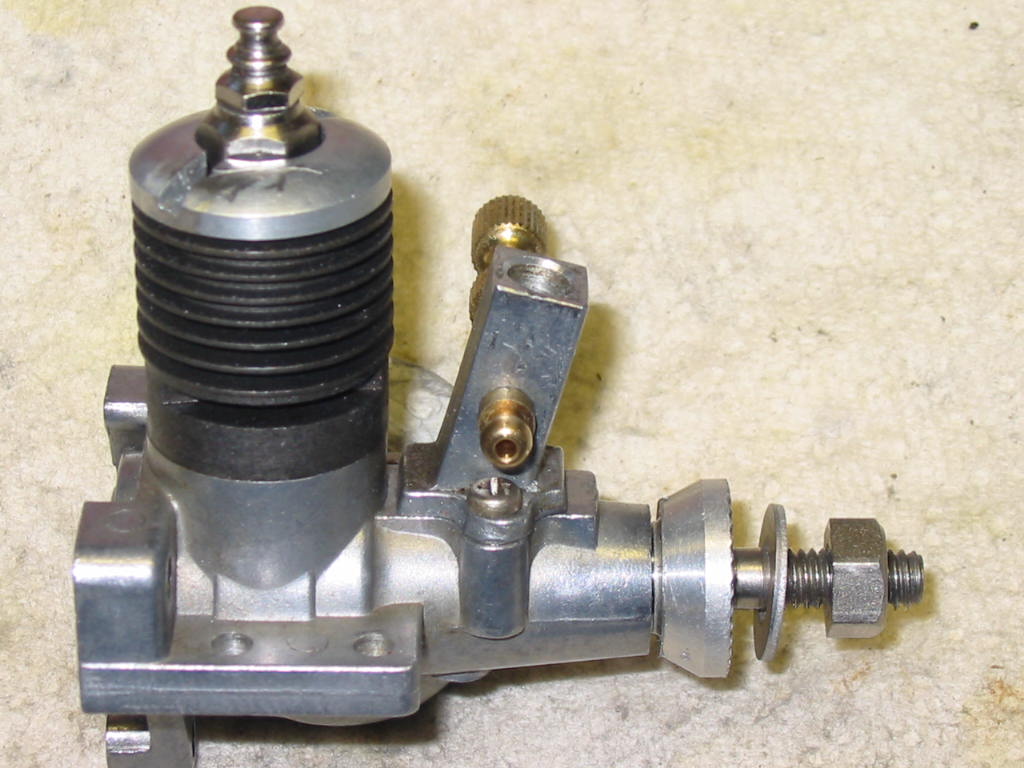

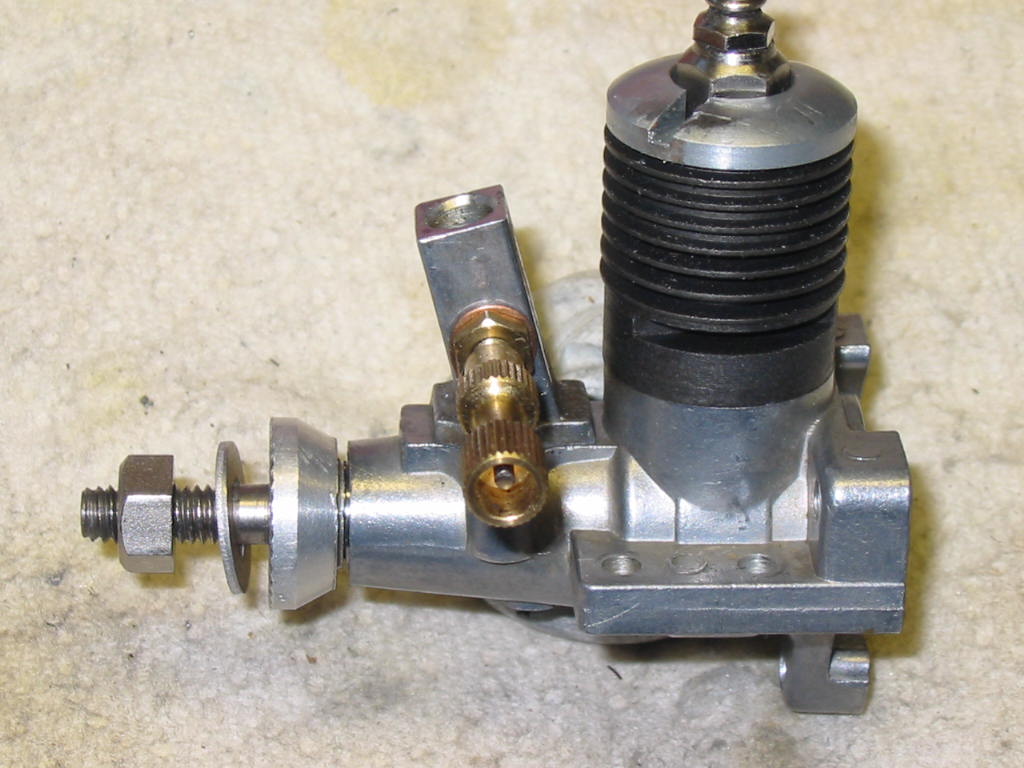

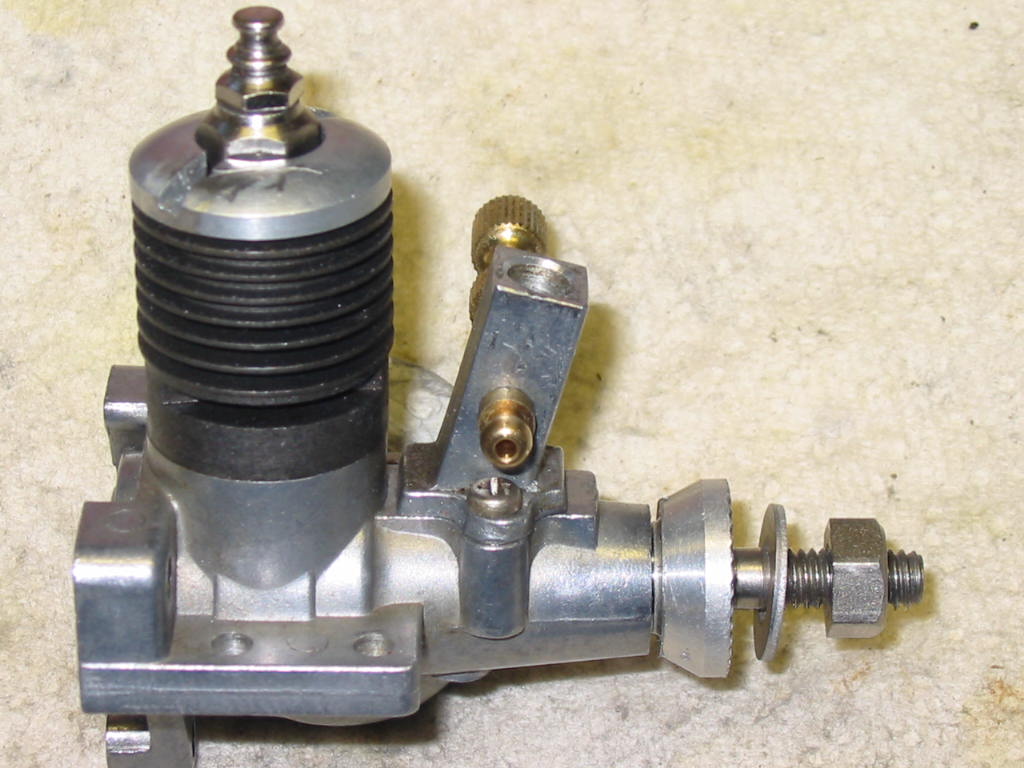

Well, I was the winning bid on this nice-looking Enya .06-II Series #1 (FreeFlight/U-control) engine.

It had no box, instructions, just the engine.

Seller said it looked like little use, crank turn freely and in the photo looked clean (maybe the seller cleaned it up?).

Well, here is the photo of the engine:

Well, when I got it, I started to look it over carefully.

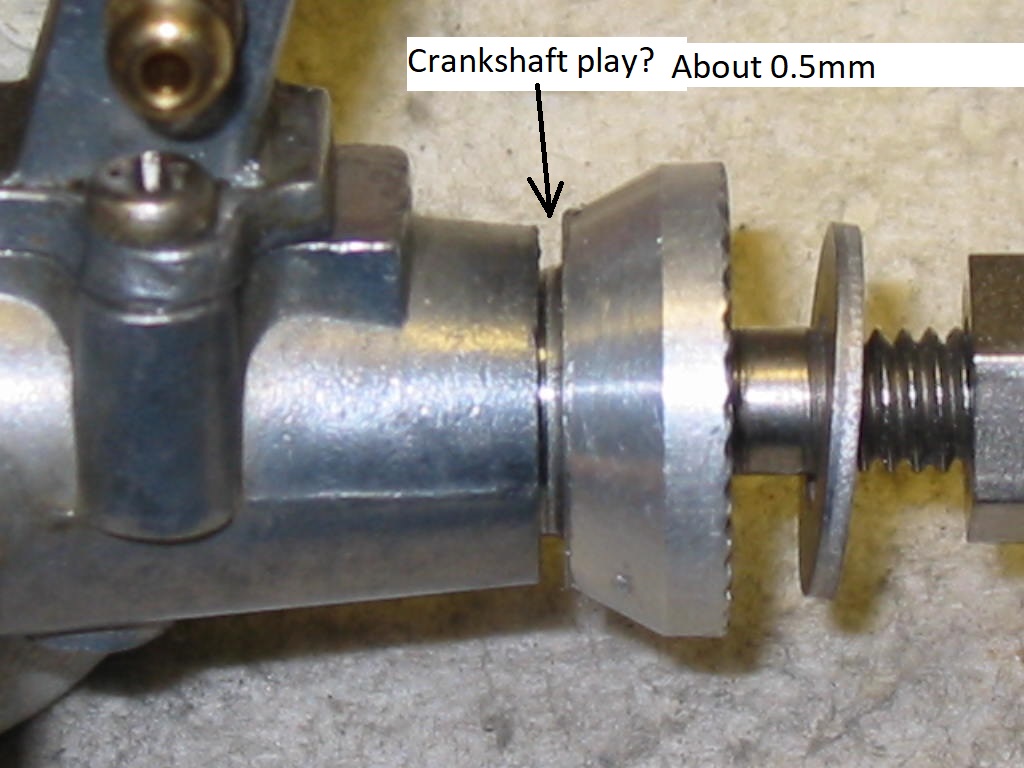

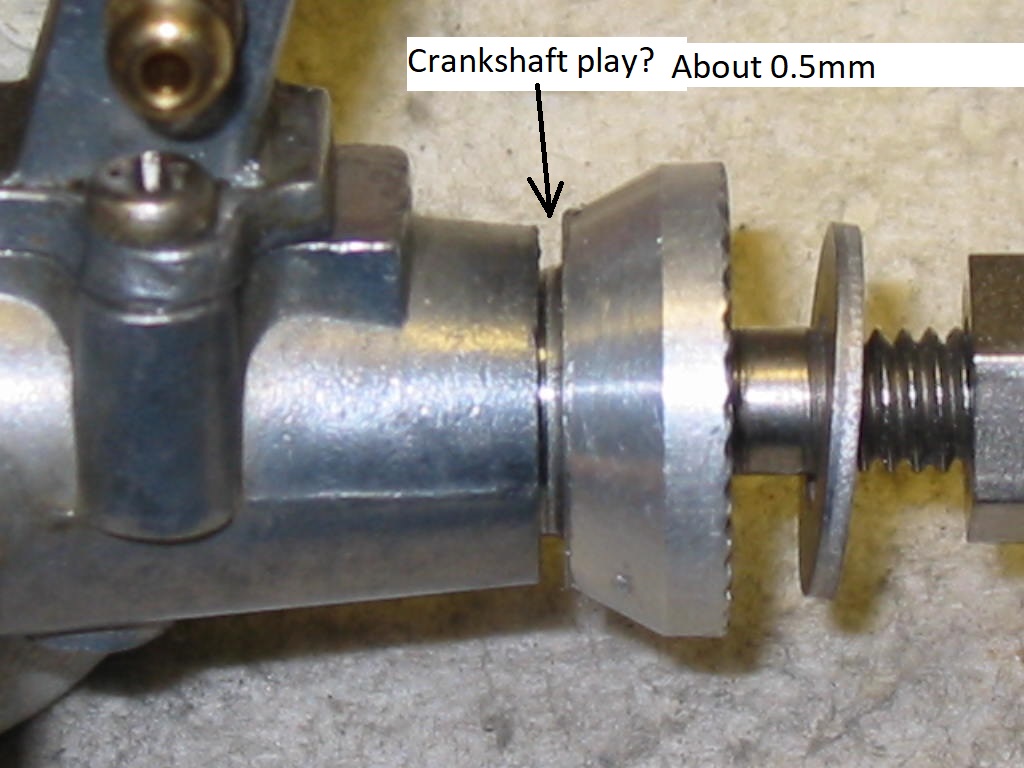

I noticed that the crank felt rough when I turned it and there seemed to be a lot of play on the crank in the crankcase?

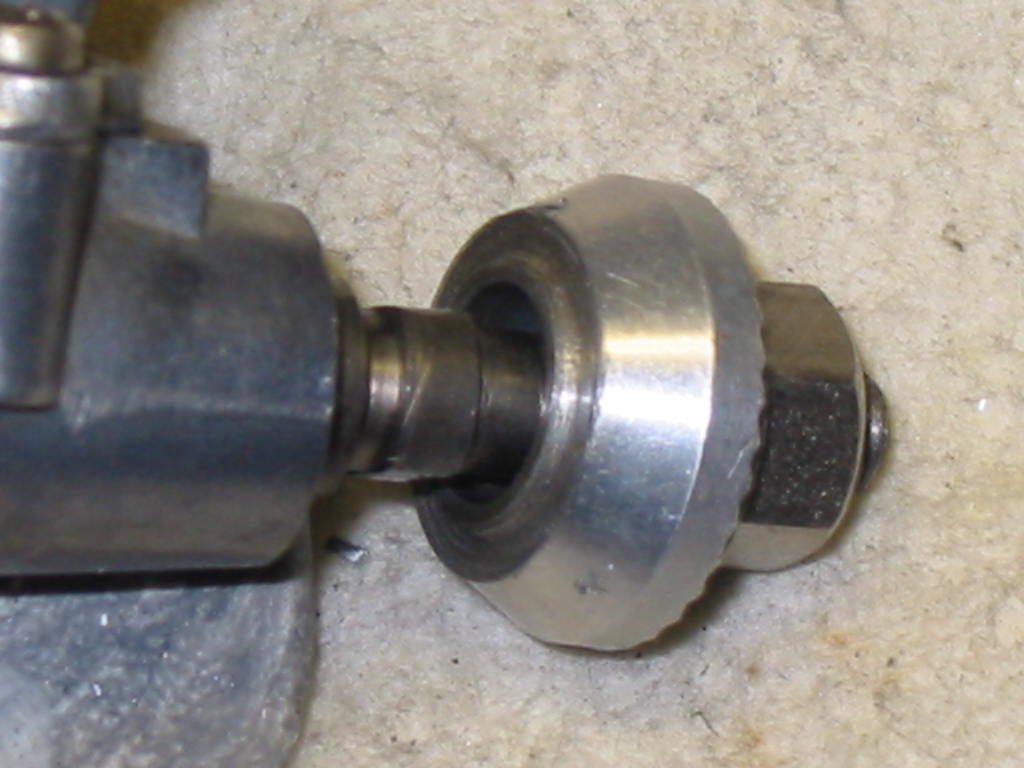

See the photo below:

I also noticed there was no thrust washer between the crank case and the prop drive washer?

So, I decided to take the engine apart and see what is going on?

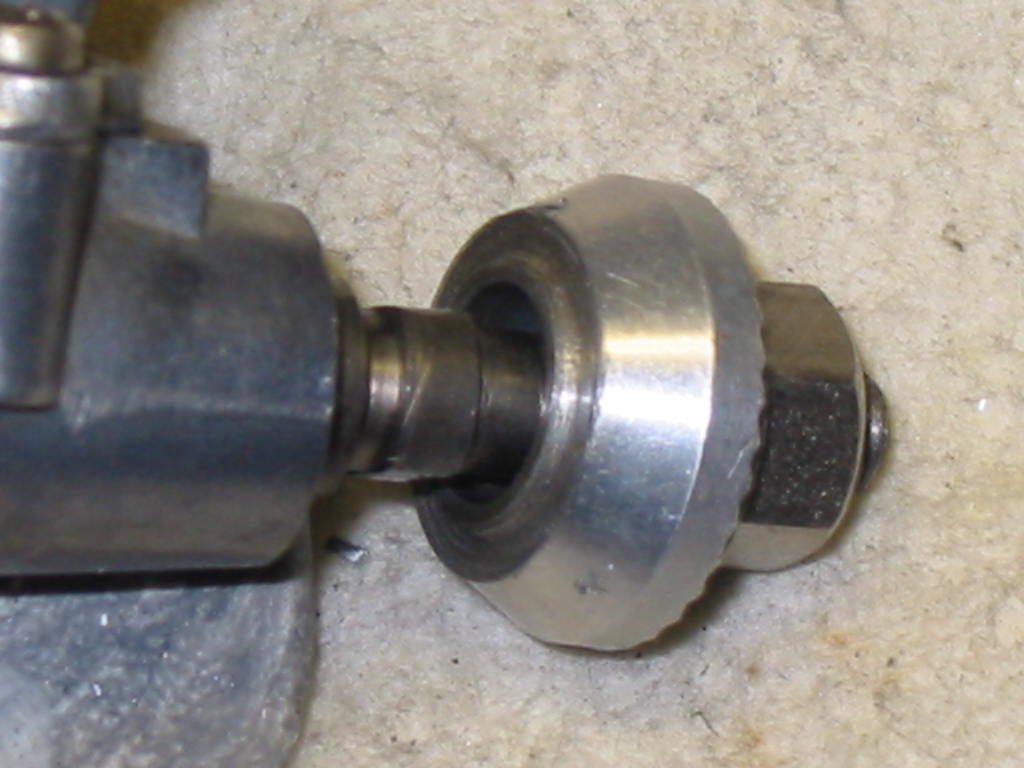

The prop drive washer came off easily the front of the engine and what I found was:

No thrust washer which caused the prop drive washer to wear down from the front the crankcase.

The wear on the prop drive washer is 0.6mm (see the photos below)

Overall length of the prop drive washer is 6.13mm

Front face of prop drive washer to wear area is 5.54mm

(6.13mm - 5.54mm = 0.59mm)

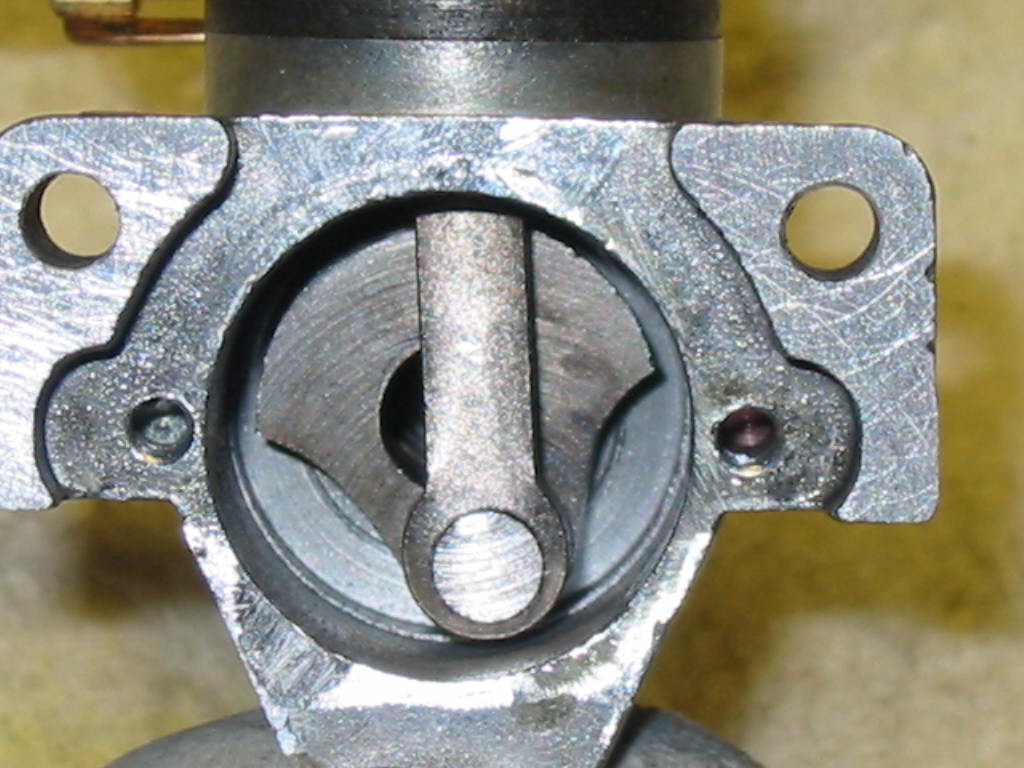

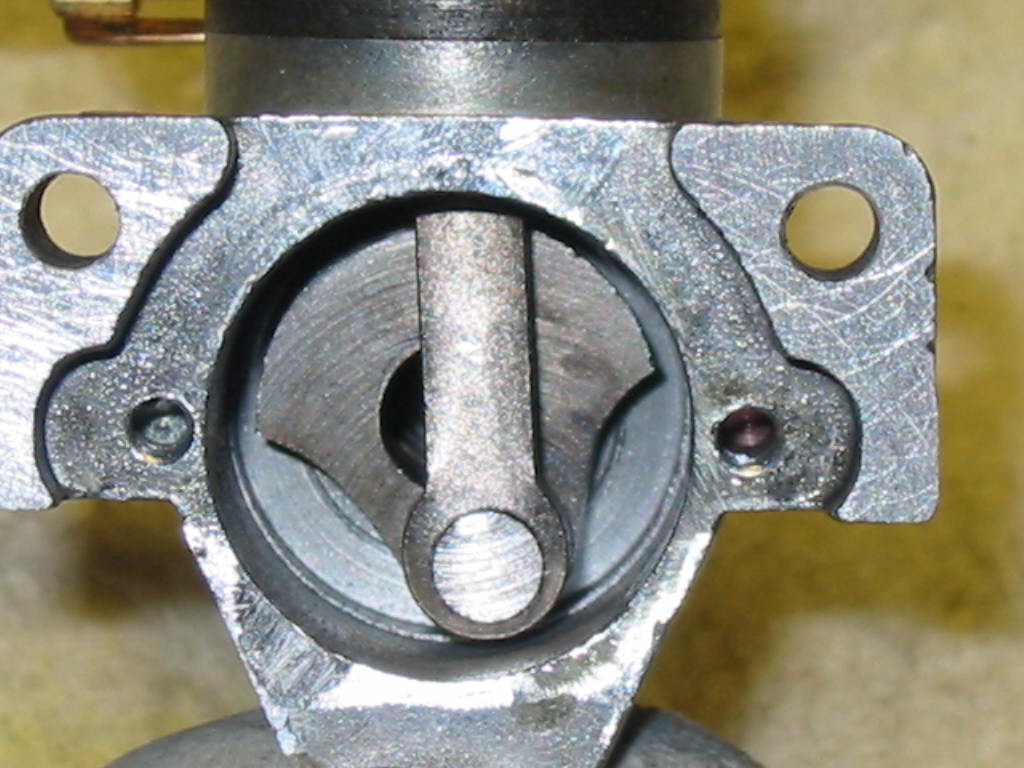

I then decided to see what the back plate looked like.

WOW! I've never seen a back plate that gouged out?

So, I measured the depth of the gouge in the back plate to see if it was te same as the prop drive washer?

Here is what I got:

It came to almost the same as the prop drive washer. (0.62mm)

Luck would have it that the end of the crank shaft and the connecting rod was not damaged.

I tore the entire engine down and checked everything over for damage.

Everything was o.k. but the 4-part piston was stuck and not free to turn so that was disassembled and cleaned before putting it back together.

Luck would have it that I had spare parts to replace the prop drive washer

And a replacement back plate --- on hand

Last thing to do is make my own thrust washer.

I tried to order (get) them from Ken Enya but he has none available.

I make my thrust washer from 0.6mm (.025) copper sheet that I have.

I have a punch set (English and metric) to make my thrust washer with.

So, the engine was not as much of a deal as it 1st was.

Prop drive washer for $3.75

Back plate for $4.50

Gaskets -- carb ($1.95) and back plate ($1.95)

Handmade thrust washer (copper) couple of pennies?

And that big cost ----- LABOR (love of rebuilding a nice engine like this?)

The engine now looks like the photos at the top without the excessive play on the crankshaft.

It had no box, instructions, just the engine.

Seller said it looked like little use, crank turn freely and in the photo looked clean (maybe the seller cleaned it up?).

Well, here is the photo of the engine:

Well, when I got it, I started to look it over carefully.

I noticed that the crank felt rough when I turned it and there seemed to be a lot of play on the crank in the crankcase?

See the photo below:

I also noticed there was no thrust washer between the crank case and the prop drive washer?

So, I decided to take the engine apart and see what is going on?

The prop drive washer came off easily the front of the engine and what I found was:

No thrust washer which caused the prop drive washer to wear down from the front the crankcase.

The wear on the prop drive washer is 0.6mm (see the photos below)

Overall length of the prop drive washer is 6.13mm

Front face of prop drive washer to wear area is 5.54mm

(6.13mm - 5.54mm = 0.59mm)

I then decided to see what the back plate looked like.

WOW! I've never seen a back plate that gouged out?

So, I measured the depth of the gouge in the back plate to see if it was te same as the prop drive washer?

Here is what I got:

It came to almost the same as the prop drive washer. (0.62mm)

Luck would have it that the end of the crank shaft and the connecting rod was not damaged.

I tore the entire engine down and checked everything over for damage.

Everything was o.k. but the 4-part piston was stuck and not free to turn so that was disassembled and cleaned before putting it back together.

Luck would have it that I had spare parts to replace the prop drive washer

And a replacement back plate --- on hand

Last thing to do is make my own thrust washer.

I tried to order (get) them from Ken Enya but he has none available.

I make my thrust washer from 0.6mm (.025) copper sheet that I have.

I have a punch set (English and metric) to make my thrust washer with.

So, the engine was not as much of a deal as it 1st was.

Prop drive washer for $3.75

Back plate for $4.50

Gaskets -- carb ($1.95) and back plate ($1.95)

Handmade thrust washer (copper) couple of pennies?

And that big cost ----- LABOR (love of rebuilding a nice engine like this?)

The engine now looks like the photos at the top without the excessive play on the crankshaft.

sosam117- Diamond Member

- Posts : 1290

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Got this great Enya .06-II Series #1 from Ebay -- So I thought?

Re: Got this great Enya .06-II Series #1 from Ebay -- So I thought?

Man what a mess , good thing you had most the parts and no how to repair it . Good Job !!

getback- Top Poster

Posts : 10127

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: Got this great Enya .06-II Series #1 from Ebay -- So I thought?

Re: Got this great Enya .06-II Series #1 from Ebay -- So I thought?

Previous owner must have used it as a pusher.

706jim- Gold Member

- Posts : 460

Join date : 2013-11-29

Re: Got this great Enya .06-II Series #1 from Ebay -- So I thought?

Re: Got this great Enya .06-II Series #1 from Ebay -- So I thought?

706jim wrote:Previous owner must have used it as a pusher.

Or he liked to use a starter on it?

I have never had one of mine start or run backwards?

sosam117- Diamond Member

- Posts : 1290

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Got this great Enya .06-II Series #1 from Ebay -- So I thought?

Re: Got this great Enya .06-II Series #1 from Ebay -- So I thought?

There are reverse pitch props that could be used to make a pusher. That would seem like a lot of wear from just a starter.

706jim- Gold Member

- Posts : 460

Join date : 2013-11-29

Re: Got this great Enya .06-II Series #1 from Ebay -- So I thought?

Re: Got this great Enya .06-II Series #1 from Ebay -- So I thought?

Good job Mike. Best part of the hobby bringing back to life a quality engine. Gives ya a good feeling.

rsv1cox- Top Poster

Posts : 10575

Join date : 2014-08-18

Location : West Virginia

Re: Got this great Enya .06-II Series #1 from Ebay -- So I thought?

Re: Got this great Enya .06-II Series #1 from Ebay -- So I thought?

That is very fine restoration work on that historic Enya .06, sosam117. I am glad that you were able to save it. My guess is probably heavy handed use from an engine starter without the thrust washer spacer in place. It doesn't take much for the hard steel piston pin to gouge the much softer aluminum backplate. Perhaps it may be also worth it to polish the crank pin end and gently chamfer the pin edges with a file to break the sharp edges?

Those half-A Enyas are classic, and from what I understand, decent performers as well.

Those half-A Enyas are classic, and from what I understand, decent performers as well.

GallopingGhostler- Top Poster

Posts : 5314

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Got this great Enya .06-II Series #1 from Ebay -- So I thought?

Re: Got this great Enya .06-II Series #1 from Ebay -- So I thought?

GallopingGhostler wrote:That is very fine restoration work on that historic Enya .06, sosam117. I am glad that you were able to save it. My guess is probably heavy handed use from an engine starter without the thrust washer spacer in place. It doesn't take much for the hard steel piston pin to gouge the much softer aluminum backplate. Perhaps it may be also worth it to polish the crank pin end and gently chamfer the pin edges with a file to break the sharp edges?

Those half-A Enyas are classic, and from what I understand, decent performers as well.

Yes, I cleaned up the crank pin compared to how Enya just cuts it to length.

With Enya it looks like they used a chop saw and it looks about right length look.

I grind the crank pin so it is radius on the end.

Then on the other end, I use copper shims to reduce the play on the crankshaft and install a thrust washer behind the prop washer (driver) so this problem doesn't happen again.

The thrust washer is the same phenolic washer used on the Cox engines. I modify them to fit the Enya engines crankshafts.

One thing I have noticed is on these little Enya engines, sometimes there is a thrust washer there and other times there isn't one?

I have asked Ken Enya about it and he told me that there should be one there?

So, I asked Ken Enya for the part number and tried to order them and Ken looked informed me that there is none "in stock" and probably will not have any more.

So, I stuck making my own.

sosam117- Diamond Member

- Posts : 1290

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Got this great Enya .06-II Series #1 from Ebay -- So I thought?

Re: Got this great Enya .06-II Series #1 from Ebay -- So I thought?

Those type parts shortage problems that will continue to be out-of-stock such as Ken Enya told you, are expected. This is because nowadays, a hardware manufacturer is going to want a minimum starting quantity of say, 500, 1000, etc. for a custom part. The Enya .06-II is a historic engine, and there is a very low demand for such parts as phenolic or stainless steel thrust washers, once the factory stock is used up.

At times, Bernie of Cox International Canada has expressed this minimum order problem he has faced with his custom newly manufactured Cox parts. Some parts just don't have the demand to order from a machinist or manufacturer. He would never be able to sell all. Besides, unsold stock is money tied up, that doesn't get reimbursed until a sale is made. So, the trick for an engine parts supplier is to have enough on-hand so they have them sold in time to make a profit.

This is why I gather, that for the avid engine collector, some have bought their own lathes, presses and milling machines, so they can manufacture parts. A few here have made limited runs of special parts, like Tee Dee / Medallion backplate mounts, special reed valve engine housings, venturis, etc.

Names now fail me, but several years back before Covid, I bought several of these backplate mounts for my .020 TD, .049 Medallion and .09 Medallion from an ad here in CEF.

At times, Bernie of Cox International Canada has expressed this minimum order problem he has faced with his custom newly manufactured Cox parts. Some parts just don't have the demand to order from a machinist or manufacturer. He would never be able to sell all. Besides, unsold stock is money tied up, that doesn't get reimbursed until a sale is made. So, the trick for an engine parts supplier is to have enough on-hand so they have them sold in time to make a profit.

This is why I gather, that for the avid engine collector, some have bought their own lathes, presses and milling machines, so they can manufacture parts. A few here have made limited runs of special parts, like Tee Dee / Medallion backplate mounts, special reed valve engine housings, venturis, etc.

Names now fail me, but several years back before Covid, I bought several of these backplate mounts for my .020 TD, .049 Medallion and .09 Medallion from an ad here in CEF.

GallopingGhostler- Top Poster

Posts : 5314

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Similar topics

Similar topics» New in Box Enya .10 Series #4 engines

» Enya .049 glow engine

» Blue printing an Enya engine (this happens to be an .049-II Series #4)

» Special tuned Enya .049-II Series-4 engine

» Saw this Enya engine on Ebay?

» Enya .049 glow engine

» Blue printing an Enya engine (this happens to be an .049-II Series #4)

» Special tuned Enya .049-II Series-4 engine

» Saw this Enya engine on Ebay?

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules