Log in

Search

Latest topics

» Irvine Mills .75 replicaby ffkiwi Today at 4:43 am

» COX .020 RC PROJECT

by 1/2A Nut Today at 4:32 am

» **VOTE-ON-THE-NEXT-COX-ENGINE-OF-THE-MONTH** (October 2024)

by Admin Today at 1:33 am

» Happy Birthday Robert ( Rsv1cox )

by balogh Today at 1:06 am

» Carburetor Sprinkler Rod Peak Tee Dee .049 / .051

by MauricioB Yesterday at 11:02 pm

» OS MAX-D

by Ken Cook Yesterday at 3:38 pm

» The Cabin.........A carpenters nightmare.

by getback Yesterday at 3:22 pm

» Cox .020 PeeWee/TeeDee prop-screw

by getback Yesterday at 7:55 am

» Wanted peewee 20 fuel tank

by GallopingGhostler Yesterday at 2:05 am

» Fox .35 Modifications

by Ken Cook Fri Oct 04, 2024 7:40 pm

» *Cox Engine of The Month* Submit your pictures! -October 2024-

by Admin Fri Oct 04, 2024 7:33 pm

» Off topic - Tonka dump truck restoration. 10:27

by rsv1cox Fri Oct 04, 2024 6:32 pm

Cox Engine of The Month

Cox .049 boat cooling upgrades

Page 1 of 1

Cox .049 boat cooling upgrades

Cox .049 boat cooling upgrades

Here's something I've wanted to do for a while. It's difficult to find a Good cooling jacket for the .049 cox engine So I made my own prototype I decided to make a two in one more complex construction but certainly more efficient That everything that already exists Equipped with an integrated exhaust manifold. The cylinder jacket is directly cooled by the water which is in direct contact with the cylinder. The part is machined so that cooling is carried out in dual air and water cooling purposes. The exhaust manifold compartment is sealed by the first small cooling fins in the water compartment, the water circulates directly around the cylinder.This compartment is sealed by the top fins which are the largest so I had to perfectly machine the space between the two so that once fixed in place the two compartments are well sealed. I also slightly modified the cylinder I cut the last top cooling fins to use a tool to screw the cylinder Also remove a small section of cooling fin

I'm planning to build a small boat I found it on amazon A really affordable little kit a little hidroplane called the Shrimp Which seems to be a good model for a cox conversion

I'm planning to build a small boat I found it on amazon A really affordable little kit a little hidroplane called the Shrimp Which seems to be a good model for a cox conversion

davidll1984- Diamond Member

- Posts : 2318

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Cox .049 boat cooling upgrades

Re: Cox .049 boat cooling upgrades

were did you get that

I kind of want one!!!!

I kind of want one!!!!

robot797- Platinum Member

- Posts : 780

Join date : 2013-07-28

Age : 34

Re: Cox .049 boat cooling upgrades

Re: Cox .049 boat cooling upgrades

..Well This is a one-off model but I may be planning to build others but if I want to sell it without the modified cylinder I will have to modify the plans of the part To use a normal cylinder. ultimately I wanted to make completely modified engines and sell them at a reasonable price depending on the crankcase engine comborobot797 wrote:were did you get that

I kind of want one!!!!

What do you think would be a reasonable price just for a cylinder piston combo with the custom liner?

What do you think would be a reasonable price just for a cylinder piston combo with the custom liner?

davidll1984- Diamond Member

- Posts : 2318

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Cox .049 boat cooling upgrades

Re: Cox .049 boat cooling upgrades

to be honnest I dont know

robot797- Platinum Member

- Posts : 780

Join date : 2013-07-28

Age : 34

Re: Cox .049 boat cooling upgrades

Re: Cox .049 boat cooling upgrades

As you already know for this to work we must have a dragonfly.. qrc ..or cars cylinder or any other n1 cylinder without SPI To make it work well with the exhaust manifold and Not losse power The necessary parts are harder to find but the fact remains that with the right components it is possible to sell the jacket I don't want to have any customer complaints This is why I had considered building like new models that had already been assembled and Ready for use

davidll1984- Diamond Member

- Posts : 2318

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Cox .049 boat cooling upgrades

Re: Cox .049 boat cooling upgrades

in that case let me know when you are done

I will get one

I will get one

robot797- Platinum Member

- Posts : 780

Join date : 2013-07-28

Age : 34

Re: Cox .049 boat cooling upgrades

Re: Cox .049 boat cooling upgrades

Your water jacket looks real good David! Very interesting that you were able to also encompass the exhaust management in the design. Options are good!

Re: Cox .049 boat cooling upgrades

Re: Cox .049 boat cooling upgrades

davidll1984 wrote:..Well This is a one-off model but I may be planning to build others but if I want to sell it without the modified cylinder I will have to modify the plans of the part To use a normal cylinder. ultimately I wanted to make completely modified engines and sell them at a reasonable price depending on the crankcase engine comborobot797 wrote:were did you get that

I kind of want one!!!!What do you think would be a reasonable price just for a cylinder piston combo with the custom liner?

I would assume that you'd keep the cylinder with the jacket for which it was machined.. right?

Re: Cox .049 boat cooling upgrades

Re: Cox .049 boat cooling upgrades

roddie wrote:davidll1984 wrote:..Well This is a one-off model but I may be planning to build others but if I want to sell it without the modified cylinder I will have to modify the plans of the part To use a normal cylinder. ultimately I wanted to make completely modified engines and sell them at a reasonable price depending on the crankcase engine comborobot797 wrote:were did you get that

I kind of want one!!!!What do you think would be a reasonable price just for a cylinder piston combo with the custom liner?

I would assume that you'd keep the cylinder with the jacket for which it was machined.. right?

Yes the cylinder is specially modified for the jacket But I will adjust the plans and try to build a model that would accommodate a normal cylinder but this involves more work and additional detail the piece will be slightly wider . I had modified the cylinder for reasons of simplicity but I believe that it is not necessary the reason for modifying the cylinder is to avoid having to make a passage for the water on my initial model the water circulates between the walls of the cylinder and the heatsink:o

Taking the example of the unmodified cylinder, I removed a section of cooling fin to create a sufficient passage for water otherwise I had to cut a narrow passage in the part So that the water circulates properly Cooling fins can cause sludge buildup Mud and small debris can get stuck and block water circulation Also modifying the cylinder provides a better contact surface for a Good seal We don't want water in the hull of the boat or in the exhaust manifold compartment. This piece is the result of a long reflection I thought carefully about Small details such as the decision to add cooling fins on the part make the construction more complex but improve heat dissipation

davidll1984- Diamond Member

- Posts : 2318

Join date : 2020-02-12

Age : 39

Location : shawinigan

davidll1984- Diamond Member

- Posts : 2318

Join date : 2020-02-12

Age : 39

Location : shawinigan

Seal questions

Seal questions

Hi, David,

This looks brilliant!

Is it a metal to metal seal between the aluminum collar and the steel piston? Or do you have an "O-Ring Groove" inside the collar to make up the differential between the expansion of the steel cylinder and aluminum collar? Is it a super tight fit where you have to chill the cylinder to slide it into the collar? I'm thinking similar to axle and pinion bearings, etc. Or am I waaaay off base?

On full size boat engines we have a water cooled exhaust as well as the engine, itself. The cooling water is injected after a "riser" , which is just a tall loop at the end of the exhaust manifold to keep from sucking water back into the engine. The exhaust manifold has its own water jacket, similar to yours, but dedicated to the exhaust manifold and block. The water in it goes through a separate heat exchanger with antifreeze/ coolant cooled by the raw seawater. I had freshwater engines in my old Chris Crafts, that bypassed having a heat exchanger and just pumped raw water through the engine/manifold and then out the exhaust.. 4 inch (100mm) copper tubes that never got over 160-180° f... we have to gasket or O-Ring every joint because there are so many different metals, hoses and plastics used. Yours looks more elegant than the big Red Beast in my Engineroom!

CT

This looks brilliant!

Is it a metal to metal seal between the aluminum collar and the steel piston? Or do you have an "O-Ring Groove" inside the collar to make up the differential between the expansion of the steel cylinder and aluminum collar? Is it a super tight fit where you have to chill the cylinder to slide it into the collar? I'm thinking similar to axle and pinion bearings, etc. Or am I waaaay off base?

On full size boat engines we have a water cooled exhaust as well as the engine, itself. The cooling water is injected after a "riser" , which is just a tall loop at the end of the exhaust manifold to keep from sucking water back into the engine. The exhaust manifold has its own water jacket, similar to yours, but dedicated to the exhaust manifold and block. The water in it goes through a separate heat exchanger with antifreeze/ coolant cooled by the raw seawater. I had freshwater engines in my old Chris Crafts, that bypassed having a heat exchanger and just pumped raw water through the engine/manifold and then out the exhaust.. 4 inch (100mm) copper tubes that never got over 160-180° f... we have to gasket or O-Ring every joint because there are so many different metals, hoses and plastics used. Yours looks more elegant than the big Red Beast in my Engineroom!

CT

Boats13- Gold Member

Posts : 117

Join date : 2018-01-28

Location : Kemah

Re: Cox .049 boat cooling upgrades

Re: Cox .049 boat cooling upgrades

No I don't use an O-ring but a high temperature sealant It's a simple but effective solution But ultimately it is the two surfaces which are in contact when the cylinder is screwed in place the pressure forms the seal between the surfaces the high temp sealant is for exactly what you described the contraction of meta vs aluminum is différent But yes with the right oring I would be able to use one on the space between the two remaining cooling fins. Of the cylinder but but I don't think it's necessary To ad oring sealBoats13 wrote:Hi, David,

This looks brilliant!

Is it a metal to metal seal between the aluminum collar and the steel piston? Or do you have an "O-Ring Groove" inside the collar to make up the differential between the expansion of the steel cylinder and aluminum collar? Is it a super tight fit where you have to chill the cylinder to slide it into the collar? I'm thinking similar to axle and pinion bearings, etc. Or am I waaaay off base?

On full size boat engines we have a water cooled exhaust as well as the engine, itself. The cooling water is injected after a "riser" , which is just a tall loop at the end of the exhaust manifold to keep from sucking water back into the engine. The exhaust manifold has its own water jacket, similar to yours, but dedicated to the exhaust manifold and block. The water in it goes through a separate heat exchanger with antifreeze/ coolant cooled by the raw seawater. I had freshwater engines in my old Chris Crafts, that bypassed having a heat exchanger and just pumped raw water through the engine/manifold and then out the exhaust.. 4 inch (100mm) copper tubes that never got over 160-180° f... we have to gasket or O-Ring every joint because there are so many different metals, hoses and plastics used. Yours looks more elegant than the big Red Beast in my Engineroom!

CT

davidll1984- Diamond Member

- Posts : 2318

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Cox .049 boat cooling upgrades

Re: Cox .049 boat cooling upgrades

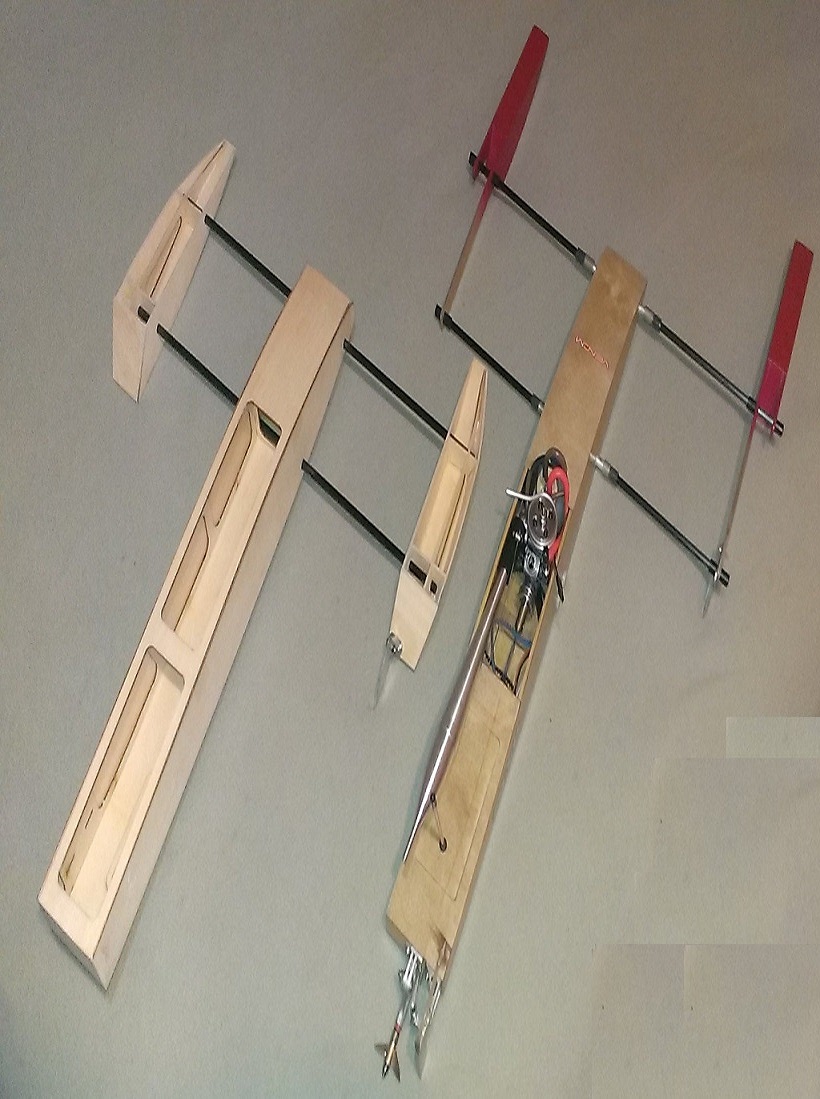

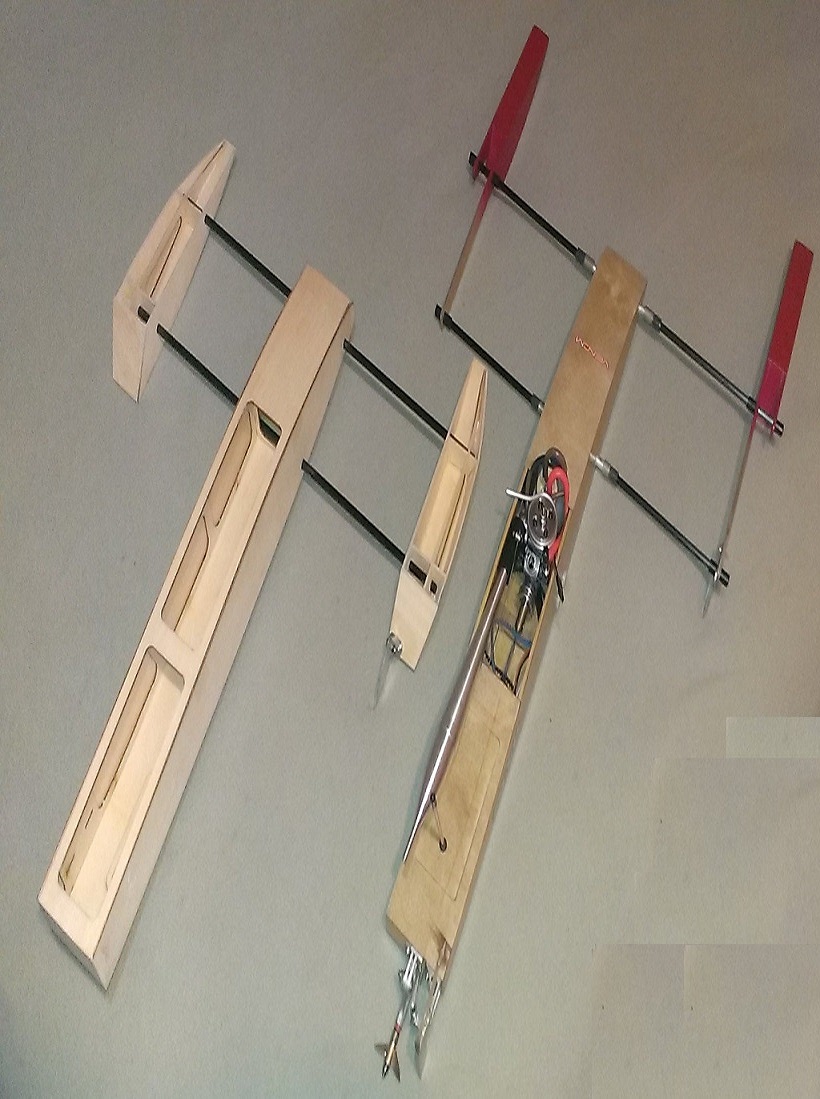

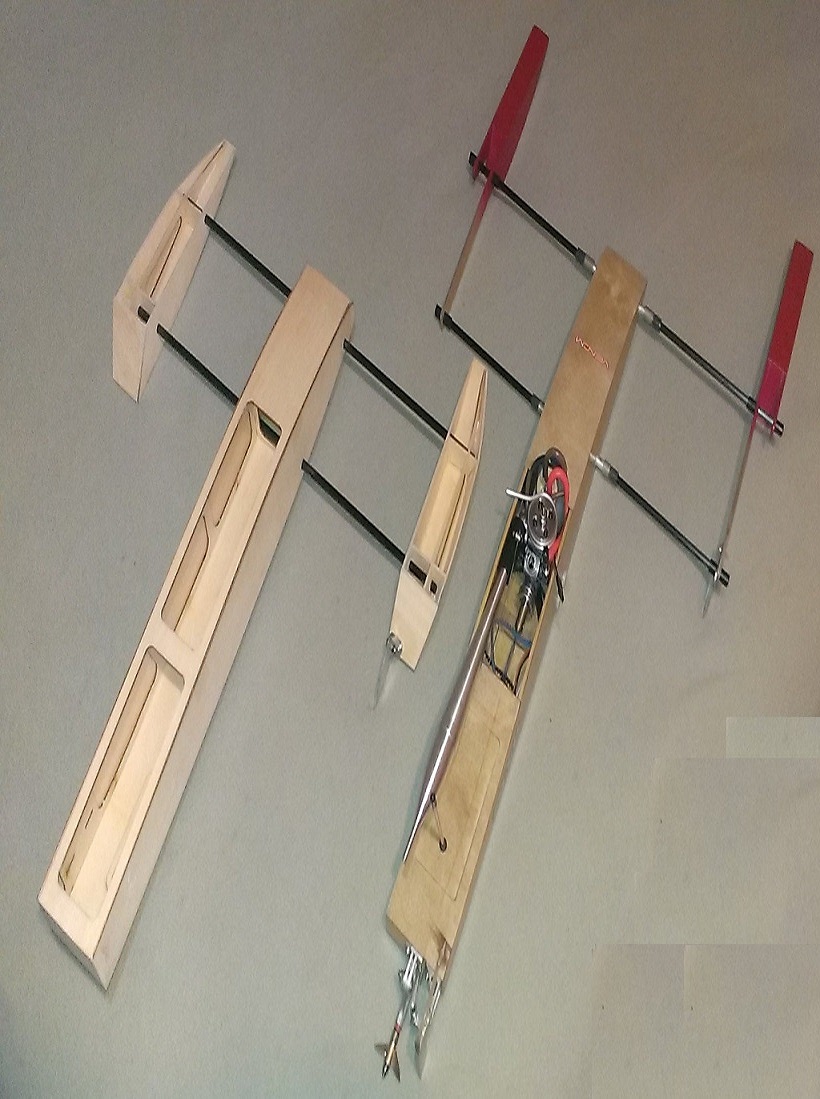

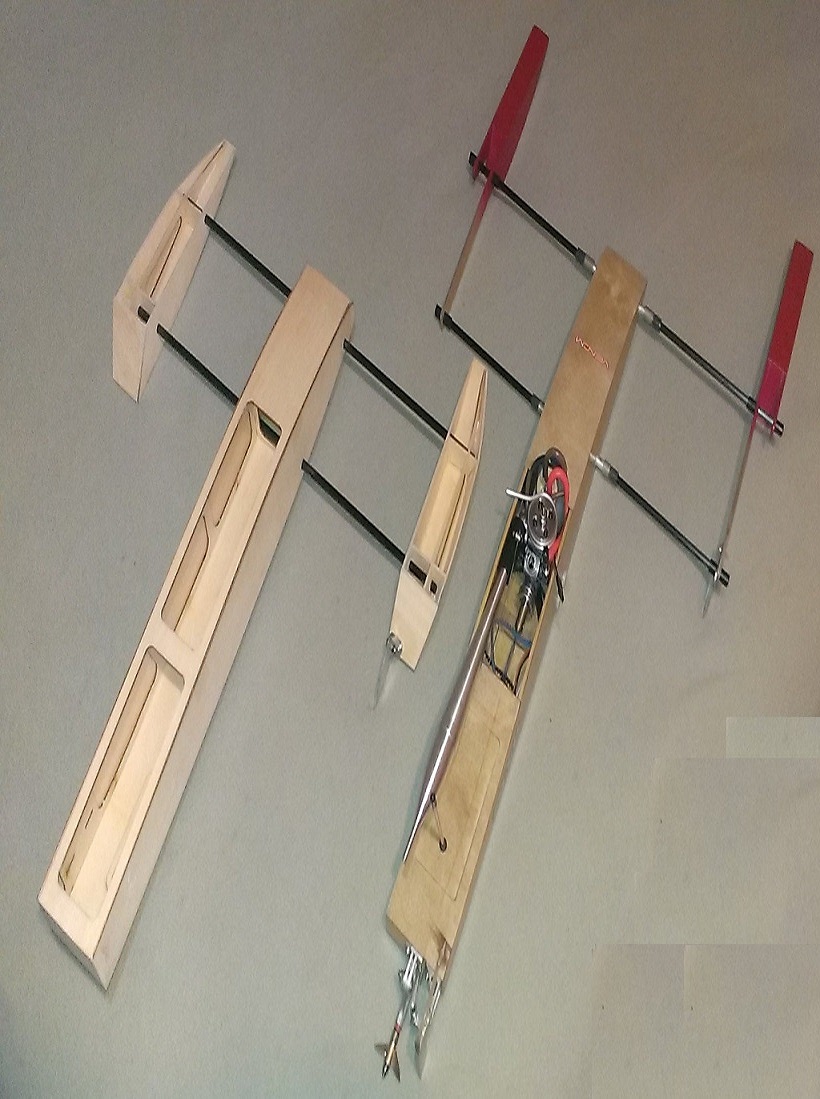

"I'm planning to build a small boat I found it on amazon. A really affordable little kit,

a little hydroplane called the Shrimp Which seems to be a good model for a cox conversion"

Very nice David, certainly will cool the engine.

Can use an elevated water source and capture to bench the cooling function.

Yours has an integrated manifold and header, great approach!

Look forward to your running vids.

The .049 will labor, but can lift the boat on plane given the use of low weight RC gear and purpose made 1/2A hardware.

Nelson plug adapter / turbo prop adapter and your water cooling jacket should make for some power.

TD rigger using a surface prop, low weight hardware and thin low drag rudder will help tip the scales as

the Shrimp boat is oversized and heavy for Cox power 1/2A .8cc use.

Example prop thoughts:

If a Dumas .049 white nylon 1" submerged prop is used expect making 17 to 21 mph with the Shrimp boat.

Should be good fun to run. With a modified Octura surface prop up to 28 mph is possible.

I have built the Shrimp boat with the AP .09 using a tuned pipe:

43 mph with a piped Picco P-Zero .85cc size comparison great fun in calm water / twice the power of a TD .049

You can see in the above photos one would need a purpose designed rigger for the TD engine to perform well.

- for max speed squeeze down the widths of the designs above, keep it long and lanky for speed and control.

65% width as an example:

a little hydroplane called the Shrimp Which seems to be a good model for a cox conversion"

Very nice David, certainly will cool the engine.

Can use an elevated water source and capture to bench the cooling function.

Yours has an integrated manifold and header, great approach!

Look forward to your running vids.

The .049 will labor, but can lift the boat on plane given the use of low weight RC gear and purpose made 1/2A hardware.

Nelson plug adapter / turbo prop adapter and your water cooling jacket should make for some power.

TD rigger using a surface prop, low weight hardware and thin low drag rudder will help tip the scales as

the Shrimp boat is oversized and heavy for Cox power 1/2A .8cc use.

Example prop thoughts:

If a Dumas .049 white nylon 1" submerged prop is used expect making 17 to 21 mph with the Shrimp boat.

Should be good fun to run. With a modified Octura surface prop up to 28 mph is possible.

I have built the Shrimp boat with the AP .09 using a tuned pipe:

43 mph with a piped Picco P-Zero .85cc size comparison great fun in calm water / twice the power of a TD .049

You can see in the above photos one would need a purpose designed rigger for the TD engine to perform well.

- for max speed squeeze down the widths of the designs above, keep it long and lanky for speed and control.

65% width as an example:

Last edited by 1/2A Nut on Sat Mar 16, 2024 1:40 am; edited 2 times in total

1/2A Nut- Top Poster

- Posts : 3471

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

My wife is gonna kill me...

My wife is gonna kill me...

Oh, like I really NEED another obsession... thanks! You're not near Kemah, TX are you? I really like to see and hear one in action!

CT

CT

Boats13- Gold Member

Posts : 117

Join date : 2018-01-28

Location : Kemah

Re: Cox .049 boat cooling upgrades

Re: Cox .049 boat cooling upgrades

Negative near 5hrs out, here is a peek of the 1/2A rigger fun.

The engine has benched up to 208w per prop calc.

The engine has benched up to 208w per prop calc.

1/2A Nut- Top Poster

- Posts : 3471

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .049 boat cooling upgrades

Re: Cox .049 boat cooling upgrades

I've seen so many people disregard the method you used for compression release. They don't understand how important that is when using a starter be it mechanical or electric. It's a simple thing to loosen the plug and tighten when running

Ken Cook- Top Poster

- Posts : 5609

Join date : 2012-03-27

Location : pennsylvania

Re: Cox .049 boat cooling upgrades

Re: Cox .049 boat cooling upgrades

Very nice David, certainly will cool the engine.

Can use an elevated water source and capture to bench the cooling function.

Yours has an integrated manifold and header, great approach!

Look forward to your running vids.

The .049 will labor, but can lift the boat on plane given the use of low weight RC gear and purpose made 1/2A hardware.

Nelson plug adapter / turbo prop adapter and your water cooling jacket should make for some power.

TD rigger using a surface prop, low weight hardware and thin low drag rudder will help tip the scales as

the Shrimp boat is oversized and heavy for Cox power 1/2A .8cc use.

Example prop thoughts:

If a Dumas .049 white nylon 1" submerged prop is used expect making 17 to 21 mph with the Shrimp boat.

Should be good fun to run. With a modified Octura surface prop up to 28 mph is possible.

I have built the Shrimp boat with the AP .09 using a tuned pipe:

43 mph with a piped Picco P-Zero .85cc size comparison great fun in calm water / twice the power of a TD .049

You can see in the above photos one would need a purpose designed rigger for the TD engine to perform well.

- for max speed squeeze down the widths of the designs above, keep it long and lanky for speed and control.

65% width as an example:

[/quote] I see in the photos that you built a second one that you seem to have remodeled a little smaler ! ? I would like to put all the luck on my side and correct what needs to be changed on the model But I'm not looking to build a racing model, just one that works and can hydroplane. I don't have much experience with this type of boat so any trick or advice would be valuable. I'm afraid that the model is too big and too heavy for a .049 I could use a .051 for more performance in the worst case I have a .09rc tee dee I noticed that the motor is not centered and the stufing tube is off center Can anyone tell me why??

[/quote] I see in the photos that you built a second one that you seem to have remodeled a little smaler ! ? I would like to put all the luck on my side and correct what needs to be changed on the model But I'm not looking to build a racing model, just one that works and can hydroplane. I don't have much experience with this type of boat so any trick or advice would be valuable. I'm afraid that the model is too big and too heavy for a .049 I could use a .051 for more performance in the worst case I have a .09rc tee dee I noticed that the motor is not centered and the stufing tube is off center Can anyone tell me why??

davidll1984- Diamond Member

- Posts : 2318

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Cox .049 boat cooling upgrades

Re: Cox .049 boat cooling upgrades

I really enjoy watching you run that skimmer ,you got a build thread somewhere on here don't know if its the same boat but an outrigger . Nice looking cooler /muffler you got there David

getback- Top Poster

Posts : 10381

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Cox .049 boat cooling upgrades

Re: Cox .049 boat cooling upgrades

65% width as an example:

[/quote]

[/quote]I see in the photos that you built a second one that you seem to have remodeled a little smaler ! ? I would like to put all the luck on my side and correct what needs to be changed on the model But I'm not looking to build a racing model, just one that works and can hydroplane. I don't have much experience with this type of boat so any trick or advice would be valuable. I'm afraid that the model is too big and too heavy for a .049 I could use a .051 for more performance in the worst case I have a .09rc tee dee I noticed that the motor is not centered and the stufing tube is off center Can anyone tell me why??

[/quote]

[/quote]David,

I believe it is for torque pushing the port side down less.

CT

Boats13- Gold Member

Posts : 117

Join date : 2018-01-28

Location : Kemah

Re: Cox .049 boat cooling upgrades

Re: Cox .049 boat cooling upgrades

I can't wait to receive it and see the plans, I have the impression that I saw a guy who built the kit wrong wit stufing tube place on the wrong side with the engine support plate At first it seems to me to be for the clearance between the propeller and the rudder but now I was wondering if I modify the hull to be narrower !...? woul it be better to center or keep a little of center ??  The guy in the video had placed the of center opposite to the ruder For more clearance and being able to use the largest prop possible ? I have some notion of aerodynamics but with water it's different And I wonder about several little things At least the kit has a good hardware kit of good parts to start a first test surely I will have to adapt parts for the cox engine I already have the flywheel and now cooling upgrades

The guy in the video had placed the of center opposite to the ruder For more clearance and being able to use the largest prop possible ? I have some notion of aerodynamics but with water it's different And I wonder about several little things At least the kit has a good hardware kit of good parts to start a first test surely I will have to adapt parts for the cox engine I already have the flywheel and now cooling upgrades

The guy in the video had placed the of center opposite to the ruder For more clearance and being able to use the largest prop possible ? I have some notion of aerodynamics but with water it's different And I wonder about several little things At least the kit has a good hardware kit of good parts to start a first test surely I will have to adapt parts for the cox engine I already have the flywheel and now cooling upgrades

The guy in the video had placed the of center opposite to the ruder For more clearance and being able to use the largest prop possible ? I have some notion of aerodynamics but with water it's different And I wonder about several little things At least the kit has a good hardware kit of good parts to start a first test surely I will have to adapt parts for the cox engine I already have the flywheel and now cooling upgrades

davidll1984- Diamond Member

- Posts : 2318

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Cox .049 boat cooling upgrades

Re: Cox .049 boat cooling upgrades

For surface drive prop systems -

Prop torque tends to push the left sponson down and swings the back end to the right.

The offset helps it track straighter, called prop walking. Using the rudder to correct this

scrubs off speed which is not ideal.

Yes long and lean for just the width of a TD engine will help put as much power towards

better performance but also to not wear out the ball socket of the engine with a heavy

draggy boat. Can push a draggy boat if you use the right prop and so prop is key.

Surface drive or submerged dependent on what you have to use.

Prop torque tends to push the left sponson down and swings the back end to the right.

The offset helps it track straighter, called prop walking. Using the rudder to correct this

scrubs off speed which is not ideal.

Yes long and lean for just the width of a TD engine will help put as much power towards

better performance but also to not wear out the ball socket of the engine with a heavy

draggy boat. Can push a draggy boat if you use the right prop and so prop is key.

Surface drive or submerged dependent on what you have to use.

1/2A Nut- Top Poster

- Posts : 3471

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .049 boat cooling upgrades

Re: Cox .049 boat cooling upgrades

Thank you very much for the information, it's been a long time since I saw your hydroplane and I always wanted to build one. I have already try built home made one but without success, to tell the truth, I never finished due to lack of time but also good parts, maybe the boat would make a good boat for the .049 As it is but no a model built with foam would not be strong and durable enough so I never finished it Another thing that slowed me down was not having the cooling jacket !I didn't want to damage an engine just for this But a few months ago I found a lot of Engine and I found some Cox engine and misc stuf landing gear fuel tank And that lots gave me a cylinder no. 1 without SPI !!!1/2A Nut wrote:For surface drive prop systems -

Prop torque tends to push the left sponson down and swings the back end to the right.

The offset helps it track straighter, called prop walking. Using the rudder to correct this

scrubs off speed which is not ideal.

Yes long and lean for just the width of a TD engine will help put as much power towards

better performance but also to not wear out the ball socket of the engine with a heavy

draggy boat. Can push a draggy boat if you use the right prop and so prop is key.

Surface drive or submerged dependent on what you have to use.

??? I have some propellers but plastic and would like to find a better one in aluminum I wonder what would be ideal for a .049 engine?? As I said I want to put all the luck on my side so that this succeeds and also any information, relevant or not, is welcome.

??? I have some propellers but plastic and would like to find a better one in aluminum I wonder what would be ideal for a .049 engine?? As I said I want to put all the luck on my side so that this succeeds and also any information, relevant or not, is welcome.

davidll1984- Diamond Member

- Posts : 2318

Join date : 2020-02-12

Age : 39

Location : shawinigan

Similar topics

Similar topics» RJ.bee rc cars build tee dee powered

» new 2.0 rc 1/16 049 powered bugy upgrade tee dee

» cox rc cars gtp 049 mod

» Making a water-cooling coil for a Cox .049 engine

» 049 water cooling ring

» new 2.0 rc 1/16 049 powered bugy upgrade tee dee

» cox rc cars gtp 049 mod

» Making a water-cooling coil for a Cox .049 engine

» 049 water cooling ring

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules