Log in

Search

Latest topics

» Stealth SB-Xby Admin Today at 8:28 pm

» ST .35 STUNT / VOODOO / ZERO POINT ZERO NITRO

by TD ABUSER Today at 7:45 pm

» SUPERTIGER .15 PROJECT

by TD ABUSER Today at 7:42 pm

» For sale -- Cox Custom Carburetors for Tee Dee engines

by sosam117 Today at 5:23 pm

» WHERE ARE YOU BUYING YOUR FUEL AND GLOW PLUGS...?

by TD ABUSER Today at 4:35 pm

» Waiting for Engines from Ken Enya

by sosam117 Today at 4:33 pm

» Unusual Cox 049 cylinder - Need help identifying

by anm2 Today at 4:12 pm

» Jim Walker Bonanza etc.

by rsv1cox Today at 2:57 pm

» What's the Best Reed for Cox Reed Valve Engines.

by roddie Today at 1:37 pm

» Fuel choice

by 1975 control line guy Yesterday at 4:01 pm

» "Fall S.M.A.L.L." Video 3.

by GallopingGhostler Yesterday at 2:37 pm

» Gifted Fox

by Ken Cook Yesterday at 11:12 am

Cox Engine of The Month

August-2024

balogh's

"Cox TD09 R/C Beast of Burden featuring Kamtechnik head and DIY metallic fuel nipple"

PAST WINNERS

balogh's

"Cox TD09 R/C Beast of Burden featuring Kamtechnik head and DIY metallic fuel nipple"

PAST WINNERS

Wen Mac .049 - Conditioning.

Page 3 of 3

Page 3 of 3 •  1, 2, 3

1, 2, 3

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

Juan, you have done a very good job!, very neat!

Thanks for your contribution.

I think the Wen Mac .049 is already at its right point, but you invite me to think.....and maybe I round the original venturi, killing the edge it has, surely something will help, I also plan to place the pressure peak in the butt, so I continue investigating and having fun.

The Wen Mac has an incredible nostalgic charm, it must be because of its shape, its aesthetics. Surely wonderful times of the generation of engines for modellers!

Thanks for your contribution.

I think the Wen Mac .049 is already at its right point, but you invite me to think.....and maybe I round the original venturi, killing the edge it has, surely something will help, I also plan to place the pressure peak in the butt, so I continue investigating and having fun.

The Wen Mac has an incredible nostalgic charm, it must be because of its shape, its aesthetics. Surely wonderful times of the generation of engines for modellers!

MauricioB- Top Poster

- Posts : 3657

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

I'm looking at photos on the web, it seems common to have a brand registration on the cylinder in these engines, above the number .049 (I indicate it in the photo with arrows)...so I wonder:

1) Will these marks be from some original acceleration control device?

either

2) Will they be factory machining marks??? and no acceleration device originally goes there?!....who knows?

appointment:

https://pocatellomarket.com/products/wen-mac-mk-ii-049-model-plane-engine-gas

1) Will these marks be from some original acceleration control device?

either

2) Will they be factory machining marks??? and no acceleration device originally goes there?!....who knows?

appointment:

https://pocatellomarket.com/products/wen-mac-mk-ii-049-model-plane-engine-gas

MauricioB- Top Poster

- Posts : 3657

Join date : 2016-02-16

Age : 53

Location : ARG

MauricioB- Top Poster

- Posts : 3657

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

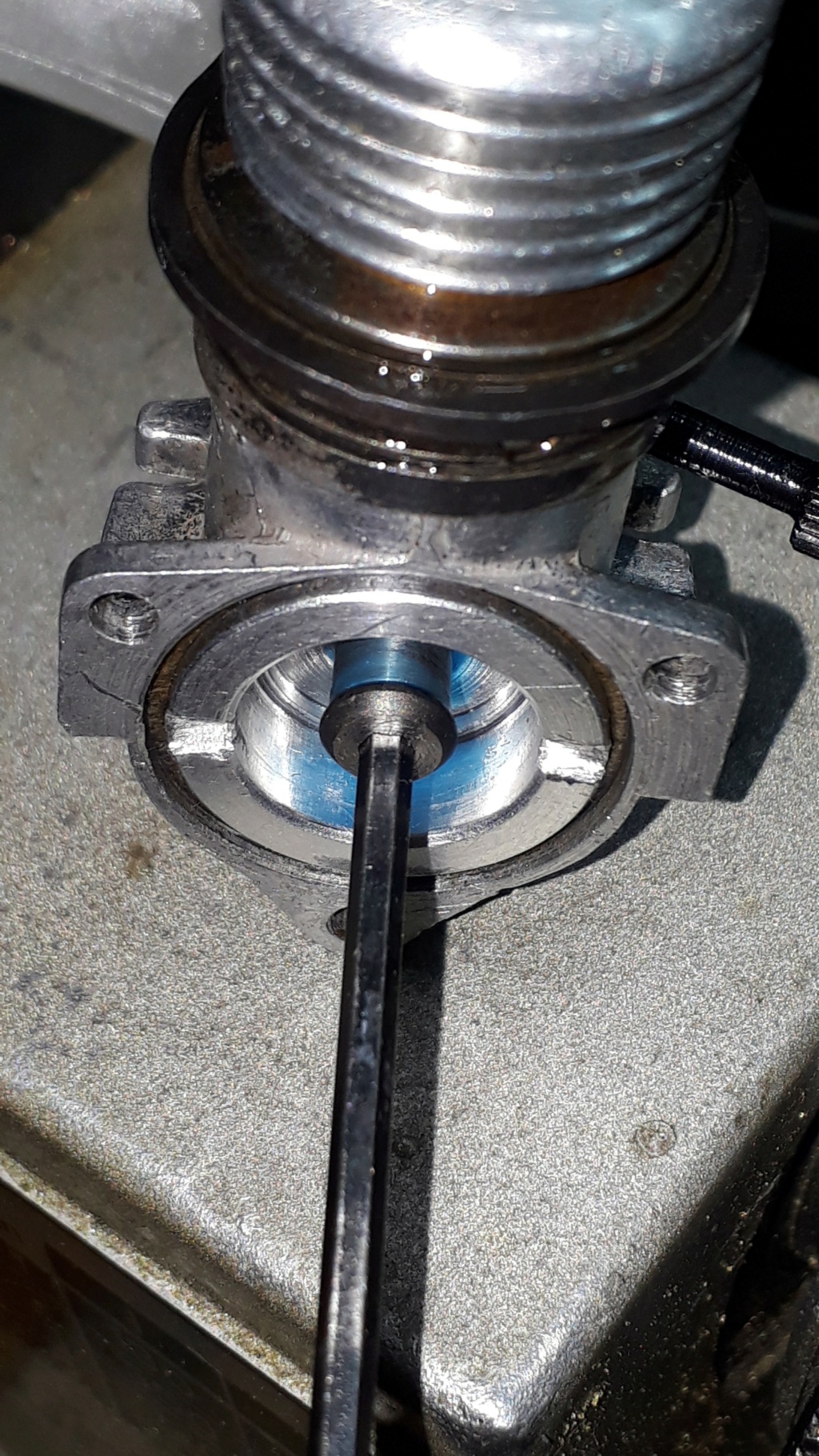

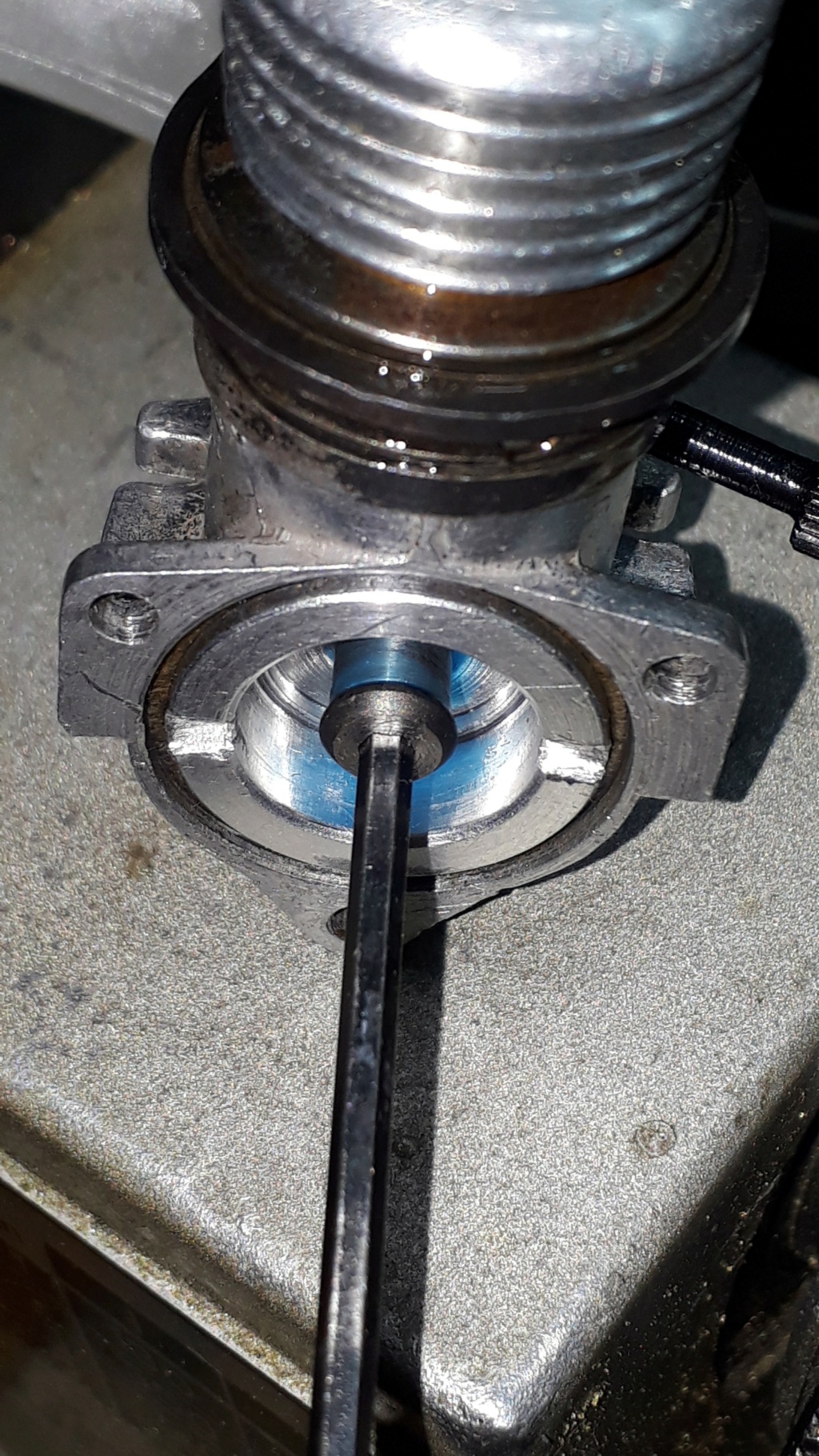

Juan, Jorge and Horacio, following some of your recommendations, it then occurred to me to improve the venturi inlet, making a ring with rounded edges, through which the air flows better.

Ok, it was worth it, the engine went up to 300 rpm!!..that is to say, it improved.

Here are the photos, this work is dedicated to you! Thanks friends!

Sorry for the quality of the photos, but wanting to do everything together and at the same time is crazy hahaha

PROCESS:

TEST:

Ring Venturi:

Ok, it was worth it, the engine went up to 300 rpm!!..that is to say, it improved.

Here are the photos, this work is dedicated to you! Thanks friends!

Sorry for the quality of the photos, but wanting to do everything together and at the same time is crazy hahaha

PROCESS:

TEST:

Ring Venturi:

MauricioB- Top Poster

- Posts : 3657

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

Juan, Jorge and Horacio, following some of your recommendations, it then occurred to me to improve the venturi inlet, making a ring with rounded edges, through which the air flows better.

Ok, it was worth it, the engine went up to 300 rpm!!..that is to say, it improved.

Here are the photos, this work is dedicated to you! Thanks friends!

Sorry for the quality of the photos, but wanting to do everything together and at the same time is crazy hahaha

Hello Mauricio

I`m glad you found a way to improve airflow with the venturi lip you made smoothing airflow into the engine and that it has brought better performance from the little engine. I also enjoy working on old engines that I didn`t have as a kid. Cox engines were available at the local hobby shop and that was how I started in Aeromodeling. I don`t remember seeing OK,Wen Mac,Royal Spitfire and Others till later when I was older.

Juan

Ok, it was worth it, the engine went up to 300 rpm!!..that is to say, it improved.

Here are the photos, this work is dedicated to you! Thanks friends!

Sorry for the quality of the photos, but wanting to do everything together and at the same time is crazy hahaha

Hello Mauricio

I`m glad you found a way to improve airflow with the venturi lip you made smoothing airflow into the engine and that it has brought better performance from the little engine. I also enjoy working on old engines that I didn`t have as a kid. Cox engines were available at the local hobby shop and that was how I started in Aeromodeling. I don`t remember seeing OK,Wen Mac,Royal Spitfire and Others till later when I was older.

Juan

F4D Phantom II- Gold Member

- Posts : 239

Join date : 2019-04-08

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

The vintage Wen Mac with throttle came out very nice Mauricio….. You are very talented to be able to make the custom parts on your lathe….. There should be some here that know more about the Aeromite…. It was a very early ready to fly control line airplane…. Maybe you could build a replica for your engine?

rdw777- Diamond Member

Posts : 1520

Join date : 2021-03-11

Location : West Texas

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

Here’s a thread about Aeromite:

https://www.coxengineforum.com/t10367-wen-mac-cox-s-early-competition

Indeed an early ready-to-fly plastic plane, probably very rare nowadays. I bet Bob (rsv) has at least one A bit special with the speed-racer looks and the later model even had a tricycle landing gear. Mauricio can re-create a slightly enlarged RC version easily, I’m sure

A bit special with the speed-racer looks and the later model even had a tricycle landing gear. Mauricio can re-create a slightly enlarged RC version easily, I’m sure

I think those markings are from the machining process. The case is cast, and the cylinder mating surface and mounting thread need to be machined. The outside surface may be for mounting and/or locating the part for correct machining of the thread, or milling/drilling of another machined feature.

Or it could be made just to separate the intake pipe from the cylinder base, but I don’t really think so

Very nice work on the engine, Mauricio!

https://www.coxengineforum.com/t10367-wen-mac-cox-s-early-competition

Indeed an early ready-to-fly plastic plane, probably very rare nowadays. I bet Bob (rsv) has at least one

MauricioB wrote:I'm looking at photos on the web, it seems common to have a brand registration on the cylinder in these engines, above the number .049 (I indicate it in the photo with arrows)...so I wonder:

1) Will these marks be from some original acceleration control device?

either

2) Will they be factory machining marks??? and no acceleration device originally goes there?!....who knows?

appointment:

https://pocatellomarket.com/products/wen-mac-mk-ii-049-model-plane-engine-gas

I think those markings are from the machining process. The case is cast, and the cylinder mating surface and mounting thread need to be machined. The outside surface may be for mounting and/or locating the part for correct machining of the thread, or milling/drilling of another machined feature.

Or it could be made just to separate the intake pipe from the cylinder base, but I don’t really think so

Very nice work on the engine, Mauricio!

KariFS- Diamond Member

- Posts : 2030

Join date : 2014-10-10

Age : 52

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

Mauricio, hay una razón que la eficiencia ha aumentado en el venturi del «carburador». La respuesta puede encontrar en la dinámica de fluidos.

Mauricio, there is a reason that the efficieny has increased in the venturi of the "carburetor". The answer can be found in fluid dynamics.

Por ejemplo, vea a este enlace:

For example, see this link:

https://lopezva.files.wordpress.com/2012/02/flujo_tuberias_cap_3_y_4.pdf , las Páginas 25 a 26.

y https://neutrium.net/fluid-flow/pressure-loss-from-pipe-entrances-and-exits/ en inglés. (in English)

Por simplicidad, use esta entrada de borde quadrado para la condición inicial.

For simplicity, use Flush/Square-Edged entrance for the initial condition.

El factor K, el Coeficiente de resistencia es 0.5 .

The K-factor, Resistance Coefficient is 0.5 .

Entonces redondeaste el borde interior de la entrada.

Then you rounded the inner edge of the entrance.

Suponiendo por ejemplo, r = 0.5 mm, D = 5.0 mm, r/d = 0.2, entonces K = 0.04 .

Supposing for example, r = 0.5 mm, D = 5.0 mm, r/d = 0.2, entonces K = 0.04 .

La resistencia es mucho menos. Por lo tanto, la efficiencia de la entrada ha aumentado.

The resistance is much less. Thus, the efficiency of the entrance has increased.

Mauricio, there is a reason that the efficieny has increased in the venturi of the "carburetor". The answer can be found in fluid dynamics.

Por ejemplo, vea a este enlace:

For example, see this link:

https://lopezva.files.wordpress.com/2012/02/flujo_tuberias_cap_3_y_4.pdf , las Páginas 25 a 26.

y https://neutrium.net/fluid-flow/pressure-loss-from-pipe-entrances-and-exits/ en inglés. (in English)

Por simplicidad, use esta entrada de borde quadrado para la condición inicial.

For simplicity, use Flush/Square-Edged entrance for the initial condition.

El factor K, el Coeficiente de resistencia es 0.5 .

The K-factor, Resistance Coefficient is 0.5 .

Entonces redondeaste el borde interior de la entrada.

Then you rounded the inner edge of the entrance.

Suponiendo por ejemplo, r = 0.5 mm, D = 5.0 mm, r/d = 0.2, entonces K = 0.04 .

Supposing for example, r = 0.5 mm, D = 5.0 mm, r/d = 0.2, entonces K = 0.04 .

La resistencia es mucho menos. Por lo tanto, la efficiencia de la entrada ha aumentado.

The resistance is much less. Thus, the efficiency of the entrance has increased.

GallopingGhostler- Top Poster

Posts : 5513

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

I think the Medallion spray bar gave a better response that the one you made ( still worked good ) I have heard that the best pressure tap would bee on the side of CC tail / end fair/ and at Crank shaft not as good . The sleeve worked good for some extra RPMs Cool !

getback- Top Poster

Posts : 10326

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

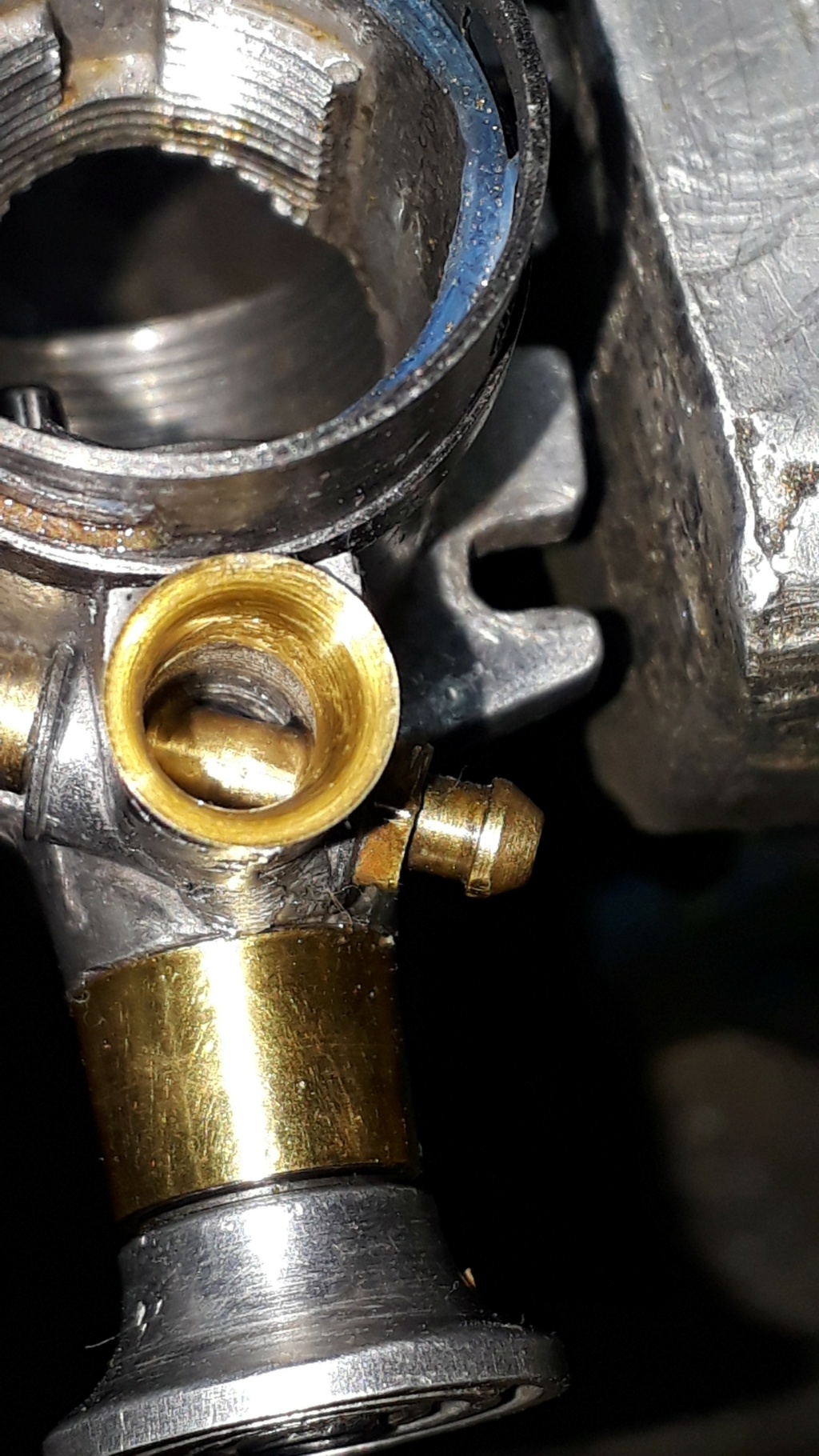

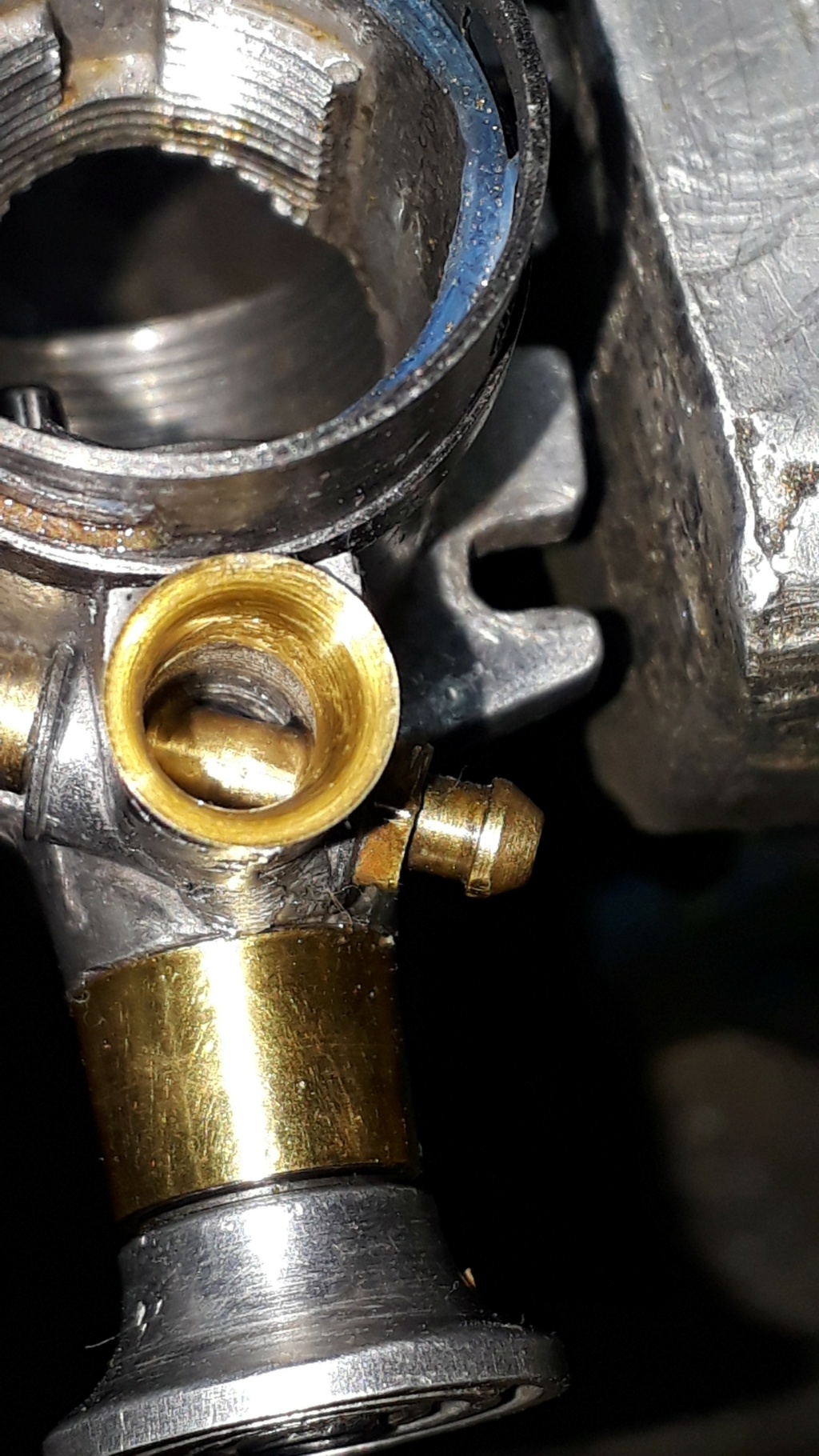

Friends, thank you for the valuable information!!, all extremely useful.

Kari, yes I agree, it is possible that the marks are a record of machining, which inspired my imagination to make the regulation ring....so great!

Jorge, very good information!!....then I started working again on the venturi, below are the processes!

Eric, dear friend, yes, the Medallion .049 spray bar seems to be what keeps the engine running most stable, so I'll leave that placed there.

Robert! and Juan... then I made a pressure peak, which you will see in the photos. You have to do test runs to see how it turns out.

I colored the regulation ring (cold peacock), just to add color.

The engine changed its appearance completely since its inception and it really now looks like a competitive engine, with less rough lines and more aesthetics, (at least in my eyes)....A customized Wen-Mac .049...I'll do it now fly God willing!

I am learning a lot thanks to you.

original venturi mouth:

Modification of the original venturi:

Manufacture of an internal insert respecting the original suction diameter:

Inserted and pasted:

Manufacture of pressure peak, if it is not better, I can remove it and place a round head threaded screw as a cap:

Finished!...time to test the result!....coming soon

Kari, yes I agree, it is possible that the marks are a record of machining, which inspired my imagination to make the regulation ring....so great!

Jorge, very good information!!....then I started working again on the venturi, below are the processes!

Eric, dear friend, yes, the Medallion .049 spray bar seems to be what keeps the engine running most stable, so I'll leave that placed there.

Robert! and Juan... then I made a pressure peak, which you will see in the photos. You have to do test runs to see how it turns out.

I colored the regulation ring (cold peacock), just to add color.

The engine changed its appearance completely since its inception and it really now looks like a competitive engine, with less rough lines and more aesthetics, (at least in my eyes)....A customized Wen-Mac .049...I'll do it now fly God willing!

I am learning a lot thanks to you.

original venturi mouth:

Modification of the original venturi:

Manufacture of an internal insert respecting the original suction diameter:

Inserted and pasted:

Manufacture of pressure peak, if it is not better, I can remove it and place a round head threaded screw as a cap:

Finished!...time to test the result!....coming soon

MauricioB- Top Poster

- Posts : 3657

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

Well friends, so I did the start-up and the experience.

With pressure peak, (with pressurizer):

The engine floods, I almost completely close the needle and when the engine rotates it sends a lot of pressure to the tank and the engine floods, it cannot start.

Without pressure peak, (without pressurizer):

The engine runs perfect, the rpm increases. It reached a peak of 13950, therefore it improved with the reform of the venturi.

The engine no longer has an erratic running pattern, it has become much more stable in rpm, which suggests that the air flow is much more even, without great turbulence.

Conclusion:

Permanently remove the pressure peak and manufacture a specific plug for the engine plate, a piece with dedication so that it is truly part of the engine and not a simple threaded screw.

I reached the end then with the Wen-Mac .049, all the work has been very pleasant and this engine generated a special affection in me, since every modification was noticeably improving the performance of the engine itself.

It's time to go get a model airplane to test it in flight.

Here are now the Cox .049 r/c with silencer and the Wen-Mac .049 r/c, waiting for me to get to work on a plane they will share.

With pressure peak, (with pressurizer):

The engine floods, I almost completely close the needle and when the engine rotates it sends a lot of pressure to the tank and the engine floods, it cannot start.

Without pressure peak, (without pressurizer):

The engine runs perfect, the rpm increases. It reached a peak of 13950, therefore it improved with the reform of the venturi.

The engine no longer has an erratic running pattern, it has become much more stable in rpm, which suggests that the air flow is much more even, without great turbulence.

Conclusion:

Permanently remove the pressure peak and manufacture a specific plug for the engine plate, a piece with dedication so that it is truly part of the engine and not a simple threaded screw.

I reached the end then with the Wen-Mac .049, all the work has been very pleasant and this engine generated a special affection in me, since every modification was noticeably improving the performance of the engine itself.

It's time to go get a model airplane to test it in flight.

Here are now the Cox .049 r/c with silencer and the Wen-Mac .049 r/c, waiting for me to get to work on a plane they will share.

MauricioB- Top Poster

- Posts : 3657

Join date : 2016-02-16

Age : 53

Location : ARG

MauricioB- Top Poster

- Posts : 3657

Join date : 2016-02-16

Age : 53

Location : ARG

Page 3 of 3 •  1, 2, 3

1, 2, 3

Page 3 of 3

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules