Log in

Search

Latest topics

» Cox 020 PeeWee rebuild questions by roddie Today at 8:21 pm

» Dodge Viper - What a waste but brilliant marketing

by roddie Today at 6:46 pm

» COX .020 POWERED SPEEDSTER

by TD ABUSER Today at 6:32 pm

» **VOTE-ON-THE-NEXT-COX-ENGINE-OF-THE-MONTH** (November 2024)

by roddie Today at 6:13 pm

» Brushless motors?

by rsv1cox Today at 4:53 pm

» Free Flight Radio Assist

by rdw777 Today at 4:28 pm

» L4 Grasshopper

by latole Today at 3:43 pm

» PAW 80 and possible use

by fit90 Today at 8:36 am

» Music-wire bending tools (DIY video)

by 1975 control line guy Today at 8:32 am

» Ultrasonic Cleaners??

by sosam117 Yesterday at 11:26 am

» My CA or CyA (super glue) allergy

by rsv1cox Yesterday at 9:52 am

» My Pseudo killerbee.

by rsv1cox Yesterday at 7:04 am

Glow plug tightening torque

Page 1 of 1

Glow plug tightening torque

Glow plug tightening torque

Gents,

after years of burning glow fuel in COX engines powering my kitchen-made RC planes, I have ventured into flying a bigger animal made by Ripmax of the UK, the Acro-Wot MK2, a very fast but forgiving ARF:

http://www2.ripmax.net/Item.aspx?ItemID=A-CF006

The engine inside is an OS Max 56 4-stroke alpha, a beautiful critter..the trouble started with the engine being hidden under the FRP cowling, with a very narrow hole I cut on it to access the glow plug built in, inclined to the cylinder axis...as obviously (and regretfully) follows, after numerous flights and subsequent application of after-run oil through the glow plug hole into the cylinder, I finally managed to severe the plug thread in the aluminum alloy engine head (a revenge by my COX engines I temporarily adultered?), which is now out for a repair in the kitchen of someone else..

(Looks like most of the modelers in this part of the world must be originally cooks)

Though I tend not to apply brute force in tightening glow heads and plugs (having been trained on e.g. COX TD 010-s), and kind of developed some surgical feel in my fingers to do so, I still make mistakes and wonder if you have any practical advice on what is "...just enough but not too much.." in terms of the torque to be applied on a glow plug wrench? Silly question I know, but I would assume the muscle limit I should set in my wrist is at least to ensure the glow plug brass gasket not be flattened while torquing? (I do feel ashamed...)

I browsed this site but have not found any thread on this topic (I should say, recipe...)

Will appreciate your advice...and promise will continue flying COX until and forever after the OS head is back from the kitchen well-done (medium-rare?)

after years of burning glow fuel in COX engines powering my kitchen-made RC planes, I have ventured into flying a bigger animal made by Ripmax of the UK, the Acro-Wot MK2, a very fast but forgiving ARF:

http://www2.ripmax.net/Item.aspx?ItemID=A-CF006

The engine inside is an OS Max 56 4-stroke alpha, a beautiful critter..the trouble started with the engine being hidden under the FRP cowling, with a very narrow hole I cut on it to access the glow plug built in, inclined to the cylinder axis...as obviously (and regretfully) follows, after numerous flights and subsequent application of after-run oil through the glow plug hole into the cylinder, I finally managed to severe the plug thread in the aluminum alloy engine head (a revenge by my COX engines I temporarily adultered?), which is now out for a repair in the kitchen of someone else..

(Looks like most of the modelers in this part of the world must be originally cooks)

Though I tend not to apply brute force in tightening glow heads and plugs (having been trained on e.g. COX TD 010-s), and kind of developed some surgical feel in my fingers to do so, I still make mistakes and wonder if you have any practical advice on what is "...just enough but not too much.." in terms of the torque to be applied on a glow plug wrench? Silly question I know, but I would assume the muscle limit I should set in my wrist is at least to ensure the glow plug brass gasket not be flattened while torquing? (I do feel ashamed...)

I browsed this site but have not found any thread on this topic (I should say, recipe...)

Will appreciate your advice...and promise will continue flying COX until and forever after the OS head is back from the kitchen well-done (medium-rare?)

balogh- Top Poster

Posts : 4940

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Glow plug tightening torque

Re: Glow plug tightening torque

50-60 inch-pounds?

http://www.junkyardgenius.com/holley/torquespec.html

http://www.engineersedge.com/torque_table_sae.htm

so 4-5 ft-lbs...

Phil

http://www.junkyardgenius.com/holley/torquespec.html

http://www.engineersedge.com/torque_table_sae.htm

so 4-5 ft-lbs...

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Glow plug tightening torque

Re: Glow plug tightening torque

Thanks, Phil,

do you think the values in the chart apply to non-.ferrous materials like aluminum alloys the OS head is made of?

do you think the values in the chart apply to non-.ferrous materials like aluminum alloys the OS head is made of?

balogh- Top Poster

Posts : 4940

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Glow plug tightening torque

Re: Glow plug tightening torque

I can't offer any advice on torque specs... but I'm curious about approximately "how often" you remove and replace the plug? You mentioned applying after-run oil through the plug hole. Does OS recommend this be done frequently on their 4-strokes? If you're following their maintenance schedule.. then you probably haven't done anything wrong yourself. The head could have been tapped with a worn tap at the factory... perhaps it was a faulty casting.. or you may have been unlucky enough to have a plug with a bad thread.. who knows. Aluminum is not real forgiving when it comes to repeated threading into it.. with any force.

There "is" something you can do, to check your plug threads... and it's well worth doing with every plug you have. You can obtain a 1/4-32 "die" for the purpose of "chasing" the threads on your plug(s) before you screw them into an expensive and possibly irreplaceable cylinder head. Keep the plugs that have been chased/checked in a labeled segregated storage area, protecting their threads from contamination or being accidentally "dinged-up". Some guys screw them into holes drilled in a small rubber block-type "caddy" that's easy to store in your flight tote too.

Lastly... whenever I assemble any threaded parts; I "rotate" the part(s) as if to "loosen" them... while also applying light pressure, until I feel the leader-thread "drop-in". This results in a "click" that can be felt through your fingers when it happens. Tightening can then be commenced with the assurance that the threads are engaged properly.

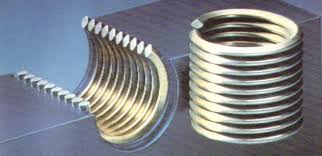

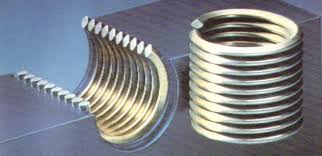

I am guessing that the thread-repair you're having done, may be what's known around these parts as a "heli-coil"... although I'm not sure about the uncommon 1/4-32 thread application. That would be the easiest way to do it. Another alternative would be to TIG-weld the hole closed.. but this requires re-grinding/polishing in the combustion chamber.. and re-drilling/re-tapping the plug hole at the correct precise angle. I'll be very curious as to how the repair is made.

I hope I've given you some advice that you can apply Balogh. Best of luck with the engine when you get it back from the cook!

There "is" something you can do, to check your plug threads... and it's well worth doing with every plug you have. You can obtain a 1/4-32 "die" for the purpose of "chasing" the threads on your plug(s) before you screw them into an expensive and possibly irreplaceable cylinder head. Keep the plugs that have been chased/checked in a labeled segregated storage area, protecting their threads from contamination or being accidentally "dinged-up". Some guys screw them into holes drilled in a small rubber block-type "caddy" that's easy to store in your flight tote too.

Lastly... whenever I assemble any threaded parts; I "rotate" the part(s) as if to "loosen" them... while also applying light pressure, until I feel the leader-thread "drop-in". This results in a "click" that can be felt through your fingers when it happens. Tightening can then be commenced with the assurance that the threads are engaged properly.

I am guessing that the thread-repair you're having done, may be what's known around these parts as a "heli-coil"... although I'm not sure about the uncommon 1/4-32 thread application. That would be the easiest way to do it. Another alternative would be to TIG-weld the hole closed.. but this requires re-grinding/polishing in the combustion chamber.. and re-drilling/re-tapping the plug hole at the correct precise angle. I'll be very curious as to how the repair is made.

I hope I've given you some advice that you can apply Balogh. Best of luck with the engine when you get it back from the cook!

Re: Glow plug tightening torque

Re: Glow plug tightening torque

The first link is a Holly carburetor reference (most carburetors are aluminum alloy), the second splits out different materials. The aluminum alloy column agrees with the carburetor reference, but the thread size on the second is 1/4-28 instead of 1/4-32.

After-run oil can be put into the exhaust without taking anything apart. Just support the model in the appropriate attitude and rotate the engine through several times. If the exhaust is really challenging using the pressure tap may be easier, just route the fuel line with a connector somewhere useful. An additional pressure tap can also be installed with little fuss for the purpose of PM (preventative maintenance)

Phil

After-run oil can be put into the exhaust without taking anything apart. Just support the model in the appropriate attitude and rotate the engine through several times. If the exhaust is really challenging using the pressure tap may be easier, just route the fuel line with a connector somewhere useful. An additional pressure tap can also be installed with little fuss for the purpose of PM (preventative maintenance)

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Glow plug tightening torque

Re: Glow plug tightening torque

I tighten plugs with a socket on a nut driver handle. That helps me to not over do it. I'm famous for giving it one more twist for good luck, so the last thing I need is more leverage.

I can add one more comment about applying after run oil. I oiled the engines in all of my planes last month by filling the venturi a couple of times and rotating the shaft while tilting it nose up and then some more inverted. Before I went flying Saturday I borrowed a plug from one of them and it was dripping wet with oil. So no real need to remove the plug or muffler to get it thoroughly oiled.

Rusty

I can add one more comment about applying after run oil. I oiled the engines in all of my planes last month by filling the venturi a couple of times and rotating the shaft while tilting it nose up and then some more inverted. Before I went flying Saturday I borrowed a plug from one of them and it was dripping wet with oil. So no real need to remove the plug or muffler to get it thoroughly oiled.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Glow plug tightening torque

Re: Glow plug tightening torque

RknRusty wrote:I tighten plugs with a socket on a nut driver handle. That helps me to not over do it. I'm famous for giving it one more twist for good luck, so the last thing I need is more leverage.

I can add one more comment about applying after run oil. I oiled the engines in all of my planes last month by filling the venturi a couple of times and rotating the shaft while tilting it nose up and then some more inverted. Before I went flying Saturday I borrowed a plug from one of them and it was dripping wet with oil. So no real need to remove the plug or muffler to get it thoroughly oiled.

Rusty

Good to know!

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Glow plug tightening torque

Re: Glow plug tightening torque

Thanks to all of you for the useful advice. OS states oil is to be applied either through the venturi or through the glow plug hole. I followed this latter so as not to flood the carb having all those tiny bores inside in oil as this I thought may make the engine start later difficult. And the glow plug is at least - or I thought was - accessible through the cowling, anyways..

Now I will have to drill a hole on the other side of the cowling to make the venturi accessible and will apply the oil with a syringe.

I am not sure how the kitchen-master will heal the ripped thread in the engine head. It is placed way too close to the valve seats and I am afraid drilling a larger hole for a brass bushing into which the new thread is to be cut will not fly.

Roddie, what do you call heli-coiling?

Anyways Tower Hobbies has those OS parts on stock (cylinder head and gasket) and already shipped them - it takes at least 5 weeks if it ships at all.

Thanks again for the valuable advice.

Now I will have to drill a hole on the other side of the cowling to make the venturi accessible and will apply the oil with a syringe.

I am not sure how the kitchen-master will heal the ripped thread in the engine head. It is placed way too close to the valve seats and I am afraid drilling a larger hole for a brass bushing into which the new thread is to be cut will not fly.

Roddie, what do you call heli-coiling?

Anyways Tower Hobbies has those OS parts on stock (cylinder head and gasket) and already shipped them - it takes at least 5 weeks if it ships at all.

Thanks again for the valuable advice.

balogh- Top Poster

Posts : 4940

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Glow plug tightening torque

Re: Glow plug tightening torque

A helicoil - if you can get one that provides the correct thread - is the neatest way of repairing a stripped thread because the original hole does not have to be enlarged by very much.

It does need a "KIT" to perform the operation.

I have done this on motorbike cylinder heads and it has worked a treat.

It does need a "KIT" to perform the operation.

I have done this on motorbike cylinder heads and it has worked a treat.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Glow plug tightening torque

Re: Glow plug tightening torque

Thanks, Roddie,

one cannot be old enough to stop learning...I like it but doubt if the kit is available in my area, so I just wait if the surgical repair will prove right.

one cannot be old enough to stop learning...I like it but doubt if the kit is available in my area, so I just wait if the surgical repair will prove right.

balogh- Top Poster

Posts : 4940

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Glow plug tightening torque

Re: Glow plug tightening torque

The 1/4-32 kt usually requires order for everybody as it is an unusual size used by models and carburetors.

Phil

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Glow plug tightening torque

Re: Glow plug tightening torque

Just a thought, by the time your order the kit and ship it, you may find a replacement head to be cheaper or the same price.

Something to consider anyway.

Ron

Something to consider anyway.

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Glow plug tightening torque

Re: Glow plug tightening torque

On the other hand, the kit is complete - drill, tap, insertion tools and, usually, over 10 inserts.

The kit cost me (many years ago) £10.

I found that after I had repaired the head - about 10 minutes - no other cost, I repaired one for a near neighbour and one for a chap at work - I was compensated with a bottle of wine from one and a six pack of Guinness from the other.

I sold the kit with the remaining inserts when I was having a clear out (about 10 years later) for £12.

More than a free repair.

The kit cost me (many years ago) £10.

I found that after I had repaired the head - about 10 minutes - no other cost, I repaired one for a near neighbour and one for a chap at work - I was compensated with a bottle of wine from one and a six pack of Guinness from the other.

I sold the kit with the remaining inserts when I was having a clear out (about 10 years later) for £12.

More than a free repair.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Glow plug tightening torque

Re: Glow plug tightening torque

That is OK, but where is the wine and the Guiness today?

balogh- Top Poster

Posts : 4940

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Glow plug tightening torque

Re: Glow plug tightening torque

balogh wrote:That is OK, but where is the wine and the Guiness today?

Eventually, after "processing" - it went on a trip down the River Thames.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Glow plug tightening torque

Re: Glow plug tightening torque

Balogh, even if you need a new cylinder head.. it will be worth the wait to have it. Many of our engines have parts that are no longer available. If this is an engine that you really enjoy and run often... you may want to research other common "wear-parts" while they're still available from OS... and order some "spares". I don't know much about 4-strokes.. but there must be valve-train components that incorporate multiple small precision parts; camshaft, valves, gaskets/seals etc., that will wear-out eventually from prolonged use. Does the case use bearings? If so; it may be worth having a replacement set of those too.

Similar topics

Similar topics» .049 glow plug

» The .049 glow plug ?

» .049 glow plug ?

» glow plug qs

» Cox Tee Dee high-compression glow head question

» The .049 glow plug ?

» .049 glow plug ?

» glow plug qs

» Cox Tee Dee high-compression glow head question

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules