Log in

Search

Latest topics

» A choke-tube with velocity-stack configured Beeby roddie Today at 6:12 am

» Jim Walkers FireBee - This is going to be fun

by cstatman Yesterday at 6:58 pm

» Prop Rod - resto to a runner

by cstatman Yesterday at 6:56 pm

» Hawk had breakfast and then took a bath

by rdw777 Yesterday at 5:38 pm

» Jim Walker Firebaby

by rdw777 Yesterday at 4:58 pm

» WenMac 049 - Glow Plug & Head Gasket replacements?

by rdw777 Yesterday at 4:32 pm

» Nostalgia alert, my 1959 Corvette revisited

by rsv1cox Yesterday at 2:25 pm

» Prayers for my Wife Please

by akjgardner Yesterday at 10:28 am

» Cox prop rod

by Wiggy Fri May 17, 2024 4:30 pm

» "Red Neck" .049 elec. starter

by getback Fri May 17, 2024 7:19 am

» Cox prop rod

by Wiggy Fri May 17, 2024 5:35 am

» Looking For Comet Tri-Pacer

by latole Fri May 17, 2024 3:45 am

wheel hub reduction/re-size

Page 1 of 1

wheel hub reduction/re-size

wheel hub reduction/re-size

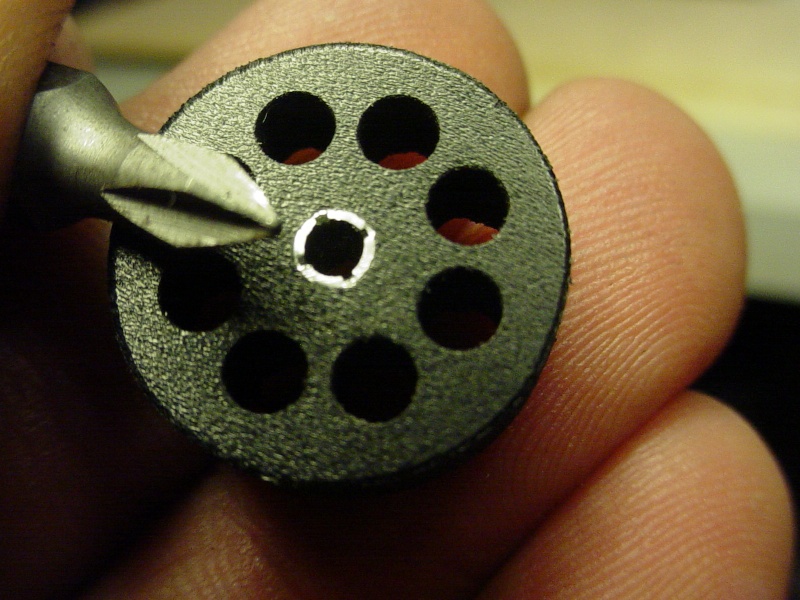

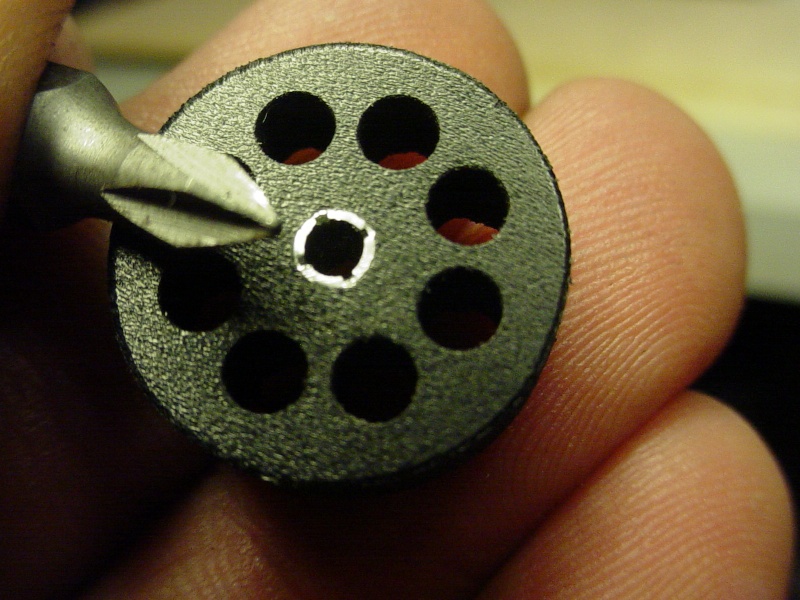

I made some tail-wheels today from 6mil (just under 1/4") sheet PVC on the CNC router. I drilled the hubs 1/8" diameter, because that was the size of the end-mill used to cut the entire wheel. I wanted a 3/32" (.093") hub, so I cut a bushing from 1/8" aluminum tubing (3/32" I.D.) on my x-acto miter box.. and inserted it into the 1/8" hub. It was a nice tight fit.. but to "secure" it in place.. I "staked" it in (both sides) with a #0 Phillips insert bit, by placing the wheel flat on my vise-anvil. and producing a light "tap" with a small hammer.

I'm sure that you can think of other ways to use this method, when installing bushings elsewhere, that you don't want to have slip out.

I'm sure that you can think of other ways to use this method, when installing bushings elsewhere, that you don't want to have slip out.

Re: wheel hub reduction/re-size

Re: wheel hub reduction/re-size

Good idea Roddie,

I wonder if that would work on aluminum hubs.

I wonder if that would work on aluminum hubs.

Cribbs74- Moderator

Posts : 11899

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: wheel hub reduction/re-size

Re: wheel hub reduction/re-size

Cribbs74 wrote:Good idea Roddie,

I wonder if that would work on aluminum hubs.

I would think.. most certainly Ron. Aluminum is soft.. and this method is merely a "pinch-fit". The idea is; not to have the reducing bushing(s) "slip-out" of the hub, or wherever they're installed.. (it's a pain if/when you take things apart.. and a small bushing falls out and gets lost) They can easily be pressed-out if needed. It's important to cut the length of the bushing to the same width/thickness; "flush" with the hub.. and support the underside on an anvil when you "set" the bushing. This will assure that the bushing expands "directly" against the hub.

If you're bushing "really thin" wheels.. this is especially important.. because if the bushing "slips" on a music-wire gear.. your wheel "could" end up camber-fouling in.. and would ride-up the gear-leg. Some modelers solder steel-washers onto their music-wire gear, for the inside bearing-surface of the hub to ride up against. This helps the hub from binding where the axle bend-angle transitions to the gear-leg.

Similar topics

Similar topics» Cox Muffler RPM Reduction

» Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

» Got sum TeeDees fer sail

» Dremel cut-off wheel tip

» Making Timing Shim for SPI Reduction at Home

» Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

» Got sum TeeDees fer sail

» Dremel cut-off wheel tip

» Making Timing Shim for SPI Reduction at Home

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules