Log in

Search

Latest topics

» Golden Bee basic running problemby roddie Yesterday at 10:51 pm

» Simple Gliders

by rdw777 Yesterday at 6:25 pm

» Foam hand kids glider converted to 0.049 CL

by rdw777 Yesterday at 6:11 pm

» Weird search for a single comic from an old Mad Magazine

by Kim Yesterday at 1:44 pm

» Scientific "Zipper" Build...Zipper Flys!.

by getback Yesterday at 7:27 am

» Cox .049 Tee Dee engines back in stock (limited availablility)

by GallopingGhostler Yesterday at 1:05 am

» Very off-topic.........Time passes and not always for the best......

by rsv1cox Thu Jul 25, 2024 2:47 pm

» Roddie-Rigger.. a 2005 original design

by roddie Wed Jul 24, 2024 11:48 pm

» Jim Walker Bonanza etc.

by rsv1cox Wed Jul 24, 2024 6:30 pm

» Throttles for Cox Tee Dee .049 / .020 / .010 engines --- videos

by sosam117 Wed Jul 24, 2024 8:54 am

» Introducing our Cox .049 TD Engines

by Admin Tue Jul 23, 2024 2:00 am

» Project Cox .049 r/c & Citabrian Champion

by getback Mon Jul 22, 2024 4:14 pm

Cox Engine of The Month

July-2024

robot797's

"ULTIMITE COX 010: it has a clutch, E starter, throttle, exhaust, aluminum tank, aluminum venturi, gearbox with forward and reverse, and now its on a custom drawn and printed stand"

PAST WINNERS

robot797's

"ULTIMITE COX 010: it has a clutch, E starter, throttle, exhaust, aluminum tank, aluminum venturi, gearbox with forward and reverse, and now its on a custom drawn and printed stand"

PAST WINNERS

Making Timing Shim for SPI Reduction at Home

Page 1 of 1

Making Timing Shim for SPI Reduction at Home

Making Timing Shim for SPI Reduction at Home

Hi,

As I have previously explained, I MUST use a muffler in the places I am able to fly. Its muffler or no fly.

I use a fairly standard Cox 049 surestart engine and use the standard Cox muffler, works well for me on the standard surestart 049 Cylinders with slits, but really doesnt work well with cylinders with SPI. It not only doesnt perform well but I believe the engine runs a LOT hotter. I am assuming the future of any newly available cylinders will be SPI TD cylinders and I have a lot of TD cylinders I would like to be able to use. But that means I MUST use a muffler and I really need to remove the SPI.

I tried making shims for the cylinder base out of shim stock with all types of methods, but none were overly successful for the effort put in to making them. I only have very basic tools and my super dremel. :-) I was having a few beers at my build bench and looking at the muffler, looking at the cylinder, thinking, thinking, how can I make a shim that is the right thickness, ID to fit the cylinder base, and the correct OD to fit inside the muffler such that it doesnt stop the cylinder screwing in. I started looking at all kinds of bits and pieces I had, and then looked at the Cox No Friction starter spring for 049 engines like the venom or engines in general that are not TD and dont use the surestart cam springs. These springs have the perfect ID to fit over a 049 cylinder and the perfect OD to fit in the gap between the muffler and the cylinder at the base. But the coils are too thick. I cut a coil off the spring placed it over the cylinder base and it fitted perfectly. Then installed the muffler and it fitted perfectly. All I needed was to get the coil thickness to the correct thickness to remove the SPI. I dont have much equipment so I got out some wet and dry paper and started the task of slowly sanding down the coil and testing it on the cylinder till I got the correct size.

The good thing is after the work and effort the shim works beautifully and is spring steel so it is strong and can be taken off and put on and reused without any problems. I have inserted photos below that I hope help make sense of my description above. Hope this is of some use to someone. Well it is to me anyway.

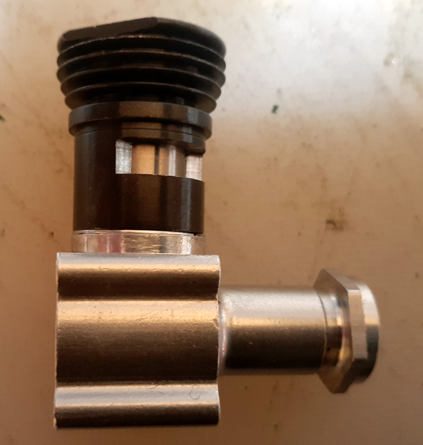

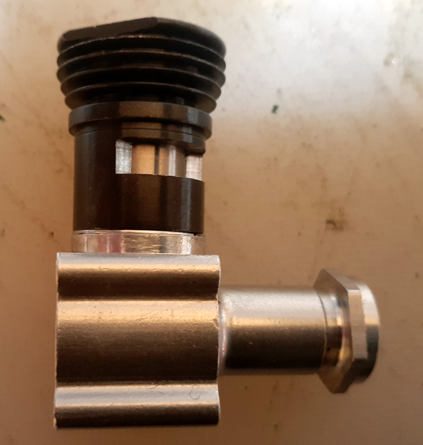

Shim installed between cylinder and Crankcase

Shim on the cylinder base

Shim on the cylinder base with the muffler going over the shim as required

The spring I cut a coil from and the shim next to it made from the coil

The final shim

Probably easier to just but them. but then again.................. Lol.

Yabby

As I have previously explained, I MUST use a muffler in the places I am able to fly. Its muffler or no fly.

I use a fairly standard Cox 049 surestart engine and use the standard Cox muffler, works well for me on the standard surestart 049 Cylinders with slits, but really doesnt work well with cylinders with SPI. It not only doesnt perform well but I believe the engine runs a LOT hotter. I am assuming the future of any newly available cylinders will be SPI TD cylinders and I have a lot of TD cylinders I would like to be able to use. But that means I MUST use a muffler and I really need to remove the SPI.

I tried making shims for the cylinder base out of shim stock with all types of methods, but none were overly successful for the effort put in to making them. I only have very basic tools and my super dremel. :-) I was having a few beers at my build bench and looking at the muffler, looking at the cylinder, thinking, thinking, how can I make a shim that is the right thickness, ID to fit the cylinder base, and the correct OD to fit inside the muffler such that it doesnt stop the cylinder screwing in. I started looking at all kinds of bits and pieces I had, and then looked at the Cox No Friction starter spring for 049 engines like the venom or engines in general that are not TD and dont use the surestart cam springs. These springs have the perfect ID to fit over a 049 cylinder and the perfect OD to fit in the gap between the muffler and the cylinder at the base. But the coils are too thick. I cut a coil off the spring placed it over the cylinder base and it fitted perfectly. Then installed the muffler and it fitted perfectly. All I needed was to get the coil thickness to the correct thickness to remove the SPI. I dont have much equipment so I got out some wet and dry paper and started the task of slowly sanding down the coil and testing it on the cylinder till I got the correct size.

The good thing is after the work and effort the shim works beautifully and is spring steel so it is strong and can be taken off and put on and reused without any problems. I have inserted photos below that I hope help make sense of my description above. Hope this is of some use to someone. Well it is to me anyway.

Shim installed between cylinder and Crankcase

Shim on the cylinder base

Shim on the cylinder base with the muffler going over the shim as required

The spring I cut a coil from and the shim next to it made from the coil

The final shim

Probably easier to just but them. but then again.................. Lol.

Yabby

Yabby- Platinum Member

Posts : 711

Join date : 2021-06-08

Location : Yorke Peninsula South Australia

Re: Making Timing Shim for SPI Reduction at Home

Re: Making Timing Shim for SPI Reduction at Home

A cooper seal for the oil change plug work but remains to be adjusted But give a good tight seal The glow plug must be modified to compensate for the loss of compression So as not to affect performance too much It is still preferable to use a cylinder without spi or try To Find the one wit less spi as smal as posible for best performance Also some back plate fuel tank ventury needs to be over size

davidll1984- Diamond Member

- Posts : 2303

Join date : 2020-02-12

Age : 39

Location : shawinigan

Making timing shim for spi reduction

Making timing shim for spi reduction

Hi yabby

Try using .09 or .074 head gaskets perfect fit bernie has them listed

Set of 3 x .010 p/n sku9074ghg

Jamesclive

Try using .09 or .074 head gaskets perfect fit bernie has them listed

Set of 3 x .010 p/n sku9074ghg

Jamesclive

James clive- Moderate Poster

- Posts : 13

Join date : 2021-05-05

Making timing shim for spi reduction

Making timing shim for spi reduction

Hi yabby

Try using .09 or .074 head gaskets perfect fit bernie has them listed

Set of 3 x .010 p/n sku9074ghg

Jamesclive

Try using .09 or .074 head gaskets perfect fit bernie has them listed

Set of 3 x .010 p/n sku9074ghg

Jamesclive

James clive- Moderate Poster

- Posts : 13

Join date : 2021-05-05

Similar topics

Similar topics» TD backplate shim

» Cox Muffler RPM Reduction

» Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

» Cox 049 timing

» Nitro % Fuel Reduction?

» Cox Muffler RPM Reduction

» Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

» Cox 049 timing

» Nitro % Fuel Reduction?

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules