Log in

Search

Latest topics

» Stealth SB-Xby Admin Today at 8:28 pm

» ST .35 STUNT / VOODOO / ZERO POINT ZERO NITRO

by TD ABUSER Today at 7:45 pm

» SUPERTIGER .15 PROJECT

by TD ABUSER Today at 7:42 pm

» For sale -- Cox Custom Carburetors for Tee Dee engines

by sosam117 Today at 5:23 pm

» WHERE ARE YOU BUYING YOUR FUEL AND GLOW PLUGS...?

by TD ABUSER Today at 4:35 pm

» Waiting for Engines from Ken Enya

by sosam117 Today at 4:33 pm

» Unusual Cox 049 cylinder - Need help identifying

by anm2 Today at 4:12 pm

» Jim Walker Bonanza etc.

by rsv1cox Today at 2:57 pm

» What's the Best Reed for Cox Reed Valve Engines.

by roddie Today at 1:37 pm

» Fuel choice

by 1975 control line guy Yesterday at 4:01 pm

» "Fall S.M.A.L.L." Video 3.

by GallopingGhostler Yesterday at 2:37 pm

» Gifted Fox

by Ken Cook Yesterday at 11:12 am

Cox Engine of The Month

August-2024

balogh's

"Cox TD09 R/C Beast of Burden featuring Kamtechnik head and DIY metallic fuel nipple"

PAST WINNERS

balogh's

"Cox TD09 R/C Beast of Burden featuring Kamtechnik head and DIY metallic fuel nipple"

PAST WINNERS

Reed Valve Design Ideas Poll

Page 1 of 2

Page 1 of 2 • 1, 2

Reed Valve Design Ideas Poll

Reed Valve Design Ideas Poll

I've heard of a few reed designs out there. I'd like to hear about all the ones people on this forum have tried.

Laying in bed last night, an idea for a reed design I haven't heard of yet, popped into my head.

I want to know if it may be worth trying or I'm just beating a dead horse.

Laying in bed last night, an idea for a reed design I haven't heard of yet, popped into my head.

I want to know if it may be worth trying or I'm just beating a dead horse.

Last edited by SkyStreak on Mon Mar 19, 2018 4:31 pm; edited 1 time in total (Reason for editing : Make more clear)

SkyStreak- Bronze Member

- Posts : 31

Join date : 2018-02-26

Location : Mo

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

SkyStreak wrote:

I've heard of a few reed designs out there. I'd like to hear about all the ones people on this forum have tried.

Laying in bed last night, an idea for a reed design I haven't heard of yet, popped into my head.

I want to know if it may be worth trying or I'm just beating a dead horse.

It's ALWAYS worth trying!! and besides...sometimes s dead horse can be jump-started...

Kim- Top Poster

Posts : 8602

Join date : 2011-09-06

Location : South East Missouri

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

Well no new reed design, but maybe an unusual induction setup... a mylar rectovular(I made that name up) reed in a parts-box Bee. fed with a pressure bladder, breathing through a rear ram air intake. I was worried the intake would float the reed and foul the crankcase vacuum, but other than JPVelo the Contest director, I won the race among the general entrants.

https://youtu.be/bxMBrStGVLY

Rusty

https://youtu.be/bxMBrStGVLY

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

Show off

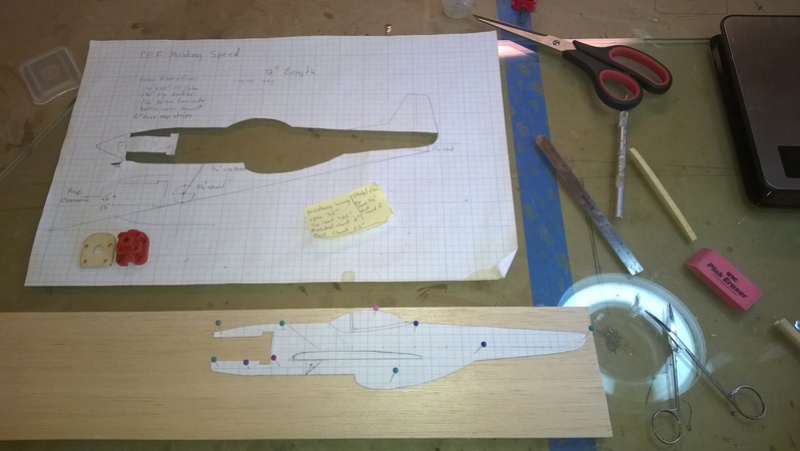

Here are some of the designs from the first Reed Speed 2014 https://www.coxengineforum.com/t7115-cef-speed-contest-design-discussions?highlight=reed+speed+2014 There are some speed plane desigds on the https://outerzone.co.uk/search/results.asp?keyword=racer

Here are some of the designs from the first Reed Speed 2014 https://www.coxengineforum.com/t7115-cef-speed-contest-design-discussions?highlight=reed+speed+2014 There are some speed plane desigds on the https://outerzone.co.uk/search/results.asp?keyword=racer

Here are some of the designs from the first Reed Speed 2014 https://www.coxengineforum.com/t7115-cef-speed-contest-design-discussions?highlight=reed+speed+2014 There are some speed plane desigds on the https://outerzone.co.uk/search/results.asp?keyword=racer

Here are some of the designs from the first Reed Speed 2014 https://www.coxengineforum.com/t7115-cef-speed-contest-design-discussions?highlight=reed+speed+2014 There are some speed plane desigds on the https://outerzone.co.uk/search/results.asp?keyword=racer

getback- Top Poster

Posts : 10326

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

I guess my question was misunderstood.

What I was looking for was... various reed valve designs. I had an Idea for a reed valve and I was curious to see if it was one that had been tried already.

What I was looking for was... various reed valve designs. I had an Idea for a reed valve and I was curious to see if it was one that had been tried already.

SkyStreak- Bronze Member

- Posts : 31

Join date : 2018-02-26

Location : Mo

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

Well i got you now sorry for my misunderstanding , If you got to the search feature in the lf. top of page i searched for MAKE YOUR OWN REEDS , there are a few here is one https://www.coxengineforum.com/t10074-special-reeds?highlight=make+your+own+reeds and https://www.coxengineforum.com/search?search_keywords=make+your+own+reeds You have to weed through some the bull  Bee intrested in seeing what you came up with ?

Bee intrested in seeing what you came up with ?

Bee intrested in seeing what you came up with ?

Bee intrested in seeing what you came up with ?

getback- Top Poster

Posts : 10326

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

Finally got the chance to run my reed valve idea in an engine.

The results were mixed. I gained 1000 RPMs but it doesn't run as consistent. More brainstorming may be required.

The results were mixed. I gained 1000 RPMs but it doesn't run as consistent. More brainstorming may be required.

SkyStreak- Bronze Member

- Posts : 31

Join date : 2018-02-26

Location : Mo

getback- Top Poster

Posts : 10326

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

Pretty vague post. You’ll have to explain your design. Not a whole lot to be done to the original design apart from reed material.

Please explain I am interested.

Ron

Please explain I am interested.

Ron

Cribbs74- Moderator

Posts : 11906

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

Somehow relieved to see that not only I with my non-native English misunderstood this thread ..I thought but was afraid to ask if this is about engines or some speedplanes or similar? I hope to have understood now it is about engines (?)...if still not then I will get myself an elementary English teacher

balogh- Top Poster

Posts : 4852

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

To contribute with some meaningful comments from my side as well here are 2 of my reedy experiences:

1. The Killer Bee red horseshoe backplate comes without the mesh screen and thus is featured with less obstructed airflow than screened intakes. I always add a screen to prevent dirt from entering the engine though and contrary to expectations have not experienced any notable performance drop attributable to the screen.

2. Plywood firewalls for horseshoe backplate reedies tend to sink the backplate after repeated engine mount bolt tightenings into the firewall such that the gap between the air intake and firewall is diminished and the engine is permanently choked. I therefore either countersink the firewall area facing the air intake or drill a hole through the firewall to help the engine breath.

Sorry if the above is obvious instead of a particularly new reed design.

1. The Killer Bee red horseshoe backplate comes without the mesh screen and thus is featured with less obstructed airflow than screened intakes. I always add a screen to prevent dirt from entering the engine though and contrary to expectations have not experienced any notable performance drop attributable to the screen.

2. Plywood firewalls for horseshoe backplate reedies tend to sink the backplate after repeated engine mount bolt tightenings into the firewall such that the gap between the air intake and firewall is diminished and the engine is permanently choked. I therefore either countersink the firewall area facing the air intake or drill a hole through the firewall to help the engine breath.

Sorry if the above is obvious instead of a particularly new reed design.

balogh- Top Poster

Posts : 4852

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

Bernie used to sell a package of different reeds. It had a stainless, Teflon, clear, and a version which appeared to look like the cloth Band-Aid brand bandages.That reed was very very good. However, it didn't typically fit and need a very slight trimming to fit. It yielded rpm's far superior to all of the others. I never found the Teflon reed to offer the claims substantiated with it. I also had it ruin one of my engines when I installed one not aware that two were stuck together. The circlip never seated properly. It came out when running and the circlip actually came out of the side of the case. I found the stainless to work well, however it distorts in short order. The clear Mylar always worked well for daily use offering good rpm's but it distorts with the center sucking into the hole. It can be flipped over and re used unlike the stainless. I like the clear the best because it squeaks like a pet toy when turned over slowly. It enables you to audibly know the reed is working well. The last one I mentioned looks like a weave of some type of fabric but it's stiff. It worked great. Bernie however mentioned that these were made in short supply and he was never compensated for them when they were produced. I have one left and certainly would like more of them. It's a night and day difference between the others. Ken

Ken Cook- Top Poster

- Posts : 5573

Join date : 2012-03-27

Location : pennsylvania

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

Thats Cool , i haven't seen these before , must have came in late . Wonder what the band aid like material is Ken i did a search and came up with PTFE Film witch is Teflon again and that reed was very flimsy and would not stay to shape when used . The Mylar is what i have been using for the best results so far.Bernie used to sell a package of different reeds. It had a stainless, Teflon, clear, and a version which appeared to look like the cloth Band-Aid brand bandages.That reed was very very good. wrote:

getback- Top Poster

Posts : 10326

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

Here's a reed that I just made.. although it's the conventional OEM oval/oblong shape.

The material is some type of plastic that measures .008" thickness and came from when I was doing the computer-recycling. It's a translucent sheet with a silk-screened print on its "matte-finished" side (square pc. on the right).. and glass-smooth on the other side (square pc. on the left). Note the reflection from my lamp. I chose to orient the smooth side rearward against the valve-seat.

I used a short pc. of 7/16" (11.11mm) O.D. alum. tubing to trace-out the approximate reed diameter onto the material. From there; it's just a matter of using scissors to trim the part to the oval/oblong-shape of the OEM-style reed.

The "blow-suck" method of testing revealed my reed to function properly in a Cox .049 "horseshoe" backplate with the cap-style retainer. This reed's thickness being .008"; would likely require the "thinning" of a circlip-style (wire) retainer, so as not to bind.

I still need to test-run.. before we'll know how/if this material will work.

The material is some type of plastic that measures .008" thickness and came from when I was doing the computer-recycling. It's a translucent sheet with a silk-screened print on its "matte-finished" side (square pc. on the right).. and glass-smooth on the other side (square pc. on the left). Note the reflection from my lamp. I chose to orient the smooth side rearward against the valve-seat.

I used a short pc. of 7/16" (11.11mm) O.D. alum. tubing to trace-out the approximate reed diameter onto the material. From there; it's just a matter of using scissors to trim the part to the oval/oblong-shape of the OEM-style reed.

The "blow-suck" method of testing revealed my reed to function properly in a Cox .049 "horseshoe" backplate with the cap-style retainer. This reed's thickness being .008"; would likely require the "thinning" of a circlip-style (wire) retainer, so as not to bind.

I still need to test-run.. before we'll know how/if this material will work.

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

My idea for an improved Cox reed valve (if it can be) involves a different shape. That is why I posted as a sort of Poll. I wanted to hear from others with more background in improving these engines than I. I wanted to hear about there own experimentation and if willing, there successes. I am not a mechanical engineer or machinist. I just have ideas that hopefully, will result in an improvement in performance that has been overlooked.

My current setup: Beige horseshoe back plate, Golden Bee crankcase, #1 cylinder, #325 head w/one shim/gasket, 5 1/2 x4 prop, 10% cool power. I have gained 2500 RPMs so far from the original berkelium star reed. 1500 was with a mylar reed and an additional 1000 when I installed my redesigned reed. I am currently at a peak RPM of 16,000 although it is not as consistent as it was before I put my design in. I get a burble that comes and goes. I'm not sure if it is the reed or I have a leak such as the tired cc gasket. New gaskets are on order. I know many will comment on the 10% fuel and say nitro is too low. I don't have any 20% or 25% on hand but I will try it later when I get some.

My current setup: Beige horseshoe back plate, Golden Bee crankcase, #1 cylinder, #325 head w/one shim/gasket, 5 1/2 x4 prop, 10% cool power. I have gained 2500 RPMs so far from the original berkelium star reed. 1500 was with a mylar reed and an additional 1000 when I installed my redesigned reed. I am currently at a peak RPM of 16,000 although it is not as consistent as it was before I put my design in. I get a burble that comes and goes. I'm not sure if it is the reed or I have a leak such as the tired cc gasket. New gaskets are on order. I know many will comment on the 10% fuel and say nitro is too low. I don't have any 20% or 25% on hand but I will try it later when I get some.

SkyStreak- Bronze Member

- Posts : 31

Join date : 2018-02-26

Location : Mo

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

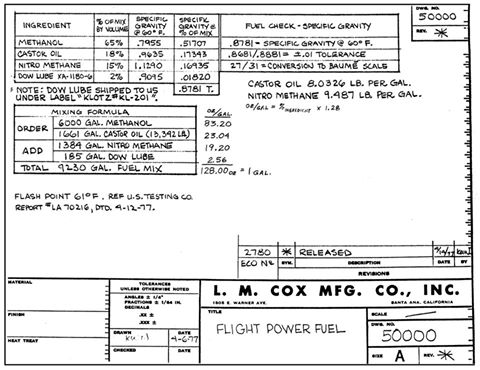

Sky , what percent of castor is in that Cool Power ? You need 20% or you may end up with the engine locking up form heat / lack of lubrication. 18-20 is good with 3% synthetic oil to keep the varnishing down . You can get 35% from tower hobbies Cox New Blend and Sig has it in 35% /25 and so on .

getback- Top Poster

Posts : 10326

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

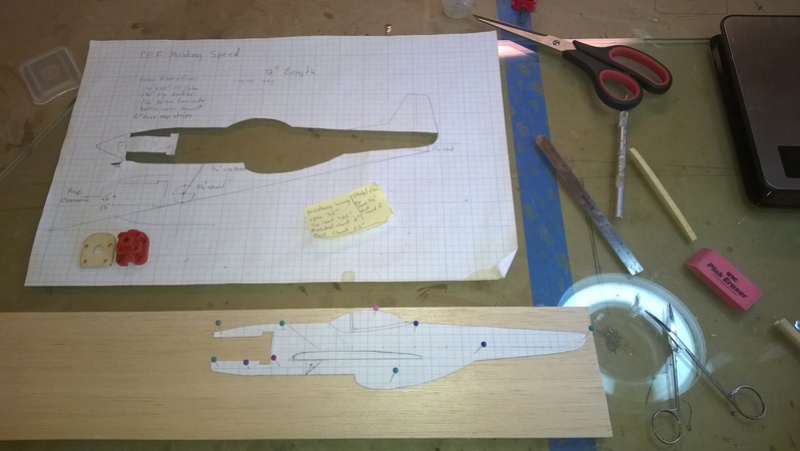

getback wrote:Sky , what percent of castor is in that Cool Power ? You need 20% or you may end up with the engine locking up form heat / lack of lubrication. 18-20 is good with 3% synthetic oil to keep the varnishing down . You can get 35% from tower hobbies Cox New Blend and Sig has it in 35% /25 and so on .

YES.. ditto.. The ball-socket conn-rod to piston joint (in particular..) was designed around a glow-fuel containing castor-oil. Synthetic (especially "full-synthetic"..) will burn-off.. prior to lubricating this "sensitive" area of the Cox engine. Some modelers may dispute this.. but most hard-core Cox-engine owners will swear-by a fuel that closely replicates the original Cox formula(s)..

Inquire with regard to the "oil-package" of the blend you intend to purchase.. with the above referenced specs. as a guide.

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

Where is the actual "Poll" in this thread?

I think it would take a few images to illustrate what you are after. The most efficient shape might be the one they used on the Thermal hopper, but I'm guessing it was too expensive to manufacture in the long run...

I think it would take a few images to illustrate what you are after. The most efficient shape might be the one they used on the Thermal hopper, but I'm guessing it was too expensive to manufacture in the long run...

Surfer_kris- Diamond Member

- Posts : 1909

Join date : 2010-11-20

Location : Sweden

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

Surfer_kris wrote:Where is the actual "Poll" in this thread?

I think it would take a few images to illustrate what you are after. The most efficient shape might be the one they used on the Thermal hopper, but I'm guessing it was too expensive to manufacture in the long run...

Different-shaped reeds seems like an interesting concept.. but I honestly don't feel that the "shape" will affect performance in this engine-design. The "material" however; I think might affect performance to a higher degree. "Reed-float" happens at a certain point. Maybe it's at a certain RPM.. or at a certain "harmonic". Do we really know? Maybe a certain material/thickness will have optimum flex-characteristics to further optimize ignition-timing.

coxaddict- Gold Member

- Posts : 429

Join date : 2013-01-27

Location : north shore oahu, Hawaii

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

roddie wrote:

Different-shaped reeds seems like an interesting concept.. but I honestly don't feel that the "shape" will affect performance in this engine-design.

I don't know really, I just feel that the reed acts as a large restriction if you try to following the path for the airflow. One tuning "trick" is to make sure that the spring-clip is far away from the reed center, so that the reed can open properly.

In larger engines the reeds have a different angle to the flowing air, it is not perpendicular like it is in our cox engines. Instead the reeds are angle in the direction of the airflow and presumably these are much less restrictive. Here is an example (from DLE):

Surfer_kris- Diamond Member

- Posts : 1909

Join date : 2010-11-20

Location : Sweden

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

They certainly appear to be the reeds I was describing. They worked very well for me in terms of performance. I can't comment on longevity. I use it only for racing purposes and I fly it once a year .Ken

Ken Cook- Top Poster

- Posts : 5573

Join date : 2012-03-27

Location : pennsylvania

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

I also have a few of those reeds I bought from Bernie a while ago, but because of their apparently rough surface I thought they would not seal well so I put them aside...now I will try. I wonder what may make them superior to mylar, teflon, stainless steel and the star berillium reeds? Maybe the raw surface helps atomize the fuel droplets better than the smooth surface of the others?

balogh- Top Poster

Posts : 4852

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

.

Last edited by Mudhen on Tue Nov 16, 2021 1:40 pm; edited 1 time in total

Mudhen- Gold Member

- Posts : 489

Join date : 2011-09-19

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

Mudhen wrote:

Although not reed related, it is a modification to improve the engine.

For the 2011 Tach Race I had a groove machined into the carburetor body that allowed for the installation of an O-ring. This fully eliminated the need for a crankcase gasket and ensured the back plate was sealed to the crankcase. It is difficult to note any improved performance because individual modifications have to be tested individually. Nevertheless, to guarantee a seal eliminates a potential problem area. Further one does not have to ‘level,’ or ‘shave’ the back of the crankcase, because the gasket is not required. I don’t remember the dimensions of the groove, but is was set to fit a “Factory Team, TC3/NTC3 Threaded Shock Collar O-Ring.”

Sorry for the Hijack.

P.S. I'm not sure why it looks warped, but it isn't.

Very neat idea. Thanks for posting that.

NEW222- Top Poster

- Posts : 3895

Join date : 2011-08-13

Age : 45

Location : oakbank, mb

Page 1 of 2 • 1, 2

Similar topics

Similar topics» New Cox Reed Design

» Reed Speed--Best Model Poll

» Reed Function and Design

» Pee Wee .020 Reed Valve

» Reed Valve

» Reed Speed--Best Model Poll

» Reed Function and Design

» Pee Wee .020 Reed Valve

» Reed Valve

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules