Log in

Search

Latest topics

» Dodge Viper - What a waste but brilliant marketingby roddie Today at 6:46 pm

» COX .020 POWERED SPEEDSTER

by TD ABUSER Today at 6:32 pm

» **VOTE-ON-THE-NEXT-COX-ENGINE-OF-THE-MONTH** (November 2024)

by roddie Today at 6:13 pm

» Brushless motors?

by rsv1cox Today at 4:53 pm

» Free Flight Radio Assist

by rdw777 Today at 4:28 pm

» Cox 020 PeeWee rebuild questions

by balogh Today at 4:15 pm

» L4 Grasshopper

by latole Today at 3:43 pm

» PAW 80 and possible use

by fit90 Today at 8:36 am

» Music-wire bending tools (DIY video)

by 1975 control line guy Today at 8:32 am

» Ultrasonic Cleaners??

by sosam117 Yesterday at 11:26 am

» My CA or CyA (super glue) allergy

by rsv1cox Yesterday at 9:52 am

» My Pseudo killerbee.

by rsv1cox Yesterday at 7:04 am

Balsa Fuel Tank?

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

edited post

edited post

Levent Suberk wrote:Very interesting idea Rod, thanks for this. If I add more than 50% alcohol with 24 hr epoxy, does it fully cure or stay rubbery? I experimented that 50% alcohol thinned 24 hr epoxy fully cured after a week. For full coating inside of tank it need to be near water consistency, at least glycerine like, so I think that I need to add alcohol more than 50%. What is your opinion?

Good points sir. As I stated; my idea isn't a proven one. You could mix small amounts for flow at a given temperature.. to get an idea of if and how it will coat the inner tank walls. Keep in mind though; that the cured epoxy need only be a fuel-proof membrane.. and not so much a structural component.

I'm thinking that an air pump would be "key".. to have running throughout the curing process. A heated air-intake box for the pump could lessen the cure-time.

You could coat the exterior of the tank with thinned epoxy if you wanted.. but thin CA would penetrate and strengthen the balsa with less weight than epoxy.

Re: Balsa Fuel Tank?

Re: Balsa Fuel Tank?

A very good engineering idea

Levent Suberk- Diamond Member

- Posts : 2257

Join date : 2017-12-24

Location : Türkiye

Re: Balsa Fuel Tank?

Re: Balsa Fuel Tank?

There are high penetrating epoxy resins available, but I've not seen them sold in reasonably small quantities (most usually available from marine related manufacturers) and they are expensive. Secondly, I would not be inclined to add a solvent since a solvent may render the epoxy brittle.

My inclination would be to mix a batch of 30 minute epoxy, apply a coat to all interior surfaces of the tank, then use a heat gun to warm and thin the epoxy to allow it to soak into the wood. I've done this routinely over the years to fuel proof firewalls and tank compartments. When warmed, you can see the epoxy being drawn into the underlying wood or plywood. The 30 minute resin will remain workable for a longer time even when heated. When cured, you will have to clean the surface to remove any amine blush that may have built up before applying a second application, if needed. Sometimes, the first application will soak in so well that it will leave pinholes and will need another coat.

Once you're satisfied that the interior walls are well fuel proofed, then clean the surfaces well and epoxy the tank together, making sure that each joint has a small fillet of resin.

My inclination would be to mix a batch of 30 minute epoxy, apply a coat to all interior surfaces of the tank, then use a heat gun to warm and thin the epoxy to allow it to soak into the wood. I've done this routinely over the years to fuel proof firewalls and tank compartments. When warmed, you can see the epoxy being drawn into the underlying wood or plywood. The 30 minute resin will remain workable for a longer time even when heated. When cured, you will have to clean the surface to remove any amine blush that may have built up before applying a second application, if needed. Sometimes, the first application will soak in so well that it will leave pinholes and will need another coat.

Once you're satisfied that the interior walls are well fuel proofed, then clean the surfaces well and epoxy the tank together, making sure that each joint has a small fillet of resin.

Re: Balsa Fuel Tank?

Re: Balsa Fuel Tank?

Hi Levent! Lots of interesting ideas! I liked what Andrew had to add.. about the balsa absorbing the epoxy through heat.. and possibly needing a 2nd coat. That would make for strong panels that are impervious to glow-fuel (up-to a certain percentage of Nitro).

Will you be testing/fueling your tank Levent? Maybe bench-run an engine?

Will you be testing/fueling your tank Levent? Maybe bench-run an engine?

Re: Balsa Fuel Tank?

Re: Balsa Fuel Tank?

Hi Rod, yes I appreciate Andrew's comment. I am going to apply third coat of thinned epoxy on inside. I'll also brush epoxy on outer surfaces three times, last coat will be metal epoxy. I'll smear metal epoxy coat like as a putty.

Yes, I am going to fill it with raw fuel and test it for a month. I also want to try it with a running engine to test against exhaust gases, but how many times I need to test it I don't know. One or two runs is enough to test the tank?

Yes, I am going to fill it with raw fuel and test it for a month. I also want to try it with a running engine to test against exhaust gases, but how many times I need to test it I don't know. One or two runs is enough to test the tank?

Levent Suberk- Diamond Member

- Posts : 2257

Join date : 2017-12-24

Location : Türkiye

Re: Balsa Fuel Tank?

Re: Balsa Fuel Tank?

I forgot to ask: Does epoxy affect by nitromethane or methanol? Or both?

Levent Suberk- Diamond Member

- Posts : 2257

Join date : 2017-12-24

Location : Türkiye

Re: Balsa Fuel Tank?

Re: Balsa Fuel Tank?

Levent Suberk wrote:Hi Rod, yes I appreciate Andrew's comment. I am going to apply third coat of thinned epoxy on inside. I'll also brush epoxy on outer surfaces three times, last coat will be metal epoxy. I'll smear metal epoxy coat like as a putty.

Yes, I am going to fill it with raw fuel and test it for a month. I also want to try it with a running engine to test against exhaust gases, but how many times I need to test it I don't know. One or two runs is enough to test the tank?

EDIT: not sure.. but I would say that higher-nitro would be the cause of any eroding tank-innards.. rather than the Methanol.

I don't know a method for testing your tank's construction against breakdown from glow-fuel. You mentioned using AL tubes to plumb the tank. I don't know how they'd react to your glow-fuel mix. I prefer Copper tubing. The automotive parts-stores sell coils of 1/8"-3mm Copper tubing for connection to oil-pres. gauges.. etc. Expensive.. but worth the $$ if you get into building tin-plate hard-tanks!!!

Re: Balsa Fuel Tank?

Re: Balsa Fuel Tank?

I wish I could offer comments about fuel resistance in tanks, but my experience has been limited to firewalls and tank compartments. These are areas that I usually would wipe down at the end of a flying session, consequently, they were not subject to long term immersion. I would think that evacuating the tank with a syringe as much as possible, then using a high volume syringe to blow air into the tank to help evaporate the methanol and nitro before putting the plane away might extend the tank life. I do this even with plastic tanks.

Vinyl ester resins are touted to be gasoline/ethanol proof, but are pricey, smelly and usually fairly thick. These resins are catalyzed with MEKP (nasty) at very small percentages which would make mixing a small batch difficult. Polyester resins (we sometimes call them laminating resin) would be totally unsuitable.

I believe Levent's approach of saturating the wood and finishing with a surface coat is about the best any of us could do. The only other method would be to construct a tank from .5 oz fiberglass cloth, but this would likely be much more difficult than building one from brass or tin sheet.

Vinyl ester resins are touted to be gasoline/ethanol proof, but are pricey, smelly and usually fairly thick. These resins are catalyzed with MEKP (nasty) at very small percentages which would make mixing a small batch difficult. Polyester resins (we sometimes call them laminating resin) would be totally unsuitable.

I believe Levent's approach of saturating the wood and finishing with a surface coat is about the best any of us could do. The only other method would be to construct a tank from .5 oz fiberglass cloth, but this would likely be much more difficult than building one from brass or tin sheet.

Re: Balsa Fuel Tank?

Re: Balsa Fuel Tank?

Thanks Andrew for fuel tank tips.

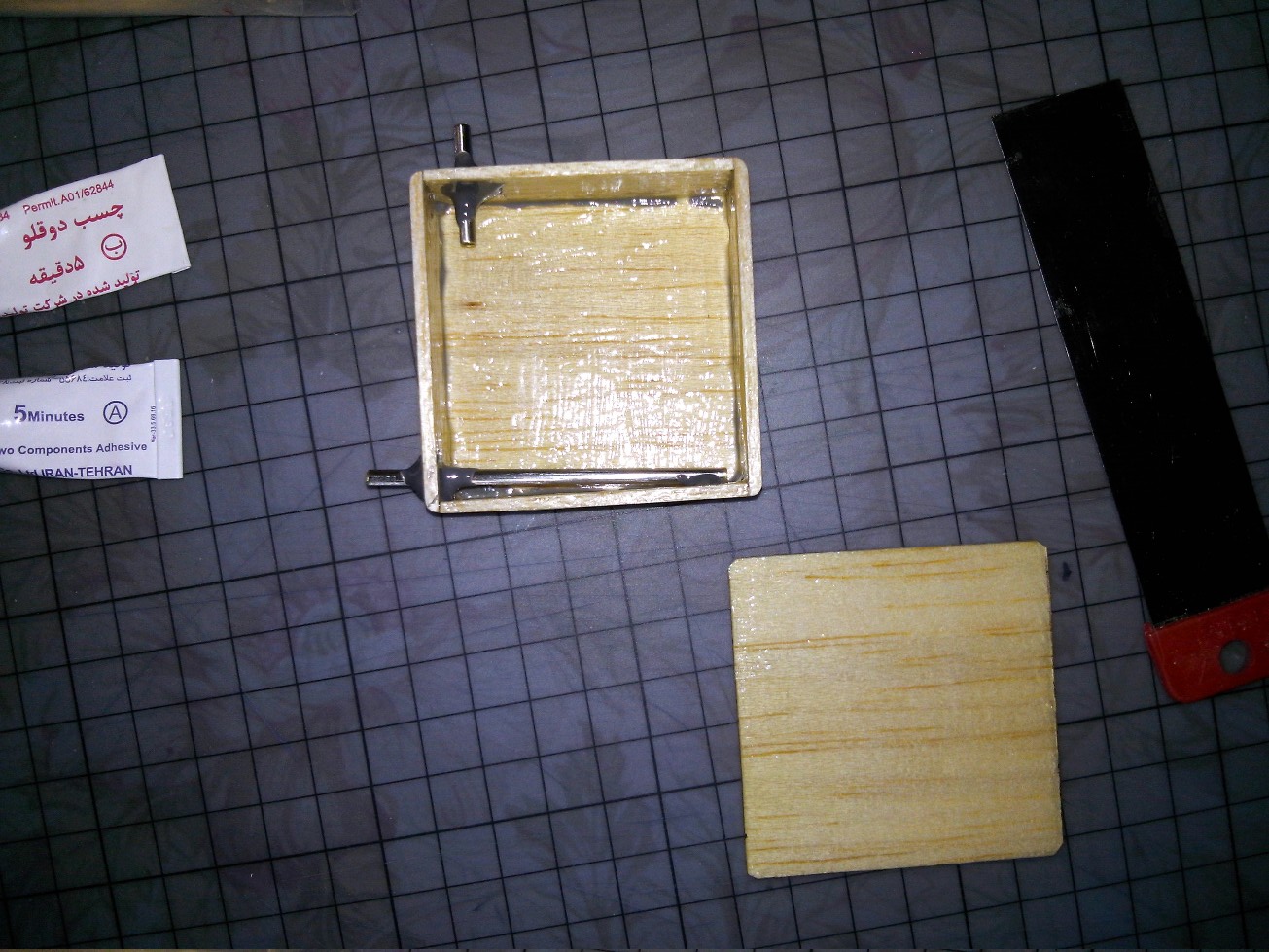

Thinned 24 hr epoxy need time to cure. Waiting coats to dry. I am going to apply third thinned coat to inside of fuel tank and install fuel tubings at tomorrow.

Thinned 24 hr epoxy need time to cure. Waiting coats to dry. I am going to apply third thinned coat to inside of fuel tank and install fuel tubings at tomorrow.

Levent Suberk- Diamond Member

- Posts : 2257

Join date : 2017-12-24

Location : Türkiye

Re: Balsa Fuel Tank?

Re: Balsa Fuel Tank?

My planned progress is:

1- All parts covered and vacuumed with 24 hr thinned epoxy

2- Parts assembled to form a box

3- Inside of fuel tank box brushed with 24 hr thinned epoxy

4- 3 repeated

5- Metal tubings installed with 5 min metal epoxy and cover glued on box with 5 min metal epoxy

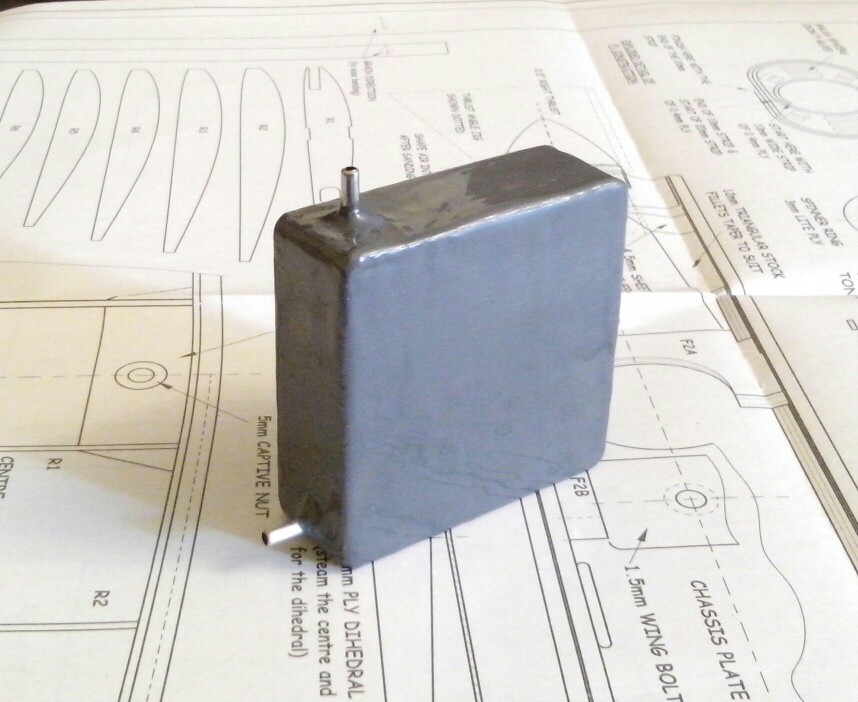

6- 24 hr thinned epoxy applied on outside of completed box

7- 6 repeated

8- Thinned metal epoxy brushed on outside of box

1- All parts covered and vacuumed with 24 hr thinned epoxy

2- Parts assembled to form a box

3- Inside of fuel tank box brushed with 24 hr thinned epoxy

4- 3 repeated

5- Metal tubings installed with 5 min metal epoxy and cover glued on box with 5 min metal epoxy

6- 24 hr thinned epoxy applied on outside of completed box

7- 6 repeated

8- Thinned metal epoxy brushed on outside of box

Last edited by Levent Suberk on Sat Dec 12, 2020 5:15 am; edited 3 times in total

Levent Suberk- Diamond Member

- Posts : 2257

Join date : 2017-12-24

Location : Türkiye

Re: Balsa Fuel Tank?

Re: Balsa Fuel Tank?

Looks good Levent ,, i think if there is a weak spot it will bee the epoxy joint .

getback- Top Poster

Posts : 10415

Join date : 2013-01-18

Age : 67

Location : julian , NC

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Balsa Fuel Tank?

Re: Balsa Fuel Tank?

Nice Levent. "Proof of concept" or it will be as soon as you fuel it up and see how it stands up.

Think of the possibilities. wedge tanks, rectangular, square......sizes and shapes adapted to fit a particular model. Balsa easier to work with than tin and solder. But I was thinking, couldn't you achieve the same results by simply air brushing on several coats of two part epoxy paint before, during, and after assembly eliminating a whole lot of work and time? I used that approach on one of my scratch built models and fuel hot or cold never bothered it.

Ah, found the picture I was looking for. Recent picture, plane at least 30 years old multiple flights, Epoxy paint.

Think of the possibilities. wedge tanks, rectangular, square......sizes and shapes adapted to fit a particular model. Balsa easier to work with than tin and solder. But I was thinking, couldn't you achieve the same results by simply air brushing on several coats of two part epoxy paint before, during, and after assembly eliminating a whole lot of work and time? I used that approach on one of my scratch built models and fuel hot or cold never bothered it.

Ah, found the picture I was looking for. Recent picture, plane at least 30 years old multiple flights, Epoxy paint.

rsv1cox- Top Poster

Posts : 11207

Join date : 2014-08-18

Location : West Virginia

Re: Balsa Fuel Tank?

Re: Balsa Fuel Tank?

Thanks.  You are right about using epoxy paint, however I can't find epoxy paint in small quantities.

You are right about using epoxy paint, however I can't find epoxy paint in small quantities.

I am going to try it with Morgan Fuel Sidewinder Race %15 nitro raw fuel.

I am going to try it with Morgan Fuel Sidewinder Race %15 nitro raw fuel.

Levent Suberk- Diamond Member

- Posts : 2257

Join date : 2017-12-24

Location : Türkiye

Re: Balsa Fuel Tank?

Re: Balsa Fuel Tank?

Nice !! Hope it holds up ,, yes the concept of building a tank to fit or of certain size is really cool !!

getback- Top Poster

Posts : 10415

Join date : 2013-01-18

Age : 67

Location : julian , NC

Page 2 of 2 •  1, 2

1, 2

Similar topics

Similar topics» A PVC fuel tank?

» "Flying Blind" a build-thread for CEF 2018 Speed

» Fuel tank cap

» fuel tank ?

» WTB: RR-1 Fuel Tank

» "Flying Blind" a build-thread for CEF 2018 Speed

» Fuel tank cap

» fuel tank ?

» WTB: RR-1 Fuel Tank

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules