Log in

Search

Latest topics

» Roddie-Rigger.. a 2005 original designby roddie Today at 2:54 am

» Golden Bee basic running problem

by roddie Yesterday at 10:51 pm

» Simple Gliders

by rdw777 Yesterday at 6:25 pm

» Foam hand kids glider converted to 0.049 CL

by rdw777 Yesterday at 6:11 pm

» Weird search for a single comic from an old Mad Magazine

by Kim Yesterday at 1:44 pm

» Scientific "Zipper" Build...Zipper Flys!.

by getback Yesterday at 7:27 am

» Cox .049 Tee Dee engines back in stock (limited availablility)

by GallopingGhostler Yesterday at 1:05 am

» Very off-topic.........Time passes and not always for the best......

by rsv1cox Thu Jul 25, 2024 2:47 pm

» Jim Walker Bonanza etc.

by rsv1cox Wed Jul 24, 2024 6:30 pm

» Throttles for Cox Tee Dee .049 / .020 / .010 engines --- videos

by sosam117 Wed Jul 24, 2024 8:54 am

» Introducing our Cox .049 TD Engines

by Admin Tue Jul 23, 2024 2:00 am

» Project Cox .049 r/c & Citabrian Champion

by getback Mon Jul 22, 2024 4:14 pm

Cox Engine of The Month

July-2024

robot797's

"ULTIMITE COX 010: it has a clutch, E starter, throttle, exhaust, aluminum tank, aluminum venturi, gearbox with forward and reverse, and now its on a custom drawn and printed stand"

PAST WINNERS

robot797's

"ULTIMITE COX 010: it has a clutch, E starter, throttle, exhaust, aluminum tank, aluminum venturi, gearbox with forward and reverse, and now its on a custom drawn and printed stand"

PAST WINNERS

3D printed R/C Pee Wee backplate

Page 1 of 1

3D printed R/C Pee Wee backplate

3D printed R/C Pee Wee backplate

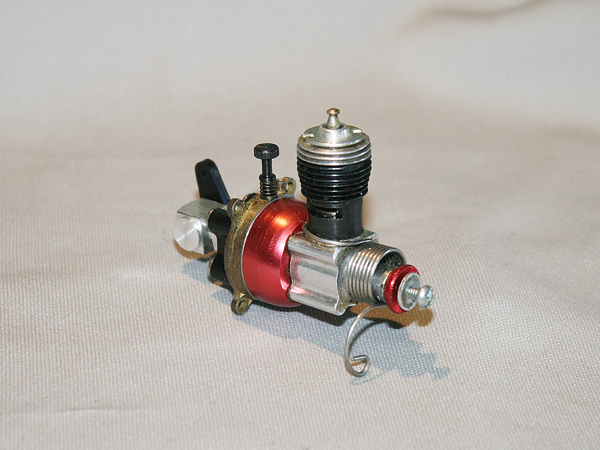

Seems like there is a huge infatuation with R/C Pee Wee engines and the like lately.

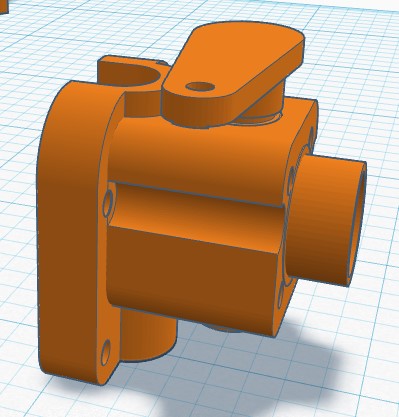

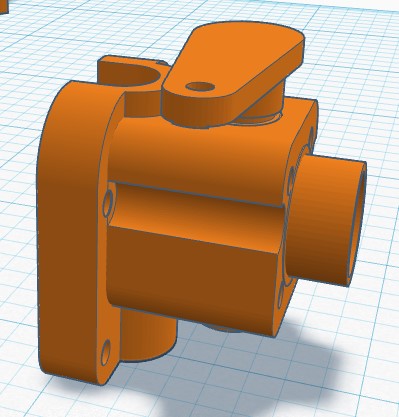

Here's my attempt to create an R/C Pee Wee engine with a modified version of the 3D printed backplate. I stretched the body of the backplate by .25" to make room for a throttle body. It will use C clips to secure it in place and o-rings to seal and prevent leaks. It should be able to kill the engine when fully closed. I have parts on order from McMaster Carr and will print a few to try out. I need to order a support filament that can handle nylon and will use my dual extruder printer to print these. The throttle body gets pretty thin at the o-ring area. Hopefully the carbon fiber Zytel is strong enough for this. No guarantees. It might end up in moth balls like the 3D printed all bearing crankcase TD.....

Here's my attempt to create an R/C Pee Wee engine with a modified version of the 3D printed backplate. I stretched the body of the backplate by .25" to make room for a throttle body. It will use C clips to secure it in place and o-rings to seal and prevent leaks. It should be able to kill the engine when fully closed. I have parts on order from McMaster Carr and will print a few to try out. I need to order a support filament that can handle nylon and will use my dual extruder printer to print these. The throttle body gets pretty thin at the o-ring area. Hopefully the carbon fiber Zytel is strong enough for this. No guarantees. It might end up in moth balls like the 3D printed all bearing crankcase TD.....

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: 3D printed R/C Pee Wee backplate

Re: 3D printed R/C Pee Wee backplate

if it is for a cox 049 i could try to print it on my sla printer

robot797- Platinum Member

- Posts : 765

Join date : 2013-07-28

Age : 33

Cribbs74- Moderator

Posts : 11904

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: 3D printed R/C Pee Wee backplate

Re: 3D printed R/C Pee Wee backplate

Looks amazing. The detail into the design is nothing short of amazing. Wish you luck on the printing and that it works out good for you.

NEW222- Top Poster

- Posts : 3895

Join date : 2011-08-13

Age : 45

Location : oakbank, mb

Re: 3D printed R/C Pee Wee backplate

Re: 3D printed R/C Pee Wee backplate

Jason y like the new desing it was Good To place bafle in befor the neadle valve just for informations the prototype tee dee wit bearing 3d print wy Not use the model for casting one made of aluminium wit sand mold ??? Y want To try To build one made of aluminium is it posible like the cox sing on parts u made very Good looking engine

davidll1984- Diamond Member

- Posts : 2303

Join date : 2020-02-12

Age : 39

Location : shawinigan

sosam117- Diamond Member

- Posts : 1310

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: 3D printed R/C Pee Wee backplate

Re: 3D printed R/C Pee Wee backplate

AHHHH! !

I look at those 3d CAD renderings of the Backplate and throttle barrel and get shivers up my spine thinking how long and difficult it would have been to produce those types of drawings back in High School Drafting #1 & #3 pencil on Velum paper, Hey Roddy, Can I borrow your French Curve? anybody got a protractor?

AAHHH ! again I'll need an eraser too.

I still get complemented on my hand writing when I take the time to print like was taught way back then.

I'm jealous of you guys who brought yourselves up into the 21st Century learning CAD and 3D Printing ! !

Hey Jason, If you go into production......I would order a couple just for fun! !

I look at those 3d CAD renderings of the Backplate and throttle barrel and get shivers up my spine thinking how long and difficult it would have been to produce those types of drawings back in High School Drafting #1 & #3 pencil on Velum paper, Hey Roddy, Can I borrow your French Curve? anybody got a protractor?

AAHHH ! again I'll need an eraser too.

I still get complemented on my hand writing when I take the time to print like was taught way back then.

I'm jealous of you guys who brought yourselves up into the 21st Century learning CAD and 3D Printing ! !

Hey Jason, If you go into production......I would order a couple just for fun! !

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 71

Location : Grand Rapids, MI

Re: 3D printed R/C Pee Wee backplate

Re: 3D printed R/C Pee Wee backplate

How you supposed to mount the engine ? .... Big hole in firewall with no strength left?...or long spacers that will surely vibrate loose?

OhBee- Platinum Member

- Posts : 698

Join date : 2016-03-23

Age : 73

Location : Minnesota

Re: 3D printed R/C Pee Wee backplate

Re: 3D printed R/C Pee Wee backplate

OhBee wrote:How you supposed to mount the engine ? .... Big hole in firewall with no strength left?...or long spacers that will surely vibrate loose?

From what I can see, they should mount normally, just the same as any horseshoe backplate. It should just mount flush. Air can draw in around the needle valve and fuel line like any similar backplate.

Oldenginerod- Top Poster

- Posts : 3985

Join date : 2012-06-15

Age : 61

Location : Drouin, Victoria

Re: 3D printed R/C Pee Wee backplate

Re: 3D printed R/C Pee Wee backplate

I think he means jasons versionOldenginerod wrote:OhBee wrote:How you supposed to mount the engine ? .... Big hole in firewall with no strength left?...or long spacers that will surely vibrate loose?

From what I can see, they should mount normally, just the same as any horseshoe backplate. It should just mount flush. Air can draw in around the needle valve and fuel line like any similar backplate.

robot797- Platinum Member

- Posts : 765

Join date : 2013-07-28

Age : 33

Similar topics

Similar topics» 3D printed PeeWee .020 tank backplate

» 3D printed beam mount .049 backplate

» 3D Printed Cox Babe Bee

» Cox .020 Skycopter fuel tank replacement

» 3D Printed .020 muffler

» 3D printed beam mount .049 backplate

» 3D Printed Cox Babe Bee

» Cox .020 Skycopter fuel tank replacement

» 3D Printed .020 muffler

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules