Log in

Search

Latest topics

» Golden Bee basic running problemby roddie Yesterday at 10:51 pm

» Simple Gliders

by rdw777 Yesterday at 6:25 pm

» Foam hand kids glider converted to 0.049 CL

by rdw777 Yesterday at 6:11 pm

» Weird search for a single comic from an old Mad Magazine

by Kim Yesterday at 1:44 pm

» Scientific "Zipper" Build...Zipper Flys!.

by getback Yesterday at 7:27 am

» Cox .049 Tee Dee engines back in stock (limited availablility)

by GallopingGhostler Yesterday at 1:05 am

» Very off-topic.........Time passes and not always for the best......

by rsv1cox Thu Jul 25, 2024 2:47 pm

» Roddie-Rigger.. a 2005 original design

by roddie Wed Jul 24, 2024 11:48 pm

» Jim Walker Bonanza etc.

by rsv1cox Wed Jul 24, 2024 6:30 pm

» Throttles for Cox Tee Dee .049 / .020 / .010 engines --- videos

by sosam117 Wed Jul 24, 2024 8:54 am

» Introducing our Cox .049 TD Engines

by Admin Tue Jul 23, 2024 2:00 am

» Project Cox .049 r/c & Citabrian Champion

by getback Mon Jul 22, 2024 4:14 pm

Cox Engine of The Month

July-2024

robot797's

"ULTIMITE COX 010: it has a clutch, E starter, throttle, exhaust, aluminum tank, aluminum venturi, gearbox with forward and reverse, and now its on a custom drawn and printed stand"

PAST WINNERS

robot797's

"ULTIMITE COX 010: it has a clutch, E starter, throttle, exhaust, aluminum tank, aluminum venturi, gearbox with forward and reverse, and now its on a custom drawn and printed stand"

PAST WINNERS

Tuning option

Page 1 of 1

coxaddict- Gold Member

- Posts : 429

Join date : 2013-01-27

Location : north shore oahu, Hawaii

coxaddict- Gold Member

- Posts : 429

Join date : 2013-01-27

Location : north shore oahu, Hawaii

Re: Tuning option

Re: Tuning option

Great eyes! That is cool that you found a perfect fit around. Can you mic the thickness too? I'd like to know how much compression is lost by lifting the glow plug/cylinder.

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2000

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: Tuning option

Re: Tuning option

Wow yes Nice Find

davidll1984- Diamond Member

- Posts : 2303

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Tuning option

Re: Tuning option

Yes, it’s good however, when you eliminate SPI on an SPI cylinder you are also altering deck height which can be detrimental to performance.

Optimal performance/timing/compression is achieved when the the piston is allowed to travel to exactly TDC. You may be able to play with heads and shimming to restore the loss of compression however, the timing can’t be corrected.

Depending on how you plan on using the engine it may not even matter.

Ron

Optimal performance/timing/compression is achieved when the the piston is allowed to travel to exactly TDC. You may be able to play with heads and shimming to restore the loss of compression however, the timing can’t be corrected.

Depending on how you plan on using the engine it may not even matter.

Ron

Cribbs74- Moderator

Posts : 11904

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Tuning option

Re: Tuning option

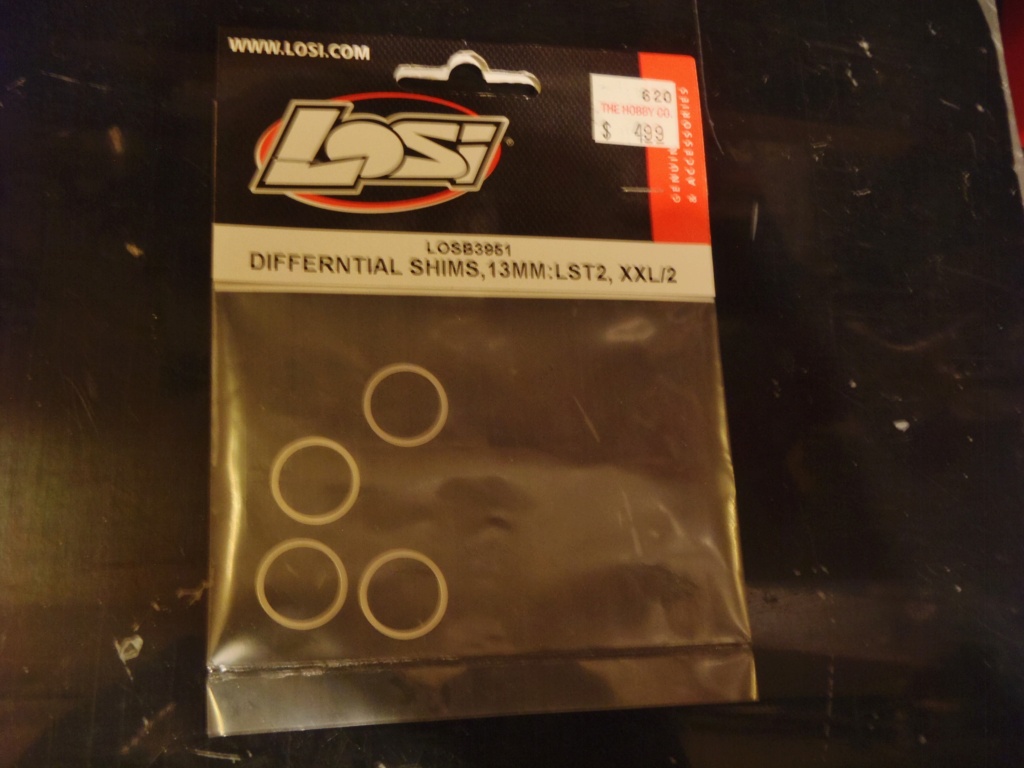

Yes the shims are about .005", or about .14 mm.

I'm learning a lot from members of this forum. My previous experience with control line was never about speed. Now i'm eager to learn about getting more speed from these little gems from Roy Cox. Never knew about SPI and how it affects running with a muffler. I want to try running a muffler on a Tee Dee .049 using the number 4 cylinder. These shims will help me do that. Since shimming the cylinder up lowers compression, maybe 60% nitro could be safely used.

I'm learning a lot from members of this forum. My previous experience with control line was never about speed. Now i'm eager to learn about getting more speed from these little gems from Roy Cox. Never knew about SPI and how it affects running with a muffler. I want to try running a muffler on a Tee Dee .049 using the number 4 cylinder. These shims will help me do that. Since shimming the cylinder up lowers compression, maybe 60% nitro could be safely used.

coxaddict- Gold Member

- Posts : 429

Join date : 2013-01-27

Location : north shore oahu, Hawaii

Re: Tuning option

Re: Tuning option

Using high nitro was never a problem in any Cox engine. My standard Cox fuel is 45% nitro. When I run TD's my standard fuel for them is about 67% nitro. My son makes the fuel for me. There's nothing crazy about using it. They start easier, needle terrific and work better. While most use 25%-35% nitro fuels, you really start seeing a difference at 50% nitro. The plug takes a beating if your not shimmed properly. The only problems I've had is the cranks on TD's cracking at the cutout in the shaft. Funny thing is the two I had that broke never separated, and the engine was still running with the broken shaft.

Ken Cook- Top Poster

- Posts : 5542

Join date : 2012-03-27

Location : pennsylvania

Re: Tuning option

Re: Tuning option

I have some cylinder-shims somewhere. I'd thought about using some for the option of "indexing" the exhaust-port(s) position up to 90 degrees from its non-shimmed position, to possibly eliminate a hot-spot. Running a cylinder "open-face" with an exhaust that's facing the needle-adjust gets hot on the fingers.

I just now did some investigating of my own (on a Cox Bee engine) and found that when using a snug-fit ball-socket jointed piston/rod; that 1/4 turn (90 radial degrees) loosened-from tight.. (no shims) of my #2 cylinder w/SPI....... closes the SPI gap by approx 25%. One "half-turn" back from tight appears to close the SPI gap by 50%. One full-turn appears to close the gap completely.

What I "don't know" (yet..) is how much a given-thickness/cylinder-shim will affect the above discovery? I'll need to find my shims to measure them.

I'll need to find my shims to measure them.

The "brain-damaged" Roddie...

I just now did some investigating of my own (on a Cox Bee engine) and found that when using a snug-fit ball-socket jointed piston/rod; that 1/4 turn (90 radial degrees) loosened-from tight.. (no shims) of my #2 cylinder w/SPI....... closes the SPI gap by approx 25%. One "half-turn" back from tight appears to close the SPI gap by 50%. One full-turn appears to close the gap completely.

What I "don't know" (yet..) is how much a given-thickness/cylinder-shim will affect the above discovery?

I'll need to find my shims to measure them.

I'll need to find my shims to measure them. The "brain-damaged" Roddie...

Re: Tuning option

Re: Tuning option

The thread is 40TPI, .025" per rev. Shimming the cylinder will change the clocking accordingly. Generally, you would remove as much head shim as you add cylinder shim. If using low compression head, this means you may have to change to high compression head to get the compression where you want it.

gkamysz- Gold Member

- Posts : 390

Join date : 2018-02-22

Location : Chicagoland

Re: Tuning option

Re: Tuning option

Greg typed faster than me, so as he says. it is a simple calculation. There are 40 threads per inch on the case/cylinder thread. That is .025". A half turn would be .0125" shim. I think that would pretty much get rid of the SPI on an average motor. To line up a cylinder 90 degrees, would need an .0063" shim. Now if someone was to shim up, say, .015", then there would not be much compression even with no shim/gasket. We used to face off or sand off a bit of the face of the head to get the compression back. Often the cylinder ring would interfere and need to be removed as well. I suppose a permanent fix would be to remove an amount of material from the bottom step of the cylinder where the head screws on. Then a similar amount should be removed from the top ring on the cylinder so the plug can bottom out properly. Of course a lathe would be needed as well as a good magnifying glass. Overall the bypass timing would be higher which may give more power at a higher rpm. Of course the ball socket may not take the abuse. It might be a simple way to test out for pipe timing. That is usually about 180 degrees total exhaust opening.

aspeed- Platinum Member

- Posts : 790

Join date : 2013-01-18

Location : Leamington Ont. Can.

Similar topics

Similar topics» .049 tuning

» Another option for you bladder users

» Bladder clip option

» Hi, please need help to identifiy a "supposed to be" COX Black Widow...

» 049 Black Widow tuning

» Another option for you bladder users

» Bladder clip option

» Hi, please need help to identifiy a "supposed to be" COX Black Widow...

» 049 Black Widow tuning

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules