Log in

Search

Latest topics

» **VOTE-ON-THE-NEXT-COX-ENGINE-OF-THE-MONTH** (November 2024)by MauricioB Today at 8:37 pm

» Cox 020 PeeWee rebuild questions

by roddie Today at 8:21 pm

» Dodge Viper - What a waste but brilliant marketing

by roddie Today at 6:46 pm

» COX .020 POWERED SPEEDSTER

by TD ABUSER Today at 6:32 pm

» Brushless motors?

by rsv1cox Today at 4:53 pm

» Free Flight Radio Assist

by rdw777 Today at 4:28 pm

» L4 Grasshopper

by latole Today at 3:43 pm

» PAW 80 and possible use

by fit90 Today at 8:36 am

» Music-wire bending tools (DIY video)

by 1975 control line guy Today at 8:32 am

» Ultrasonic Cleaners??

by sosam117 Yesterday at 11:26 am

» My CA or CyA (super glue) allergy

by rsv1cox Yesterday at 9:52 am

» My Pseudo killerbee.

by rsv1cox Yesterday at 7:04 am

Another option for you bladder users

Page 1 of 1

Another option for you bladder users

Another option for you bladder users

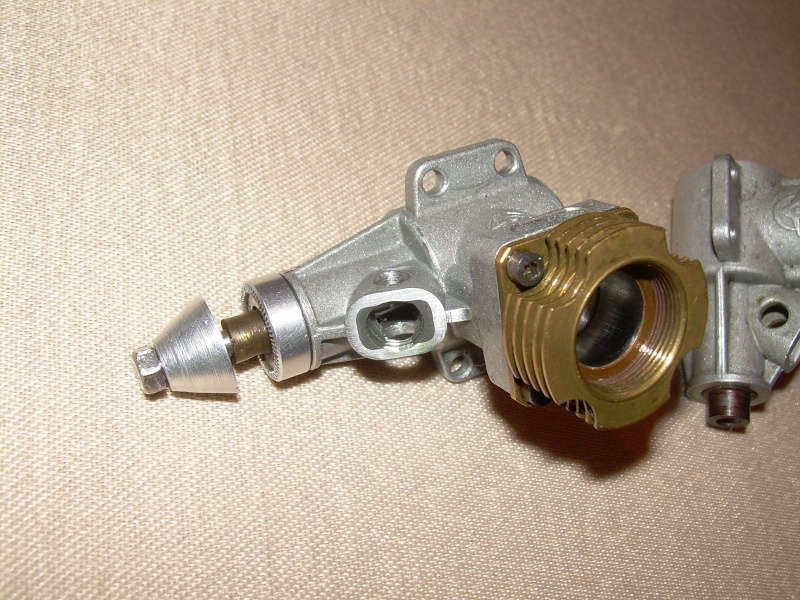

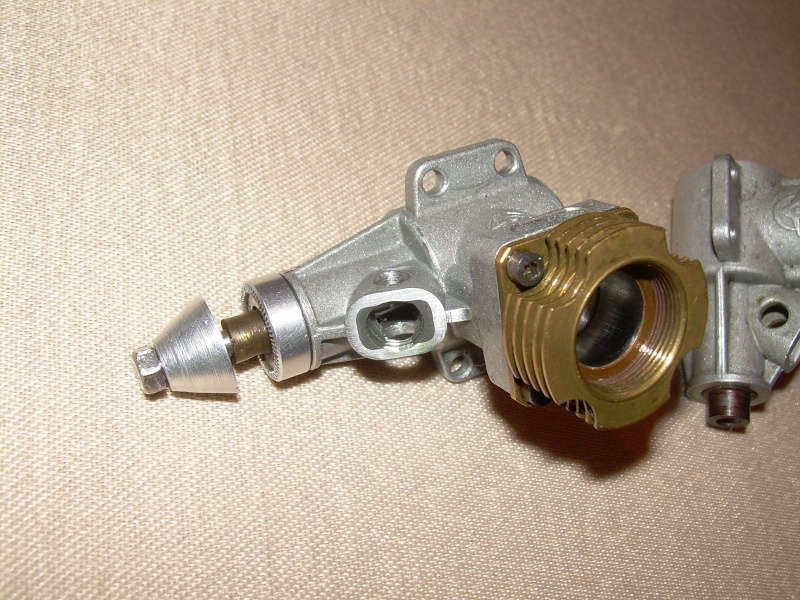

I recently tried this experiment and I'm quite happy with the results. I've seen this mod done using all JB weld but I didn't want to do that. This would work quite well with a Norvel equally. I use APC type props. One day after breaking one, we've all been there as all you have to do is look at them and they're broke. I thought, maybe I could make a adapter out of the broken prop hub and glue it inside the crankcase and drill and tap it for use with a TD needle valve setup.

I ca'd the hub to a hardwood stick and proceeded to rough it out on the bandsaw. I then carefully sanded the part as squarely as possible using the prop hole as a guideline to keep the overall piece centered. Your eyes will pick up if your going off center. I sanded a slight taper into the small rectangle and this allowed for a friction fit. I JB welded the small rectangular piece into the case with the crank in place and cotton to prevent any JB weld from going into the crank area.

Once dried 24 hrs, I proceeded to drill the bushing in which the prop hole easily assisted my drill bit. I then ran a 1/4-32 tap through the adapter. This is noticeable in the pic as the APC prop hub is the dark gray areas. I slightly radiused the corners so that it fits quite nicely into the case. The adapter now becomes two pieces due to the 1/4" tap and the tap cuts and threads into the side walls of the case. This mod worked exceptionally well and a Kirn Kraft setup can now be used for extremely reliable and simple pressure useage. You can run stock or modified venturi's. I then checked to make sure the venturi was sitting square on the case and a bit of filing of the case was required. My dad always called the file the" Nicholson mill ". I never really new why he would say that but later in life I figured it out and it made me laugh.

After the venturi is screwed in, I lay the case on it's side and fill the holes on the side of the case in which the needle valve bolt or spray bar passed through. This is simply done by using JB weld. I don't clean the threads on the Cox venturi in fact I oil them first. This way the JB weld doesn't stick to the aluminum. Don't panic, if it does as it will come loose if needed to be removed. Ken

I ca'd the hub to a hardwood stick and proceeded to rough it out on the bandsaw. I then carefully sanded the part as squarely as possible using the prop hole as a guideline to keep the overall piece centered. Your eyes will pick up if your going off center. I sanded a slight taper into the small rectangle and this allowed for a friction fit. I JB welded the small rectangular piece into the case with the crank in place and cotton to prevent any JB weld from going into the crank area.

Once dried 24 hrs, I proceeded to drill the bushing in which the prop hole easily assisted my drill bit. I then ran a 1/4-32 tap through the adapter. This is noticeable in the pic as the APC prop hub is the dark gray areas. I slightly radiused the corners so that it fits quite nicely into the case. The adapter now becomes two pieces due to the 1/4" tap and the tap cuts and threads into the side walls of the case. This mod worked exceptionally well and a Kirn Kraft setup can now be used for extremely reliable and simple pressure useage. You can run stock or modified venturi's. I then checked to make sure the venturi was sitting square on the case and a bit of filing of the case was required. My dad always called the file the" Nicholson mill ". I never really new why he would say that but later in life I figured it out and it made me laugh.

After the venturi is screwed in, I lay the case on it's side and fill the holes on the side of the case in which the needle valve bolt or spray bar passed through. This is simply done by using JB weld. I don't clean the threads on the Cox venturi in fact I oil them first. This way the JB weld doesn't stick to the aluminum. Don't panic, if it does as it will come loose if needed to be removed. Ken

Ken Cook- Top Poster

- Posts : 5627

Join date : 2012-03-27

Location : pennsylvania

Re: Another option for you bladder users

Re: Another option for you bladder users

Ken this is a great mod

I know you previously you had used 5/32 tube over a Cox fine thread NVA and that is what I did and it too works very well...you used solder but I did the whole lash up with JB like Rusty's version

Now I have to ask (not being critical...seriously want your opinion)

History: While assigned to Taiwan in the 60s EVERYTHING was six to eight weeks away to order and I broke two ears off my BabyBee .049. My dad carved the outline of the tank back into a piece of hard wood slightly larger than the tank back. He put bees wax in the mold cavity and bees wax on the slot for the venturi air channel of the tank back. Then laid a strand of wire around the perimeter in the "mold" and mixed up JB weld. Lightly sanded and then degreased the tank back. He filled the mold outside edges and set the tank back down in the JB weld and smoothed away all the excess. Later when hard he pin vise drilled out the holes in all four ears. I ran and crashed that engine for two more years before we left to come back to USA. The JB weld ears and embedded wire took a LOT of abuse. I have seen JB weld drilled and tapped on some curious locations of outboard motors and I think it is some damned tough stuff.

OK back to your carving the prop hub as an insert... Do you suppose that you could accomplish the same thing JUST with JB weld?

I know you previously you had used 5/32 tube over a Cox fine thread NVA and that is what I did and it too works very well...you used solder but I did the whole lash up with JB like Rusty's version

Now I have to ask (not being critical...seriously want your opinion)

History: While assigned to Taiwan in the 60s EVERYTHING was six to eight weeks away to order and I broke two ears off my BabyBee .049. My dad carved the outline of the tank back into a piece of hard wood slightly larger than the tank back. He put bees wax in the mold cavity and bees wax on the slot for the venturi air channel of the tank back. Then laid a strand of wire around the perimeter in the "mold" and mixed up JB weld. Lightly sanded and then degreased the tank back. He filled the mold outside edges and set the tank back down in the JB weld and smoothed away all the excess. Later when hard he pin vise drilled out the holes in all four ears. I ran and crashed that engine for two more years before we left to come back to USA. The JB weld ears and embedded wire took a LOT of abuse. I have seen JB weld drilled and tapped on some curious locations of outboard motors and I think it is some damned tough stuff.

OK back to your carving the prop hub as an insert... Do you suppose that you could accomplish the same thing JUST with JB weld?

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Another option for you bladder users

Re: Another option for you bladder users

Fred, Larry Driskill used to do just that. My largest problem nowadays is gaining access to machinery to do the job properly. My father suffered a career ending accident 3 years ago which now leaves me bartering and begging for some machine time. My mods are mainly done at home, but many of my operations are done in a shop. Trying to accurately hold and drill certain parts are just not going to work well for the average hobbyist. So to answer your question, yes the JB weld would work. The problem is holding the case squarely and accurately to drill and tap it. Many times, I've used a 4 jaw chuck to support the engine and made fixtures that attach to the tool rest to do certain drilling operations. This particular mod was in fact done at home and I used a dowel through the prop hole and aligned the adapter by trying to make the dowel as square as I possibly could in the case. After all was done, I had to file the case slightly to allow the needle assembly to sit tightly to the case. It took very little work to accomplish this. Ken

Ken Cook- Top Poster

- Posts : 5627

Join date : 2012-03-27

Location : pennsylvania

Re: Another option for you bladder users

Re: Another option for you bladder users

Good work, Ken, thanks for pioneering the project. I have a Big Mig in need of this, and two busted APC props. Thank goodness i haven't taken out the shop trash lately. I need to go trash diving now.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

OK now a tad sheepish

OK now a tad sheepish

So sorry Ken I did not read your first paragraph very carefully where you had already answered the question

True gentleman to not bust my butt for that

Thanks for the interesting mod

Just for curiosity sake.. as I said before I took my Aero .049 and added the NVA with a well prepped piece of 5/32 and set it in with JB weld (tube to NVA then assy to Norvel venturi)

This worked well and the Aero needles fine with bladder and I think is up over 24,000 RPM now (my cheap hobbico tack gets flaky above 20K for some reason)

Any way I know you have done the mod both ways... does the KK /Cox smaller venturi have a positive or negative effect on perceived torque or RPM with your flying props? I suspect the smaller venturi area chokes down the total air flow vs the wide open casting venturi.

That said the Cox /KK set up sprays fuel from three holes and the combination of faster air flow (I assume less volume) and more efficient atomization probably gains torque

True gentleman to not bust my butt for that

Thanks for the interesting mod

Just for curiosity sake.. as I said before I took my Aero .049 and added the NVA with a well prepped piece of 5/32 and set it in with JB weld (tube to NVA then assy to Norvel venturi)

This worked well and the Aero needles fine with bladder and I think is up over 24,000 RPM now (my cheap hobbico tack gets flaky above 20K for some reason)

Any way I know you have done the mod both ways... does the KK /Cox smaller venturi have a positive or negative effect on perceived torque or RPM with your flying props? I suspect the smaller venturi area chokes down the total air flow vs the wide open casting venturi.

That said the Cox /KK set up sprays fuel from three holes and the combination of faster air flow (I assume less volume) and more efficient atomization probably gains torque

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Similar topics

Similar topics» Bladder clip option

» Cox servos, any users?

» Visual Option

» Tuning option

» Cox Engines - Proposed Users

» Cox servos, any users?

» Visual Option

» Tuning option

» Cox Engines - Proposed Users

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules