Log in

Search

Latest topics

» Cox 020 PeeWee rebuild questions by roddie Today at 8:21 pm

» Dodge Viper - What a waste but brilliant marketing

by roddie Today at 6:46 pm

» COX .020 POWERED SPEEDSTER

by TD ABUSER Today at 6:32 pm

» **VOTE-ON-THE-NEXT-COX-ENGINE-OF-THE-MONTH** (November 2024)

by roddie Today at 6:13 pm

» Brushless motors?

by rsv1cox Today at 4:53 pm

» Free Flight Radio Assist

by rdw777 Today at 4:28 pm

» L4 Grasshopper

by latole Today at 3:43 pm

» PAW 80 and possible use

by fit90 Today at 8:36 am

» Music-wire bending tools (DIY video)

by 1975 control line guy Today at 8:32 am

» Ultrasonic Cleaners??

by sosam117 Yesterday at 11:26 am

» My CA or CyA (super glue) allergy

by rsv1cox Yesterday at 9:52 am

» My Pseudo killerbee.

by rsv1cox Yesterday at 7:04 am

Po'boy's exhaust throttle for thin wall cylinder

Page 1 of 2

Page 1 of 2 • 1, 2

Po'boy's exhaust throttle for thin wall cylinder

Po'boy's exhaust throttle for thin wall cylinder

Old-stock 049 and 051 COX cylinders have thin wall. A rim at the cylinder bottom prevents a conventional exhaust throttle ring to be slipped on the cylinder for performance control.

"What can a po'boy do??"

I cut a long strip from an repurposed aluminum beer can and folded it along its length to double it up. Then cut its width to match the height of the thin wall cylinder section between the bottom rim and the lowermost cylinder fin, and cleared the band top for 2 exhaust openings. Wound it tight around the cylinder and cut it to length with some overlap.

A 1mm piano wire wound and bent around a ballpoint pen shell of 16mm diameter ended up in a relatively soft spring, that will hold the aluminum ring tight on the cylinder.

Next thing is to bench test it. No way it will provide the low idle speed known from the real exhaust throttle drums, owing to the poor fit between the aluminum ring and the cylinder...but this prototype is worth the try...there is no other efficient way of throttling an old-stock, thin wall cylinder TD051...the COX or Tarno R/C carb has no real throttle effect either, due to the SPI cylinder.

Lets see then decide if I continue with a more accurate ring..

"What can a po'boy do??"

I cut a long strip from an repurposed aluminum beer can and folded it along its length to double it up. Then cut its width to match the height of the thin wall cylinder section between the bottom rim and the lowermost cylinder fin, and cleared the band top for 2 exhaust openings. Wound it tight around the cylinder and cut it to length with some overlap.

A 1mm piano wire wound and bent around a ballpoint pen shell of 16mm diameter ended up in a relatively soft spring, that will hold the aluminum ring tight on the cylinder.

Next thing is to bench test it. No way it will provide the low idle speed known from the real exhaust throttle drums, owing to the poor fit between the aluminum ring and the cylinder...but this prototype is worth the try...there is no other efficient way of throttling an old-stock, thin wall cylinder TD051...the COX or Tarno R/C carb has no real throttle effect either, due to the SPI cylinder.

Lets see then decide if I continue with a more accurate ring..

Last edited by balogh on Fri Mar 05, 2021 10:58 am; edited 1 time in total

balogh- Top Poster

Posts : 4940

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

Very good idea Balogh  Perhaps spring wire needs to be epoxy glued on throttle.

Perhaps spring wire needs to be epoxy glued on throttle.

Levent Suberk- Diamond Member

- Posts : 2257

Join date : 2017-12-24

Location : Türkiye

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

Levent Suberk wrote:Very good idea BaloghPerhaps spring wire needs to be epoxy glued on throttle.

Thanks, Levent, yes, this is yet to be worked out. I wanted to fix the spring end somehow in a hole punched in the aluminum ring, but the latter is very soft and delicate and tends to get inadvertently bent that just adds to its inherently poor fit around the cylinder.

Epoxy may help, providing it endures the hot temperature of the aluminum ring that conducts the exhaust gas temperature almost unobstructed thanks to the high heat conductivity of aluminum..but yes, there definitely needs to be some mechanical bond between the ring and the wire. Because each cylinder has the exhaust openings at different angle, a circlip allowing the readjustment of the position of openings on the ring, like on the "real" COX exhaust throttle rings, to make it interchangeable between cylinders, might be good. But the ring here is very soft for a standard circlip...

balogh- Top Poster

Posts : 4940

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

Perhaps thin copper or tin sheet is better than aluminum, because you can solder wire at one or two spot.

This idea can also work on TD .010 cu. in. engines. I once thought to split a copper tubing lengthwise to make it springy and solder a piece of round steel wire. Yet I didn't make it, but want to make if I can find suitable diameter copper tubing.

This idea can also work on TD .010 cu. in. engines. I once thought to split a copper tubing lengthwise to make it springy and solder a piece of round steel wire. Yet I didn't make it, but want to make if I can find suitable diameter copper tubing.

Levent Suberk- Diamond Member

- Posts : 2257

Join date : 2017-12-24

Location : Türkiye

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

Y have Good trick y just use the surstart carb fixed on the cox new exaust fit tube on the exaust and fit the carb wit just tube very simple Not cheap parts y like the one u made posible To build one for the litle .010 m'y is just bether for sound lost performance litle and works wit bee no tee dee

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

This one is a different example:

https://coxengines.ca/cox-.010-rc-tee-dee-engine-micro-flite-very-rare.html

I want to make a throttle ring in a very simple way.

https://coxengines.ca/cox-.010-rc-tee-dee-engine-micro-flite-very-rare.html

I want to make a throttle ring in a very simple way.

Levent Suberk- Diamond Member

- Posts : 2257

Join date : 2017-12-24

Location : Türkiye

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

I have this from the inventor the late and great Mr. Freiheit. The copper based sleeves expand and allow free passage of exhaust gases, then contracts on the cylinder when the engine is throttled. The patented name is PET aka Proportional Exhaust Throttle.

balogh- Top Poster

Posts : 4940

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

Yes its a intersting desing Not To hard To build one just time consuming that y dont have and take chance Not working have To build second one its posible option tink one day y try To build one rc litle .010

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

Brass tubing can work?

Levent Suberk- Diamond Member

- Posts : 2257

Join date : 2017-12-24

Location : Türkiye

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

Y have lots of difrent size copper tube tink of use one larger size slit the tube Fold the excess tube so that two ends join Bolt together it nead fixation that can rotate like the .049 one the hardes parts is To make the parts Perfect round wit correct size y tink of build sort of a piece to mold the right diameter

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

Hi Andras, You gave me some inspiration to try something. I had some K & S brand .005" (.15mm) sheet brass which is quite easy to perforate using a standard (1/4" dia.) paper hole-punch. Using ordinary scissors; I cut a piece 7/16" (11.11mm) wide by approximately 2.5" long.. and punched a hole on-center of the strip.

The hole "could have been" offset more; so as to expose more of the exhaust-port.. but this was just to test the feasibility of the idea. I like the "roundness" of a hole (or bore).. because it would seem to provide for more fine resolution/metering; as with a carb-jet/barrel.

The strips' 2.5" length leaves excess material to cinch-together.. by some means. I had thought about using an aluminum pop-rivet with backing plates which would allow pulling the band tight enough around the cylinder to create a decent seal without binding. Treating the strip with some lube would be in order. The pop-rivet could possibly serve as a point for a pushrod to a servo.

The hole "could have been" offset more; so as to expose more of the exhaust-port.. but this was just to test the feasibility of the idea. I like the "roundness" of a hole (or bore).. because it would seem to provide for more fine resolution/metering; as with a carb-jet/barrel.

The strips' 2.5" length leaves excess material to cinch-together.. by some means. I had thought about using an aluminum pop-rivet with backing plates which would allow pulling the band tight enough around the cylinder to create a decent seal without binding. Treating the strip with some lube would be in order. The pop-rivet could possibly serve as a point for a pushrod to a servo.

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

This is great Roddie, the brass is more solid than the beercan sheet and offers a better grip for the servo arm.

I was looking at a similar solution instead of wrapping the sheet and holding it by a spring, by using a strong paper clip to pull the 2 end tabs of your solution tight, but aluminum is not strong enough

I am looking forward to seeing how these will work. I will bench test mine next week. Thank you for giving thoughts to the idea and developing it further

I was looking at a similar solution instead of wrapping the sheet and holding it by a spring, by using a strong paper clip to pull the 2 end tabs of your solution tight, but aluminum is not strong enough

I am looking forward to seeing how these will work. I will bench test mine next week. Thank you for giving thoughts to the idea and developing it further

balogh- Top Poster

Posts : 4940

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

This is the kinda' thing that I love to experiment with. The thread's title piqued my interest immediately.. but I didn't have a chance to read what you'd done, until this afternoon. The "pop-rivet" idea needs to be explored.. I think. There are aluminum backing-plates which help to support thin materials.. and those plates can actually be sanded "thinner" for an application such as this.. without it affecting the integrity. An assembly would be very lightweight. It's a thin brass strip and an all-aluminum fastener for it. A pop-rivet could also fasten a control-horn for a linkage.

This design doesn't have the indexing/adjusting clip-ring.. but some thought can be put into the location of the punched-hole on the brass-strip. One could make-up several strips with alternate hole locations to fit certain cylinder port profiles. It's a CHEAP experiment.. that could be well worth the effort.

This design doesn't have the indexing/adjusting clip-ring.. but some thought can be put into the location of the punched-hole on the brass-strip. One could make-up several strips with alternate hole locations to fit certain cylinder port profiles. It's a CHEAP experiment.. that could be well worth the effort.

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

Hello András, I have looked for my own publications from a few years ago in CEF but I did not find them, I think they do not exist anymore for some reason that I do not know.

At that time I had posted a throttle ring that I called "belt" type for Cox Pee Wee .020, these are some photos.

It works, but it is not very effective.

At that time I had posted a throttle ring that I called "belt" type for Cox Pee Wee .020, these are some photos.

It works, but it is not very effective.

MauricioB- Top Poster

- Posts : 3699

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

Thanks Mauricio. I think your throttle works quite well. I do not need a very low idle, only a tool to reduce engine power in an emergency like elevator or aileron servo failure that hit me sometime and left me with limited flight control and the Providence to save my plane.

balogh- Top Poster

Posts : 4940

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

Y have save one of m'y plane using ruder for elevator landed safe hardes parts is keap fling knife edge and without rc engine It would end in a crash y was Lucky its stuck just in the Good position that the plane circle Not To mutch Forced landing wit. No damage it was wit m'y 3d carbone z yak y want To convert To nitro m'y litle guilow edge 540 wit one of m'y .010 or .020 y wil try build one smal for the litle .010

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

I started my day "baking".. 77 cookies were baked.

... I even cleaned as I baked. So later on... I decided to mess around a little further with my version of a Po' boy's exhaust-throttle. The pop-rivet idea needed to be tried. It wasn't as easy as I thought.. but then again, not too bad if your dexterity is good. I needed to drill-through the "tabs" to accept a 1/8" pop-rivet.. leaving enough clearance for using backing-plates on both sides.

So later on... I decided to mess around a little further with my version of a Po' boy's exhaust-throttle. The pop-rivet idea needed to be tried. It wasn't as easy as I thought.. but then again, not too bad if your dexterity is good. I needed to drill-through the "tabs" to accept a 1/8" pop-rivet.. leaving enough clearance for using backing-plates on both sides.

I held the brass-strip in place with an appropriate-size slotted-screwdriver on a block of wood while drilling. I didn't want to risk getting my finger cut if the drill grabbed the strip when breaking-through. An unused rivet can be used to open-up the holes prior to assembly. At this point I proceeded to install the rivet w/backing-plates through the tabs on the strap. It's easier to start the rivet before the strap is placed on the cylinder. One or two pulls on the rivet-tool handle.. and the outer backing-plate will be held captive.

I applied some light oil to the outside of the cylinder, slipped the strap assembly over it and gave the rivet-tool another squeeze on the handle.. whilst revolving the barrel.. and checking for binding. I ended up with a decent fit after the rivet popped.

I would say that the backing-plates are a MUST.. and should not be omitted. The 1/8" size aluminum backing-plates that I have, are radiussed on one side.. and sharp on the other. I faced the radiussed sides against the brass strip, so as not to cut into it when the rivet cinched-up tight.

EDIT: There was some binding (twist-binding) which I corrected by squaring-up the backing-plates using sm. pliers.

... I even cleaned as I baked.

I held the brass-strip in place with an appropriate-size slotted-screwdriver on a block of wood while drilling. I didn't want to risk getting my finger cut if the drill grabbed the strip when breaking-through. An unused rivet can be used to open-up the holes prior to assembly. At this point I proceeded to install the rivet w/backing-plates through the tabs on the strap. It's easier to start the rivet before the strap is placed on the cylinder. One or two pulls on the rivet-tool handle.. and the outer backing-plate will be held captive.

I applied some light oil to the outside of the cylinder, slipped the strap assembly over it and gave the rivet-tool another squeeze on the handle.. whilst revolving the barrel.. and checking for binding. I ended up with a decent fit after the rivet popped.

I would say that the backing-plates are a MUST.. and should not be omitted. The 1/8" size aluminum backing-plates that I have, are radiussed on one side.. and sharp on the other. I faced the radiussed sides against the brass strip, so as not to cut into it when the rivet cinched-up tight.

EDIT: There was some binding (twist-binding) which I corrected by squaring-up the backing-plates using sm. pliers.

Last edited by roddie on Sun Mar 07, 2021 5:27 pm; edited 1 time in total (Reason for editing : added photos)

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

Great result Roddie (cookies included  ). Too bad there are no milled flats on the top fin for the wrench. Like on my old stock 051 cylinder. These cylinders tend to bake into the crankcase and removing them without the wrench is not easy. I have never managed to remove a cylinder with the leather strap no matter if I preheated the aluminum crankcase..not that it needs to be removed so often. But the exhaust throttle will not make it easier either.

). Too bad there are no milled flats on the top fin for the wrench. Like on my old stock 051 cylinder. These cylinders tend to bake into the crankcase and removing them without the wrench is not easy. I have never managed to remove a cylinder with the leather strap no matter if I preheated the aluminum crankcase..not that it needs to be removed so often. But the exhaust throttle will not make it easier either.

Will you bench test it? One of the claim points in the Proportional Exhaust Throttle patent by the inventor Mr. Roger Freiheit was the bimetallic throttle and cylinder combo, that will allow more blow-by thru the throttle when the engine runs hot and the brass throttle expands more than the steel cylinder, and better fit for throttling when idling with the engine temperature dropping lower...so fitting it tight when cold is just good the way you did it Roddie..

Will you bench test it? One of the claim points in the Proportional Exhaust Throttle patent by the inventor Mr. Roger Freiheit was the bimetallic throttle and cylinder combo, that will allow more blow-by thru the throttle when the engine runs hot and the brass throttle expands more than the steel cylinder, and better fit for throttling when idling with the engine temperature dropping lower...so fitting it tight when cold is just good the way you did it Roddie..

Last edited by balogh on Mon Mar 08, 2021 5:50 am; edited 2 times in total

balogh- Top Poster

Posts : 4940

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

Hey guys,

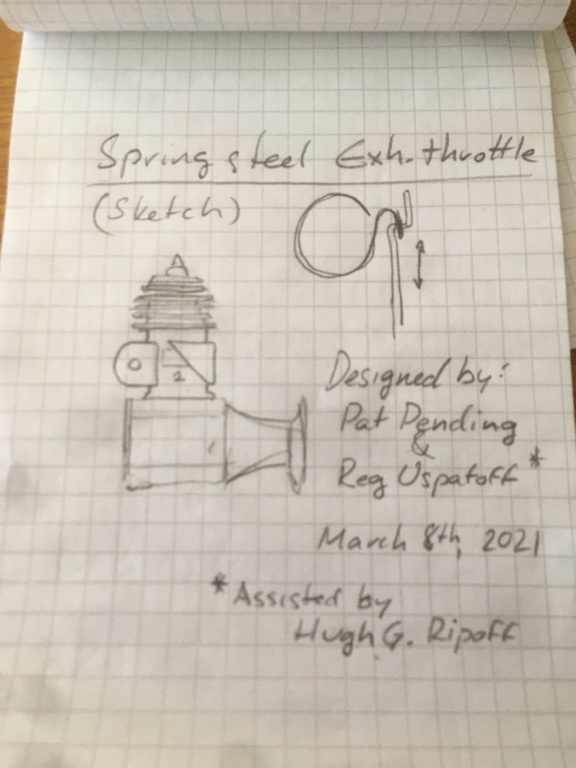

Your experiments got me thinking (uh oh), and this morning I woke up with a design in mind. Must be getting old, I used to have completely different things in my mind... Well, anyway. You know how the original Cox mufflers have the adjustable port, where the adjustment is done by a spring steel clip that you can move back and forth to adjust the noise?

How about using a similar principle for an exhaust throttle? Spring steel sleeve would stay tight around the cylinder just by the spring force. Spring steel is difficult to drill, but if you can do with just one exhaust port in use (the ports are huge after all), the opening could be made just by making the ”clip” just a little short so that its end reveals the exhaust port. Additionally, you could cut the end of the spring in an angle to allow better adjustability, like Roddie described about the round port. You’d still need to drill (or punch) a hole for the pushrod, but a small hole like that would be easier to make.

There are at least a couple of drawbacks:

1. Only one exhaust port in use (not sure if it is a drawback after all)

2. The cylinder needs to be indexed in a certain way for a certain clip/pushrod combination.

3. Spring steel is not easy to work with. Maybe the clip could me made of something ”easy” and then tempered to give it spring characteristics?

The benefits obviously include simplicity and minimum amount of parts (my favourites) and light weight (everybody’s favourite ).

).

Here’s a rough sketch of what I mean. Just some food for thought

Your experiments got me thinking (uh oh), and this morning I woke up with a design in mind. Must be getting old, I used to have completely different things in my mind... Well, anyway. You know how the original Cox mufflers have the adjustable port, where the adjustment is done by a spring steel clip that you can move back and forth to adjust the noise?

How about using a similar principle for an exhaust throttle? Spring steel sleeve would stay tight around the cylinder just by the spring force. Spring steel is difficult to drill, but if you can do with just one exhaust port in use (the ports are huge after all), the opening could be made just by making the ”clip” just a little short so that its end reveals the exhaust port. Additionally, you could cut the end of the spring in an angle to allow better adjustability, like Roddie described about the round port. You’d still need to drill (or punch) a hole for the pushrod, but a small hole like that would be easier to make.

There are at least a couple of drawbacks:

1. Only one exhaust port in use (not sure if it is a drawback after all)

2. The cylinder needs to be indexed in a certain way for a certain clip/pushrod combination.

3. Spring steel is not easy to work with. Maybe the clip could me made of something ”easy” and then tempered to give it spring characteristics?

The benefits obviously include simplicity and minimum amount of parts (my favourites) and light weight (everybody’s favourite

Here’s a rough sketch of what I mean. Just some food for thought

KariFS- Diamond Member

- Posts : 2041

Join date : 2014-10-10

Age : 53

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

That is also an interesting solution, Kari.

In my experience, at least on stepped wall cylinders, where the full contact between the ring and the cylinder outer wall is not there, as long as the exhaust opening on the cylinder is at least 1/3 open, the position of the exhaust throttle drum is not really influencing the rpm. Therefore, the inclined cut at the end of the ring may even be omitted?

Thick wall cylinders and thin walls with straight cylinder contour are more efficiently throttled, in principle, due to the better seal between the cylinder and the ring, then with stepped-wall cylinders.

I wish I had the tooling to create what Roddie and you are proposing, but with my limited resources, I will stick to my beer-can skin solution ...hence the product name "po'boy's exhaust.."

In my experience, at least on stepped wall cylinders, where the full contact between the ring and the cylinder outer wall is not there, as long as the exhaust opening on the cylinder is at least 1/3 open, the position of the exhaust throttle drum is not really influencing the rpm. Therefore, the inclined cut at the end of the ring may even be omitted?

Thick wall cylinders and thin walls with straight cylinder contour are more efficiently throttled, in principle, due to the better seal between the cylinder and the ring, then with stepped-wall cylinders.

I wish I had the tooling to create what Roddie and you are proposing, but with my limited resources, I will stick to my beer-can skin solution ...hence the product name "po'boy's exhaust.."

balogh- Top Poster

Posts : 4940

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

Some black spring steel that I use for a lot of things is from strapping for lumber. What I have is 3/4" wide and about .024" thick. Works well for control horns, small bellcranks and throttle arms It would be great for making the strap throttle, but pretty hard to bend up. As another somewhat unrelated thought-the thin walled cylinders might benefit from an appropriate size silicone tube stretched over the ports so that it seals. Two 1/8" holes punched across from each other would likely work well. I can foresee problems at low throttle expanding the tubing, and getting the pushrod attached. Maybe the sheet metal sleeve with the patent could slide over the tubing? Just a thought. Another option might or might not be to punch two larger holes in two or three inch long silicone tubing and slide the cylinder through it at 90 degrees. Ace used to sell that part to control the goop coming out the exhaust. I think it mostly spit it on the wings instead of the fuselage though. They mentioned in the advertising that it could be used as a throttle by plugging the end, and varying the exit hole on the other end. I think this would be pretty big and ugly, but may work somewhat. Even if these exhaust throttles slow the plane down a bit just in case you get in trouble, it could save some repair work. I've had a few RC .049s that were a bit of a handful on the first flight that would have been less thrilling with a throttle.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

Good points, aspeed, thank you. Especially the silicone tube pulled on the cylinder...it inspired my mind, and maybe I will replace the steel spring on my design with a properly , but not overly, tight silicone O-ring that will push the aluminum throttle ring to the cylinder for a good seal. Then the pushrod will be fixed to the throttle ring separately, by something else. This solution will allow the non-destructive remocval of the aluminum throttle and the O-ring even if I cannot remove the cylinder from the crankcase.

The last option you mention, however, i.e. sliding the cylinder through a silicone tube at 90 degrees would compromise the SPI engine performance, like any normal muffler. It is good for goo control, but would keep the exhaust gases near the SPI opening, I guess.

The last option you mention, however, i.e. sliding the cylinder through a silicone tube at 90 degrees would compromise the SPI engine performance, like any normal muffler. It is good for goo control, but would keep the exhaust gases near the SPI opening, I guess.

balogh- Top Poster

Posts : 4940

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

this. Morning I decided to build an rc ring for me just to try if y can build one tink y have Good one seal Good once close y wanted m'y smallest engine rc now m'y tee dee .010 is rc y y use k&s coper tube the challenge was To make the parts Perfect round right size y have laped the parts on its cylinder in dril tight the Bolt holding the two parts til its flush now y have To test the engine wit tachometer de nos engine lost rpm tink it run slow litle like 1000 To 2000 rpm down full open y tink y lost performance its the négatifs point tink y can upgrades like its normal rpm just wil Not run as slow

Y want To use in the nitro world Smales rc cars y have

Y want To use in the nitro world Smales rc cars y have

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

Result litle vidéo

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

Good handwarming experiment in the cold Canadian winter!  Your 010 was running a bit on the rich side David. With leaner and faster run the effect of throttling can be better heard.

Your 010 was running a bit on the rich side David. With leaner and faster run the effect of throttling can be better heard.

balogh- Top Poster

Posts : 4940

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Cox thin-wall .049 Cylinder...

» What is a thin cylinder wall?

» Wanted: unstamped thin wall #1 cylinder

» Early thin walled cylinder??

» 020 cylinder with exhaust throttle on ebay

» What is a thin cylinder wall?

» Wanted: unstamped thin wall #1 cylinder

» Early thin walled cylinder??

» 020 cylinder with exhaust throttle on ebay

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules