Log in

Search

Latest topics

» Foam hand kids glider converted to 0.049 CLby roddie Today at 4:33 am

» Cox PT-19 Wing

by latole Today at 4:28 am

» Roddie-Rigger.. a 2005 original design

by roddie Today at 2:54 am

» Golden Bee basic running problem

by roddie Yesterday at 10:51 pm

» Simple Gliders

by rdw777 Yesterday at 6:25 pm

» Weird search for a single comic from an old Mad Magazine

by Kim Yesterday at 1:44 pm

» Scientific "Zipper" Build...Zipper Flys!.

by getback Yesterday at 7:27 am

» Cox .049 Tee Dee engines back in stock (limited availablility)

by GallopingGhostler Yesterday at 1:05 am

» Very off-topic.........Time passes and not always for the best......

by rsv1cox Thu Jul 25, 2024 2:47 pm

» Jim Walker Bonanza etc.

by rsv1cox Wed Jul 24, 2024 6:30 pm

» Throttles for Cox Tee Dee .049 / .020 / .010 engines --- videos

by sosam117 Wed Jul 24, 2024 8:54 am

» Introducing our Cox .049 TD Engines

by Admin Tue Jul 23, 2024 2:00 am

Cox Engine of The Month

July-2024

robot797's

"ULTIMITE COX 010: it has a clutch, E starter, throttle, exhaust, aluminum tank, aluminum venturi, gearbox with forward and reverse, and now its on a custom drawn and printed stand"

PAST WINNERS

robot797's

"ULTIMITE COX 010: it has a clutch, E starter, throttle, exhaust, aluminum tank, aluminum venturi, gearbox with forward and reverse, and now its on a custom drawn and printed stand"

PAST WINNERS

An Airplane Story from My Facebook Page

Page 1 of 1

An Airplane Story from My Facebook Page

An Airplane Story from My Facebook Page

I think I've posted about this before but, here we go again:

----------------------------------------------------------------------------------------

"So, besides being Ground Hog Day, today is also the anniversary of a literal miracle than happened at Cape's Airport back in 2007.

Just past 9:30am, on February 2nd, 2007, a Beechcraft "King Air" B200 landed at KCGI with several important parts of its airframe either missing or severely bent.

I was working Line Service there, and heard some strange conversations on the portable scanner I always packed around.

The first was from an Arch Medical Helicopter on its way back to Cape where it was based. The pilot reported seeing "debris falling to the ground".

Then, some more one-way conversations---only hearing the tower talking to a plane that was still too far away for my scanner to pick up. I thought I heard some wind reports, followed by the phrase, "The Airport is Yours".

This happens only when some serious crap is about to go down, and I hoofed it out to one of the fuel trucks with my ever-present video camera.

Gloves off in the cold wind, with one hand holding the camera, and the other grasping the scanner, I barely got up the ladder before the King Air showed up on right base for runway 10.

Through the viewfinder, the landing looked pretty normal...actually very smooth...and the plane was passing by on its rollout before I noticed some truly odd stuff.

The photos tell the story: A near-totally missing left hand stabilizer with half of the elevator still hanging on, an almost intact right hand stabilizer with the remainder of its elevator cranked downward at 45 degrees. The only real pitch control the pilots had was through applying power to raise or lower the nose. This caused a VERY fast touchdown, which ground flat spots on the tires.

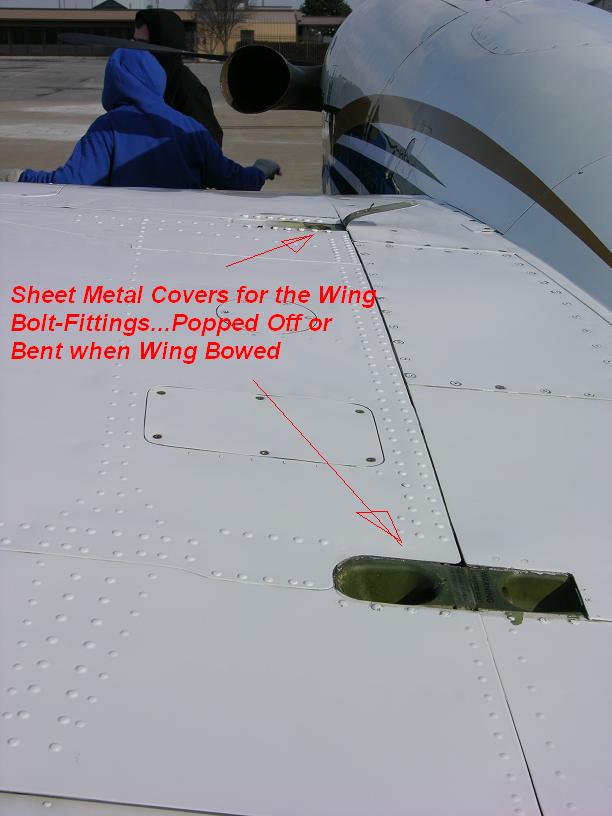

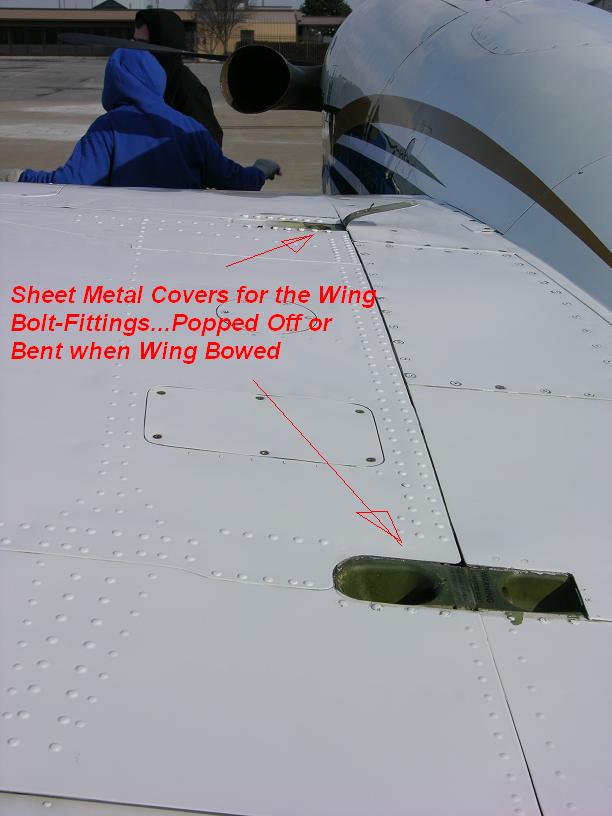

Both wings were bent, with several of their wing-bolt covers blown away in the slipstream, the fuselage was kinked between the wing and tail, and the pilot's side windshield had one of its layers shattered.

But it brought its pilots home, and I wanted to paint (but didn't) the phrase, "Beechcraft---We Build Airplanes and Bridges."---on the fuselage in honor of the plane's incredibly strong airframe.

Among other details, the cause was found to be the depressurization of the cabin at altitude, causing the pilots to pass out, and with the King Air rolling into a vertical dive. Coming back to consciousness at a lower altitude, the pilots used all their strength to pull the plane back to level flight, shedding parts as they went.

There are plenty of other details in the official report, and we were wading in assorted "Chuck Yeager Wannabe's", passing judgement in the weeks following the plane's landing. But this is a fairly common thing around airplanes, guns, or motorcycles, so I just used my standard, "Mmm..." and nod response.

One slightly humorous result was that it became somewhat of an aviation tourist attraction. For a while, it was fairly common for an arriving plane to ignore my parking instructions, taxiing by with the pilot pointing to the east ramp where the bent King Air was tied down. The planes would usually circle around the carcass, then taxi back out for takeoff.

Other pilots, climbing from their planes would ask, "Is that 'it'?", and it was.

Lastly, concerning the video...I KNOW...I was a dork, as was pointed out to me a couple times, but in my defense, I'd intended to just drop off the video at the local TV station and get out of Dodge.

Goofy as it might have been, they actually wanted my thoughts on the subject, which I knew could put me in the realm of a hillbilly talking about witnessing a tornado, "Wulh, it sounded jes like a freight train coming up the holler!"

https://www.youtube.com/watch?v=OWuPmGPBW8o&t=23s

Thanks to Line Man Mark Perry for his photo coverage of the King Air's salvage and load-out."

................................................................

...............................................................

............................................................................

.........................................................

..............................................................

----------------------------------------------------------------------------------------

"So, besides being Ground Hog Day, today is also the anniversary of a literal miracle than happened at Cape's Airport back in 2007.

Just past 9:30am, on February 2nd, 2007, a Beechcraft "King Air" B200 landed at KCGI with several important parts of its airframe either missing or severely bent.

I was working Line Service there, and heard some strange conversations on the portable scanner I always packed around.

The first was from an Arch Medical Helicopter on its way back to Cape where it was based. The pilot reported seeing "debris falling to the ground".

Then, some more one-way conversations---only hearing the tower talking to a plane that was still too far away for my scanner to pick up. I thought I heard some wind reports, followed by the phrase, "The Airport is Yours".

This happens only when some serious crap is about to go down, and I hoofed it out to one of the fuel trucks with my ever-present video camera.

Gloves off in the cold wind, with one hand holding the camera, and the other grasping the scanner, I barely got up the ladder before the King Air showed up on right base for runway 10.

Through the viewfinder, the landing looked pretty normal...actually very smooth...and the plane was passing by on its rollout before I noticed some truly odd stuff.

The photos tell the story: A near-totally missing left hand stabilizer with half of the elevator still hanging on, an almost intact right hand stabilizer with the remainder of its elevator cranked downward at 45 degrees. The only real pitch control the pilots had was through applying power to raise or lower the nose. This caused a VERY fast touchdown, which ground flat spots on the tires.

Both wings were bent, with several of their wing-bolt covers blown away in the slipstream, the fuselage was kinked between the wing and tail, and the pilot's side windshield had one of its layers shattered.

But it brought its pilots home, and I wanted to paint (but didn't) the phrase, "Beechcraft---We Build Airplanes and Bridges."---on the fuselage in honor of the plane's incredibly strong airframe.

Among other details, the cause was found to be the depressurization of the cabin at altitude, causing the pilots to pass out, and with the King Air rolling into a vertical dive. Coming back to consciousness at a lower altitude, the pilots used all their strength to pull the plane back to level flight, shedding parts as they went.

There are plenty of other details in the official report, and we were wading in assorted "Chuck Yeager Wannabe's", passing judgement in the weeks following the plane's landing. But this is a fairly common thing around airplanes, guns, or motorcycles, so I just used my standard, "Mmm..." and nod response.

One slightly humorous result was that it became somewhat of an aviation tourist attraction. For a while, it was fairly common for an arriving plane to ignore my parking instructions, taxiing by with the pilot pointing to the east ramp where the bent King Air was tied down. The planes would usually circle around the carcass, then taxi back out for takeoff.

Other pilots, climbing from their planes would ask, "Is that 'it'?", and it was.

Lastly, concerning the video...I KNOW...I was a dork, as was pointed out to me a couple times, but in my defense, I'd intended to just drop off the video at the local TV station and get out of Dodge.

Goofy as it might have been, they actually wanted my thoughts on the subject, which I knew could put me in the realm of a hillbilly talking about witnessing a tornado, "Wulh, it sounded jes like a freight train coming up the holler!"

https://www.youtube.com/watch?v=OWuPmGPBW8o&t=23s

Thanks to Line Man Mark Perry for his photo coverage of the King Air's salvage and load-out."

................................................................

...............................................................

............................................................................

.........................................................

..............................................................

Kim- Top Poster

Posts : 8590

Join date : 2011-09-06

Location : South East Missouri

Re: An Airplane Story from My Facebook Page

Re: An Airplane Story from My Facebook Page

Amazing story and luck..one would think that as much as the wing sheeting buckled and yielded permanently, the wing spars should have snapped under the bending moment when the pilots took the plane out if the vertical dive...

balogh- Top Poster

Posts : 4803

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Re: An Airplane Story from My Facebook Page

Re: An Airplane Story from My Facebook Page

balogh wrote:Amazing story and luck..one would think that as much as the wing sheeting buckled and yielded permanently, the wing spars should have snapped under the bending moment when the pilots took the plane out if the vertical dive...

It reminded me of the favorite phrase the "The Right Stuff" test pilots used in describing their stress in engineering terms, "You GOT to maintain an even strain!"

I, of course, ain't no engineer, but believe that all these failures HAD to occur with the plane's components bending in support of each other just enough to keep the original frame in some kind of flying balance.

Thus, "The Miracle" part.

Kim- Top Poster

Posts : 8590

Join date : 2011-09-06

Location : South East Missouri

Re: An Airplane Story from My Facebook Page

Re: An Airplane Story from My Facebook Page

Well it's just past lunch time and my regular viewing of the Smithsonian Channels "Air Disasters".

https://www.smithsonianchannel.com/shows/air-disasters

I never miss an episode. Watched with some remorse, people die, but always with respect for the effort that the producers put into each production. People don't always perish in these. There have been some heroic actions performed by the flight crews saving everyone on board. Post accident analysis by the NTSB (National Transportation Safety Board) is an education in itself.

A recent episode related the story of an Airbus 380 that blew an engine sending parts into the wing and fuselage. Hundreds at risk, yet the pilots brought it in for a safe landing.

It would be interesting if they picked up on this. Kim's input would be front and center.

https://www.smithsonianchannel.com/shows/air-disasters

I never miss an episode. Watched with some remorse, people die, but always with respect for the effort that the producers put into each production. People don't always perish in these. There have been some heroic actions performed by the flight crews saving everyone on board. Post accident analysis by the NTSB (National Transportation Safety Board) is an education in itself.

A recent episode related the story of an Airbus 380 that blew an engine sending parts into the wing and fuselage. Hundreds at risk, yet the pilots brought it in for a safe landing.

It would be interesting if they picked up on this. Kim's input would be front and center.

rsv1cox- Top Poster

Posts : 10851

Join date : 2014-08-18

Location : West Virginia

Re: An Airplane Story from My Facebook Page

Re: An Airplane Story from My Facebook Page

Yes, I remember your post, Kim, can't recall exactly where, haven't searched, may have been in another model airplane forum. Didn't know you were part of the ground servicing crew. Yes, with that buckling of the main wing spar, plus wouldn't be surprised of all the popped, cracked riveting, can understand why the airframe overall except for a few places didn't have much salvageable left except for engines, landing gear and some of the other mechanical / electrical parts.

On the hangar floor, one of the tests they were doing was the C-17 main spar section passing through the fuselage. In a test jig, they had million pound hydraulic actuators with all sorts of instrumentation hooked up, strain gauges, etc. to measure movement and internal metallic strains.

With roped off guards around to keep traffic and people away, there was also a sign posted stating the brief title and test number, component involved, flight numbers, "Keep Away", "Test in Progress", etc. Because I was badged as part of the testing staff, I was permitted to walk the floor and observe the test in this high security area (when test in progress). Even went in the adjacent test trailer with our Perkin-Elmer 3220 minicomputer there (it did both the loading and data capturing), looking over the computer operator's shoulders.

The system had fail safes throughout. Tests were sometimes around the clock with 3 shifts. Sometimes it was just two shifts with a shutdown during 3rd shift. (Depended on schedules, priorities and cost.) It was amazing to watch the test in action. Basically these hydraulic actuators would apply pressure, then release, done in an accelerated manner to simulating thousands of hours of stresses to be encountered during the life time, or several life times of the aircraft. We used the same data system to both apply the predetermined loads through a spectrum tape, loaded before the test began. Then, test would run for days on end. Periodically, data sets from our recorded data tape to the structural engineers, for their evaluation.

Continuing months on end, when the test specimen finally fatigued to the point of serious yielding, sometimes even total fracturing with clean breakage, the sound was a loud "boom!" heard even inside the building, system would dump hydraulic pressure and shut the test down.

To blow off steam, I'd take a 3 day weekend and head up to Santa Maria up north, a couple hour drive along scenic Highway 101. (Passed through a Santa Claus village on the way up.) Take my half-A medium flight box and Minnie. Fly at a secluded park portion on Vandenburg Air Force Base. I was doing my wild spiral dive with the Cox .049 R/C Bee screaming with muffler cover off. Just when I neutralized Minnie about 50 feet above ground and was executing the start of a loop, the spar in one wing panel failed, sending Minnie into a lawn dart corkscrew.

Take my half-A medium flight box and Minnie. Fly at a secluded park portion on Vandenburg Air Force Base. I was doing my wild spiral dive with the Cox .049 R/C Bee screaming with muffler cover off. Just when I neutralized Minnie about 50 feet above ground and was executing the start of a loop, the spar in one wing panel failed, sending Minnie into a lawn dart corkscrew.

Rest of the damage was superficial except the broken spar. Repaired the spar, recovered affected wing panel with silk and clear dope. Several weeks later was back at it again, with Minnie as strong as ever.

That was my single days without a yard to take care of and otherwise without a care in the world except for my R/C planes.

C-17 Main Wing Spar Fatigue Test

The buckling reminds me of the C-17 Structural Testing Program in the late 1980's at Douglas Aircraft Company in Long Beach, CA where I worked on the 2nd floor of the 4 story high auxiliary admin building 41A attached to Test Hangar 41. (2nd story was actually 3 stories high. 3rd floor was both flight test and structural test engineering offices. 4th floor was the flight test control room and more engineer offices, some manager offices. Equivalent to 1st and 2nd floor of 41A was the Simulations Lab. In the main room, they had a portion of I think the DC-10 cockpit, used to work on software there quietly as much of the time it was unoccupied.)On the hangar floor, one of the tests they were doing was the C-17 main spar section passing through the fuselage. In a test jig, they had million pound hydraulic actuators with all sorts of instrumentation hooked up, strain gauges, etc. to measure movement and internal metallic strains.

With roped off guards around to keep traffic and people away, there was also a sign posted stating the brief title and test number, component involved, flight numbers, "Keep Away", "Test in Progress", etc. Because I was badged as part of the testing staff, I was permitted to walk the floor and observe the test in this high security area (when test in progress). Even went in the adjacent test trailer with our Perkin-Elmer 3220 minicomputer there (it did both the loading and data capturing), looking over the computer operator's shoulders.

The system had fail safes throughout. Tests were sometimes around the clock with 3 shifts. Sometimes it was just two shifts with a shutdown during 3rd shift. (Depended on schedules, priorities and cost.) It was amazing to watch the test in action. Basically these hydraulic actuators would apply pressure, then release, done in an accelerated manner to simulating thousands of hours of stresses to be encountered during the life time, or several life times of the aircraft. We used the same data system to both apply the predetermined loads through a spectrum tape, loaded before the test began. Then, test would run for days on end. Periodically, data sets from our recorded data tape to the structural engineers, for their evaluation.

Continuing months on end, when the test specimen finally fatigued to the point of serious yielding, sometimes even total fracturing with clean breakage, the sound was a loud "boom!" heard even inside the building, system would dump hydraulic pressure and shut the test down.

My Sterling Minnie Mambo Spar Failure

My Minnie Mambo suffered structural wing spar failure back in the late 1980's, when I was still working there. Previously, I had crashed my Minnie, but didn't know the wing spar had been weakened by the crash.To blow off steam, I'd take a 3 day weekend and head up to Santa Maria up north, a couple hour drive along scenic Highway 101. (Passed through a Santa Claus village on the way up.)

Rest of the damage was superficial except the broken spar. Repaired the spar, recovered affected wing panel with silk and clear dope. Several weeks later was back at it again, with Minnie as strong as ever.

That was my single days without a yard to take care of and otherwise without a care in the world except for my R/C planes.

GallopingGhostler- Top Poster

Posts : 5432

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Kim- Top Poster

Posts : 8590

Join date : 2011-09-06

Location : South East Missouri

Re: An Airplane Story from My Facebook Page

Re: An Airplane Story from My Facebook Page

Cool beans, Kim. That classic tug with the cool name on it almost demands to be modeled with a dog in the passenger seat.

I was searching the net for a photo of the old building I used to work in, Test Admin Building 41A adjacent to Test Hangar 41, located on the northwest side of the airport. Historic photos of Douglas Aircraft Co. are now available at the Library of Congress:

https://www.loc.gov/search/?in=&q=douglas+aircraft+%22CA-315-L%22&new=true&st=gallery

But, documents contain no photos of Hangar 41 nor 41A. They were built less than 50 years prior to the photos taken, not considered historically significant (built in the mid 1960's).

Around 2002, Boeing sold the DC-10 / MD-11 commercial manufacturing properties except DC-9 / MD-90 program (now Boeing 717) on the north side of the airport, east of Lakewood Boulevard. I have photos stashed somewhere of the piles of construction debris inside a temporary construction fence on the north side of the airport, taken that Fall when I returned to the area for additional continuing education training.

2006, last DC-9 derivative, Boeing 717 rolled off the assembly line.

http://s80.flight1.net/forums/fly-dc-jets_topic1039.html

Courtesy of flight1.net Forums.

Now, one of those large manufacturing hangar buildings not demolished is operated by Mercedes Benz. (Perhaps a historic preservation move?)

2015, last C-17 rolls off the assembly line.

2018, Boeing sells off all C-17 manufacturing facilities on the south side of the airport.

https://www.thedrive.com/the-war-zone/24774/boeing-is-selling-off-its-historic-c-17-production-line-facility-in-long-beach

Now, Boeing does all C-17 overhaul and refitting in San Antonio, Texas:

Another aerospace company now occupies those C-17 facilities at Long Beach. Douglas Aircraft Company of Long Beach, CA is no more. Do I miss it? No, knowing where your next paycheck is coming from, going home from work on time, and having holidays off is more important.

Douglas Aircraft Company of Long Beach, CA is no more. Do I miss it? No, knowing where your next paycheck is coming from, going home from work on time, and having holidays off is more important.

I was searching the net for a photo of the old building I used to work in, Test Admin Building 41A adjacent to Test Hangar 41, located on the northwest side of the airport. Historic photos of Douglas Aircraft Co. are now available at the Library of Congress:

https://www.loc.gov/search/?in=&q=douglas+aircraft+%22CA-315-L%22&new=true&st=gallery

But, documents contain no photos of Hangar 41 nor 41A. They were built less than 50 years prior to the photos taken, not considered historically significant (built in the mid 1960's).

Around 2002, Boeing sold the DC-10 / MD-11 commercial manufacturing properties except DC-9 / MD-90 program (now Boeing 717) on the north side of the airport, east of Lakewood Boulevard. I have photos stashed somewhere of the piles of construction debris inside a temporary construction fence on the north side of the airport, taken that Fall when I returned to the area for additional continuing education training.

2006, last DC-9 derivative, Boeing 717 rolled off the assembly line.

http://s80.flight1.net/forums/fly-dc-jets_topic1039.html

Courtesy of flight1.net Forums.

Now, one of those large manufacturing hangar buildings not demolished is operated by Mercedes Benz. (Perhaps a historic preservation move?)

2015, last C-17 rolls off the assembly line.

2018, Boeing sells off all C-17 manufacturing facilities on the south side of the airport.

https://www.thedrive.com/the-war-zone/24774/boeing-is-selling-off-its-historic-c-17-production-line-facility-in-long-beach

Now, Boeing does all C-17 overhaul and refitting in San Antonio, Texas:

Another aerospace company now occupies those C-17 facilities at Long Beach.

Douglas Aircraft Company of Long Beach, CA is no more. Do I miss it? No, knowing where your next paycheck is coming from, going home from work on time, and having holidays off is more important.

Douglas Aircraft Company of Long Beach, CA is no more. Do I miss it? No, knowing where your next paycheck is coming from, going home from work on time, and having holidays off is more important.

GallopingGhostler- Top Poster

Posts : 5432

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Similar topics

Similar topics» Cox Facebook page

» Looking for contributions for our upcoming Facebook page

» More Rattling from My Facebook Page: The Carl Goldberg Shoestring Profile Stunter

» It's either here or Facebook.

» Ebay and Facebook tracking

» Looking for contributions for our upcoming Facebook page

» More Rattling from My Facebook Page: The Carl Goldberg Shoestring Profile Stunter

» It's either here or Facebook.

» Ebay and Facebook tracking

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules