Log in

Search

Latest topics

» Irvine Mills .75 replicaby ffkiwi Today at 5:43 am

» COX .020 RC PROJECT

by 1/2A Nut Today at 5:32 am

» **VOTE-ON-THE-NEXT-COX-ENGINE-OF-THE-MONTH** (October 2024)

by Admin Today at 2:33 am

» Happy Birthday Robert ( Rsv1cox )

by balogh Today at 2:06 am

» Carburetor Sprinkler Rod Peak Tee Dee .049 / .051

by MauricioB Today at 12:02 am

» OS MAX-D

by Ken Cook Yesterday at 4:38 pm

» The Cabin.........A carpenters nightmare.

by getback Yesterday at 4:22 pm

» Cox .020 PeeWee/TeeDee prop-screw

by getback Yesterday at 8:55 am

» Wanted peewee 20 fuel tank

by GallopingGhostler Yesterday at 3:05 am

» Fox .35 Modifications

by Ken Cook Fri Oct 04, 2024 8:40 pm

» *Cox Engine of The Month* Submit your pictures! -October 2024-

by Admin Fri Oct 04, 2024 8:33 pm

» Off topic - Tonka dump truck restoration. 10:27

by rsv1cox Fri Oct 04, 2024 7:32 pm

Cox Engine of The Month

Experimental Throttle for Tee Dee .010

Page 1 of 2

Page 1 of 2 • 1, 2

Experimental Throttle for Tee Dee .010

Experimental Throttle for Tee Dee .010

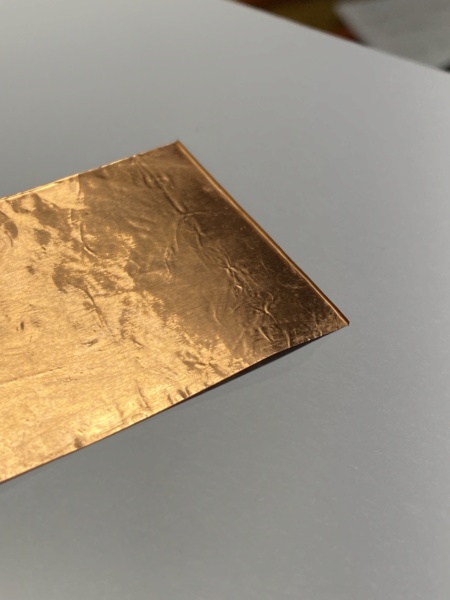

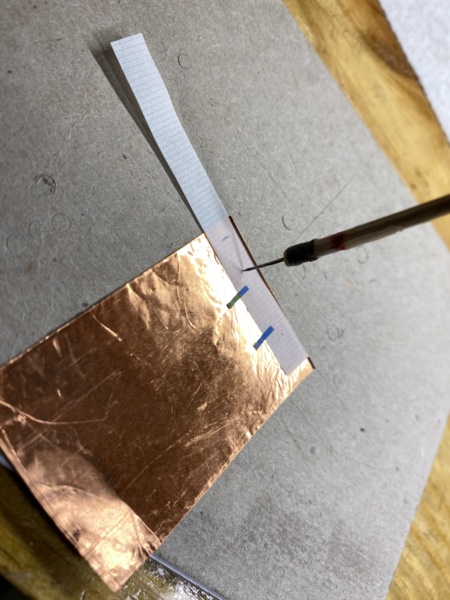

Was made from copper foil, copper wire, and a paper that is used for rolling cigarettes…

The copper foil was from a piece of copper tape that I had, About.001” best I can tell, I soaked it in acetone to get the adhesive off…The paper was both to get the pattern and also became the gasket…. The seams of the copper and paper are opposite each other… A couple of small copper wires are soldered on to the seam in the back…. Then a little bigger one for the control arm in the front…..I used 95/5 solder I found in the hardware store which has a little higher melting temp than the 60/40 I had in the shop…No mods to the cylinder except for polishing the area where the throttle will turn…It’s semi permanent but easily removed if needed…The control arm can be bent a little to tweak orientation….The seal is good enough to turn it completely off if closed too far…

I ran it today and am pleased with the results so far…. Will hold idle around 11 - 12 K and top end doesn’t seem to be hurt … Will test it some more when it’s a little warmer outside!!!

The copper foil was from a piece of copper tape that I had, About.001” best I can tell, I soaked it in acetone to get the adhesive off…The paper was both to get the pattern and also became the gasket…. The seams of the copper and paper are opposite each other… A couple of small copper wires are soldered on to the seam in the back…. Then a little bigger one for the control arm in the front…..I used 95/5 solder I found in the hardware store which has a little higher melting temp than the 60/40 I had in the shop…No mods to the cylinder except for polishing the area where the throttle will turn…It’s semi permanent but easily removed if needed…The control arm can be bent a little to tweak orientation….The seal is good enough to turn it completely off if closed too far…

I ran it today and am pleased with the results so far…. Will hold idle around 11 - 12 K and top end doesn’t seem to be hurt … Will test it some more when it’s a little warmer outside!!!

rdw777- Diamond Member

Posts : 1592

Join date : 2021-03-11

Location : West Texas

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

Wow Robert, looks interesting! I cannot wait how it will work out on the bench! The paper may be a vulnerable component, but lets see!

balogh- Top Poster

Posts : 4904

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

You are becoming the copper king Robert. Takes patience and a steady hand. And, it looks great!

rsv1cox- Top Poster

Posts : 11070

Join date : 2014-08-18

Location : West Virginia

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

Well done, good to see your having fun with it!

I ground the cylinder flange flush, used thick wall aluminum metric tube. Grooved the sleeve to retain a clip on

spring steel throttle arm see vid. Exhaust slots size to produce some throttle use without robbing power.

DYI throttle sleeve.

Cox Tee Dee .010 / HQ T3 x3 prop with back cut. 75 mph pitch speed

Best peak 26,566 rpm / .032hp - 23w / 2.5oz thrust per prop calc.

This prop blows away the stock prop and did it with a TD .020

spinner mass / weight.

HQ Prop T2.5 x2 Peak 29,635 rpm - DYI Throttle

I ground the cylinder flange flush, used thick wall aluminum metric tube. Grooved the sleeve to retain a clip on

spring steel throttle arm see vid. Exhaust slots size to produce some throttle use without robbing power.

DYI throttle sleeve.

Cox Tee Dee .010 / HQ T3 x3 prop with back cut. 75 mph pitch speed

Best peak 26,566 rpm / .032hp - 23w / 2.5oz thrust per prop calc.

This prop blows away the stock prop and did it with a TD .020

spinner mass / weight.

HQ Prop T2.5 x2 Peak 29,635 rpm - DYI Throttle

1/2A Nut- Top Poster

- Posts : 3471

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

It is a beautiful job dear Roberto!!, my sincere congratulations!!

MauricioB- Top Poster

- Posts : 3672

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

Hey Robert, I love the throttle. The copper has a Ye old worldy. SteamPunk look to it.  Looks great and I love the throttles all of you have made using equipment and materials readily at hand

Looks great and I love the throttles all of you have made using equipment and materials readily at hand

GaryB

'Yabby'

GaryB

'Yabby'

Yabby- Platinum Member

Posts : 711

Join date : 2021-06-08

Location : Yorke Peninsula South Australia

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

Good work Robert, I want to make one. I also want to make another one as Andras made from thin stock aluminium, I have been searching his thread.

Levent Suberk- Diamond Member

- Posts : 2236

Join date : 2017-12-24

Location : Türkiye

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

Levent Suberk wrote:Good work Robert, I want to make one. I also want to make another one as Andras made from thin stock aluminium, I have been searching his thread.

Here it comes Levent, go to the end of the 2nd page of the thread, where the experiment concluded in a usable version

https://www.coxengineforum.com/t14943-po-boy-s-exhaust-throttle-for-thin-wall-cylinder?highlight=Po+boy+s+exhaust+throttle

balogh- Top Poster

Posts : 4904

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

That looks Great and don't look to weigh much at all with few components of light material. Keep us up to date on longevity.

getback- Top Poster

Posts : 10381

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

Thank you Gentlemen …. I have looked at and studied the throttles that have been shop made and published here …. Amazing precision and excellent outcomes in operation…. Thinking outside the box for sure….I would not have tried this meager attempt if I had not seen these examples …. A sincere appreciation for what you have achieved…

I got the idea for the paper gasket from a drawing that was for a vintage throttle….. I think one of you may have posted it, I forgot or I would credit…

The paper may be a weak link or who knows, Maybe a help…. I soaked the paper in castor before installing….Thermal expansion is another one that might come into play on this thin metal…. Maybe the paper might help a bit with that….I think I’m OK with the solder melting temps ….

I like that copper king and steam punk thing Bob and Yabby…. I think I’ll keep it!!!

It’s light for sure Eric, It was hard to tell any weight difference on the engine before and after… Maybe a tenth or two of a gram

Will update as I am able

I got the idea for the paper gasket from a drawing that was for a vintage throttle….. I think one of you may have posted it, I forgot or I would credit…

The paper may be a weak link or who knows, Maybe a help…. I soaked the paper in castor before installing….Thermal expansion is another one that might come into play on this thin metal…. Maybe the paper might help a bit with that….I think I’m OK with the solder melting temps ….

I like that copper king and steam punk thing Bob and Yabby…. I think I’ll keep it!!!

It’s light for sure Eric, It was hard to tell any weight difference on the engine before and after… Maybe a tenth or two of a gram

Will update as I am able

rdw777- Diamond Member

Posts : 1592

Join date : 2021-03-11

Location : West Texas

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

Before I run the .010 much more I really need to reset the piston ( I know, Scary, )…. I ordered the tool so while I’m waiting I made one for .020…. Some minor differences:

I shaped the copper to form a flange to hug the fin on the top and hug the skirt on the bottom of the cylinder….

I left a gap at the seam of about .020” and covered it with a narrow section of the same shape, overlapping just a bit, Instead of using wire like on the .010…. I allowed the paper gasket to overlap just a little since it’s so thin…

I paired it up with a heli backplate for a test run… So good so far

The batteries went out on my tach so was not able to get that info… It was running on the standard Cox 4.5 x 2…. 24 % nitro…. Two head gaskets…. I left the starter spring off because I didn’t want it to jump and mar the throttle….Hand starts really easy though….Let me know what you think!!

Robert

I shaped the copper to form a flange to hug the fin on the top and hug the skirt on the bottom of the cylinder….

I left a gap at the seam of about .020” and covered it with a narrow section of the same shape, overlapping just a bit, Instead of using wire like on the .010…. I allowed the paper gasket to overlap just a little since it’s so thin…

I paired it up with a heli backplate for a test run… So good so far

The batteries went out on my tach so was not able to get that info… It was running on the standard Cox 4.5 x 2…. 24 % nitro…. Two head gaskets…. I left the starter spring off because I didn’t want it to jump and mar the throttle….Hand starts really easy though….Let me know what you think!!

Robert

rdw777- Diamond Member

Posts : 1592

Join date : 2021-03-11

Location : West Texas

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

Good work, Robert, that is one smooth operating exhaust restrictor throttle, for the Pew Wee no less!

GallopingGhostler- Top Poster

Posts : 5611

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

Congrats, Robert, works really well..it is not clear where you have added the thin layer of paper, but I suppose this is between the cylinder and the throttle ring gor a perfect seal?

.has it endured the hot castor without morphong into some pulp?

.has it endured the hot castor without morphong into some pulp?

balogh- Top Poster

Posts : 4904

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

Thank you George, Appreciate you Sir  …. Thank you Andras

…. Thank you Andras  …. Yes the paper gasket is between the cylinder and copper throttle…. I had to make a few assumptions which may or may not be correct…. One being the paper will stay and work as a gasket… The drawing for vintage throttle in the photo above suggests that it can….Maybe paper intended for rolling cigarettes can withstand heat better than some others…. Just guessing….The best I can tell the paper is still intact after running…..I have a few more photos I will post with a little write up of some of the details of how it was made ….It’s not terribly difficult, just tedious….

…. Yes the paper gasket is between the cylinder and copper throttle…. I had to make a few assumptions which may or may not be correct…. One being the paper will stay and work as a gasket… The drawing for vintage throttle in the photo above suggests that it can….Maybe paper intended for rolling cigarettes can withstand heat better than some others…. Just guessing….The best I can tell the paper is still intact after running…..I have a few more photos I will post with a little write up of some of the details of how it was made ….It’s not terribly difficult, just tedious….

rdw777- Diamond Member

Posts : 1592

Join date : 2021-03-11

Location : West Texas

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

Robert, if the engine was running so hot  that the paper was smoking,

that the paper was smoking,  isn't that what it is there for?

isn't that what it is there for?

that the paper was smoking,

that the paper was smoking,  isn't that what it is there for?

isn't that what it is there for?

GallopingGhostler- Top Poster

Posts : 5611

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

Way to go Robert. From full throttle to a nice tick-over idle. I think you have joined a very small group of engine masters here.....

but I'm wondering about durability?

but I'm wondering about durability?

rsv1cox- Top Poster

Posts : 11070

Join date : 2014-08-18

Location : West Virginia

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

I think you have a point George, so we need to encourage it to stop smoking  …. But that gives me another idea, I wonder how the wrappers from that stop smoking gum would work???

…. But that gives me another idea, I wonder how the wrappers from that stop smoking gum would work???

Thank Bob, Appreciated …. I wonder about durability too…. I’m hoping for it and I think we have a chance…. Still very ‘spirimental…….One good thing, The materials are cheap to nothing…. Just costs a little time….

…. I wonder about durability too…. I’m hoping for it and I think we have a chance…. Still very ‘spirimental…….One good thing, The materials are cheap to nothing…. Just costs a little time….

…. But that gives me another idea, I wonder how the wrappers from that stop smoking gum would work???

…. But that gives me another idea, I wonder how the wrappers from that stop smoking gum would work???

Thank Bob, Appreciated

rdw777- Diamond Member

Posts : 1592

Join date : 2021-03-11

Location : West Texas

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

rdw777 wrote:I think you have a point George, so we need to encourage it to stop smoking…. But that gives me another idea, I wonder how the wrappers from that stop smoking gum would work???

But what would you call it? Nitro-Ban? Nitro-Quit? Nitro-Chew? Castor-Nix? Cox-Vape?

GallopingGhostler- Top Poster

Posts : 5611

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

Those are all good George!!! …. Witty

Those are all good George!!! …. Witty

A few steps of this loco-ness:

Polish the cylinder really good where the throttle ring will ride…. I have not had any problems so far with the gasket slipping…

I started this one with the metal first by forming the flange at the top…. It can’t be very long at all because it has to stretch as it forms a circle…. A note pad makes a good sheet metal brake to hold it while you bend over the flange with a small dowel or toothpick….

A small drafting divider is used to get the width between the flange and bottom skirt…Also to get the position where the holes will be punched out…

The locations are transferred from the paper to the copper then punched… Smooth out the ridge on the back from the punch….

You have to tease the metal into a ring shape by burnishing it into the corners, Top and bottom, a little at a time…I put a little file mark on the cylinder at the center of the transfer port area to locate and use that flat place as a form to shape it into a ring…

Tie it up tight with thread so you can locate the holes for the paper gasket…

Wet the paper good with castor to help stick it in place…Make and install the piece that will cover the seam of the metal….Tie it on with thread fairly tight …. The thread holds it temporarily because it will just burn up when you solder it….I used enameled magnet wire from an old relay at the top and bottom for the final clamp…. The wire is coated so the solder is less likely to stick to it…The thread is just easier to manage in the beginning of wrapping it up…

Remove the thread and set final tension with the wire…. Better to be a little on the tight side than too loose… We can work it out later…Solder away (it’s own detailed subject)… I used 95/5 and plumbers solder flux…. Start in the middle and work out…. Removing the wire and solder top and bottom last….I used needle files, Files from a cutting torch cleaner set, And a re-shaped fingernail file to clean up excess solder….

Make and install the control arm orienting it as needed…

If it’s too tight and/or the ports became deformed from wrapping, Carefully smooth the rough places on the flat part of cylinder with a round wooden tool coaxing the ring rotate all the way around…

It’s still purely experimental at this point with only a few runs on the bench…. I do intend to eventually fly it so we’ll see how it goes…. It may spark another thought on how to build it better … A lot of this was abbreviated so feel free if there are other details of interest

rdw777- Diamond Member

Posts : 1592

Join date : 2021-03-11

Location : West Texas

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

That has got to be one of the most impressive pieces of handbuilt workmanship I've seen. Working with such small and thin metal is difficult at best and you've done an absolutely excellent job!!

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

That is a really great job you did making the throttle for that .010 engine. It was very creative too. Many kudos to you for it.

earlwb- New Member

- Posts : 4

Join date : 2011-08-15

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

A most respectful thank you Gentlemen…. I have learned a lot here on CEF and have had just a lot of plane fun too

rdw777- Diamond Member

Posts : 1592

Join date : 2021-03-11

Location : West Texas

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

Robert, I think you have a potential winner in the next Cox Engine of the Month Contest.

GallopingGhostler- Top Poster

Posts : 5611

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

Plenty of excellent tips to apply in preparing such DIY items, and excellent execution of details, my sincere congratulations, Robert! I see you also managed to file flats in the top fin of the 010 cylinder..

balogh- Top Poster

Posts : 4904

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Re: Experimental Throttle for Tee Dee .010

Re: Experimental Throttle for Tee Dee .010

Robert that is absolutely amazing!  As I said before its got that Ye olde World Steampunk look as if its been made by a craftsman jewller of the ages. amazing how you can work with such intricate and thin material and shape it to work on an engine as a throttle, very very few people would be capable of such detailed craftsman type work.

As I said before its got that Ye olde World Steampunk look as if its been made by a craftsman jewller of the ages. amazing how you can work with such intricate and thin material and shape it to work on an engine as a throttle, very very few people would be capable of such detailed craftsman type work.

I think GG is right about you haveing a Cox engine of the month winner there! You have crafted am individual unique engine.

As I said before its got that Ye olde World Steampunk look as if its been made by a craftsman jewller of the ages. amazing how you can work with such intricate and thin material and shape it to work on an engine as a throttle, very very few people would be capable of such detailed craftsman type work.

As I said before its got that Ye olde World Steampunk look as if its been made by a craftsman jewller of the ages. amazing how you can work with such intricate and thin material and shape it to work on an engine as a throttle, very very few people would be capable of such detailed craftsman type work.

I think GG is right about you haveing a Cox engine of the month winner there! You have crafted am individual unique engine.

Yabby- Platinum Member

Posts : 711

Join date : 2021-06-08

Location : Yorke Peninsula South Australia

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Medallion .000 cu. in. engine

» COX engine throttles

» Cox .049 Experimental "Crystal" reeds are now available

» Experimental Aircraft Designs

» experimental reed-valve test 5-5-18

» COX engine throttles

» Cox .049 Experimental "Crystal" reeds are now available

» Experimental Aircraft Designs

» experimental reed-valve test 5-5-18

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules