Log in

Search

Latest topics

» Simple Glidersby getback Today at 7:13 am

» Cox PT-19 Wing

by getback Today at 6:24 am

» Foam hand kids glider converted to 0.049 CL

by getback Today at 6:23 am

» Roddie-Rigger.. a 2005 original design

by getback Today at 6:17 am

» Golden Bee basic running problem

by roddie Yesterday at 10:51 pm

» Weird search for a single comic from an old Mad Magazine

by Kim Yesterday at 1:44 pm

» Scientific "Zipper" Build...Zipper Flys!.

by getback Yesterday at 7:27 am

» Cox .049 Tee Dee engines back in stock (limited availablility)

by GallopingGhostler Yesterday at 1:05 am

» Very off-topic.........Time passes and not always for the best......

by rsv1cox Thu Jul 25, 2024 2:47 pm

» Jim Walker Bonanza etc.

by rsv1cox Wed Jul 24, 2024 6:30 pm

» Throttles for Cox Tee Dee .049 / .020 / .010 engines --- videos

by sosam117 Wed Jul 24, 2024 8:54 am

» Introducing our Cox .049 TD Engines

by Admin Tue Jul 23, 2024 2:00 am

Cox Engine of The Month

July-2024

robot797's

"ULTIMITE COX 010: it has a clutch, E starter, throttle, exhaust, aluminum tank, aluminum venturi, gearbox with forward and reverse, and now its on a custom drawn and printed stand"

PAST WINNERS

robot797's

"ULTIMITE COX 010: it has a clutch, E starter, throttle, exhaust, aluminum tank, aluminum venturi, gearbox with forward and reverse, and now its on a custom drawn and printed stand"

PAST WINNERS

my attempt at making an exhaust throttle for Cox .049

Page 1 of 1

my attempt at making an exhaust throttle for Cox .049

my attempt at making an exhaust throttle for Cox .049

I bought some .750" OD Aluminum tubing.. hoping it would be a candidate for my muffler design. It's just a 12" length piece.. which is good because it won't work for what I originally hoped.

The tubing might work-out for making cylinder-sleeves as exhaust throttles.

Shown below with your "garden variety" Cox .049 cylinder inserted..

.5885" pipe ID..

.5935" cylinder-neck OD on crankcase...

Deburring the pipe's "bottom" to fit the case.. along with a cross-drilled "relief-port".. might work. We'll see...

The tubing might work-out for making cylinder-sleeves as exhaust throttles.

Shown below with your "garden variety" Cox .049 cylinder inserted..

.5885" pipe ID..

.5935" cylinder-neck OD on crankcase...

Deburring the pipe's "bottom" to fit the case.. along with a cross-drilled "relief-port".. might work. We'll see...

Re: my attempt at making an exhaust throttle for Cox .049

Re: my attempt at making an exhaust throttle for Cox .049

Roddie, a very interesting project. Remember though when designing the ring internal diameter, that aluminum has about 2 times higher thermal expansion coefficient than steel, therefore when fitted cold, the throttle should be sitting on the cylinder almost tight, so as when running hot, and expanding more in diameter than the cylinder, there should still be a very small radial gap that, if excessive, would compromise sealing for an efficient throttle.

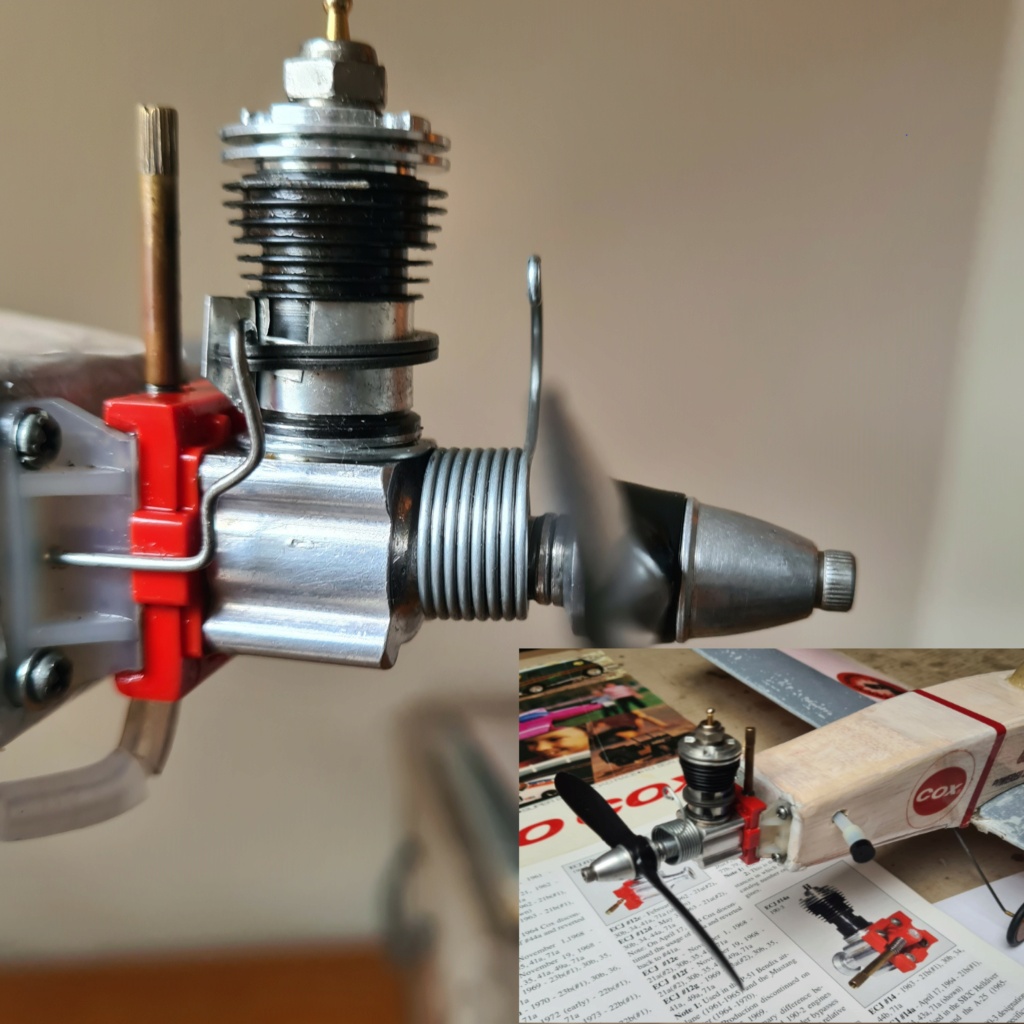

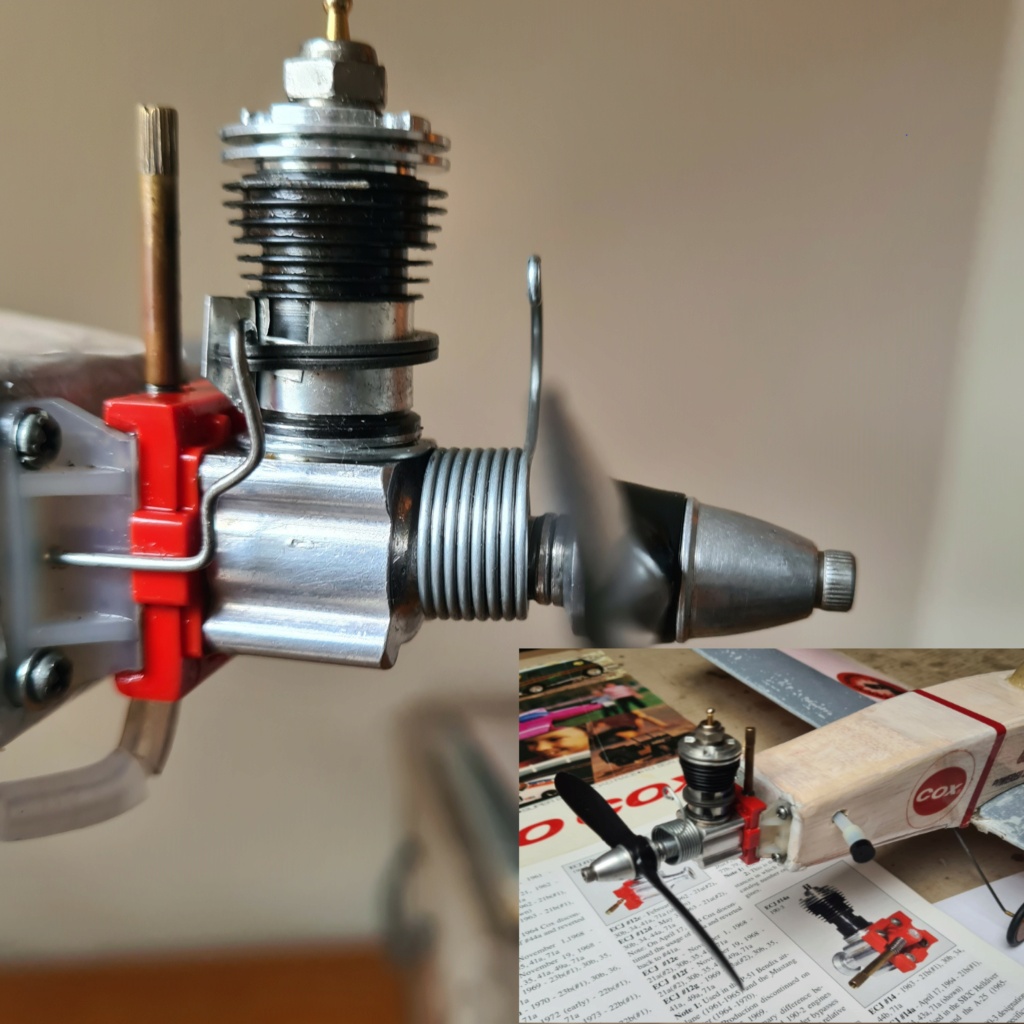

I make my home made exhaust throttles out of thin aluminum coil cut from beer cans, wound around the cylinder neck with free ends allowing free expansion with no diamater increase, and use a steel circlip to keep them tight on the cylinder neck even if hot..a photo below, showing my March 2024 COX engine of the month winner queenie features such a DIY exhaust throttle on a thin wall No1 cylinder with a bottom flange on it, that would not allow the use of a normal throttle.

I keep watching your posts with excitement.

I make my home made exhaust throttles out of thin aluminum coil cut from beer cans, wound around the cylinder neck with free ends allowing free expansion with no diamater increase, and use a steel circlip to keep them tight on the cylinder neck even if hot..a photo below, showing my March 2024 COX engine of the month winner queenie features such a DIY exhaust throttle on a thin wall No1 cylinder with a bottom flange on it, that would not allow the use of a normal throttle.

I keep watching your posts with excitement.

balogh- Top Poster

Posts : 4803

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Re: my attempt at making an exhaust throttle for Cox .049

Re: my attempt at making an exhaust throttle for Cox .049

Nice work Guys. Way beyond my skills

Greenman38633- Gold Member

- Posts : 150

Join date : 2024-02-05

Re: my attempt at making an exhaust throttle for Cox .049

Re: my attempt at making an exhaust throttle for Cox .049

Good start Roddie, Will be interested to see what you come up with!!…. Throttled engines are fun to play with

rdw777- Diamond Member

Posts : 1470

Join date : 2021-03-11

Location : West Texas

Re: my attempt at making an exhaust throttle for Cox .049

Re: my attempt at making an exhaust throttle for Cox .049

Even a little loose the ring still changes the rpm just less efficient for very low rpm I like the idea of an simple rc silencer

davidll1984- Diamond Member

- Posts : 2303

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: my attempt at making an exhaust throttle for Cox .049

Re: my attempt at making an exhaust throttle for Cox .049

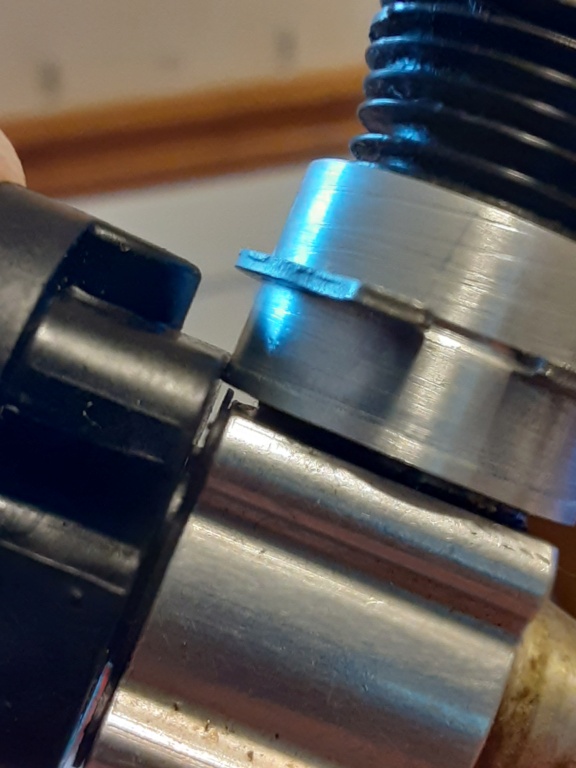

I measured, marked/scribed and cut a ring from my 12" length pipe.. to the approx. length of 7/16".. using my new "Rigid" cutting-wheel plumber's tool.

This gets it fairly close..

Then I used my deburring tool to gradually produce a beveled slip-fit.

Not sure how I want to proceed.. Cut a groove for a clip-ring I guess.

This gets it fairly close..

Then I used my deburring tool to gradually produce a beveled slip-fit.

Not sure how I want to proceed.. Cut a groove for a clip-ring I guess.

Re: my attempt at making an exhaust throttle for Cox .049

Re: my attempt at making an exhaust throttle for Cox .049

So.... the ID of the clip-ring is .692" and the OD of the barrel is .748".......... That's a difference of .056". A groove in the barrel that's .028" deep should then measure-out to that .692" diameter. If I go halfway; with a .014" deep groove.. that should be adequate for the clip-ring to seat and hold position.

I'm planning to make a mandrel for the barrel; that I can "chuck" in my VSR drill and either file a groove.. or use a Dremel/cut-off wheel. I'm leaning toward trying one of my V-cutting riffler-files.

I bought those file and rasp sets 30 years ago at a local job-lot outlet... on the cheap.. and have used them countless times for different things.

Re: my attempt at making an exhaust throttle for Cox .049

Re: my attempt at making an exhaust throttle for Cox .049

The mandrel... I made from one of my 1/4" square-drive socket-wrenches.. and some D/S foam tape.. (the same concept I used to finish-sand my aluminum muffler-rings..)

I'll admit; I wrapped X3 sockets before I arrived at the size that worked.. peeled the adhesive-liner from the D/S tape... and applied the talcum-powder (anti-sticky) treatment to the exposed adhesive.. but the fit was so tight.. that I couldn't get the barrel to go on all the way. I ended up using triple antibiotic ointment for its petroleum-jelly base to get the barrel all the way on. A comedy of errors.. but I managed to cut a groove which was deep enough for the clip-ring I'd picked-out.

It's a redneck way to do it.. I know.. but I don't have access to the machinery that I used to when I was employed..

I know.. but I don't have access to the machinery that I used to when I was employed..

I'll admit; I wrapped X3 sockets before I arrived at the size that worked.. peeled the adhesive-liner from the D/S tape... and applied the talcum-powder (anti-sticky) treatment to the exposed adhesive.. but the fit was so tight.. that I couldn't get the barrel to go on all the way. I ended up using triple antibiotic ointment for its petroleum-jelly base to get the barrel all the way on. A comedy of errors.. but I managed to cut a groove which was deep enough for the clip-ring I'd picked-out.

It's a redneck way to do it..

Re: my attempt at making an exhaust throttle for Cox .049

Re: my attempt at making an exhaust throttle for Cox .049

So now......... I'm wondering if I can simply drill a "cross-hole" for the exhaust-relief.. or does it need to be a pair of "slots".. 180 degrees apart? I blocked the crankcase openings (crankshaft and backplate) and with cylinder and barrel installed; used my mouth to blow-through the top of the cylinder. Some very slight leakage is present.. but I think I have something that will work.

I'm hoping that this will work on the stepped-wall cylinders.. as well as the "two-slit" type. We'll see..

I'm hoping that this will work on the stepped-wall cylinders.. as well as the "two-slit" type. We'll see..

Re: my attempt at making an exhaust throttle for Cox .049

Re: my attempt at making an exhaust throttle for Cox .049

Very well done, Roddie, looking forward to seeing the end product. I would suggest a rectangular relief to be cut instead of 2 holes drilled, even if this is less difficult..the latter will block the exhaust even if fully open..

balogh- Top Poster

Posts : 4803

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Re: my attempt at making an exhaust throttle for Cox .049

Re: my attempt at making an exhaust throttle for Cox .049

Redneck or not you are getting it done with Good progress , like the file set handy to have , drill two holes side by side and file out the rest to get the oval hole is what i would do but its ur puppy .

getback- Top Poster

Posts : 10280

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: my attempt at making an exhaust throttle for Cox .049

Re: my attempt at making an exhaust throttle for Cox .049

Great work Roddie!….Just for reference on the round hole type: I have one on an .049 I use in my Zoomslot Saucer…. Idle’s great when fully closed but will not kill the engine…. The hole size is a #23 dill …. Obviously smaller area than the cylinder’s exhaust port but doesn’t seem to take away top end….. Photo for reference of the hole to the engine’s port…. The lower left corner of the port is the last to close (I don’t know if that makes any difference). The engine has SPI…I used it as a model for a homemade throttle for an .020…

I have a rectangular port factory throttle on an .020 that works good as well… Just don’t have one in .049 to measure for comparison…

I have a rectangular port factory throttle on an .020 that works good as well… Just don’t have one in .049 to measure for comparison…

rdw777- Diamond Member

Posts : 1470

Join date : 2021-03-11

Location : West Texas

Re: my attempt at making an exhaust throttle for Cox .049

Re: my attempt at making an exhaust throttle for Cox .049

Thanks guys, The "drilled-hole" (#23 drill, thanks Robert) is what I'm going to try first.

Similar topics

Similar topics» Tee Dee .09 exhaust throttle

» Cox .010 exhaust throttle... the U.E.T

» exhaust throttle ring - again

» exhaust throttle idea-redneck

» 020 cylinder with exhaust throttle on ebay

» Cox .010 exhaust throttle... the U.E.T

» exhaust throttle ring - again

» exhaust throttle idea-redneck

» 020 cylinder with exhaust throttle on ebay

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules