Log in

Search

Latest topics

» Happy Anzac Day!by Boats13 Today at 11:03 pm

» Three -- sold out (making two more) Cox .010 Carburetors with wrench

by sosam117 Today at 10:41 pm

» Fox .35 Modifications

by Ken Cook Today at 10:20 pm

» Project Cox .049 r/c & Citabrian Champion

by MauricioB Today at 4:08 pm

» Jim Walkers FireBee - This is going to be fun

by rsv1cox Today at 3:56 pm

» Revivng Some Childhood Classics

by rsv1cox Today at 7:17 am

» Introducing our Cox .049 TD Engines

by getback Today at 6:20 am

» Roddie's flat-bottomed boat..

by Levent Suberk Today at 12:23 am

» Cox powered jet-pump for model Sprint Boat

by roddie Yesterday at 10:25 pm

» Micro Draco Gets to Fly on a Beautiful Morning.

by rdw777 Yesterday at 8:15 pm

» Jim Walker Firebaby

by rdw777 Yesterday at 8:06 pm

» Hydro-bat by Vic Smeed: engine probs

by GallopingGhostler Yesterday at 5:12 pm

Cox Engine of The Month

.049 Needle Valve Setting Too Touchy

Page 1 of 1

.049 Needle Valve Setting Too Touchy

.049 Needle Valve Setting Too Touchy

I have a one excellent running .049 reed. Number 4 cylinder and peaks at about 18,300 RPM. Pretty good run. Using diskette reed valve as don't have any mylar left. However the backplate I'm using is so touchy. even 1/8 turn will either starve or over fuel the motor. The needle is not broken or bent. The fuel inlet hole doesn't appear to be huge but actually normal size or slightly on the small side?

What can make a backplate so touchy with the needle? The backplate is one of those ones that has the pressed rim around inside comes up like a grommet sort of dimple. Sometimes I drill them out for the .082 but this one is still original. Haven't adjusted yet. But with the high RPM wasn't too concerned yet. Can it be that the dimple backplate is restricting air and that makes the needle so touchy? Really curious.

Just wondered what the experience might say.

Thanks

Ice

What can make a backplate so touchy with the needle? The backplate is one of those ones that has the pressed rim around inside comes up like a grommet sort of dimple. Sometimes I drill them out for the .082 but this one is still original. Haven't adjusted yet. But with the high RPM wasn't too concerned yet. Can it be that the dimple backplate is restricting air and that makes the needle so touchy? Really curious.

Just wondered what the experience might say.

Thanks

Ice

Iceberg- Gold Member

- Posts : 381

Join date : 2018-11-03

Location : Suva Fiji Islands

Re: .049 Needle Valve Setting Too Touchy

Re: .049 Needle Valve Setting Too Touchy

Hi Darren, you may want to check if the black seal holds the NV tight. Especially the long NV-s with the large black knob on the top are prone to vibration, that will result in loose seal and self adjustment. The enhanced sensitivity of the NV may be an indication that when you touch the NV with your finger, you open a radial gap between the seal and NV stem that makes the mix suddenly lean..

Just an idea...IMHO most erratic runs of COX engines are somehow attributable to false airflow finding its way into the crankcase...worn out crankcase to shaft seal...torn gaskets...bad NV seal...you name it..

Just an idea...IMHO most erratic runs of COX engines are somehow attributable to false airflow finding its way into the crankcase...worn out crankcase to shaft seal...torn gaskets...bad NV seal...you name it..

balogh- Top Poster

Posts : 4745

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Re: .049 Needle Valve Setting Too Touchy

Re: .049 Needle Valve Setting Too Touchy

HI Andras

This needle is not turning it stays put. I also added silicone tube down to backplate and removed spring to ensure no leak? Very sensitive.

Thanks!

This needle is not turning it stays put. I also added silicone tube down to backplate and removed spring to ensure no leak? Very sensitive.

Thanks!

Iceberg- Gold Member

- Posts : 381

Join date : 2018-11-03

Location : Suva Fiji Islands

Re: .049 Needle Valve Setting Too Touchy

Re: .049 Needle Valve Setting Too Touchy

Darren my other guess is if the conical tip of the NV and the spraybar throat are worn out then a unit turn of the NV may result in much larger annulus area increment for fuel passage than when new.

One sign of worn out NV and spraybar is that you cannot completely close it and your sweet spot for NV setting is at fewer opening turns than written in the engine handbook..check the number of turns for best NV setting, and whether the NV can completely close?...typical with the 010 and 020 TeeDee-s with aluminum NV housing, and likely with 049 reedies too.

One sign of worn out NV and spraybar is that you cannot completely close it and your sweet spot for NV setting is at fewer opening turns than written in the engine handbook..check the number of turns for best NV setting, and whether the NV can completely close?...typical with the 010 and 020 TeeDee-s with aluminum NV housing, and likely with 049 reedies too.

balogh- Top Poster

Posts : 4745

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Re: .049 Needle Valve Setting Too Touchy

Re: .049 Needle Valve Setting Too Touchy

Hey Ice,  Cool that you're using the diskette material for reed-valves.

Cool that you're using the diskette material for reed-valves.

There were no replies when I started mine... so FWIW..

You're referring to a tank-backplate I assume? The Babe Bee type has a .063" diameter air-intake hole going into the venturi-tube. It wouldn't/shouldn't be causing a touchy-needle condition.

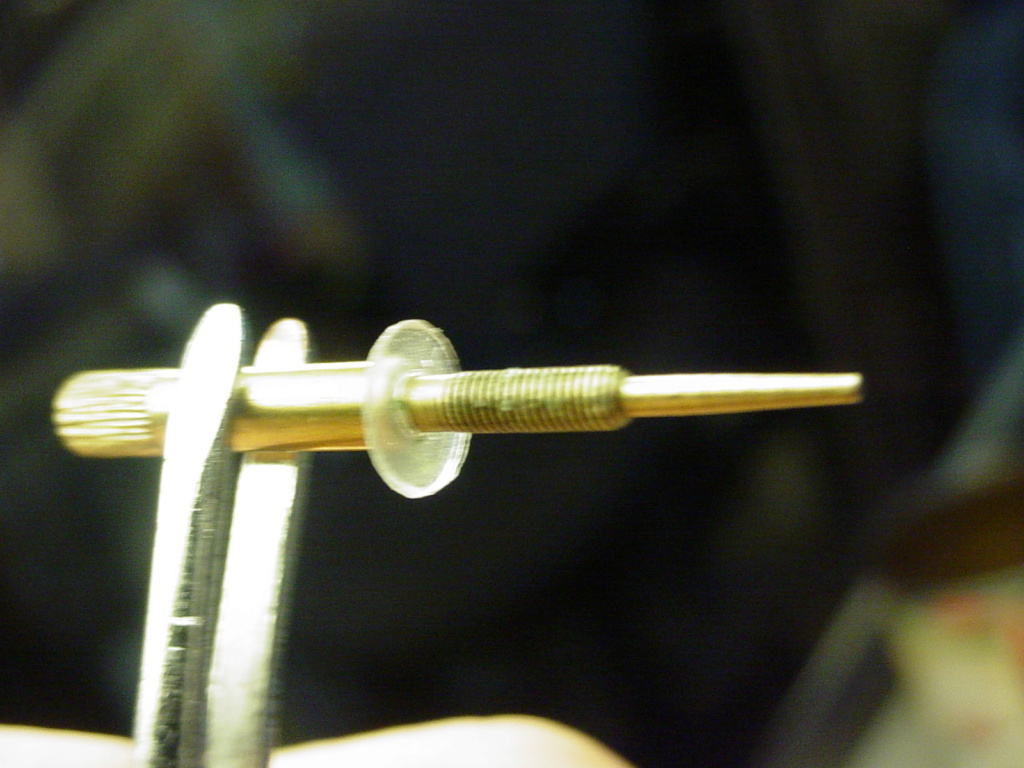

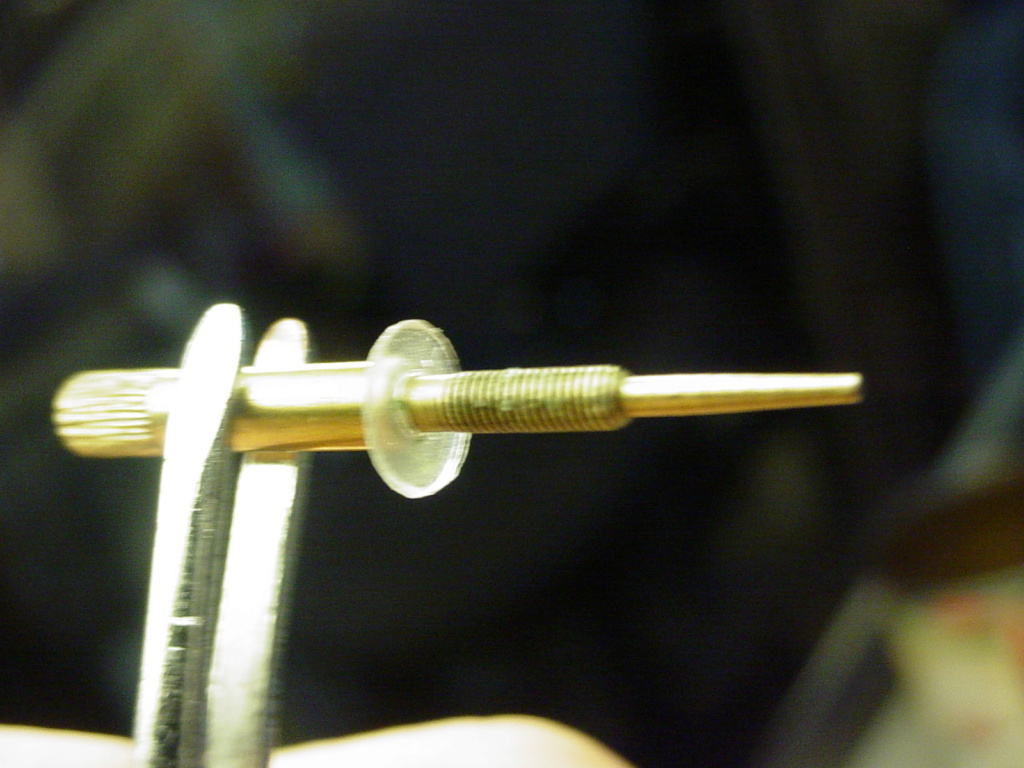

Your needle "threads" may be leaking air.. which will cause trouble. You could try removing the needle to install a short length of sm. size (snug-fitting) silicone fuel-tubing over it. The idea is to provide a "seal" where the needle threads-into the backplate. The tubing can actually replace the "spring".. if the tubing is cut to a certain length. A small rigid flat-washer installed on the needle "first".. provides a shoulder to bear on the tubing as the needle is turned inward. This compresses the tubing against the opening where the needle enters the backplate, creating the needed seal.

A photo is worth...

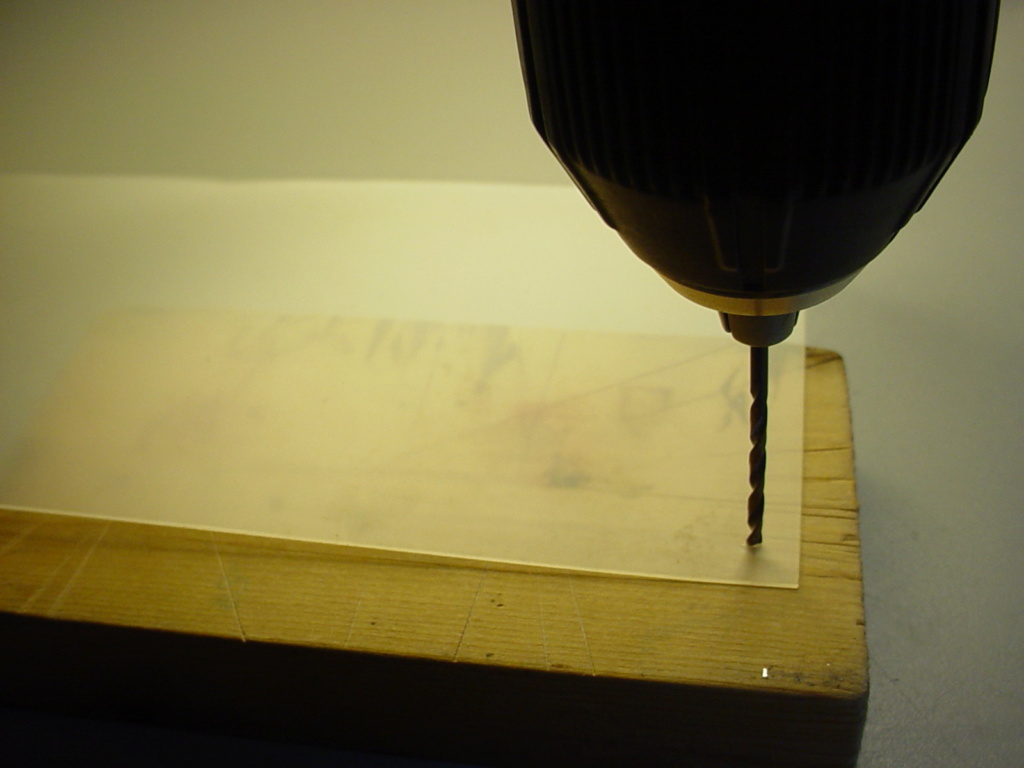

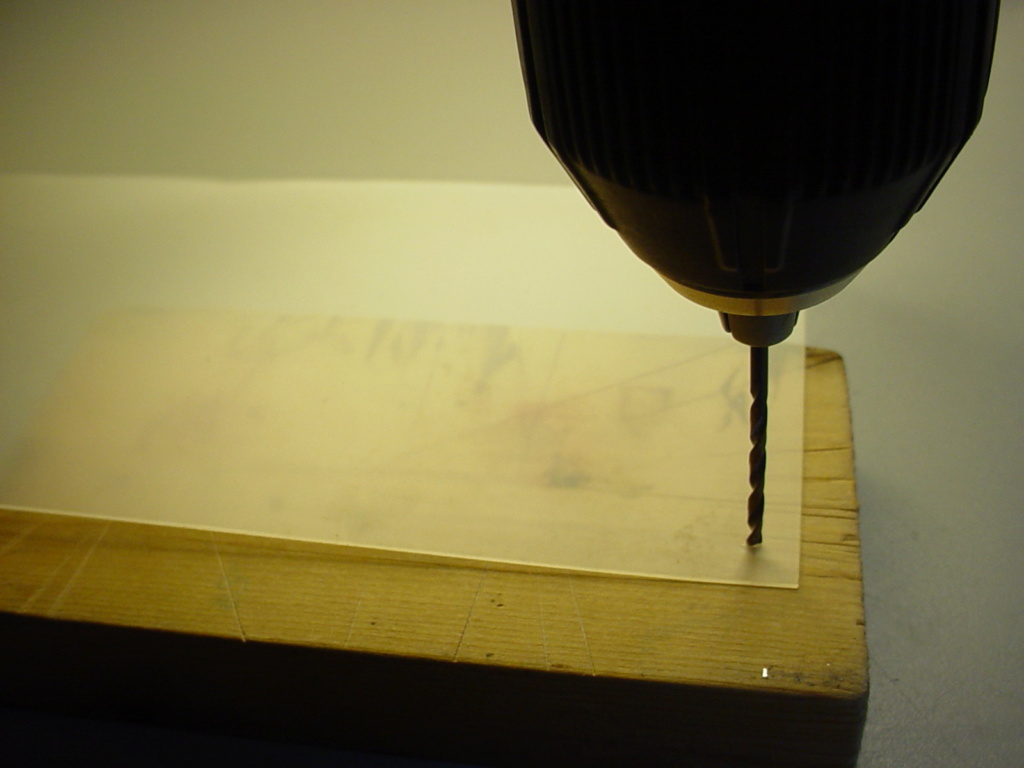

The "Bee" (.049) style needle-shaft has a .1095" (7/64") diameter. You can make a flat-washer from thin plastic sheet.. (thin enough to cut-out with a paper-punch) Drill near the edge of a subject plastic sheet first; using a 7/64" drill bit. Then cut-out with the paper-punch centering the "drilled-hole" in the eye of the punch.

Below shows the smaller (.078" diameter) product-engine's needle getting the same procedure.

There were no replies when I started mine... so FWIW..

You're referring to a tank-backplate I assume? The Babe Bee type has a .063" diameter air-intake hole going into the venturi-tube. It wouldn't/shouldn't be causing a touchy-needle condition.

Your needle "threads" may be leaking air.. which will cause trouble. You could try removing the needle to install a short length of sm. size (snug-fitting) silicone fuel-tubing over it. The idea is to provide a "seal" where the needle threads-into the backplate. The tubing can actually replace the "spring".. if the tubing is cut to a certain length. A small rigid flat-washer installed on the needle "first".. provides a shoulder to bear on the tubing as the needle is turned inward. This compresses the tubing against the opening where the needle enters the backplate, creating the needed seal.

A photo is worth...

The "Bee" (.049) style needle-shaft has a .1095" (7/64") diameter. You can make a flat-washer from thin plastic sheet.. (thin enough to cut-out with a paper-punch) Drill near the edge of a subject plastic sheet first; using a 7/64" drill bit. Then cut-out with the paper-punch centering the "drilled-hole" in the eye of the punch.

Below shows the smaller (.078" diameter) product-engine's needle getting the same procedure.

Re: .049 Needle Valve Setting Too Touchy

Re: .049 Needle Valve Setting Too Touchy

Hey Roddie that is very professional how you make it..luckily I have small, matching metric steel washers for that purpose but basically I apply the silicon tube and washer the same way

balogh- Top Poster

Posts : 4745

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Re: .049 Needle Valve Setting Too Touchy

Re: .049 Needle Valve Setting Too Touchy

Thanks Roddie

Nice work.

I find the diskette works excellent. One time had an issue when glow plug started leaking. Motor speed slowed but engine temperature climbed. Diskette warped had to change. But normally runs awesome.

Yes the time is what I use. I found some small washers for brakes on a car that were perfect. I use this but your plastic one would also be really good. Nice idea.

I'll keep fighting this backplate to get decent runs. Just have to be careful because even 1/8 turn one way or the other can spoil a great run.

Thanks

Ice

Nice work.

I find the diskette works excellent. One time had an issue when glow plug started leaking. Motor speed slowed but engine temperature climbed. Diskette warped had to change. But normally runs awesome.

Yes the time is what I use. I found some small washers for brakes on a car that were perfect. I use this but your plastic one would also be really good. Nice idea.

I'll keep fighting this backplate to get decent runs. Just have to be careful because even 1/8 turn one way or the other can spoil a great run.

Thanks

Ice

Iceberg- Gold Member

- Posts : 381

Join date : 2018-11-03

Location : Suva Fiji Islands

Re: .049 Needle Valve Setting Too Touchy

Re: .049 Needle Valve Setting Too Touchy

balogh wrote:Hey Roddie that is very professional how you make it..luckily I have small, matching metric steel washers for that purpose but basically I apply the silicon tube and wssher the same way

Hi Darren

I've heard that the vintage Copper star-shaped reeds can flutter/float, when the revs get up over 17-18K.. but I don't know if that condition is exclusive to the "circlip" style reed-retainer.

Does your engine utilize the circlip-style reed-retainer? If so; this clip is engineered to provide enough clearance; so as not to "pinch/bind" the original .001" thickness copper-beryllium 4-star shaped reed.

There's HUGE debate here..

concerning reed-valve induction.. and its related components. It's all good.. especially if it helps you to get an engine running consistently.

concerning reed-valve induction.. and its related components. It's all good.. especially if it helps you to get an engine running consistently.  Re: .049 Needle Valve Setting Too Touchy

Re: .049 Needle Valve Setting Too Touchy

Roddie regarding reed floating..check out my Quickie 100 video..

https://www.coxengineforum.com/t13833-quickie-100-rc-flight-video?highlight=Quickie#178701

Both Brad and I audiotached 28k+ rpm on the flight with my red postage backplate 190 reedy in defiance of the float theory..

That lil gem has the stock beryllium star reed in it.

https://www.coxengineforum.com/t13833-quickie-100-rc-flight-video?highlight=Quickie#178701

Both Brad and I audiotached 28k+ rpm on the flight with my red postage backplate 190 reedy in defiance of the float theory..

That lil gem has the stock beryllium star reed in it.

balogh- Top Poster

Posts : 4745

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Re: .049 Needle Valve Setting Too Touchy

Re: .049 Needle Valve Setting Too Touchy

Nice run Andras. Reed was real good. Heard a couple chatters at the start but smoothed out quick. Nice.

Thanks

Thanks

Iceberg- Gold Member

- Posts : 381

Join date : 2018-11-03

Location : Suva Fiji Islands

Re: .049 Needle Valve Setting Too Touchy

Re: .049 Needle Valve Setting Too Touchy

it hapen to me have same back plate is a extra part in there that sort of washer in back plate jet hole my is black widow size my 2 is from texaco smaler size wit simple dual bypas cylinder rpm is 18000 to 19k wit dual bypas wit two boost port 22000 plus if u place engine to control line hi angle like on side fuel pickup tube is short not like standar bee in drag car is same tube lenght as plane fly fuel is push in tube it wil change seting du to its jet cofiguration and tube lenght is wat i tink ??

davidll1984- Diamond Member

- Posts : 2287

Join date : 2020-02-12

Age : 39

Location : shawinigan

Similar topics

Similar topics» Tee Dee .010 Needle valve setting

» Re-setting a piston?

» fuel pickup tube spring

» Setting up a poll

» Needle Setting For Cox Engine With Fine Thread Needle

» Re-setting a piston?

» fuel pickup tube spring

» Setting up a poll

» Needle Setting For Cox Engine With Fine Thread Needle

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules