Log in

Search

Latest topics

» Dodge Viper - What a waste but brilliant marketingby roddie Today at 6:46 pm

» COX .020 POWERED SPEEDSTER

by TD ABUSER Today at 6:32 pm

» **VOTE-ON-THE-NEXT-COX-ENGINE-OF-THE-MONTH** (November 2024)

by roddie Today at 6:13 pm

» Brushless motors?

by rsv1cox Today at 4:53 pm

» Free Flight Radio Assist

by rdw777 Today at 4:28 pm

» Cox 020 PeeWee rebuild questions

by balogh Today at 4:15 pm

» L4 Grasshopper

by latole Today at 3:43 pm

» PAW 80 and possible use

by fit90 Today at 8:36 am

» Music-wire bending tools (DIY video)

by 1975 control line guy Today at 8:32 am

» Ultrasonic Cleaners??

by sosam117 Yesterday at 11:26 am

» My CA or CyA (super glue) allergy

by rsv1cox Yesterday at 9:52 am

» My Pseudo killerbee.

by rsv1cox Yesterday at 7:04 am

Fuel Blends

Page 1 of 1

Fuel Blends

Fuel Blends

Hello,

What are best fuel blends for sport flying Cox .049 Bees & Widows, a TD .049, and a TD .09. How do I break-in these engines. I am just now returning to flying Cox engines since the early 1960's.

Thanks

Robert

What are best fuel blends for sport flying Cox .049 Bees & Widows, a TD .049, and a TD .09. How do I break-in these engines. I am just now returning to flying Cox engines since the early 1960's.

Thanks

Robert

Ro31415- New Member

- Posts : 1

Join date : 2022-04-20

Re: Fuel Blends

Re: Fuel Blends

Hello Robert,

many topics address these issues here. In a nutshell, the minimum lube content is 20% that you need to blend in a COX engine fuel, of which at least half should be castor. I, for one, prefer all-castor lube and avoid synthetic oils. This is true for all COX engines with balljoint between the piston and rod. Nitro may vary between 5% up to even 50% or higher, but that may take its toll on the engine longevity. I usually run all my COX engines on 20%castor/20%nitro /60% methanol blend, with the only exception of the smallest 010 TeeDees that get 30% nitro on 20% castor and 50% methanol.

For running in, while COX advertised their finely fitted engines are ready for service once out of the box, some people begin with a few short runs of 1 minutes each, with rich fuel-air mixture, letting the engine run slow, in a "4-stroke " manner. Restart after cooled down and repeat a few times, when you finally set the engine speed to max by leaning the fuel air mixture with the needle valve setting accordingly. This is not just a mechanical "lapping" process, but also a thermal stress-relief of the machined cylinder and piston mating surfaces, where finally everything will drop in its place with best compression and minimum friction.

Old stock, taper bore cylinder and piston combos are good for hundreds of hours of dependable service, thanks to the fantastic production accuracy of COX manufacturing in its heydays, as well as to the self-healing effect of castor that leaves varnish in occasionally inflicted wear patterns by dirt, scratched in the cylinder wall..

many topics address these issues here. In a nutshell, the minimum lube content is 20% that you need to blend in a COX engine fuel, of which at least half should be castor. I, for one, prefer all-castor lube and avoid synthetic oils. This is true for all COX engines with balljoint between the piston and rod. Nitro may vary between 5% up to even 50% or higher, but that may take its toll on the engine longevity. I usually run all my COX engines on 20%castor/20%nitro /60% methanol blend, with the only exception of the smallest 010 TeeDees that get 30% nitro on 20% castor and 50% methanol.

For running in, while COX advertised their finely fitted engines are ready for service once out of the box, some people begin with a few short runs of 1 minutes each, with rich fuel-air mixture, letting the engine run slow, in a "4-stroke " manner. Restart after cooled down and repeat a few times, when you finally set the engine speed to max by leaning the fuel air mixture with the needle valve setting accordingly. This is not just a mechanical "lapping" process, but also a thermal stress-relief of the machined cylinder and piston mating surfaces, where finally everything will drop in its place with best compression and minimum friction.

Old stock, taper bore cylinder and piston combos are good for hundreds of hours of dependable service, thanks to the fantastic production accuracy of COX manufacturing in its heydays, as well as to the self-healing effect of castor that leaves varnish in occasionally inflicted wear patterns by dirt, scratched in the cylinder wall..

Last edited by balogh on Wed Apr 20, 2022 7:26 am; edited 1 time in total (Reason for editing : typo correction)

balogh- Top Poster

Posts : 4940

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Fuel Blends

Re: Fuel Blends

Balogh Good informations I would like to add after the brake in period of the engine I suggest to reset the ball joint of the piston Or shortly after brake in They tend to come loose very quickly the first time. Befor the first reset Personally this is a point that I check and sometimes I reset even before the first try. For the fuel i like the bugy fuel 20%nitro 9%oil ad castor oil To 21%oil

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Fuel Blends

Re: Fuel Blends

Fred Krueger wrote:...

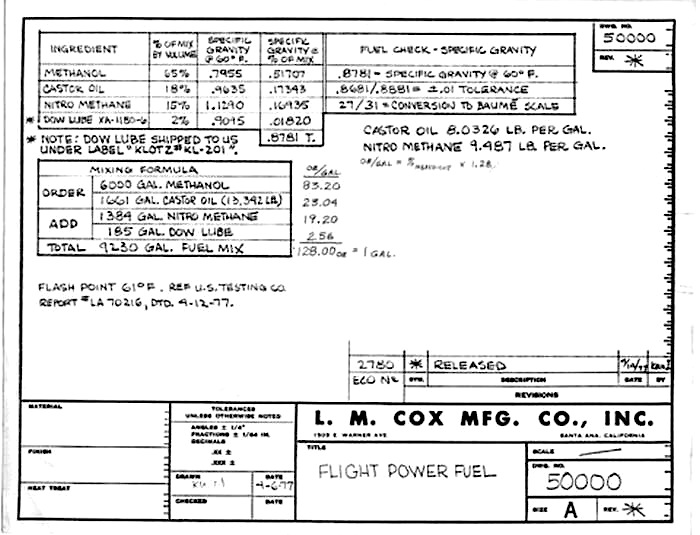

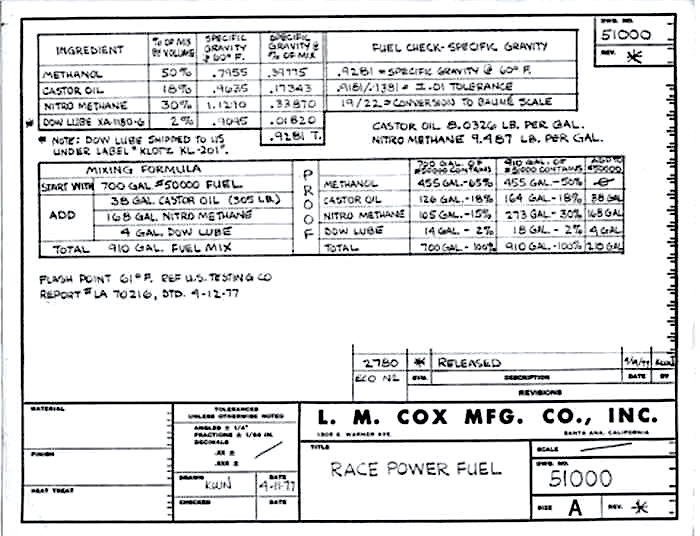

So, the castor oil is 18% and the Klotz is 2% --- equals 20% oil

I have some of that Klotz for my diesel mixing.

sosam117- Diamond Member

- Posts : 1344

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Fuel Blends

Re: Fuel Blends

On the issue of all castor oil vs. 50/50 castor oil/synthetic oil, check out, over at coxengines.ca, under "info links", their fuel guide information...... basically saying the 50/50 oil blend is now considered fine and probably more readily available retail..... all synthetic is cautioned against.

Over at the rcgroups.com forum, there is a interesting thread, that started in 2010 and, as of today, went to 2020, kicked off by someone who did some good tests on various oil blends (with the tests supporting the 50/50 castor oil/synthetic oil blend), along with lots of other tidbits on the higher quality (i.e. tolerances) of older Cox engines (generally pre 1985), etc.

https://www.rcgroups.com/forums/showthread.php?1325147-Cox-oil-testing-findings

Very few people run very small displacement engines, such as the Cox engines (.15 and under) with less than 20% total oil

content, on basis of concern for longevity.

Michael in Ontario, Canada

Over at the rcgroups.com forum, there is a interesting thread, that started in 2010 and, as of today, went to 2020, kicked off by someone who did some good tests on various oil blends (with the tests supporting the 50/50 castor oil/synthetic oil blend), along with lots of other tidbits on the higher quality (i.e. tolerances) of older Cox engines (generally pre 1985), etc.

https://www.rcgroups.com/forums/showthread.php?1325147-Cox-oil-testing-findings

Very few people run very small displacement engines, such as the Cox engines (.15 and under) with less than 20% total oil

content, on basis of concern for longevity.

Michael in Ontario, Canada

michaely- Beginner Poster

- Posts : 9

Join date : 2013-10-19

Similar topics

Similar topics» Diesel fuel blends ? Low/No Ether content?

» What fuel here in the UK

» Sidewinder Fuel for .049?

» Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

» Fuel line that stays on a td fuel niibble

» What fuel here in the UK

» Sidewinder Fuel for .049?

» Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

» Fuel line that stays on a td fuel niibble

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules