Log in

Search

Latest topics

» Golden Bee basic running problemby roddie Yesterday at 10:51 pm

» Simple Gliders

by rdw777 Yesterday at 6:25 pm

» Foam hand kids glider converted to 0.049 CL

by rdw777 Yesterday at 6:11 pm

» Weird search for a single comic from an old Mad Magazine

by Kim Yesterday at 1:44 pm

» Scientific "Zipper" Build...Zipper Flys!.

by getback Yesterday at 7:27 am

» Cox .049 Tee Dee engines back in stock (limited availablility)

by GallopingGhostler Yesterday at 1:05 am

» Very off-topic.........Time passes and not always for the best......

by rsv1cox Thu Jul 25, 2024 2:47 pm

» Roddie-Rigger.. a 2005 original design

by roddie Wed Jul 24, 2024 11:48 pm

» Jim Walker Bonanza etc.

by rsv1cox Wed Jul 24, 2024 6:30 pm

» Throttles for Cox Tee Dee .049 / .020 / .010 engines --- videos

by sosam117 Wed Jul 24, 2024 8:54 am

» Introducing our Cox .049 TD Engines

by Admin Tue Jul 23, 2024 2:00 am

» Project Cox .049 r/c & Citabrian Champion

by getback Mon Jul 22, 2024 4:14 pm

Cox Engine of The Month

July-2024

robot797's

"ULTIMITE COX 010: it has a clutch, E starter, throttle, exhaust, aluminum tank, aluminum venturi, gearbox with forward and reverse, and now its on a custom drawn and printed stand"

PAST WINNERS

robot797's

"ULTIMITE COX 010: it has a clutch, E starter, throttle, exhaust, aluminum tank, aluminum venturi, gearbox with forward and reverse, and now its on a custom drawn and printed stand"

PAST WINNERS

Help with Cox identification and piston issue

Page 1 of 1

Help with Cox identification and piston issue

Help with Cox identification and piston issue

Dear Cox enthusiasts,

I was recently given this engine, which was stuck solid and I have degummed using methanol. It has good compression and it is now fully free. I could identify smoke out of the chamber after applying 1.5v to the Glow plug so I presume that it works and I have managed to remove the back plate and carburettor. However, the cilinder head and glow plug plate are reluctant to unscrew and I do not have any Cox tool available. I do not want to force them using unspecified tools. I will be happy to purchase two Cox tools if available from Europe. Postage from the other side of Atlantic looks crazy to me. This will eventually be another post. Cheers.

First, I would like to know the engine version and production year if possible. The engine is not for sale in any case. It might be a .09 but have no clue TBO. See pictures:

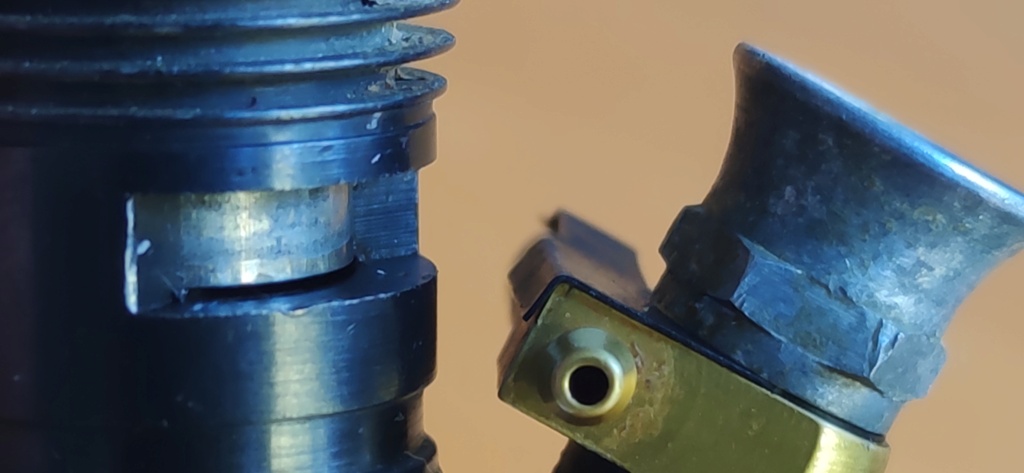

Additionally, I have realised about one disturbing fact. When I move the cilinder to the TDC, the piston overpasses the ports leaving a gap and potentially allowing air leaking. This is not so evident when the engine is lubricated as the oil closes the gap.

I honestly do not think that the piston was replaced but maybe the cilinder was over screwed and therefore, the piston now travels higher up than supposed. Can anyone tell by looking at the position of the ports? Thanks.

The crankshaft and rod do not seem to have been replaced but I can not tell either.

Position of the cilinder at BDC

I would appreciate any help regarding the model and the gap issue before starting the engine. Finally, the person who gave me the engine told me that brew his own fuel using 20% castor oil and 0% nitro. Any advice about the oil content for these Cox engines (have my own fuel components; methanol, synthetic, castor, nitro, etc at home).

Best regards and thanks for your help.

Pepo

P.s. the engine will eventually be mounted on an RC airplane to be built. I have no decided model or scale and are open to suggestions.

I was recently given this engine, which was stuck solid and I have degummed using methanol. It has good compression and it is now fully free. I could identify smoke out of the chamber after applying 1.5v to the Glow plug so I presume that it works and I have managed to remove the back plate and carburettor. However, the cilinder head and glow plug plate are reluctant to unscrew and I do not have any Cox tool available. I do not want to force them using unspecified tools. I will be happy to purchase two Cox tools if available from Europe. Postage from the other side of Atlantic looks crazy to me. This will eventually be another post. Cheers.

First, I would like to know the engine version and production year if possible. The engine is not for sale in any case. It might be a .09 but have no clue TBO. See pictures:

Additionally, I have realised about one disturbing fact. When I move the cilinder to the TDC, the piston overpasses the ports leaving a gap and potentially allowing air leaking. This is not so evident when the engine is lubricated as the oil closes the gap.

I honestly do not think that the piston was replaced but maybe the cilinder was over screwed and therefore, the piston now travels higher up than supposed. Can anyone tell by looking at the position of the ports? Thanks.

The crankshaft and rod do not seem to have been replaced but I can not tell either.

Position of the cilinder at BDC

I would appreciate any help regarding the model and the gap issue before starting the engine. Finally, the person who gave me the engine told me that brew his own fuel using 20% castor oil and 0% nitro. Any advice about the oil content for these Cox engines (have my own fuel components; methanol, synthetic, castor, nitro, etc at home).

Best regards and thanks for your help.

Pepo

P.s. the engine will eventually be mounted on an RC airplane to be built. I have no decided model or scale and are open to suggestions.

Pepo- New Member

- Posts : 3

Join date : 2022-07-27

Re: Help with Cox identification and piston issue

Re: Help with Cox identification and piston issue

I saw your intro post, so I'll sayWELCOME to the CEF! on this thread.

"Mind the Gap"may be appropriate upon entering the Tube, but it can be ignored when starting a Cox engine. In this case the gap is called "SPI" or Sub Piston Induction.

https://www.coxengineforum.com/t1439-sub-piston-induction-what-does-it-do

The gap between the crankcase and piston from the bottom is similar in function allowing fuel/air mixture to be induced into the combustion chamber for the next compression cycle.

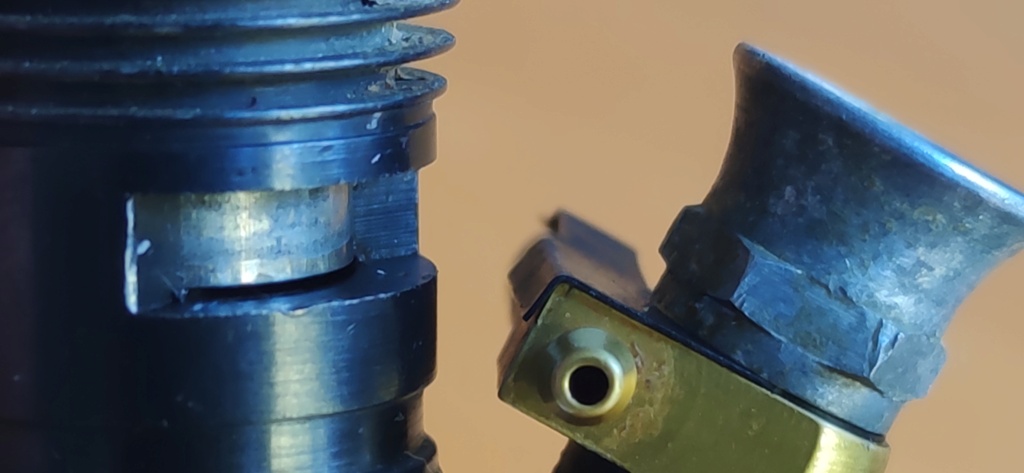

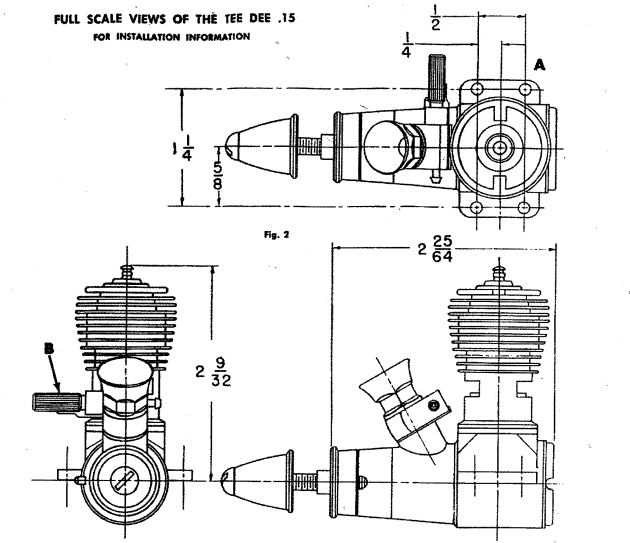

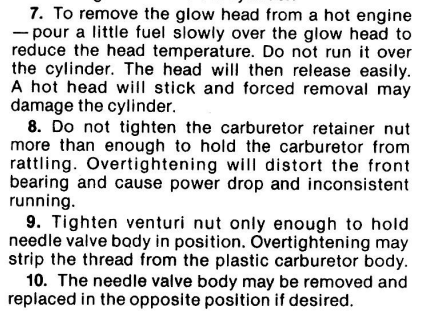

It is almost impossible to remove the glowhead and/or cylinder from any Cox engine without causing damage using regular hand tools. A good set of proper Cox wrenches are always recommended. In a pinch a leather strap(old belt) wrapped around the cylinder can be used to prevent plier marks on the cylinder fins, Here is the factory recommendation on how to remove the glowhead:

In your case, you could "Heat" the cylinder with a hair dryer or the tip of a soldering gun to soften up the old castor oil and use an Ice Cube to quickly cool the aluminum glow head for a somewhat easier removal.

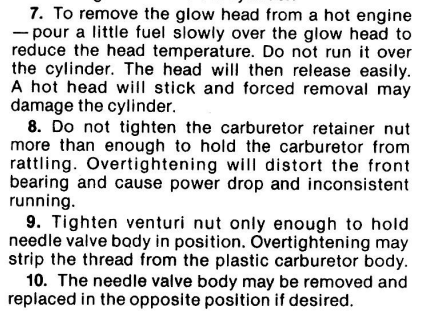

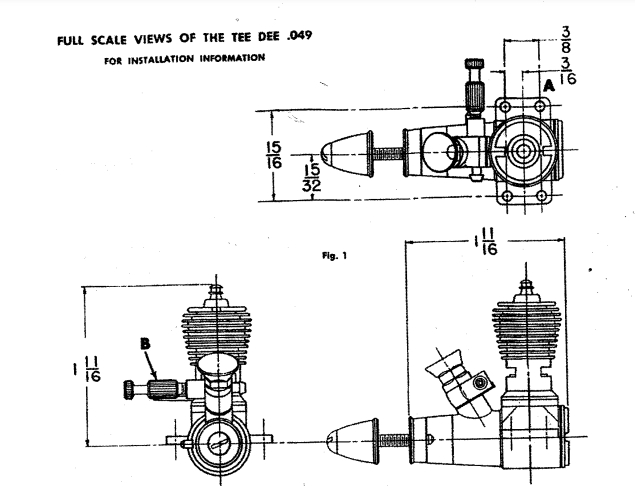

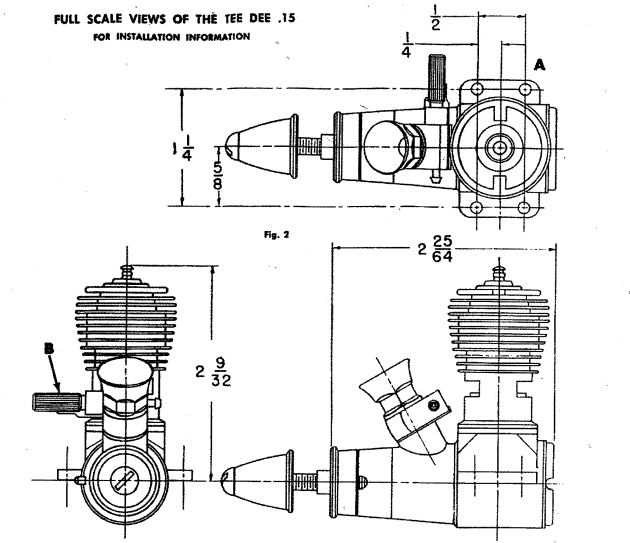

IS it a 049, 09 or 15 ? ? Use these drawing to determine what size your engine is:

"Mind the Gap"may be appropriate upon entering the Tube, but it can be ignored when starting a Cox engine. In this case the gap is called "SPI" or Sub Piston Induction.

https://www.coxengineforum.com/t1439-sub-piston-induction-what-does-it-do

The gap between the crankcase and piston from the bottom is similar in function allowing fuel/air mixture to be induced into the combustion chamber for the next compression cycle.

It is almost impossible to remove the glowhead and/or cylinder from any Cox engine without causing damage using regular hand tools. A good set of proper Cox wrenches are always recommended. In a pinch a leather strap(old belt) wrapped around the cylinder can be used to prevent plier marks on the cylinder fins, Here is the factory recommendation on how to remove the glowhead:

In your case, you could "Heat" the cylinder with a hair dryer or the tip of a soldering gun to soften up the old castor oil and use an Ice Cube to quickly cool the aluminum glow head for a somewhat easier removal.

IS it a 049, 09 or 15 ? ? Use these drawing to determine what size your engine is:

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 71

Location : Grand Rapids, MI

Re: Help with Cox identification and piston issue

Re: Help with Cox identification and piston issue

Your engine seems to be an 09 TeeDee. If that is the size indeed, pm me your postal address, I live in Budapest, and have an extra 09 wrench that I would send you for use on the glow head only. The fork end to remove the cylinder by slipping it over the parallel exhaust openings may cause harm, so I would advise NOT to use that.

For the removal of the cylinder you may want to file 2 parallel flats on the top fin, and use a regular, 19mm or so flat wrench:

For the removal of the cylinder you may want to file 2 parallel flats on the top fin, and use a regular, 19mm or so flat wrench:

balogh- Top Poster

Posts : 4803

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Re: Help with Cox identification and piston issue

Re: Help with Cox identification and piston issue

Dear Marleysky and Balogh,

Thanks very much for your replays and the valuable information provided. I just need to pump some fuel in the engine and give it a try.

Regards

Thanks very much for your replays and the valuable information provided. I just need to pump some fuel in the engine and give it a try.

Regards

Pepo- New Member

- Posts : 3

Join date : 2022-07-27

Re: Help with Cox identification and piston issue

Re: Help with Cox identification and piston issue

I have soaked the entire engine in a bath of antifreeze then heated it to boil. When it cools enough that I can hold it with a gloved hand I tap the cylinder with a flat strap several times then hold it with a small pair of channel locks and the cylinder comes of without much effort

C 15- New Member

- Posts : 2

Join date : 2022-10-02

Re: Help with Cox identification and piston issue

Re: Help with Cox identification and piston issue

Way to go! Before you reassemble the engine, put some silicon containing oil like WD40 on the cylinder thread that will help prevent caking of castor in the thread, and allow easier disassembly next time.

balogh- Top Poster

Posts : 4803

Join date : 2011-11-06

Age : 65

Location : Budapest Hungary

Similar topics

Similar topics» What causes a piston head to mushroom when you reset the piston rod?

» Wanted: Cox .15 piston, or piston/cylinder - FOUND!

» The non-issue (to me) of engine RPM's

» Cox Pee Wee 020 age identification

» Help with identification

» Wanted: Cox .15 piston, or piston/cylinder - FOUND!

» The non-issue (to me) of engine RPM's

» Cox Pee Wee 020 age identification

» Help with identification

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules