Log in

Search

Latest topics

» Cox 020 PeeWee rebuild questions by roddie Today at 8:21 pm

» Dodge Viper - What a waste but brilliant marketing

by roddie Today at 6:46 pm

» COX .020 POWERED SPEEDSTER

by TD ABUSER Today at 6:32 pm

» **VOTE-ON-THE-NEXT-COX-ENGINE-OF-THE-MONTH** (November 2024)

by roddie Today at 6:13 pm

» Brushless motors?

by rsv1cox Today at 4:53 pm

» Free Flight Radio Assist

by rdw777 Today at 4:28 pm

» L4 Grasshopper

by latole Today at 3:43 pm

» PAW 80 and possible use

by fit90 Today at 8:36 am

» Music-wire bending tools (DIY video)

by 1975 control line guy Today at 8:32 am

» Ultrasonic Cleaners??

by sosam117 Yesterday at 11:26 am

» My CA or CyA (super glue) allergy

by rsv1cox Yesterday at 9:52 am

» My Pseudo killerbee.

by rsv1cox Yesterday at 7:04 am

OS/Graupner Wankel - It had to happen

Page 3 of 6

Page 3 of 6 •  1, 2, 3, 4, 5, 6

1, 2, 3, 4, 5, 6

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

"For the lead weights poured embedded in the balance holes to melt meant the engine severely overheated. Someone had mentioned, forgot who (sorry!) that he saw a cowled scale aircraft severely overheat, ruining the engine."

That's an option that I hadn't thought of George. But I think it melted when I torched it as evidenced by it's position within the engine. I'll just recycle it back into the proper holes. .

"Bob, if you can restore this damaged engine to a decent runner will mean you are a genius."

Ah, you give me incentive.

That's an option that I hadn't thought of George. But I think it melted when I torched it as evidenced by it's position within the engine. I'll just recycle it back into the proper holes. .

"Bob, if you can restore this damaged engine to a decent runner will mean you are a genius."

Ah, you give me incentive.

rsv1cox- Top Poster

Posts : 11207

Join date : 2014-08-18

Location : West Virginia

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

Model engines are often found in condition much worse than this, just poorly stored for decades.

There were no obvious changes of materials in later versions of this engine. The part numbers of the first PI and the PI Type II are the same. OS is good about using new part numbers for even small changes.

If you have any interest in the OS Wankel, you must have run across this ancient web page describing clearances. https://ludens.cl/aeromod/wankel/wankel.html I have not measured any of mine. Castor may have helped with sealing in the looser engines.

The first version seems to have problems. I don't know much about it. Looking at youtube videos of OS wankels actually being flown, there were none of the first version. Those flying the PI run very well, even a few tightly cowled models. Somebody put a spark ignition on a PI version and ran gas. It ran fine, without the benefit of cooling from methanol.

There were no obvious changes of materials in later versions of this engine. The part numbers of the first PI and the PI Type II are the same. OS is good about using new part numbers for even small changes.

If you have any interest in the OS Wankel, you must have run across this ancient web page describing clearances. https://ludens.cl/aeromod/wankel/wankel.html I have not measured any of mine. Castor may have helped with sealing in the looser engines.

The first version seems to have problems. I don't know much about it. Looking at youtube videos of OS wankels actually being flown, there were none of the first version. Those flying the PI run very well, even a few tightly cowled models. Somebody put a spark ignition on a PI version and ran gas. It ran fine, without the benefit of cooling from methanol.

gkamysz- Gold Member

- Posts : 412

Join date : 2018-02-22

Location : Chicagoland

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

Lead melts at 327.5 °C. Most nitro engines withstand to about 250 Celsius degrees so I don't think any steel or aluminum material degraded. Am I wrong?

Levent Suberk- Diamond Member

- Posts : 2257

Join date : 2017-12-24

Location : Türkiye

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

Yes, so I heard, and yes, Castor is a chore to clean off. 20 to 50 years ago, I used all Castor fuel even with the Coxes, and I would immediately wipe down the plane with Fantastic spray cleaner. Castor can soften the "fuel proof" paint if not cleaned promptly. It would remove the pain on Cox RTF's. The oil spray would be all over the cockpit of the plane and elevator. The price of carrying away all the heat of the engine in those little droplets.sosam117 wrote:The old McCoy and Fox stunt engines required 25% castor oil. If you didn't, they would cease up and score the piston/sleeve. Those engines loved the oil like a slobbering mouth on a dog and it took 1/2 a roll and 1/2 the bottle of cleaner to clean your plane off at the end of the day.

Some say that 25% Castor is insufficient and opt for 29%. The other engines, the Torpedoes, Red Heads, Stallions, etc. benefit from the higher 25% Castor, although I have been running 10% Synth and 15% Castor (8 pint bottle of Castor added to a Gallon of standard R/C fuel) in the Red Head with no apparent ill effects.

However, it sits outside a profile fuselage open in the breeze for adequate cooling. I'd dare think how it would perform (or no perform) fully cowled up. I prefer the heads and cylinders on all my engines to be sticking out in the breeze when flying.

The degradation is caused by the overheating expanding the rotor and with the oil vaporizing and being combusted, loses it lubricating quality with the rubbing metal surfaces, causing them to bind and grind. This damages (scores) the seals, rotor and cylinder walls. They no longer have their sealing precision fit.Levent Suberk wrote:Lead melts at 327.5 °C. Most nitro engines withstand to about 250 Celsius degrees so I don't think any steel or aluminum material degraded. Am I wrong?

In an automobile, if the scoring is minor, the cylinders on a standard (not Wankel) plain steel block can be overbored (within limits) and oversized pistons and rings installed. Those blocks with replaceable liners, the liners can be pushed out and replaced. This is impractical with model aircraft engines, and as such, the parts are replaced. However, sometimes the cost of the parts is so high that a replacement engine is in order. Now with parts no longer manufactured, one either manufacturers their own or take parts from a parts engine with good parts.

GallopingGhostler- Top Poster

Posts : 5688

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

GallopingGhostler wrote:

The degradation is caused by the overheating expanding the rotor and with the oil vaporizing and being combusted, loses it lubricating quality with the rubbing metal surfaces, causing them to bind and grind. This damages (scores) the seals, rotor and cylinder walls. They no longer have their sealing precision fit.

In an automobile, if the scoring is minor, the cylinders on a standard (not Wankel) plain steel block can be overbored (within limits) and oversized pistons and rings installed. Those blocks with replaceable liners, the liners can be pushed out and replaced. This is impractical with model aircraft engines, and as such, the parts are replaced. However, sometimes the cost of the parts is so high that a replacement engine is in order. Now with parts no longer manufactured, one either manufacturers their own or take parts from a parts engine with good parts.

I meant if a non running engine heated with a torch then any steel or aluminium material degrade?

Levent Suberk- Diamond Member

- Posts : 2257

Join date : 2017-12-24

Location : Türkiye

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

Oil carries away an insignificant amount of combustion heat in a two stroke, a little math proves. Before F2C (control line team race)engines switched away from iron/steel piston and liners they were running as little as 10% castor. Tightly (properly) cowled. in some cases 500-1000 laps....

Oil is not used to save engines or cool them. It's there to lubricate. Poor designs, poor materials, poor manufacturing, excepted. I concede that the crankpin is critical of lube, and even small details can make the difference on high performance engines.

Oil is not used to save engines or cool them. It's there to lubricate. Poor designs, poor materials, poor manufacturing, excepted. I concede that the crankpin is critical of lube, and even small details can make the difference on high performance engines.

gkamysz- Gold Member

- Posts : 412

Join date : 2018-02-22

Location : Chicagoland

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

rsv1cox wrote:"For the lead weights poured embedded in the balance holes to melt meant the engine severely overheated. Someone had mentioned, forgot who (sorry!) that he saw a cowled scale aircraft severely overheat, ruining the engine."

That's an option that I hadn't thought of George. But I think it melted when I torched it as evidenced by it's position within the engine. I'll just recycle it back into the proper holes. .

"Bob, if you can restore this damaged engine to a decent runner will mean you are a genius."

Ah, you give me incentive.

Bob,

One thing you can do after you melt the lead back into the holes there were originally in.

If there is enough room (not filled to the face of the driver).

You could fill it in with JB Weld epoxy?

I've used it on some exhaust systems and to fill a stripped thread and redrill new holes on a car header.

That would keep the lead in the next time you heat up the prop driver.

Just remember the JB Weld will add a little more weight to the counterweight mass as well.

sosam117- Diamond Member

- Posts : 1344

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

Good thought, JB Weld has saved me many times. I'll give it a try.

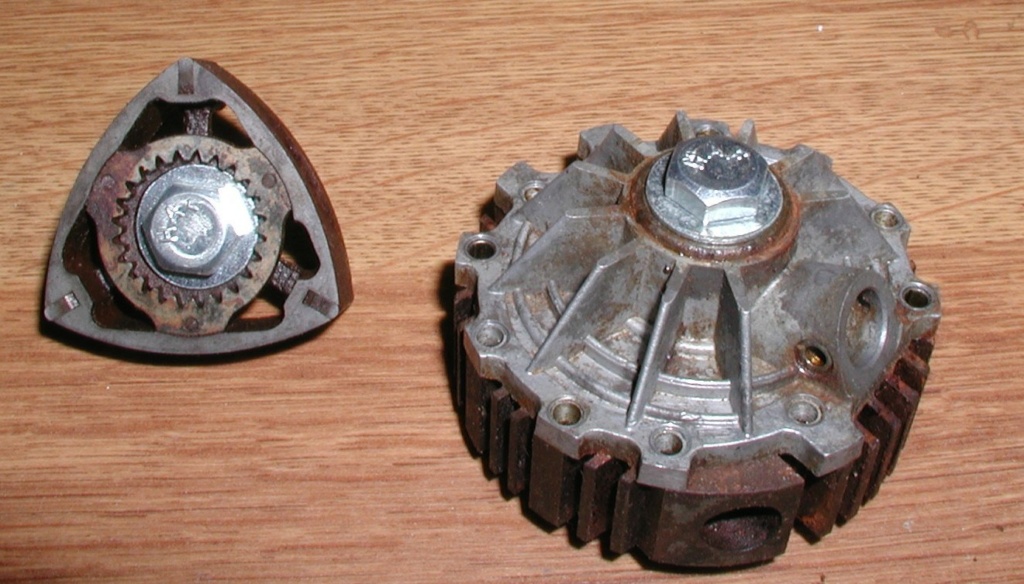

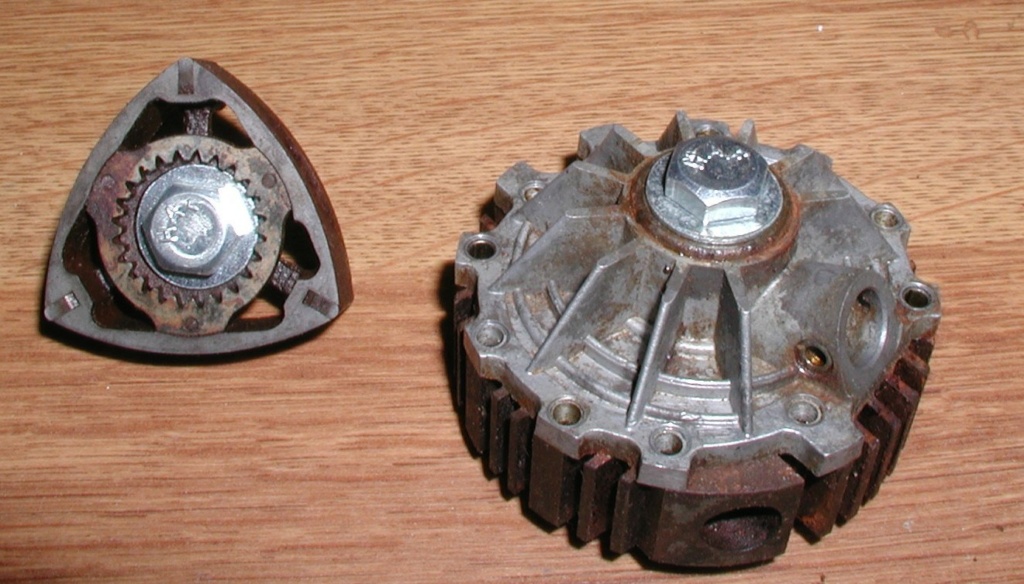

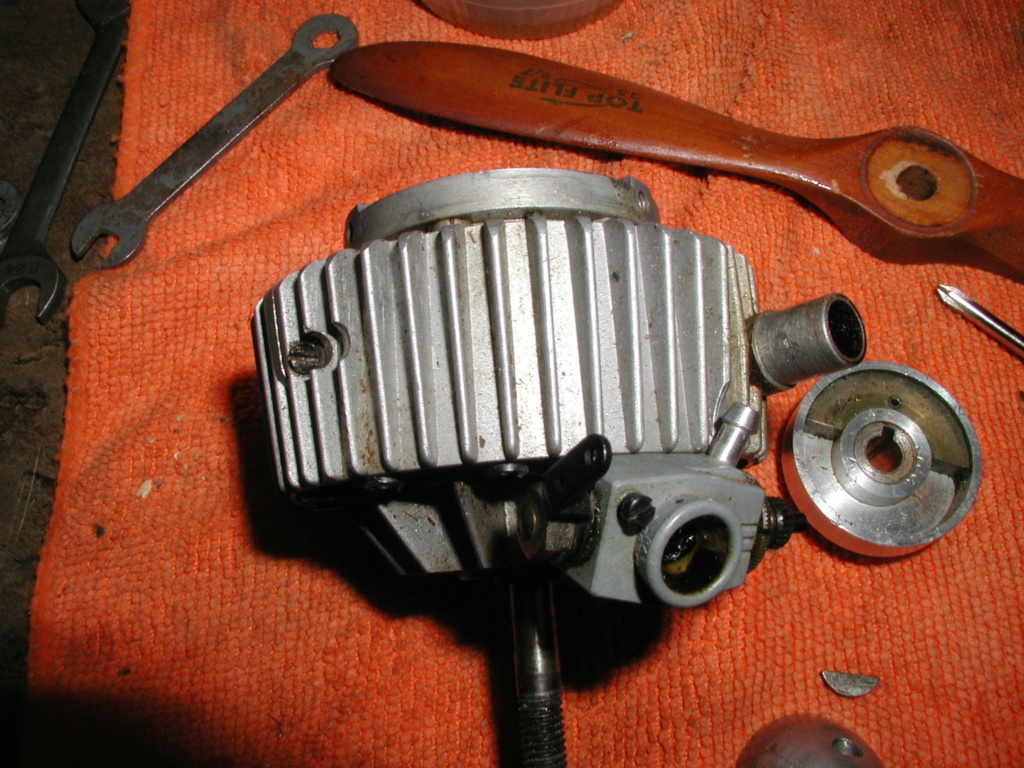

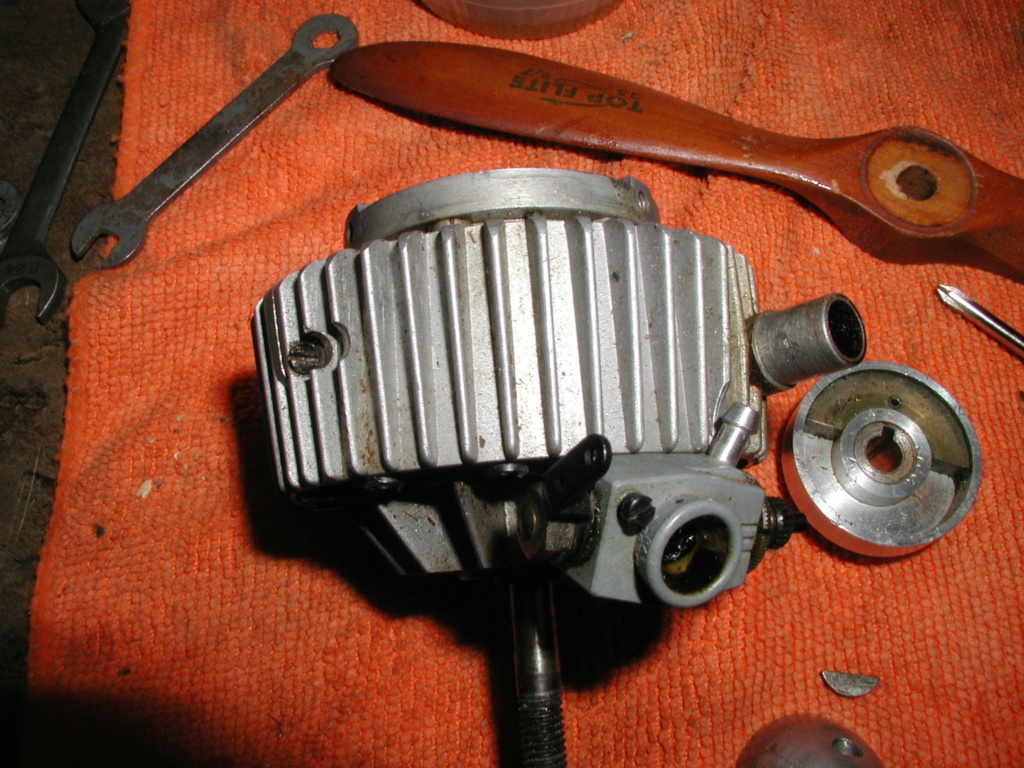

Lightly sandblasted it (Aluminum oxide) this morning. Old media that I need to replace since it has lost much of it's cutting properties. BTW - Harbor Freight has about doubled it's cost on this.

Rather than press out the bearings, I protected the bearings with a paper gasket and this arraingment.

Then removed the protection and dumped it in Berrymans.

Turned out well, but exposed a bad spot on the cylinder where rust bubbled up. Smoothed it out with 800 grit but it will degrade preformance. Some parts will have to go back to the sandblaster. The rotor turned out really well, but I should have drifted out the apex seals first.

Lightly sandblasted it (Aluminum oxide) this morning. Old media that I need to replace since it has lost much of it's cutting properties. BTW - Harbor Freight has about doubled it's cost on this.

Rather than press out the bearings, I protected the bearings with a paper gasket and this arraingment.

Then removed the protection and dumped it in Berrymans.

Turned out well, but exposed a bad spot on the cylinder where rust bubbled up. Smoothed it out with 800 grit but it will degrade preformance. Some parts will have to go back to the sandblaster. The rotor turned out really well, but I should have drifted out the apex seals first.

rsv1cox- Top Poster

Posts : 11207

Join date : 2014-08-18

Location : West Virginia

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

First Congratulation's on the new engines and the project engine ,, or should I say problem child  So I gather your going to have to balance the prop for it after all is put together ? Can another prop washer w/counter weights already inside be purchased ?

So I gather your going to have to balance the prop for it after all is put together ? Can another prop washer w/counter weights already inside be purchased ?

So I gather your going to have to balance the prop for it after all is put together ? Can another prop washer w/counter weights already inside be purchased ?

So I gather your going to have to balance the prop for it after all is put together ? Can another prop washer w/counter weights already inside be purchased ?

getback- Top Poster

Posts : 10415

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

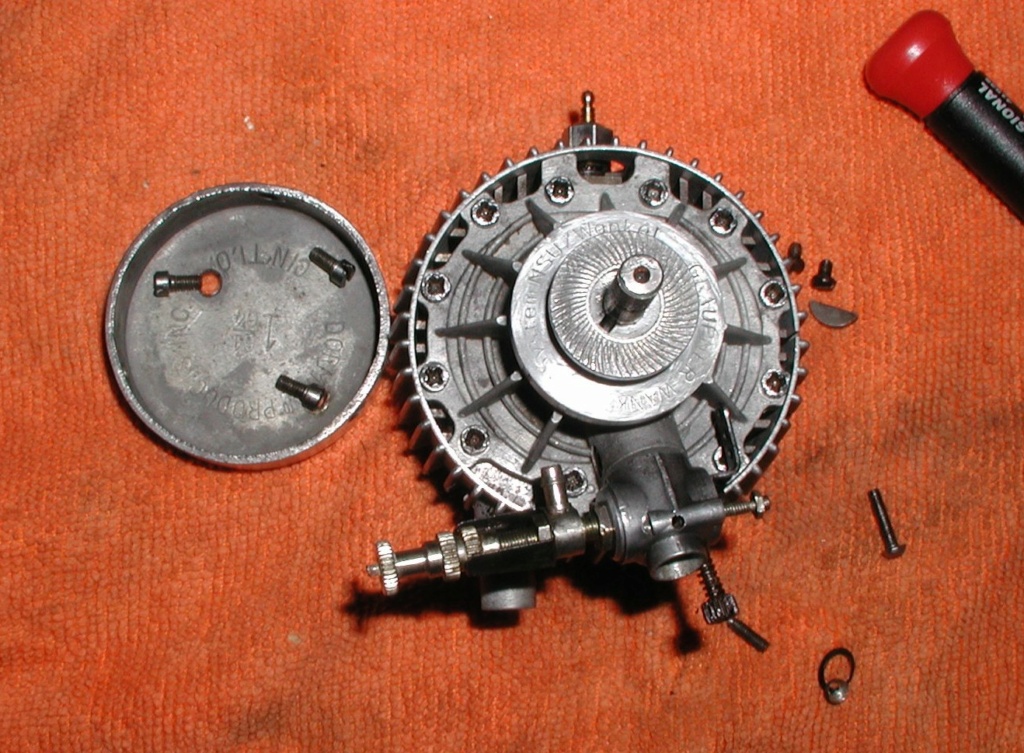

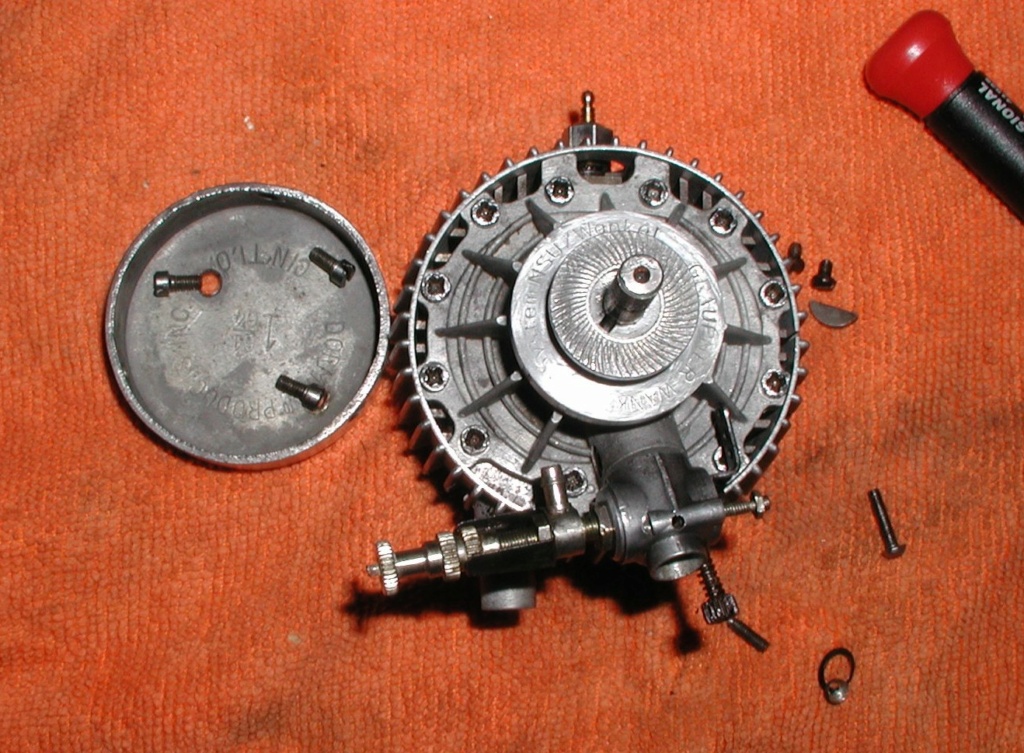

Limping it back together this morning. Just enough to figure out how it goes together and what I need to finish it.

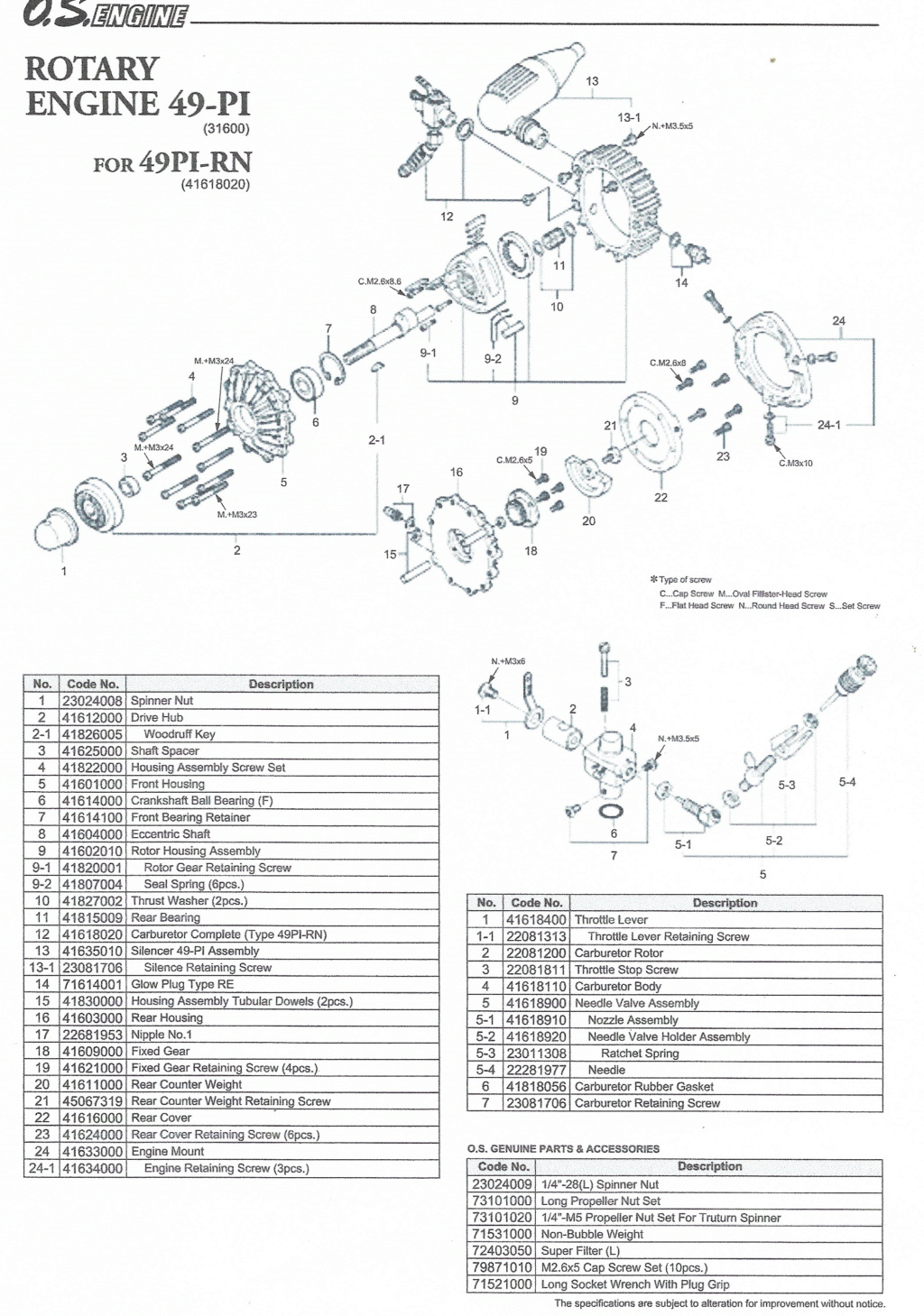

Some spare parts left over. The end of shaft spring washer. Shows as #10 on the diagram as the same, but they are different, one is the spring washer, the other a plain washer. I don't know which one goess where so I left the spring out.

All the phillips heads are hogged out, so I tightened nothing down. Missing three on the back plate too. Drive washer turns smooth with no compression, those case screws not tightened and the glow plug not screwed down.

Not an educated calculation on my part when dropping the tri rotor down into the irregular shaped chamber. Took several attempts to get it right. Seems the excentric and the rotor and the chamber all have to be in agreement. I'm not happy with the way the surface turned out. Aluminum oxide is not the answer. My son has a soda blaster, I may try that. Buffing aluminum with a wire wheel tends to gaul. I have some Mothers aluminum polish I may try that. Also the cooling ring, I can't find the screw for it. The long screw pictured doesn't work. It looks like a 2-56 but when I try a replacement it doesn't seem right.

Oh well, this was a Make an offer engine, very cheap as these go. My learner.

Some spare parts left over. The end of shaft spring washer. Shows as #10 on the diagram as the same, but they are different, one is the spring washer, the other a plain washer. I don't know which one goess where so I left the spring out.

All the phillips heads are hogged out, so I tightened nothing down. Missing three on the back plate too. Drive washer turns smooth with no compression, those case screws not tightened and the glow plug not screwed down.

Not an educated calculation on my part when dropping the tri rotor down into the irregular shaped chamber. Took several attempts to get it right. Seems the excentric and the rotor and the chamber all have to be in agreement. I'm not happy with the way the surface turned out. Aluminum oxide is not the answer. My son has a soda blaster, I may try that. Buffing aluminum with a wire wheel tends to gaul. I have some Mothers aluminum polish I may try that. Also the cooling ring, I can't find the screw for it. The long screw pictured doesn't work. It looks like a 2-56 but when I try a replacement it doesn't seem right.

Oh well, this was a Make an offer engine, very cheap as these go. My learner.

rsv1cox- Top Poster

Posts : 11207

Join date : 2014-08-18

Location : West Virginia

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

Those Thrust washers (should bee 2 of the same ) need to bee in there they keep the needle bearing from moving ,, at least put them both in there !!!

getback- Top Poster

Posts : 10415

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

Hi Bob, you meant one is conical spring washer? There must no difference between those thrust washers as far as I know.

Levent Suberk- Diamond Member

- Posts : 2257

Join date : 2017-12-24

Location : Türkiye

Levent Suberk- Diamond Member

- Posts : 2257

Join date : 2017-12-24

Location : Türkiye

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

Yes, you can see it in all six pictures above. I just didn't want to fiddle with it until I knew for sure how it goes. Long time before it goes active.

I did remove the drive washer off #3, just came off easy, no heat no nothing. It has the counterweight, not the lead filled holes. Also removed the heat ring screw to see what it's like and what I'm looking for. M2 something really tiny.

Also, vendor is just selling the tension springs for the apex seals, not the seals themselves. Video maker must have just reused the seals but with new springs.

I did remove the drive washer off #3, just came off easy, no heat no nothing. It has the counterweight, not the lead filled holes. Also removed the heat ring screw to see what it's like and what I'm looking for. M2 something really tiny.

Also, vendor is just selling the tension springs for the apex seals, not the seals themselves. Video maker must have just reused the seals but with new springs.

rsv1cox- Top Poster

Posts : 11207

Join date : 2014-08-18

Location : West Virginia

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

getback wrote:Those Thrust washers (should bee 2 of the same ) need to bee in there they keep the needle bearing from moving ,, at least put them both in there !!!

If you need help --- go back and watch the Dave McIntire video again to see where everything goes and how it comes together.

It will help jog that old grey matter.

OS Wankel A Look Inside Part 1

OS Wankel A Look Inside Part 2

sosam117- Diamond Member

- Posts : 1344

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

getback wrote:First Congratulation's on the new engines and the project engine ,, or should I say problem childSo I gather your going to have to balance the prop for it after all is put together ? Can another prop washer w/counter weights already inside be purchased ?

Dave McIntire purchased replacement screws, spring, nuts, and prop driver.

The new prop driver he received was for the newer version of the OS-Graupner engine.

I don't think you'll be able to find/get the earlier prop driver washer.

See the video at 7:39 where he tries to use the "new" part (prop driver) and what happens and what Dave has to do to fix the difference from the 1st edition prop driver verses the 2nd edition prop driver. (can't be used)

sosam117- Diamond Member

- Posts : 1344

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

Thanks Mike, I do that occasionally but I'm trying to achieve balance between it and the big Wankel out in the garage. Both I'm afraid are long term projects. The new Wankel #3, should be easier, no bad screws. I still can't find those what / M3X23 mm's that he shows in his video for #1. I come up with M3X22mm only. #2 will remain untouched, what a nice engine.

I thought I could find replacements among my Enya screw inventory but no-luck.

If this is hard, think of the RX-7...............finding parts for the GSL-SE is no picnic. The SE upgraded parts are scarse and expensive. No matter, I will get it sorted out.

Edit. Ah, we were typing together.

Did come up with this that shows the part numbers:

Ran them all and they come up "out of stock".. Left my email address should they ever reappear, probably never.

I thought I could find replacements among my Enya screw inventory but no-luck.

If this is hard, think of the RX-7...............finding parts for the GSL-SE is no picnic. The SE upgraded parts are scarse and expensive. No matter, I will get it sorted out.

Edit. Ah, we were typing together.

Did come up with this that shows the part numbers:

Ran them all and they come up "out of stock".. Left my email address should they ever reappear, probably never.

rsv1cox- Top Poster

Posts : 11207

Join date : 2014-08-18

Location : West Virginia

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

rsv1cox wrote:Thanks Mike, I do that occasionally but I'm trying to achieve balance between it and the big Wankel out in the garage. Both I'm afraid are long term projects. The new Wankel #3, should be easier, no bad screws. I still can't find those what / M3X23 mm's that he shows in his video for #1. I come up with M3X22mm only. #2 will remain untouched, what a nice engine.

I thought I could find replacements among my Enya screw inventory but no-luck.

If this is hard, think of the RX-7...............finding parts for the GSL-SE is no picnic. The SE upgraded parts are scarse and expensive. No matter, I will get it sorted out.

Edit. Ah, we were typing together.

Did come up with this that shows the part numbers:

Ran them all and they come up "out of stock".. Left my email address should they ever reappear, probably never.

Bob,

Here are my "two" go to places to go to on the web to find the screws I need and add to my screw inventory.

You should be able to get all the screws you need from these two sources?

1st one is Fastener express:

https://www.fastener-express.com/metric-pan-head-phillips-machine-screws-stainless.aspx

The 2nd one is McMaster-Carr:

https://www.mcmaster.com/screws/thread-size~m3/system-of-measurement~metric/

You should find the screws, nuts and washers you'll need. If they are longer that what is required, you can always cut them shorter with the old Dremel.

I like McMaster-Carr because I can take a quick trip over to their warehouse (one in my area 1/4 mile away), walk in with my part, screw, bolt and they'll help me find what I need.

If it's not there, they'll get it from the main warehouse in California and I'll have it in 3 to 5 days.

As for the three "wipers" on the rotor gear, Dave McIntire reused the old ones but installed the new springs.

Don't see any part number for them either?

sosam117- Diamond Member

- Posts : 1344

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

The problem is finding them in a fillister head for the backplate (these are all recessed). Pan heads won't work. Sometime you can find them in a hex head but the lengths are wrong. I'm still looking at both sites though. I thought for sure I could find Enya screws that would work as I have screws for most models.

Thanks - Bob

Oh, yes. Something else. Remember someone has been in there before. No telling what went on with that.

Thanks - Bob

Oh, yes. Something else. Remember someone has been in there before. No telling what went on with that.

rsv1cox- Top Poster

Posts : 11207

Join date : 2014-08-18

Location : West Virginia

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

My, what a complicated little engine it looks like. After seeing you do this to yours, if I was to ever get or find one, I now know to NOT disassemble it in fear of losing both parts, and my mind while trying to reassemble it!

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

Yeah, that caught my eye, Bob. I had bad rust with my K&B Stallion that spent part of its life with excess moisture, but cylinder didn't reflect that bad of damage in the compression / combustion end of the cylinder.

It is times like this that one would like access to a 4 axis machine suitable for a Swiss watch maker, and to weld a series of beads to be machined off to restore the damaged and missing metal.

With the rotor going past that area to complete the combustion of your 4-cycle Wankel, looks like it will have significant leakage as the apex wiper goes over that section. At least it will make a good static display.

GallopingGhostler- Top Poster

Posts : 5688

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

GallopingGhostler wrote:Yeah, that caught my eye, Bob. I had bad rust with my K&B Stallion that spent part of its life with excess moisture, but cylinder didn't reflect that bad of damage in the compression / combustion end of the cylinder.

It is times like this that one would like access to a 4 axis machine suitable for a Swiss watch maker, and to weld a series of beads to be machined off to restore the damaged and missing metal.

With the rotor going past that area to complete the combustion of your 4-cycle Wankel, looks like it will have significant leakage as the apex wiper goes over that section. At least it will make a good static display.

If there was only a way to chrome plat the combustion section.

Just like they chrome plate the sleeve on a regular 2 stroke model plane engine.

There was a guy in Texas that I sent an old engine to him, and he chromed the old sleeve for me and when I got it back, the engine was like new with excellent compression.

The guy has long passed away about 10 years ago.

sosam117- Diamond Member

- Posts : 1344

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

I'm fairly certain the housing interior is plated. The hard part of a Wankel is grinding the required shape. Even a decent cnc mill probably isn't good enough. I understand the grinders for the housing were quite unique. Quite different than lapping a cylinder.

gkamysz- Gold Member

- Posts : 412

Join date : 2018-02-22

Location : Chicagoland

Levent Suberk- Diamond Member

- Posts : 2257

Join date : 2017-12-24

Location : Türkiye

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

I've used that. It is mainly to restore cathodic protection to an outdoor finish (like rusted flashing on roof edges or vents of a house or exposed rusted electrical boxes). Otherwise, it is a paint product, IMO, not like electroplating real metal.

An interesting concept to make the engine useful may be to remove the innards and run an extended driveshaft through it, with an electric motor behind it. It would then have the authentic look of a Wankel engine front. Someone did that with a 48 inch (1220 mm) Sterling Mambo trainer not long ago. I think he used a gutted Fox .15 (perhaps sacrilege for a glow purist, but hey, it looked realistic, and spared an engine from the dreaded Fox hurl contest!)

GallopingGhostler- Top Poster

Posts : 5688

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Page 3 of 6 •  1, 2, 3, 4, 5, 6

1, 2, 3, 4, 5, 6

Similar topics

Similar topics» OS graupner wankel 1-49

» Graupner Wankel Typ 7/67 Prototype

» A butane torch, containers, some lead and my Graupner Wankel

» Those things that you don't know why happen... but they happen.

» OS Wankel engine

» Graupner Wankel Typ 7/67 Prototype

» A butane torch, containers, some lead and my Graupner Wankel

» Those things that you don't know why happen... but they happen.

» OS Wankel engine

Page 3 of 6

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules