Log in

Search

Latest topics

» Golden Bee basic running problemby roddie Today at 10:51 pm

» Simple Gliders

by rdw777 Today at 6:25 pm

» Foam hand kids glider converted to 0.049 CL

by rdw777 Today at 6:11 pm

» Weird search for a single comic from an old Mad Magazine

by Kim Today at 1:44 pm

» Scientific "Zipper" Build...Zipper Flys!.

by getback Today at 7:27 am

» Cox .049 Tee Dee engines back in stock (limited availablility)

by GallopingGhostler Today at 1:05 am

» Very off-topic.........Time passes and not always for the best......

by rsv1cox Yesterday at 2:47 pm

» Roddie-Rigger.. a 2005 original design

by roddie Wed Jul 24, 2024 11:48 pm

» Jim Walker Bonanza etc.

by rsv1cox Wed Jul 24, 2024 6:30 pm

» Throttles for Cox Tee Dee .049 / .020 / .010 engines --- videos

by sosam117 Wed Jul 24, 2024 8:54 am

» Introducing our Cox .049 TD Engines

by Admin Tue Jul 23, 2024 2:00 am

» Project Cox .049 r/c & Citabrian Champion

by getback Mon Jul 22, 2024 4:14 pm

Cox Engine of The Month

July-2024

robot797's

"ULTIMITE COX 010: it has a clutch, E starter, throttle, exhaust, aluminum tank, aluminum venturi, gearbox with forward and reverse, and now its on a custom drawn and printed stand"

PAST WINNERS

robot797's

"ULTIMITE COX 010: it has a clutch, E starter, throttle, exhaust, aluminum tank, aluminum venturi, gearbox with forward and reverse, and now its on a custom drawn and printed stand"

PAST WINNERS

Fun with Foam Board - modeling related

Page 1 of 1

Fun with Foam Board - modeling related

Fun with Foam Board - modeling related

Lately, I’ve been working with foam board, partially due to the high cost and availability of quality balsa. For me, a good wing design has been challenging, but I have had some success – here is a late example. I used ROSS 3/16” foam board (this is now becoming difficult to source) for all the foam structure.

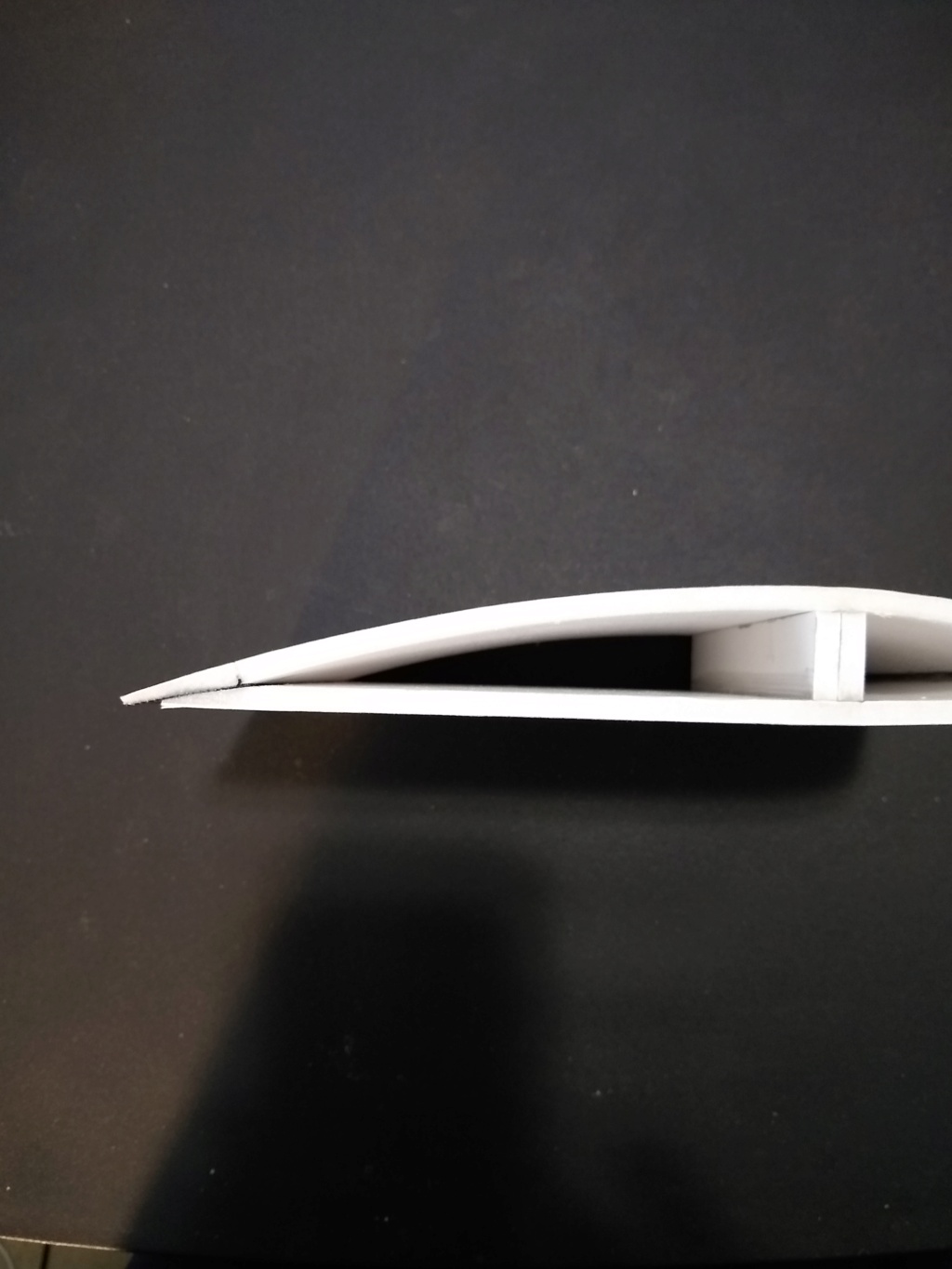

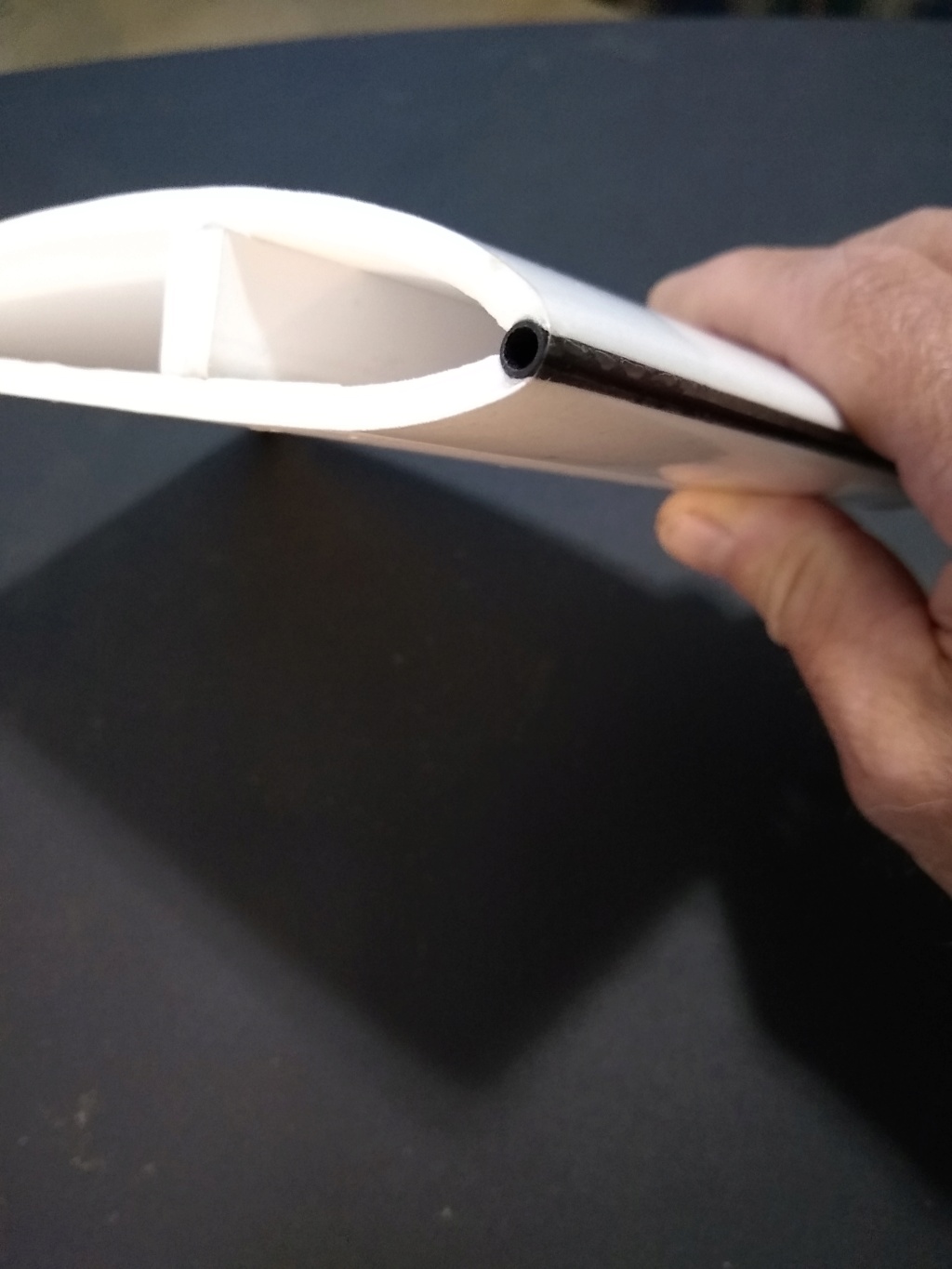

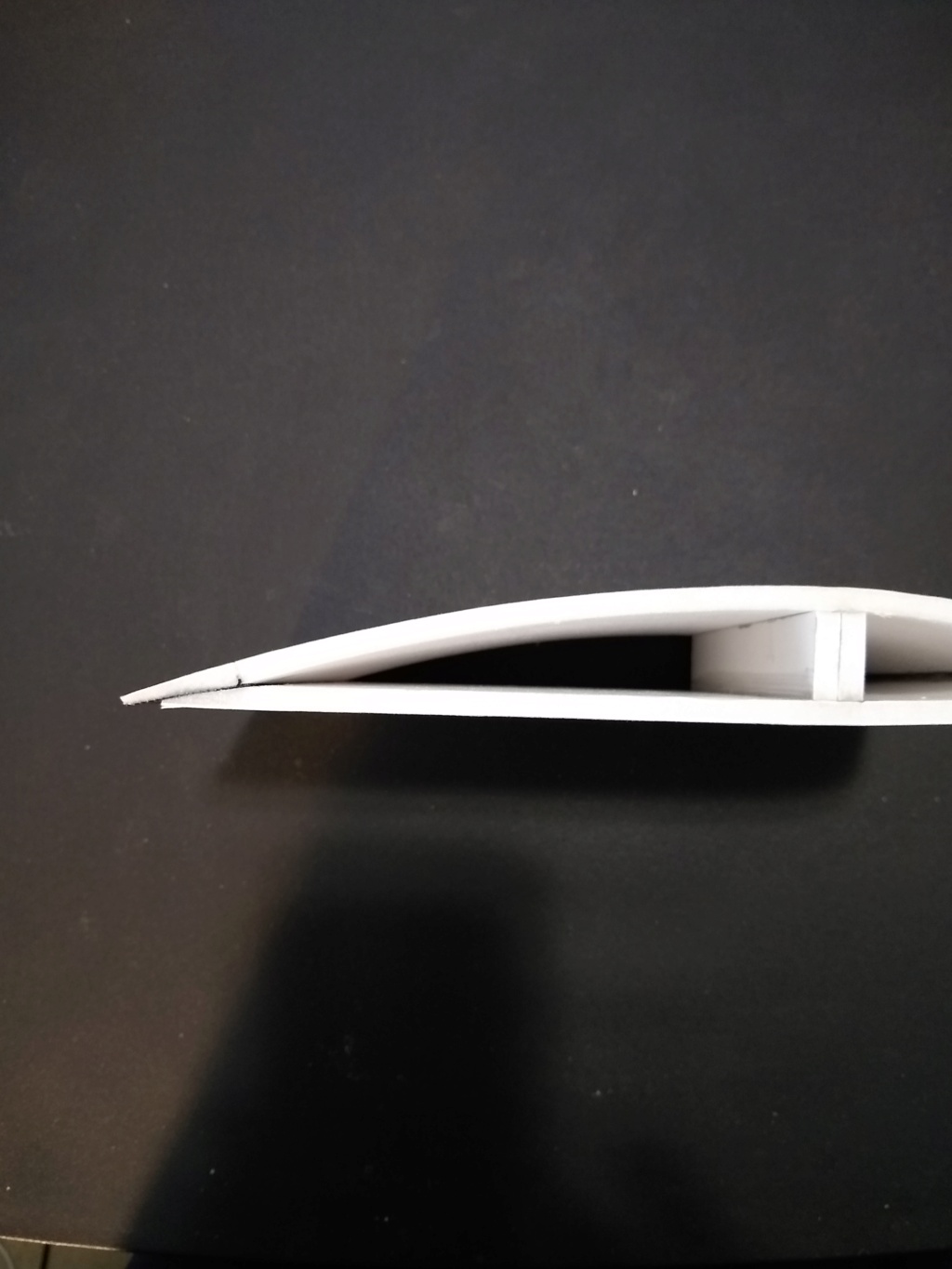

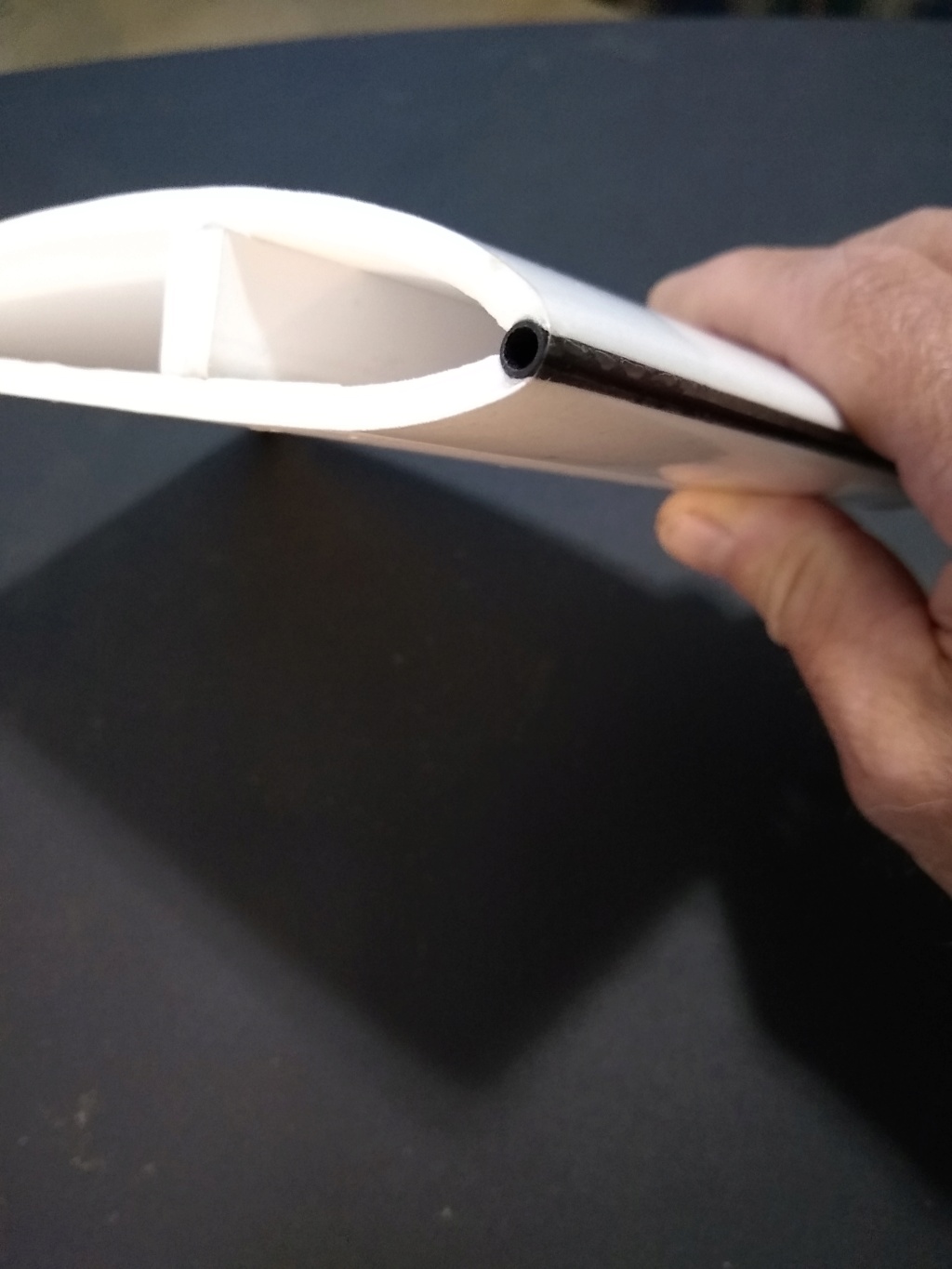

The top skin has had all the paper removed from one side; the bottom skin has a strip of paper removed from the LE to allow for bending and a strip removed from the TE to allow a taper to be sanded in. I used a thin wall 5mm carbon fiber tube to form the LE. It is stiff, straight, light and gives some impact resistance to the LE - I wrapped the tubing with 220 grit and sanded grooves into the foam to accept the tubing. The trailing edge of the top skin has a strip of nylon window screen laminated to stiffen and strengthen the foam – when sanded thin, the foam board can be flimsy. The spar is just two pieces of board glued together – alone, it is not real stiff, but its main use is a spacer. The strength of the wing lengthwise comes from the spar acting as an I-beam web with the upper and lower skins being the I-beam flanges. The skins were laid flat with a 4mm separation between them and then taped with DUCK HDclear packaging tape. They were flipped over, the LE tubing pressed in, folded into the airfoil shape, then glued and weighted.

This is not a wet weather or heavy dew construction nor would it work well without some sort of surface treatment with wet engines since the paper is susceptible to moisture.

I’ve estimated the weight of an untreated 36” wing with 7 5/8” chord at 6.6 ounces – I can live with that. I have used very thin colored packing tape to add trim to other planes with little additional weight.

Full wing airfoil, 7 5/8" chord, very close to a Clark Y 15% foil.

Trailing edge -- these are sanded to a taper nearing 1/16"

[/url]

[/url]

Leading edge - the grooves for the CF tubing show up here

Trailing edge reinforcement - nylon window screen works really well for strength and stiffening foam board

5mm CF tubing -- the DUCK tape shows with the CF tubing pressed into it. The tubing is glued into the grooves in the skin and gives a nice rounded LE.

The top skin has had all the paper removed from one side; the bottom skin has a strip of paper removed from the LE to allow for bending and a strip removed from the TE to allow a taper to be sanded in. I used a thin wall 5mm carbon fiber tube to form the LE. It is stiff, straight, light and gives some impact resistance to the LE - I wrapped the tubing with 220 grit and sanded grooves into the foam to accept the tubing. The trailing edge of the top skin has a strip of nylon window screen laminated to stiffen and strengthen the foam – when sanded thin, the foam board can be flimsy. The spar is just two pieces of board glued together – alone, it is not real stiff, but its main use is a spacer. The strength of the wing lengthwise comes from the spar acting as an I-beam web with the upper and lower skins being the I-beam flanges. The skins were laid flat with a 4mm separation between them and then taped with DUCK HDclear packaging tape. They were flipped over, the LE tubing pressed in, folded into the airfoil shape, then glued and weighted.

This is not a wet weather or heavy dew construction nor would it work well without some sort of surface treatment with wet engines since the paper is susceptible to moisture.

I’ve estimated the weight of an untreated 36” wing with 7 5/8” chord at 6.6 ounces – I can live with that. I have used very thin colored packing tape to add trim to other planes with little additional weight.

Full wing airfoil, 7 5/8" chord, very close to a Clark Y 15% foil.

Trailing edge -- these are sanded to a taper nearing 1/16"

[/url]

[/url]Leading edge - the grooves for the CF tubing show up here

Trailing edge reinforcement - nylon window screen works really well for strength and stiffening foam board

5mm CF tubing -- the DUCK tape shows with the CF tubing pressed into it. The tubing is glued into the grooves in the skin and gives a nice rounded LE.

Last edited by andrew on Fri Mar 29, 2024 5:33 pm; edited 1 time in total

Re: Fun with Foam Board - modeling related

Re: Fun with Foam Board - modeling related

Really nice, @andrew, your work confirms my suspicions, successful use is only limited to the modeler's imagination and making use of its qualities to produce a very acceptable result.

GallopingGhostler- Top Poster

Posts : 5432

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Fun with Foam Board - modeling related

Re: Fun with Foam Board - modeling related

Absolutely the nicest dtfb style wing section I've seen. Josh Bixler would be proud! I have some CF tubing in my stunt kite spares. I believe I'll try it. I shrunk the Maricardo (think English Magnum 40) and have been unhappy with all of my efforts at a decent airfoil. I haven't tried the cf tube leading edge and the folded edge looks so wrong. I did use a 1/8" x 3/8's" spruce vertically for a trailing edge to mount 1/4 x 1" balsa aileron stock... didn't weigh it. But it felt heavy. I thought I saw where someone on the flitetest forum was going to mount a Cox on a foamboard plane. I don't know how that turned out. If it went well, I wonder what he sealed it up with...

C.T.

C.T.

Boats13- Gold Member

Posts : 117

Join date : 2018-01-28

Location : Kemah

Re: Fun with Foam Board - modeling related

Re: Fun with Foam Board - modeling related

Very nice work on the foam board Andrew!!…. Airfoil looks quite proper including the entry under the leading edge….Excellent use of alternative materials!!… I’m going to try another flying wing one of these days and I’ll be borrowing some of your method

rdw777- Diamond Member

Posts : 1470

Join date : 2021-03-11

Location : West Texas

Re: Fun with Foam Board - modeling related

Re: Fun with Foam Board - modeling related

Amazing work, if I do say so myself!

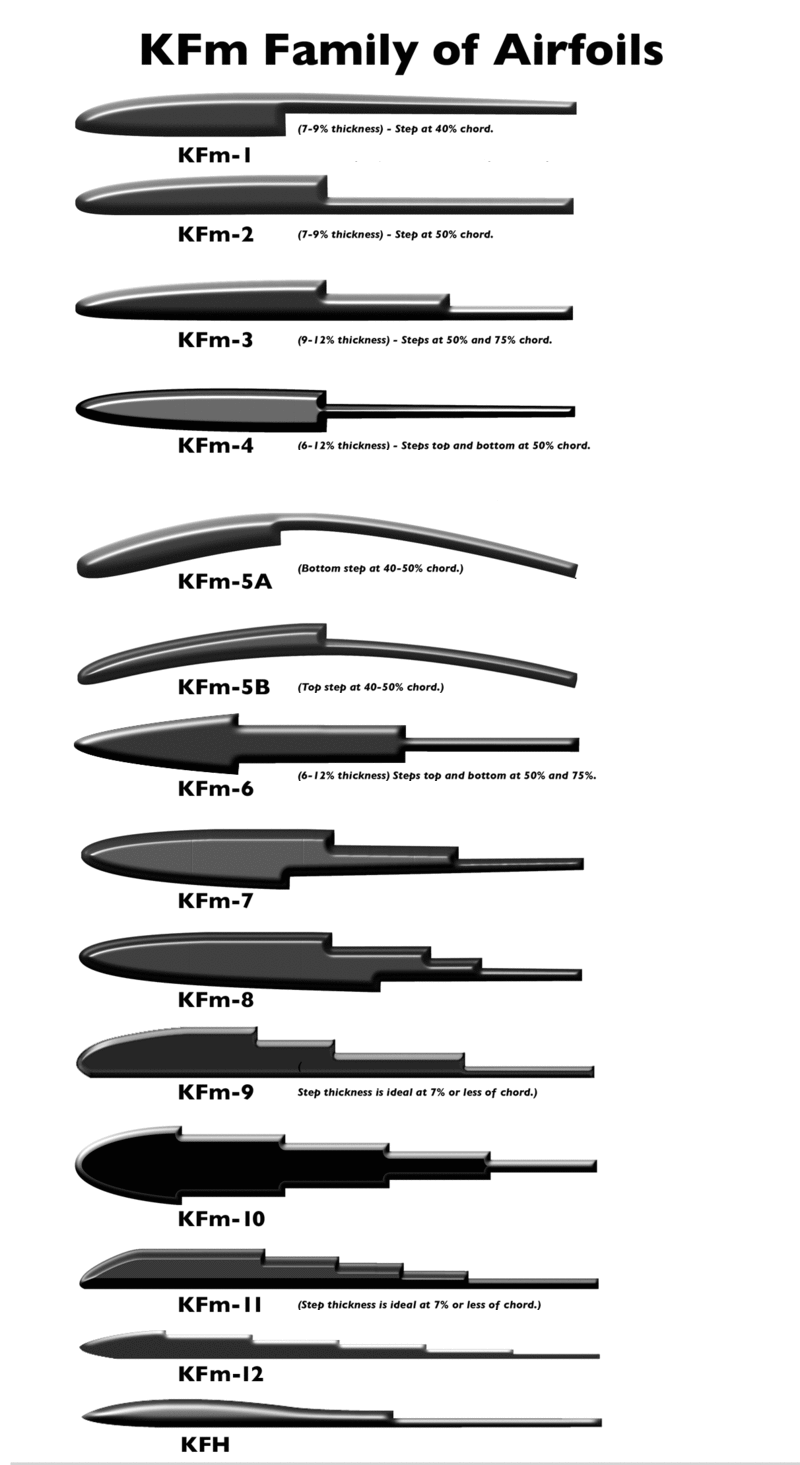

Great for a more 'true' airfoil for sure. Not sure what your endgame is or what you are currently building, and while they do not look as nice as yours by any stretch, have you heard of or seen a KFm airfoiled wing? More a less, same foam, but layered differently gets you different 'airfoils'. First us standard 'undercambered wing with no ribs, lightest airfoil. Then yu got KFm 2 and KFm3 which are just a flat piece of foam with either 1 or 2 layers glued on top. While it sounds simple, the different layers are cut and glued back to a 'proven' range and not just where it looks good. But these too are very good, strong and sturdy wings.

Not sure about posting a link to another RC site here, so I will not. But if you just do a search for KFm airfoil. Top 4 results should have one covered.

Great for a more 'true' airfoil for sure. Not sure what your endgame is or what you are currently building, and while they do not look as nice as yours by any stretch, have you heard of or seen a KFm airfoiled wing? More a less, same foam, but layered differently gets you different 'airfoils'. First us standard 'undercambered wing with no ribs, lightest airfoil. Then yu got KFm 2 and KFm3 which are just a flat piece of foam with either 1 or 2 layers glued on top. While it sounds simple, the different layers are cut and glued back to a 'proven' range and not just where it looks good. But these too are very good, strong and sturdy wings.

Not sure about posting a link to another RC site here, so I will not. But if you just do a search for KFm airfoil. Top 4 results should have one covered.

NEW222- Top Poster

- Posts : 3895

Join date : 2011-08-13

Age : 45

Location : oakbank, mb

Re: Fun with Foam Board - modeling related

Re: Fun with Foam Board - modeling related

Those K-flex wing profiles used with 3/16 inch thick poster foamboard gives inspiration into quick and simple plane designs.

GallopingGhostler- Top Poster

Posts : 5432

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Fun with Foam Board - modeling related

Re: Fun with Foam Board - modeling related

Looking Good Andrew Here is some info if you haven't seen it on the Ross (Elmer's) Foam Board > https://www.flitetest.com/articles/ross-foam-board Seems the real stuff is only available at Walmart

getback- Top Poster

Posts : 10276

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: Fun with Foam Board - modeling related

Re: Fun with Foam Board - modeling related

I have built several planes that use different versions of the Kline-Fogleman airfoil -- they are quick and dirty and work reasonably well on park flyers. A few years ago, when our club was trying to attract younger members, I built several models of a plane called the Blue Baby to use for give-aways that used one of the KF foils. The building was fun, but we could not compete with video games.

As the years have gone by, I find myself more inclined to building rather than flying and really like working with different construction media to see if I can match the traditional balsa construction. The number of builders in my club is dwindling both due to attrition and the advent of mostly ARFs today. I help out with repairs and building replacement parts for mostly foam planes. Although foam board pretty much restricts you to electrics, it builds fast, uses readily available materials, and when I screw up, well, there goes another $0.25.

I have two planes in mind to build from foam, a glider called the 2x4 (OZ6544) and a 43" Citabria (OZ7824). The wing section I posted would be for the Citabria; the 2x4 uses a Jedelsky plan form.

Thanks for your comments.

andrew

As the years have gone by, I find myself more inclined to building rather than flying and really like working with different construction media to see if I can match the traditional balsa construction. The number of builders in my club is dwindling both due to attrition and the advent of mostly ARFs today. I help out with repairs and building replacement parts for mostly foam planes. Although foam board pretty much restricts you to electrics, it builds fast, uses readily available materials, and when I screw up, well, there goes another $0.25.

I have two planes in mind to build from foam, a glider called the 2x4 (OZ6544) and a 43" Citabria (OZ7824). The wing section I posted would be for the Citabria; the 2x4 uses a Jedelsky plan form.

Thanks for your comments.

andrew

Re: Fun with Foam Board - modeling related

Re: Fun with Foam Board - modeling related

First of all I love this airfoil Andrew, It just appeals to me.

[i]"The building was fun, but we could not compete with video games."

Yes, Control line is dying. I don't think anyone is making plastic C/L ARF's anymore which with amazing box graphics used to draw the Kids/Dads in maintaning a following. Plastic Drones have taken over. It's just us older guys that remember the thrill of C/L flying that are carrying on.

I have only built one plane using foam board, then just the fuselage only. Simple, about my speed. Rest is balsa.

[i]"The building was fun, but we could not compete with video games."

Yes, Control line is dying. I don't think anyone is making plastic C/L ARF's anymore which with amazing box graphics used to draw the Kids/Dads in maintaning a following. Plastic Drones have taken over. It's just us older guys that remember the thrill of C/L flying that are carrying on.

I have only built one plane using foam board, then just the fuselage only. Simple, about my speed. Rest is balsa.

rsv1cox- Top Poster

Posts : 10851

Join date : 2014-08-18

Location : West Virginia

Re: Fun with Foam Board - modeling related

Re: Fun with Foam Board - modeling related

rsv1cox wrote:First of all I love this airfoil Andrew, It just appeals to me.

I would like to say, "Yeah, I whipped that out one afternoon." , but in reality, it was really an iterative process. I would try something, then if it worked, I would add on another feature. Obviously, the more you work with a particular material, the better you become at knowing how it might behave. The most challenging for me was building in the lower curvature while maintaining a reasonable radius for the leading edge. Even now, I would like for the LE to be a bit more rounded, so I may try a larger diameter CF tube on the next panel.

Re: Fun with Foam Board - modeling related

Re: Fun with Foam Board - modeling related

andrew wrote: I would like for the LE to be a bit more rounded, so I may try a larger diameter CF tube on the next panel.

Hi Andrew, I'm enjoying what you're doing here! Carbon fiber arrow-shafts are commonly available in 9/32" (.281" 7.1438mm) and 5/16" (.313" 7.9375mm) diameters. I searched Amazon and found that 6.2mm seems to be a popular diameter for arrow-shafts.

Here's an option that you may want to explore.. AMAZON product

Re: Fun with Foam Board - modeling related

Re: Fun with Foam Board - modeling related

roddie wrote:

......Carbon fiber arrow-shafts are commonly available in 9/32" (.281" 7.1438mm) and 5/16" (.313" 7.9375mm) diameters. I searched Amazon and found that 6.2mm seems to be a popular diameter for arrow-shafts.

Thanks, Roddie, for the heads-up.

I almost always keep some arrow shafts on hand, both in carbon and aluminum (repurposed from my bow hunting days). CF arrow shafts are readily available, but are a little too heavy for smaller planes -- I try to keep the wall thickness 0.5mm. Aliexpress also seems to be a good source for thin-wall CF tubes, if you don't mind the longer ship times.

However, here is a 48" wing using an aluminum arrow shaft LE, spliced with CF inserts. I call this a Lowe's wing -- built with yard sticks and paint stir sticks.

Re: Fun with Foam Board - modeling related

Re: Fun with Foam Board - modeling related

NICEandrew wrote:roddie wrote:

......Carbon fiber arrow-shafts are commonly available in 9/32" (.281" 7.1438mm) and 5/16" (.313" 7.9375mm) diameters. I searched Amazon and found that 6.2mm seems to be a popular diameter for arrow-shafts.

Thanks, Roddie, for the heads-up.

I almost always keep some arrow shafts on hand, both in carbon and aluminum (repurposed from my bow hunting days). CF arrow shafts are readily available, but are a little too heavy for smaller planes -- I try to keep the wall thickness 0.5mm. Aliexpress also seems to be a good source for thin-wall CF tubes, if you don't mind the longer ship times.

However, here is a 48" wing using an aluminum arrow shaft LE, spliced with CF inserts. I call this a Lowe's wing -- built with yard sticks and paint stir sticks.

akjgardner- Diamond Member

Posts : 1527

Join date : 2014-12-28

Age : 64

Location : Greensberg Indiana

Re: Fun with Foam Board - modeling related

Re: Fun with Foam Board - modeling related

rdw777 wrote:.....… I’m going to try another flying wing one of these days and I’ll be borrowing some of your method

Robert,

Here is a 36" flying wing with a KFM-1 construction. The foam has had the paper stripped from both sides for lightness and uses a 3/16" balsa spar/separator, however, without paper, it's pretty susceptible to hanger and field rash. The elevons have a DUCK tape hinge and are taped over for strength and stiffness. Typical build is to bevel the leading edges, tape together then fold, glue and weight. I just taped on a strip of DUCK tape, then hot glued the servos to the wing. The tip fins were covered on the outside with black/yellow trim sheet to help see it better at a distance. The Rx, battery and ESC all fit in the balsa cubby. Weight without battery, Rx or ESC is just under 5 oz.

Re: Fun with Foam Board - modeling related

Re: Fun with Foam Board - modeling related

Thank you Andrew KFM-1 Looks both quick easy and efficient for a flying wing….. Wing are a lot of fun…Wide speed envelope and can handle a breeze well…. Nice glide with a light loading….. I’ve still got a couple of Go Brushless kit motors I bought for wings…. Do have a favorite wing calculator you like to use?….. Like that cooling scoop for battery

rdw777- Diamond Member

Posts : 1470

Join date : 2021-03-11

Location : West Texas

Similar topics

Similar topics» foam board

» Foam Board

» Cap for Poster Foam Board Wing Leading Edges

» Hey Bob! You related to this guy??

» OCD TV-a pictorial of modeling madness

» Foam Board

» Cap for Poster Foam Board Wing Leading Edges

» Hey Bob! You related to this guy??

» OCD TV-a pictorial of modeling madness

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules