Log in

Search

Latest topics

» Cox 020 PeeWee rebuild questions by roddie Today at 8:21 pm

» Dodge Viper - What a waste but brilliant marketing

by roddie Today at 6:46 pm

» COX .020 POWERED SPEEDSTER

by TD ABUSER Today at 6:32 pm

» **VOTE-ON-THE-NEXT-COX-ENGINE-OF-THE-MONTH** (November 2024)

by roddie Today at 6:13 pm

» Brushless motors?

by rsv1cox Today at 4:53 pm

» Free Flight Radio Assist

by rdw777 Today at 4:28 pm

» L4 Grasshopper

by latole Today at 3:43 pm

» PAW 80 and possible use

by fit90 Today at 8:36 am

» Music-wire bending tools (DIY video)

by 1975 control line guy Today at 8:32 am

» Ultrasonic Cleaners??

by sosam117 Yesterday at 11:26 am

» My CA or CyA (super glue) allergy

by rsv1cox Yesterday at 9:52 am

» My Pseudo killerbee.

by rsv1cox Yesterday at 7:04 am

Ball - Socket Joints

Page 1 of 3

Page 1 of 3 • 1, 2, 3

Ball - Socket Joints

Ball - Socket Joints

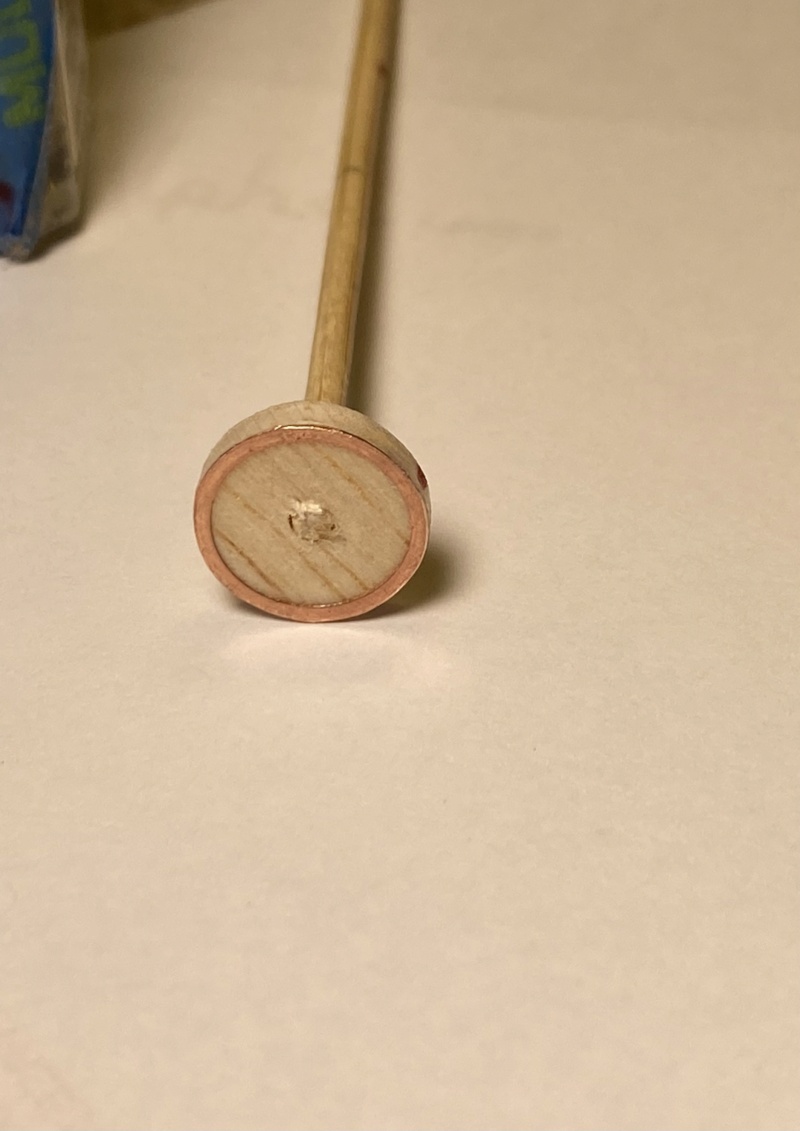

I was working on a castor locked Atwood Wasp this afternoon and after a little solvent and heat got it to turn (That’s always satisfying  )…. Has a ball/socket - Piston/Rod like Cox with about .008” play…. Doesn’t look as reset friendly (I think?) as Cox so that’s how I’ll leave it…. One thing I’ve noticed on this kind of joint (Cox too) if they are a little sloppy is that they can be coated with castor and worked a little to get it inside and the joint feels sorta OK again…. Still has the play but much damped, Like a hydraulic cylinder…. I’m sure this is by design but how much play is too much?…. Or other opinions?

)…. Has a ball/socket - Piston/Rod like Cox with about .008” play…. Doesn’t look as reset friendly (I think?) as Cox so that’s how I’ll leave it…. One thing I’ve noticed on this kind of joint (Cox too) if they are a little sloppy is that they can be coated with castor and worked a little to get it inside and the joint feels sorta OK again…. Still has the play but much damped, Like a hydraulic cylinder…. I’m sure this is by design but how much play is too much?…. Or other opinions?

rdw777- Diamond Member

Posts : 1672

Join date : 2021-03-11

Location : West Texas

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Ball - Socket Joints

Re: Ball - Socket Joints

The reason for the copper on the inside of a Cox piston is so that the steel doesn't obtain hardness and remains malleable. I tried to reset a Fox .074 piston and totally FUBAR'D it. It shattered into about 6 pieces and I barely tapped it. I think that the Atwood piston would be quite similar to the Fox piston . Too much is when it stops working, then you know it was too much.

Ken Cook- Top Poster

- Posts : 5627

Join date : 2012-03-27

Location : pennsylvania

rdw777- Diamond Member

Posts : 1672

Join date : 2021-03-11

Location : West Texas

Re: Ball - Socket Joints

Re: Ball - Socket Joints

Nice project engine Robert, out of the mainstream. I was fooling around with one awhile back, might have done a thread on it. I had no problem with the piston, but those split case threads drove me nuts. Your's looks like it should have an appointment with Dr. Berryman.

I do the same with overly castor locked engines. Heat and a little Marvel Mystery oil or RemOil in the ports loosens them right up.

Waiting to see the finished product.

I do the same with overly castor locked engines. Heat and a little Marvel Mystery oil or RemOil in the ports loosens them right up.

Waiting to see the finished product.

rsv1cox- Top Poster

Posts : 11207

Join date : 2014-08-18

Location : West Virginia

Re: Ball - Socket Joints

Re: Ball - Socket Joints

Thanks Bob, Love to get in the nuts and bolts of them every once in a while…. I’ll have try Berryman’s one of these days…..Initially I soaked it in WD-40 overnight then heated till smokin before it started to turn …. After that disassembled and soaked in Hoppes #9 and scrubbed…. Rinsed in hot soapy water….

I thought I better try for a head gasket next because without that the rest is no bueno…..

A Cox gasket’s ID was good but to large OD to fit down in the head seat…. So I glued a Cox gasket with Duco to a disc of balsa and added a little piece of dowel for a handle…. Then gently rotated against a Dremel cutoff wheel to reduce diameter…. After it would fit I dissolved the glue off with acetone…. Also faced the top of the cylinder where it meets the gasket with fine sandpaper and oil on glass for a better seal…. I think paper gaskets will work for under the cylinder and be easier to make….

I thought I better try for a head gasket next because without that the rest is no bueno…..

A Cox gasket’s ID was good but to large OD to fit down in the head seat…. So I glued a Cox gasket with Duco to a disc of balsa and added a little piece of dowel for a handle…. Then gently rotated against a Dremel cutoff wheel to reduce diameter…. After it would fit I dissolved the glue off with acetone…. Also faced the top of the cylinder where it meets the gasket with fine sandpaper and oil on glass for a better seal…. I think paper gaskets will work for under the cylinder and be easier to make….

rdw777- Diamond Member

Posts : 1672

Join date : 2021-03-11

Location : West Texas

Re: Ball - Socket Joints

Re: Ball - Socket Joints

I beat the Berryman's drum alot but it's amazing stuff. Kind to plastic and metal alike. 20 minute soak gets the worst off, maybe a little tooth brush application, label "No agitation necessary" then the warm soapy water rinse and within 30 minutes your done. Dry well with a heat gun and apply some oil, I use Marvels.

I still use the dregs of my first gallon (think about 3 years) of Berrymans to clean the really nasty stuff, saving the new gallon for the not-so-bad.

Remembering your use of a dremel/balsa wheel. Great idea to shave a bit off.

I still use the dregs of my first gallon (think about 3 years) of Berrymans to clean the really nasty stuff, saving the new gallon for the not-so-bad.

Remembering your use of a dremel/balsa wheel. Great idea to shave a bit off.

rsv1cox- Top Poster

Posts : 11207

Join date : 2014-08-18

Location : West Virginia

Re: Ball - Socket Joints

Re: Ball - Socket Joints

To tell the truth I don't really know I found the engine like this disassembled in a box I never found the connecting rod but everything on this engine seems in good condition no sign of rust or old hardened castor oil very clean but without the connecting rod so I assume that it is possible that this could happen by dismantling it but why have it taken apart then no idea Other than possibly the loose connecting rod I don't see why the engine would be in pieces but I think I can repair it anyway I could modify the piston in order to fix the connecting rod like with the three piece pistons from Cox

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Ball - Socket Joints

Re: Ball - Socket Joints

Last edited by getback on Wed Apr 03, 2024 8:29 am; edited 1 time in total (Reason for editing : add on)

getback- Top Poster

Posts : 10415

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Ball - Socket Joints

Re: Ball - Socket Joints

Thanks for the additional information David, Hopefully you can come up with a repair…. You’ve turned out some pretty nice machine work so it may entirely be possible …

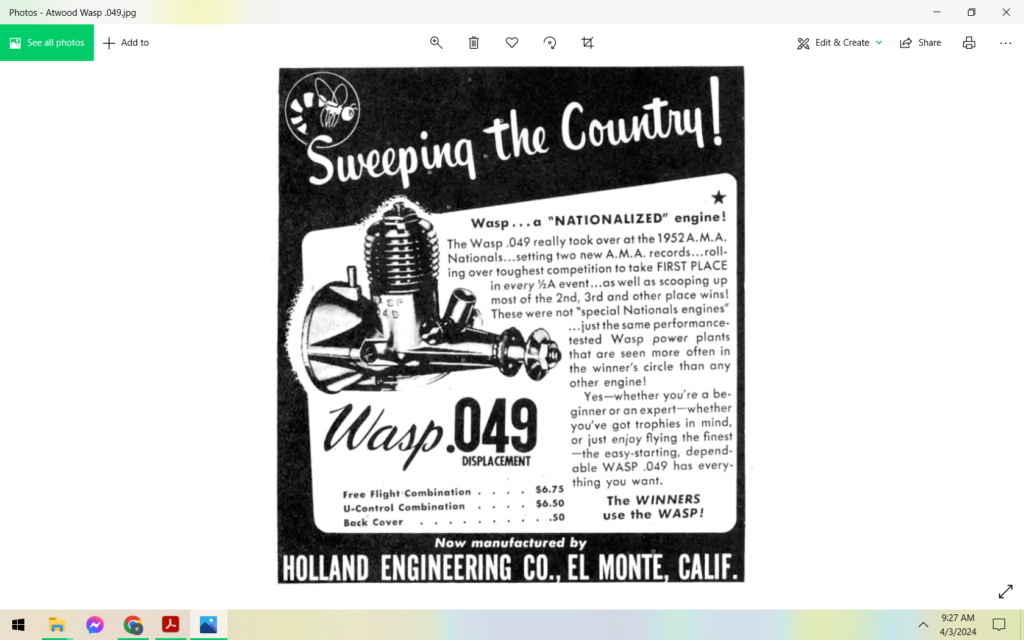

Hopefully you can find another piston/rod Eric, As Ken mentioned the piston is probably very hard and could break easily attempting a reset…. Love that old ad…. 1952 was a long time ago!!…..The Wasp I’m working on is the one you and I traded for about a year ago by the way….. Hope it’ll make a runner

Made up some paper gaskets for the lower cylinder and got the crank polished up….

Hopefully you can find another piston/rod Eric, As Ken mentioned the piston is probably very hard and could break easily attempting a reset…. Love that old ad…. 1952 was a long time ago!!…..The Wasp I’m working on is the one you and I traded for about a year ago by the way….. Hope it’ll make a runner

Made up some paper gaskets for the lower cylinder and got the crank polished up….

rdw777- Diamond Member

Posts : 1672

Join date : 2021-03-11

Location : West Texas

Re: Ball - Socket Joints

Re: Ball - Socket Joints

rsv1cox wrote:I beat the Berryman's drum alot but it's amazing stuff. Kind to plastic and metal alike. 20 minute soak gets the worst off, maybe a little tooth brush application, label "No agitation necessary" then the warm soapy water rinse and within 30 minutes your done. Dry well with a heat gun and apply some oil, I use Marvels.

I still use the dregs of my first gallon (think about 3 years) of Berrymans to clean the really nasty stuff, saving the new gallon for the not-so-bad.

Remembering your use of a dremel/balsa wheel. Great idea to shave a bit off.

I’ll second the Berrymans.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Ball - Socket Joints

Re: Ball - Socket Joints

Cribbs74 wrote:rsv1cox wrote:I beat the Berryman's drum alot but it's amazing stuff. Kind to plastic and metal alike. 20 minute soak gets the worst off, maybe a little tooth brush application, label "No agitation necessary" then the warm soapy water rinse and within 30 minutes your done. Dry well with a heat gun and apply some oil, I use Marvels.

I still use the dregs of my first gallon (think about 3 years) of Berrymans to clean the really nasty stuff, saving the new gallon for the not-so-bad.

Remembering your use of a dremel/balsa wheel. Great idea to shave a bit off.

I’ll second the Berrymans.

It would be great if they could actually sell the stuff out here, but they don't. We used to have a product which I suspect was the same called GUNK Parts Cleaner, mainly used to clean carburettors. Can't get that anymore either.

Oldenginerod- Top Poster

- Posts : 4017

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: Ball - Socket Joints

Re: Ball - Socket Joints

Gunk is what we use to use (still out there but expensive ) Chem-Dip was resent at work what they got don't know if i have used Berrymans or not ...

getback- Top Poster

Posts : 10415

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Ball - Socket Joints

Re: Ball - Socket Joints

Last edited by getback on Thu Apr 04, 2024 7:45 am; edited 1 time in total (Reason for editing : Wheeeee)

getback- Top Poster

Posts : 10415

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Ball - Socket Joints

Re: Ball - Socket Joints

So that's a cup pressed onto the socket? Shrinking it won't be an easy task.

In theory, the piston of a two stroke is always pushing against the rod while running. As RPM increases, a point is reached when the combustion gasses can't keep the piston against the rod near TDC. Above this RPM the constant loading and unloading is why we see a lot of wear at high RPM, but sport applications tend to last. It's also why lightening a piston, and increasing compression improve ball socket durability at high RPM. Throttling and misfires obviously reduce combustion pressures and have an impact of what's happening. And, of course, lubrication is a factor overall.

In theory, the piston of a two stroke is always pushing against the rod while running. As RPM increases, a point is reached when the combustion gasses can't keep the piston against the rod near TDC. Above this RPM the constant loading and unloading is why we see a lot of wear at high RPM, but sport applications tend to last. It's also why lightening a piston, and increasing compression improve ball socket durability at high RPM. Throttling and misfires obviously reduce combustion pressures and have an impact of what's happening. And, of course, lubrication is a factor overall.

gkamysz- Gold Member

- Posts : 412

Join date : 2018-02-22

Location : Chicagoland

Re: Ball - Socket Joints

Re: Ball - Socket Joints

Thanks Roddie…. It took about ten tries to get four I liked… Used a knife on the id and scissors on the od….

That photo offers a lot of insight on how these were made Eric…. Looks like a cap pressed on after the piston was machined, I’m sure in a special fixture….. Maybe a weak link with these engines….Mine may blow up when I try to run it lol!!!….Is the cap loose on yours when you try to fit it back on?….

That photo offers a lot of insight on how these were made Eric…. Looks like a cap pressed on after the piston was machined, I’m sure in a special fixture….. Maybe a weak link with these engines….Mine may blow up when I try to run it lol!!!….Is the cap loose on yours when you try to fit it back on?….

rdw777- Diamond Member

Posts : 1672

Join date : 2021-03-11

Location : West Texas

Re: Ball - Socket Joints

Re: Ball - Socket Joints

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Ball - Socket Joints

Re: Ball - Socket Joints

I wonder if the inside of that cap could be "tinned" with silver solder.. and refitted over the piston's "cup" using a small torch ("cub" or similar)... whether it would hold-up to the forces of combustion? Or alternately; melting a small "pool" of solder around the outside of the "cup".. and refitting the cap while applying torch-heat?

Re: Ball - Socket Joints

Re: Ball - Socket Joints

David, I have a parts engine that still has the rod but no piston, It was given to me about forty years ago by a coworker that found out I liked model airplanes…. But a Neanderthal got it before I did and shoved the rod thru the top of the piston using the prop on the castor locked engine…… I would be glad to send you the rod if you want to try and make the cup to attach….. Or you could use it to measure with as well…..PM me your address if you would like to have it….

I got the one I was working on put back together and gave it a try…. The

70+ year old glow plug still worked!!…. Kept it rich until a little more lean toward the end….I don’t think this was the needle that came with it and is pretty touchy…. I ordered a new one and spray bar as well from MECOA…..I’m happy with this old timer

I got the one I was working on put back together and gave it a try…. The

70+ year old glow plug still worked!!…. Kept it rich until a little more lean toward the end….I don’t think this was the needle that came with it and is pretty touchy…. I ordered a new one and spray bar as well from MECOA…..I’m happy with this old timer

rdw777- Diamond Member

Posts : 1672

Join date : 2021-03-11

Location : West Texas

Re: Ball - Socket Joints

Re: Ball - Socket Joints

Ah, a well used Black & Decker Workmate with a Craftsman Phillips sticking up and the ability to take videos and post them. I haven't figured that one out yet, or I haven't tried to.

Nice run on the old-timer Robert, sounds a bit like my Dad's old model T at full chat. Needle looks like a replacement Testors or Kap Pak.

Needle looks like a replacement Testors or Kap Pak.

Nice run on the old-timer Robert, sounds a bit like my Dad's old model T at full chat.

rsv1cox- Top Poster

Posts : 11207

Join date : 2014-08-18

Location : West Virginia

Re: Ball - Socket Joints

Re: Ball - Socket Joints

Thanks Bob, That old Work Mate is kind of special, Mom gave it to me as a gift about thirty years ago….. It’s done a lot of work and had its own share of repairs….. The screwdriver handle is really 5/16 nut driver for the glow plug…..

Thanks for sharing that needle info….. Either the needle I have or the spay bar is worn cause it’s a little loosey-goosey…..I wanted to see it try to run before ordering the new ones….

Thanks for sharing that needle info….. Either the needle I have or the spay bar is worn cause it’s a little loosey-goosey…..I wanted to see it try to run before ordering the new ones….

rdw777- Diamond Member

Posts : 1672

Join date : 2021-03-11

Location : West Texas

Re: Ball - Socket Joints

Re: Ball - Socket Joints

It would be great to have a real original part I would be happy to make the part and repair this engine I would only need a glow plug i have the gasket and the needle valverdw777 wrote:David, I have a parts engine that still has the rod but no piston, It was given to me about forty years ago by a coworker that found out I liked model airplanes…. But a Neanderthal got it before I did and shoved the rod thru the top of the piston using the prop on the castor locked engine…… I would be glad to send you the rod if you want to try and make the cup to attach….. Or you could use it to measure with as well…..PM me your address if you would like to have it….

I got the one I was working on put back together and gave it a try…. The

70+ year old glow plug still worked!!…. Kept it rich until a little more lean toward the end….I don’t think this was the needle that came with it and is pretty touchy…. I ordered a new one and spray bar as well from MECOA…..I’m happy with this old timer

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Ball - Socket Joints

Re: Ball - Socket Joints

Congratulations Robert!!! You have to wonder when was the last time that little engine ran prior to your rebuild.. it made me smile! You'll figure out a better NVA I'm sure. I wonder if replacing the vinyl sleeve with a silicone one might dampen and seal better?

The workbench is great.. I need to find or make one. That might be a worthwhile project. The 5/16" nut-driver... I figured it was a Craftsman Phillips driver like Bob did.. (got any Wen-Macs to bench-run?)

The workbench is great.. I need to find or make one. That might be a worthwhile project. The 5/16" nut-driver... I figured it was a Craftsman Phillips driver like Bob did.. (got any Wen-Macs to bench-run?)

Re: Ball - Socket Joints

Re: Ball - Socket Joints

David, I received your PM with address…. Will get it in the mail to you in a day or two

Thanks Roddie!!….That poor thing has probably been castor locked for decades….. Fortunately very little to no corrosion so it cleaned up pretty well…. No WenMacs but have a couple of Ok Cubs and a Space Bug Jr. I run from time to time….. I may build something from that period for them one of these days….

Thanks Roddie!!….That poor thing has probably been castor locked for decades….. Fortunately very little to no corrosion so it cleaned up pretty well…. No WenMacs but have a couple of Ok Cubs and a Space Bug Jr. I run from time to time….. I may build something from that period for them one of these days….

rdw777- Diamond Member

Posts : 1672

Join date : 2021-03-11

Location : West Texas

Page 1 of 3 • 1, 2, 3

Similar topics

Similar topics» seized Medallion .049

» Cox Piston/Rod Ball Socket Resetting

» old glue joints

» 5-40 x 1" socket head bolts

» Need help selecting socket screws

» Cox Piston/Rod Ball Socket Resetting

» old glue joints

» 5-40 x 1" socket head bolts

» Need help selecting socket screws

Page 1 of 3

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules

could you measure it I would like to make a new one for my engine

could you measure it I would like to make a new one for my engine