Log in

Search

Latest topics

» Cox PT-19 Wingby latole Today at 4:28 am

» Roddie-Rigger.. a 2005 original design

by roddie Today at 2:54 am

» Golden Bee basic running problem

by roddie Yesterday at 10:51 pm

» Simple Gliders

by rdw777 Yesterday at 6:25 pm

» Foam hand kids glider converted to 0.049 CL

by rdw777 Yesterday at 6:11 pm

» Weird search for a single comic from an old Mad Magazine

by Kim Yesterday at 1:44 pm

» Scientific "Zipper" Build...Zipper Flys!.

by getback Yesterday at 7:27 am

» Cox .049 Tee Dee engines back in stock (limited availablility)

by GallopingGhostler Yesterday at 1:05 am

» Very off-topic.........Time passes and not always for the best......

by rsv1cox Thu Jul 25, 2024 2:47 pm

» Jim Walker Bonanza etc.

by rsv1cox Wed Jul 24, 2024 6:30 pm

» Throttles for Cox Tee Dee .049 / .020 / .010 engines --- videos

by sosam117 Wed Jul 24, 2024 8:54 am

» Introducing our Cox .049 TD Engines

by Admin Tue Jul 23, 2024 2:00 am

Cox Engine of The Month

July-2024

robot797's

"ULTIMITE COX 010: it has a clutch, E starter, throttle, exhaust, aluminum tank, aluminum venturi, gearbox with forward and reverse, and now its on a custom drawn and printed stand"

PAST WINNERS

robot797's

"ULTIMITE COX 010: it has a clutch, E starter, throttle, exhaust, aluminum tank, aluminum venturi, gearbox with forward and reverse, and now its on a custom drawn and printed stand"

PAST WINNERS

Homemade tool to check/set .049/.051 Cox cylinder deck-height

Page 1 of 1

Homemade tool to check/set .049/.051 Cox cylinder deck-height

Homemade tool to check/set .049/.051 Cox cylinder deck-height

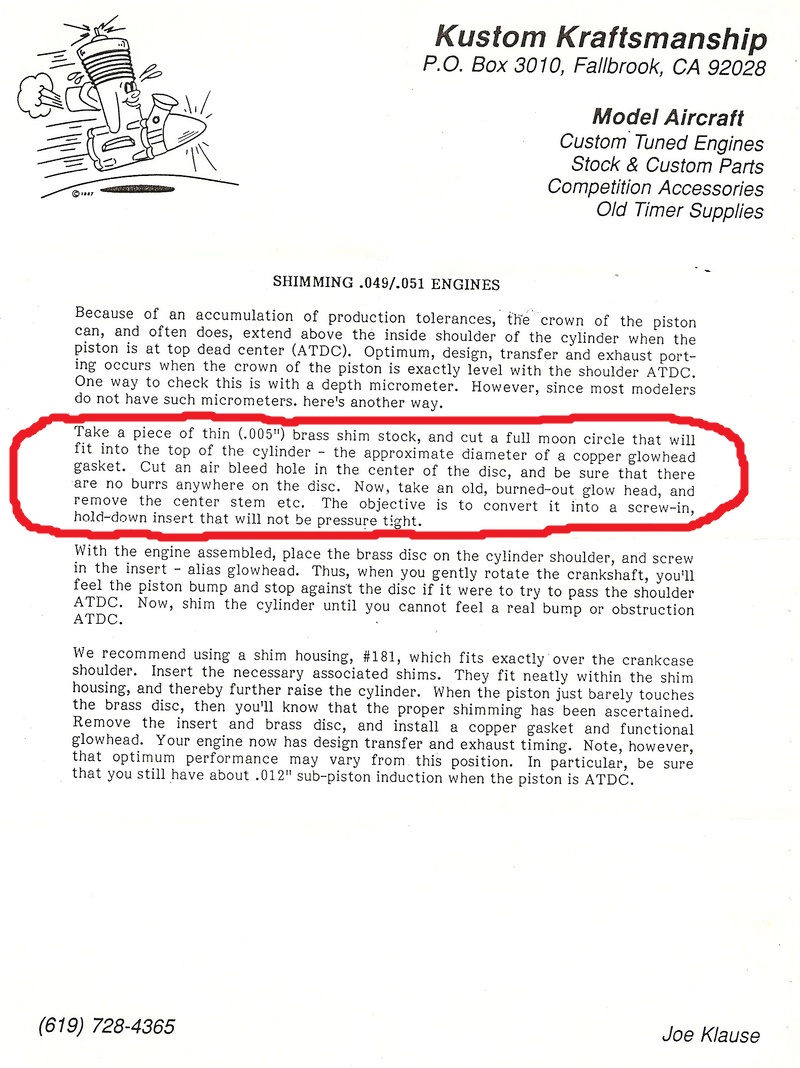

This is a Joe Klause (Kustom Kraftsmanship) idea that seemed like a simple rainy day project to make.

I knew that I had the .005" sheet-brass on hand.. so I measured the inside-circumference of the top of a cylinder and used my circle template and a scribe to mark-out the disc.

I also knew that I had an old glowhead from years ago.. that I tried converting to accept a std. 1/4"-32 plug which would work for this little project.

I saved a few of those OEM protective plastic caps which will help to keep the two components from getting separated when not in use.

I made-up a little ID storage-bag.. and tossed the tool in my "engine project box" for when I'm ready to use it.

I knew that I had the .005" sheet-brass on hand.. so I measured the inside-circumference of the top of a cylinder and used my circle template and a scribe to mark-out the disc.

I also knew that I had an old glowhead from years ago.. that I tried converting to accept a std. 1/4"-32 plug which would work for this little project.

I saved a few of those OEM protective plastic caps which will help to keep the two components from getting separated when not in use.

I made-up a little ID storage-bag.. and tossed the tool in my "engine project box" for when I'm ready to use it.

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Nice work!

The time to use it is now! You are 64 not 24 buddy!

The time to use it is now! You are 64 not 24 buddy!

Cribbs74- Moderator

Posts : 11904

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Great job Roddie!! …. The tool will give you a little more feel for how an engine is “set”….Will be interesting to try on some of your engines and track down differences…. I made one for .020’s …. Need to take the time and make some shims…

rdw777- Diamond Member

Posts : 1470

Join date : 2021-03-11

Location : West Texas

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

rdw777 wrote:Great job Roddie!! …. The tool will give you a little more feel for how an engine is “set”….Will be interesting to try on some of your engines and track down differences…. I made one for .020’s …. Need to take the time and make some shims…

After reading Joe Klause's explanation of timing adjustment.. it just seemed "worth it" to make a tool for measurement. I had bought .049/.051 timing-shims a while ago.. when they were available from our CEF/Cox vendors. I don't know if they're still available though.

Matt had these..

as received; with some other parts..

How would you go about making timing-shims Robert?

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Bookmark this thread; for "More Inspirational Quotes by Ronald"..

Bookmark this thread; for "More Inspirational Quotes by Ronald".. Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

roddie wrote:rdw777 wrote:Great job Roddie!! …. The tool will give you a little more feel for how an engine is “set”….Will be interesting to try on some of your engines and track down differences…. I made one for .020’s …. Need to take the time and make some shims…

After reading Joe Klause's explanation of timing adjustment.. it just seemed "worth it" to make a tool for measurement. I had bought .049/.051 timing-shims a while ago.. when they were available from our CEF/Cox vendors. I don't know if they're still available though.

Matt had these..

as received; with some other parts..

How would you go about making timing-shims Robert?

I just bought timing shims from Burnie (Cox International) for C.T.'s(boats) engines and there were "four" in the pack.

Burnie has "eleven" in stock.

Cylinder shims

They worked out very well.

One I had to use a sanding "flat" block (with 320 grit sandpaper) to sand it down to .006" (0.153mm)

If you're measuring for the .020 engines, then you'll have to make them yourself?

If you purchased a custom-built engine from Joe Klause (Kustom Kraftsanship) the timing was done on that hand built engine.

But of course, the cost of those engines was more than a "stock" Cox engine.

I find it interesting that everyone is interested in the deck height now?

Mike Mac

sosam117- Diamond Member

- Posts : 1310

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Just to let you know, I did a "tutorial" back in 2020 on how I did my Texaco engines which also covers most Cox engines as well.

Shimming Cox Cylinder for Transfer and Exhaust Timing

Click on the link above.

And here are "FIVE" of the shim kits that Joe Klause (Kustom Kraftsmanship) sold.

These kits were very helpful to reproduce the shims that I needed to rebuild many of my Cox engines.

Shimming Cox Cylinder for Transfer and Exhaust Timing

Click on the link above.

And here are "FIVE" of the shim kits that Joe Klause (Kustom Kraftsmanship) sold.

These kits were very helpful to reproduce the shims that I needed to rebuild many of my Cox engines.

sosam117- Diamond Member

- Posts : 1310

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

roddie wrote: How would you go about making timing-shims Robert?

Well, I could tell it wouldn’t be nearly as elegant as Mike’s methods and tools

rdw777- Diamond Member

Posts : 1470

Join date : 2021-03-11

Location : West Texas

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Yes, deck height makes a difference, hard core engine runners shim .010's

Down wind passes thus far:

.010 / 42k unloaded stock black prop

.020 / 38.6k U 3x3 full carbon prop

.049 / 33.1k U 4x4.5 carbon blend

The TD .020 really benefits from checking deck height and performs well with a sealed turbo plug adapter.

Oil the threads, run it up check for snug while it's hot able to cold pop with after run oil.

1 ball socket reset will be enough for many flights - oil in the loose socket before resetting.

A hot TD .20 will really jam in a sport plane with 15cc to 20cc of fuel.

Like KK Pro Mods this man below was keen on setting up TD .020's for solid premium running.

The Great Bob Mattes Custom Rework - Cox TD .020 / APC 4.2x2

He had a passion to produce the best possible power for popular .020 FF competitions.

Solid radial mounts he made sealed well compared to plastic.

He made adapters for the small Nelson insert plugs, offering superior potential.

Deck height was set, element height from deck was set with the adapter.

Kamtechnik makes aluminum mounts / turbo plug adapters to improve power.

https://kamtechnik.com/shop/

Results,

Sep 29, 2018

Nano TD.020 Nelson Flat Coil Plug / HQ Carbon 3.6 x 4.5N Prop

Static: 24,870 rpm / 106 mph Pitch Speed / .083 hp / 62w

Static Peak: 25,113 rpm /107 mph Pitch Speed / .086 hp / 64w

4.6oz thrust. Bob Mattes Plug Adapter / 30% Nitro / 20% oil

Thanks to the pressure tap the tank was bone dry when the engine

stopped providing steady rpm throughout the run. Kamtechnik

1 off custom muffler allowed good breathing. KK 128 tpi NV was

special made for the TD .020 very rare part and worth having

for all TD .020 projects.

Pure scream mode open exhaust / no comparison to stock engines.

Static: 3.6x4.5 @ 30,604 rpm so much power can be allowed to run a bit rich at 28k

This condition will help soak more oil setting the stage for a long use performance engine.

For new folks note Kamtechnik makes aluminum mounts / turbo plug adapters to improve power.

Low weight APC prop centering hubs / low mass spinners to sus out more rpm!

https://kamtechnik.com/shop/

Down wind passes thus far:

.010 / 42k unloaded stock black prop

.020 / 38.6k U 3x3 full carbon prop

.049 / 33.1k U 4x4.5 carbon blend

The TD .020 really benefits from checking deck height and performs well with a sealed turbo plug adapter.

Oil the threads, run it up check for snug while it's hot able to cold pop with after run oil.

1 ball socket reset will be enough for many flights - oil in the loose socket before resetting.

A hot TD .20 will really jam in a sport plane with 15cc to 20cc of fuel.

Like KK Pro Mods this man below was keen on setting up TD .020's for solid premium running.

The Great Bob Mattes Custom Rework - Cox TD .020 / APC 4.2x2

He had a passion to produce the best possible power for popular .020 FF competitions.

Solid radial mounts he made sealed well compared to plastic.

He made adapters for the small Nelson insert plugs, offering superior potential.

Deck height was set, element height from deck was set with the adapter.

Kamtechnik makes aluminum mounts / turbo plug adapters to improve power.

https://kamtechnik.com/shop/

Results,

Sep 29, 2018

Nano TD.020 Nelson Flat Coil Plug / HQ Carbon 3.6 x 4.5N Prop

Static: 24,870 rpm / 106 mph Pitch Speed / .083 hp / 62w

Static Peak: 25,113 rpm /107 mph Pitch Speed / .086 hp / 64w

4.6oz thrust. Bob Mattes Plug Adapter / 30% Nitro / 20% oil

Thanks to the pressure tap the tank was bone dry when the engine

stopped providing steady rpm throughout the run. Kamtechnik

1 off custom muffler allowed good breathing. KK 128 tpi NV was

special made for the TD .020 very rare part and worth having

for all TD .020 projects.

Pure scream mode open exhaust / no comparison to stock engines.

Static: 3.6x4.5 @ 30,604 rpm so much power can be allowed to run a bit rich at 28k

This condition will help soak more oil setting the stage for a long use performance engine.

For new folks note Kamtechnik makes aluminum mounts / turbo plug adapters to improve power.

Low weight APC prop centering hubs / low mass spinners to sus out more rpm!

https://kamtechnik.com/shop/

1/2A Nut- Top Poster

- Posts : 3464

Join date : 2013-10-20

Age : 60

Location : Brad in Texas

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

That Bob Mattes .020TD run was Screaming and and and nice . most people want pay much for the .020TD engines as the .010TD alot more 128TPI needle for the .020 just makes it i see he was still using a piece of hose for a seal , those are not available to replace are they ?

getback- Top Poster

Posts : 10276

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Bob retired from it all, lucky for us Kamtechnik has a good backplate design, turbo plug adapter and

low weight prop plate drive hub to center vibration free APC props. The APC 4.6x3 can be cut to 4x3N

4.3x3E works better proper blade thickness for thrust with and a bit of speed. Can use back cut on

the blades to maintain thrust while gaining rpm. The APC 4.1x4.1 can be back cut for speed 3.6x4.1N

Bob set up the engines with the APC 4.2x2 req. FF prop. He had a bit of fuel line over a stock NV.

Mattes adds gasket goo to seal before mounting his aluminum backplate. Kamtechnik uses an O ring.

It's possible the .049 head gasket can be used as a cylinder shim for the .020 engines. I recall, using a

.09 head gasket on a .049 cylinder and it fits as a shim.

On a side note for 1/2A engine projects in general,

Having sub 250g / 8.82oz 1/2A projects to fly RC is a must these days to enjoy IC freely. Possible to fly a TD.09

sleeved 3ch at or under 250g less fuel. 144mph down wind with 106sq. in. TD .09 @ 11oz / sub 9oz RTF with a

redesign is possible or sport fly with throttle projects at 120sq. in. for sub 250g design with careful planning.

3ch 6.19oz Lil Speedy TD .049 has been done 66sq. in. wing, more reasonable 80-110 for sport flying.

low weight prop plate drive hub to center vibration free APC props. The APC 4.6x3 can be cut to 4x3N

4.3x3E works better proper blade thickness for thrust with and a bit of speed. Can use back cut on

the blades to maintain thrust while gaining rpm. The APC 4.1x4.1 can be back cut for speed 3.6x4.1N

Bob set up the engines with the APC 4.2x2 req. FF prop. He had a bit of fuel line over a stock NV.

Mattes adds gasket goo to seal before mounting his aluminum backplate. Kamtechnik uses an O ring.

It's possible the .049 head gasket can be used as a cylinder shim for the .020 engines. I recall, using a

.09 head gasket on a .049 cylinder and it fits as a shim.

On a side note for 1/2A engine projects in general,

Having sub 250g / 8.82oz 1/2A projects to fly RC is a must these days to enjoy IC freely. Possible to fly a TD.09

sleeved 3ch at or under 250g less fuel. 144mph down wind with 106sq. in. TD .09 @ 11oz / sub 9oz RTF with a

redesign is possible or sport fly with throttle projects at 120sq. in. for sub 250g design with careful planning.

3ch 6.19oz Lil Speedy TD .049 has been done 66sq. in. wing, more reasonable 80-110 for sport flying.

1/2A Nut- Top Poster

- Posts : 3464

Join date : 2013-10-20

Age : 60

Location : Brad in Texas

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

I always appreciate your data and statistics Brad, Thanks for sharing those…. I’ve taken a few notes!!!  ….. TeeDee .020’s are one my favorites and I have a few…..Amazing power for their size and weight….. Need to make something for them to fly!….. Yes, A sub 250g TeeDee .020 design would be a hoot!…..When I was still working I had access to a lab with 3-D printers…. I drew up and printed a false tank in Nylon to mimic the normal tank footprint ….Photo below….. …. Allows the use of the Kamtechnik backplate…..Might help to streamline the front of a nose section with remote tank…..

….. TeeDee .020’s are one my favorites and I have a few…..Amazing power for their size and weight….. Need to make something for them to fly!….. Yes, A sub 250g TeeDee .020 design would be a hoot!…..When I was still working I had access to a lab with 3-D printers…. I drew up and printed a false tank in Nylon to mimic the normal tank footprint ….Photo below….. …. Allows the use of the Kamtechnik backplate…..Might help to streamline the front of a nose section with remote tank…..

rdw777- Diamond Member

Posts : 1470

Join date : 2021-03-11

Location : West Texas

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Very nice engine Robert, great photo with a vintage thin wall cylinder.

A solid ridged mount helps to keep the prop singing.

.020 and .049 turbo plug adapters can be used to lock down disk plates.

It is to note thin carbon plate will not be anything but flat by nature.

-soft metal warps during the cutting out phase. No doubt any protrusion

above the natural piston crown from the piston or plate will skew the results.

If anyone tries to set the deck height on a TD .010 / .020 please share the

before and after results!

A solid ridged mount helps to keep the prop singing.

.020 and .049 turbo plug adapters can be used to lock down disk plates.

It is to note thin carbon plate will not be anything but flat by nature.

-soft metal warps during the cutting out phase. No doubt any protrusion

above the natural piston crown from the piston or plate will skew the results.

If anyone tries to set the deck height on a TD .010 / .020 please share the

before and after results!

1/2A Nut- Top Poster

- Posts : 3464

Join date : 2013-10-20

Age : 60

Location : Brad in Texas

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

1/2A Nut wrote:If anyone tries to set the deck height on a TD .010 / .020 please share the

before and after results!

Yes, I'm curious. I've never seen a before/after. Obviously if the cylinder is low, port durations are low so power may be down. Weather is finally turning this week. Maybe I'll play with this some, assuming a have a combo of components that needs shimming.

gkamysz- Gold Member

- Posts : 390

Join date : 2018-02-22

Location : Chicagoland

rdw777- Diamond Member

Posts : 1470

Join date : 2021-03-11

Location : West Texas

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

rdw777 wrote:I made a couple from .002” copper to correct an .020 that would not rotate thru the test disc….. A little crude but workable…. Cut with a sharpened piece of .032 music wire….Has that slight “bump” now at TDC ….Will live test when I get some time….

Hey, What ever works and gets the job done!

sosam117- Diamond Member

- Posts : 1310

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

WTG this looks promising, look forward to your results.

Pee Wizzers can make some good power. My first Cox engine was the red tanked .020

Pee Wizzers can make some good power. My first Cox engine was the red tanked .020

1/2A Nut- Top Poster

- Posts : 3464

Join date : 2013-10-20

Age : 60

Location : Brad in Texas

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

1/2A Nut wrote:WTG this looks promising, look forward to your results

Thanks Brad!… Working on a couple of P-Wizzers on this deck height thing to see what the results/changes may be…. Interesting to fiddle with!

sosam117 wrote:Hey, What ever works and gets the job done!

Mike, Do you ever run across situations where the piston does not touch the test disc at TDC?…. I suppose then it’s a simple matter to mill (fine sandpaper on glass) the crankcase a bit to cause cylinder to sit a little lower?….. To get some kind of visual I have on one like this I used a little ball of modeling clay then rotate thru to squish it….I flipped the disc and tried both sides for similar results….The disc is .005” for reference…

rdw777- Diamond Member

Posts : 1470

Join date : 2021-03-11

Location : West Texas

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

This sounds interesting and to see some RPM results would bee a hoot

This sounds interesting and to see some RPM results would bee a hoot  Making it worth while . You sharpened a piece of .032 music wire ! Well you still got it !

Making it worth while . You sharpened a piece of .032 music wire ! Well you still got it !

getback- Top Poster

Posts : 10276

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

rdw777 wrote:1/2A Nut wrote:WTG this looks promising, look forward to your results

Thanks Brad!… Working on a couple of P-Wizzers on this deck height thing to see what the results/changes may be…. Interesting to fiddle with!sosam117 wrote:Hey, What ever works and gets the job done!

Mike, Do you ever run across situations where the piston does not touch the test disc at TDC?…. I suppose then it’s a simple matter to mill (fine sandpaper on glass) the crankcase a bit to cause cylinder to sit a little lower?….. To get some kind of visual I have on one like this I used a little ball of modeling clay then rotate thru to squish it….I flipped the disc and tried both sides for similar results….The disc is .005” for reference…

Yes,

I have had very few that did not touch the disk.

And yes, I use some sandpaper on a flat surface (glass) and sand down the crankcase (a little at a time) until I get the "slight" bump.

Last edited by sosam117 on Sat Apr 13, 2024 6:48 am; edited 1 time in total (Reason for editing : spelling error)

sosam117- Diamond Member

- Posts : 1310

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Re: Homemade tool to check/set .049/.051 Cox cylinder deck-height

Thanks Mike!! I appreciate your tutorial and insight on the engines and sharing the know how!! ….CEF is like a custom encyclopedia for Cox Engines

Robert

Robert

rdw777- Diamond Member

Posts : 1470

Join date : 2021-03-11

Location : West Texas

Similar topics

Similar topics» Back Plate stem Height on .049

» # 190 product engine exhaust port height

» Cylinder Performance Figures

» Carrier Deck Flying

» Roddie's new deck-Spring 2019

» # 190 product engine exhaust port height

» Cylinder Performance Figures

» Carrier Deck Flying

» Roddie's new deck-Spring 2019

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules