Log in

Search

Latest topics

» Foam hand kids glider converted to 0.049 CLby roddie Today at 4:33 am

» Cox PT-19 Wing

by latole Today at 4:28 am

» Roddie-Rigger.. a 2005 original design

by roddie Today at 2:54 am

» Golden Bee basic running problem

by roddie Yesterday at 10:51 pm

» Simple Gliders

by rdw777 Yesterday at 6:25 pm

» Weird search for a single comic from an old Mad Magazine

by Kim Yesterday at 1:44 pm

» Scientific "Zipper" Build...Zipper Flys!.

by getback Yesterday at 7:27 am

» Cox .049 Tee Dee engines back in stock (limited availablility)

by GallopingGhostler Yesterday at 1:05 am

» Very off-topic.........Time passes and not always for the best......

by rsv1cox Thu Jul 25, 2024 2:47 pm

» Jim Walker Bonanza etc.

by rsv1cox Wed Jul 24, 2024 6:30 pm

» Throttles for Cox Tee Dee .049 / .020 / .010 engines --- videos

by sosam117 Wed Jul 24, 2024 8:54 am

» Introducing our Cox .049 TD Engines

by Admin Tue Jul 23, 2024 2:00 am

Cox Engine of The Month

July-2024

robot797's

"ULTIMITE COX 010: it has a clutch, E starter, throttle, exhaust, aluminum tank, aluminum venturi, gearbox with forward and reverse, and now its on a custom drawn and printed stand"

PAST WINNERS

robot797's

"ULTIMITE COX 010: it has a clutch, E starter, throttle, exhaust, aluminum tank, aluminum venturi, gearbox with forward and reverse, and now its on a custom drawn and printed stand"

PAST WINNERS

22mm 2-blade nylon marine prop and solid-shaft drive

Page 1 of 1

22mm 2-blade nylon marine prop and solid-shaft drive

22mm 2-blade nylon marine prop and solid-shaft drive

Hi gang, My focus lately has been with custom-built model boats.. powered by our little (.049) Cox engines. There isn't much to see on YouTube.. probably because of the inherent challenges involved with setting-up a small IC (glow) engine powered model. The Dumas company offers small boat kits and hardware for Cox engines.. but their kits are expensive and I think that most boat modelers today would be more apt to build a "RTR" electric-powered model because of the convenience.

Like many of us here; I'm a "tinkerer"... and prefer to take non-orthodox measures when it comes to my models. I enjoy the challenges involved with taking that approach. I recently sourced a jet-pump drive kit designed for a "380" brushed electric motor that I'm going to power with a Cox .049 reed-valve engine. Here's that thread.

That said; I recently searched Amazon for components to build a more conventional "surface-drive" (drive-shaft running in a stuffing-tube with exposed propeller) system for the same type Cox .049 reed-valve engine.

I found some propellers that looked promising. They were cheap.. and came with the option to run CW/CCW rotation.

Ten "pairs" for ten "bucks"...

There was the matter of how to "lock" the hub on a prospective "drive-shaft".. as they are not slotted for a "drive-dog". There's just a 1.9mm (.078") dia. through-hole.. and that's it. I did some researching on bicycle-wheel "spokes".. which are commonly 2.0mm (14GA)/2.3mm (13GA) sizes. The 2.0mm spoke has a shaft dia. of .078" and a threaded (2.2mm X 0.45mm thread) dia. of .0865" which seemed promising. They were also available in stainless steel.. which is a big plus for this application.

Ten spokes for eight bucks...

Once I received the components.. i proceeded to screw one of the props onto the threaded-end of the spoke. A tight "self-threading" fit.. which required chucking the spoke in my cordless VSR drill to "drive" the prop further onto the shaft. The hub's thickness is 10mm which is approximately the threaded length on the spoke.

The photo below shows a 1/8" OD brass tube (K & S) which has an ID of .096". That's too large for the spoke's .078" diameter.. so I need to source a tube that's a little smaller.. maybe having a 2.1mm (.083") inner diameter.

This should work well. There's no way that the prop is going to loosen on the shaft. Next step is to source a 2mm to 3.17mm adaptive coupling. I may even try to drill and tap a 2mm coupling to accept a 5-40 threaded stub-shaft for the engine side..

I like the reed-valve engines.. because they're capable of running equally well in either direction of rotation. Consider the possibility of building a twin-engine boat with counter-rotating propellers.. which would eliminate the "prop-walk" (paddle-wheel) effect. This is a possibility with reed-valve engines running these propellers.

Like many of us here; I'm a "tinkerer"... and prefer to take non-orthodox measures when it comes to my models. I enjoy the challenges involved with taking that approach. I recently sourced a jet-pump drive kit designed for a "380" brushed electric motor that I'm going to power with a Cox .049 reed-valve engine. Here's that thread.

That said; I recently searched Amazon for components to build a more conventional "surface-drive" (drive-shaft running in a stuffing-tube with exposed propeller) system for the same type Cox .049 reed-valve engine.

I found some propellers that looked promising. They were cheap.. and came with the option to run CW/CCW rotation.

Ten "pairs" for ten "bucks"...

There was the matter of how to "lock" the hub on a prospective "drive-shaft".. as they are not slotted for a "drive-dog". There's just a 1.9mm (.078") dia. through-hole.. and that's it. I did some researching on bicycle-wheel "spokes".. which are commonly 2.0mm (14GA)/2.3mm (13GA) sizes. The 2.0mm spoke has a shaft dia. of .078" and a threaded (2.2mm X 0.45mm thread) dia. of .0865" which seemed promising. They were also available in stainless steel.. which is a big plus for this application.

Ten spokes for eight bucks...

Once I received the components.. i proceeded to screw one of the props onto the threaded-end of the spoke. A tight "self-threading" fit.. which required chucking the spoke in my cordless VSR drill to "drive" the prop further onto the shaft. The hub's thickness is 10mm which is approximately the threaded length on the spoke.

The photo below shows a 1/8" OD brass tube (K & S) which has an ID of .096". That's too large for the spoke's .078" diameter.. so I need to source a tube that's a little smaller.. maybe having a 2.1mm (.083") inner diameter.

This should work well. There's no way that the prop is going to loosen on the shaft. Next step is to source a 2mm to 3.17mm adaptive coupling. I may even try to drill and tap a 2mm coupling to accept a 5-40 threaded stub-shaft for the engine side..

I like the reed-valve engines.. because they're capable of running equally well in either direction of rotation. Consider the possibility of building a twin-engine boat with counter-rotating propellers.. which would eliminate the "prop-walk" (paddle-wheel) effect. This is a possibility with reed-valve engines running these propellers.

Re: 22mm 2-blade nylon marine prop and solid-shaft drive

Re: 22mm 2-blade nylon marine prop and solid-shaft drive

You may have to drill one end of the coupler out to fit https://www.google.com/search?q=2mm+to+3.17mm+adaptive+coupling&sourceid=chrome&ie=UTF-8 may want to give this a read too https://www.mikipulley.co.jp/EN/Products/FlexibleCouplings/about.html The tubing as close as I can get is 2.0 >> https://www.amazon.com/s?k=.083+mmhobby+brass+tubing&crid=38EJHPCVGTRMZ&sprefix=083+mmhobby+brass+tubing%2Caps%2C85&ref=nb_sb_noss

getback- Top Poster

Posts : 10276

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: 22mm 2-blade nylon marine prop and solid-shaft drive

Re: 22mm 2-blade nylon marine prop and solid-shaft drive

getback wrote:You may have to drill one end of the coupler out to fit https://www.google.com/search?q=2mm+to+3.17mm+adaptive+coupling&sourceid=chrome&ie=UTF-8 may want to give this a read too https://www.mikipulley.co.jp/EN/Products/FlexibleCouplings/about.html The tubing as close as I can get is 2.0 >> https://www.amazon.com/s?k=.083+mmhobby+brass+tubing&crid=38EJHPCVGTRMZ&sprefix=083+mmhobby+brass+tubing%2Caps%2C85&ref=nb_sb_noss

Hi Eric, Thanks for those links. I appreciate your taking the time to help me out with this project.

Re: 22mm 2-blade nylon marine prop and solid-shaft drive

Re: 22mm 2-blade nylon marine prop and solid-shaft drive

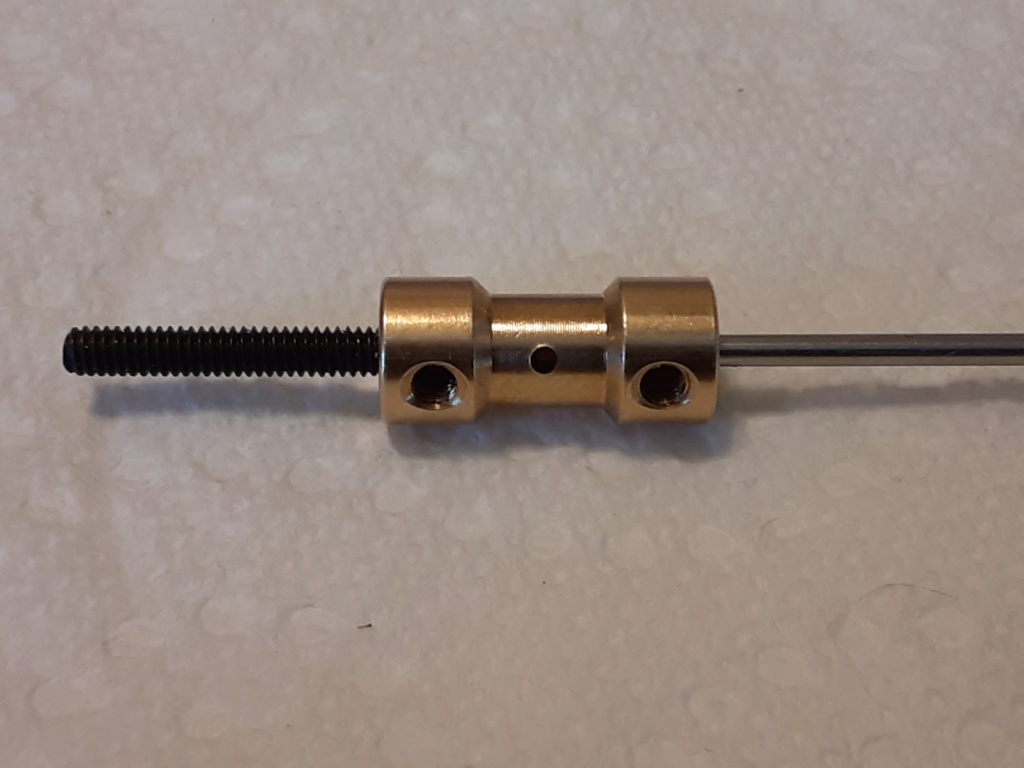

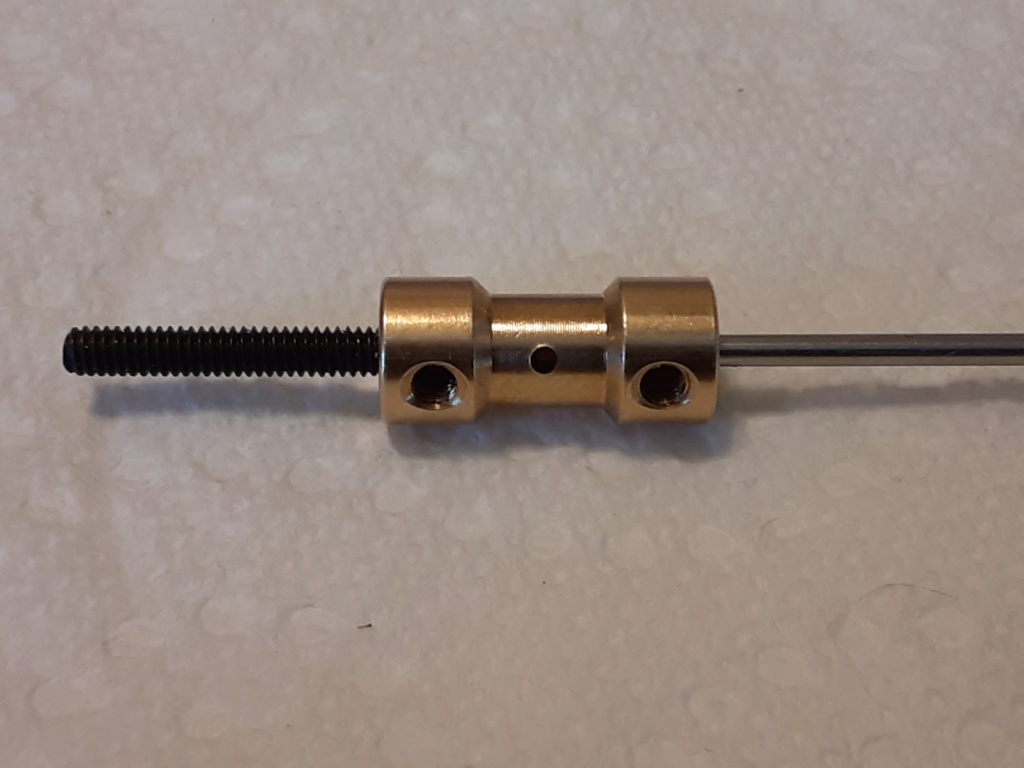

I drilled-out a 2.0mm coupler to 3.17mm to accept a 5-40 cap-screw with head removed.. and flats filed for grub-screws. The other (2.0mm) side receives my 2.0mm stainless-steel wire-drive.

I drilled a .063" dia. cross-hole through the coupler, which accepts a 1/16" music-wire stub for a "wrench".. to manually rotate (or lock) the drive if.. necessary.

I drilled a .063" dia. cross-hole through the coupler, which accepts a 1/16" music-wire stub for a "wrench".. to manually rotate (or lock) the drive if.. necessary.

Similar topics

Similar topics» Pee Wee - Play in prop shaft?

» 3 Blade Prop For Cox Engine

» Cox 3 blade pusher prop cracks

» ok cub 099 crankcase and prop drive

» Prop drive washer for ok cub 074

» 3 Blade Prop For Cox Engine

» Cox 3 blade pusher prop cracks

» ok cub 099 crankcase and prop drive

» Prop drive washer for ok cub 074

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules