Log in

Search

Latest topics

» Tired of it all…by balogh Yesterday at 11:55 pm

» Jim Walkers FireBee - This is going to be fun

by MauricioB Yesterday at 11:53 pm

» Project Cox .049 r/c & Citabrian Champion

by MauricioB Yesterday at 11:36 pm

» Roddie's flat-bottomed boat..

by 1/2A Nut Yesterday at 10:51 pm

» PT-19 Mayhem at Buder Park...a Decade Ago!!!!

by Kim Yesterday at 7:41 am

» Three -- sold out (making two more) Cox .010 Carburetors with wrench

by balogh Yesterday at 12:34 am

» Joe Wagners Sioux

by GallopingGhostler Sat Apr 27, 2024 9:03 pm

» Happy Anzac Day!

by GallopingGhostler Sat Apr 27, 2024 4:16 pm

» Revivng Some Childhood Classics

by getback Sat Apr 27, 2024 7:31 am

» Fox .35 Modifications

by Ken Cook Sat Apr 27, 2024 3:16 am

» Introducing our Cox .049 TD Engines

by getback Fri Apr 26, 2024 6:20 am

» Cox powered jet-pump for model Sprint Boat

by roddie Thu Apr 25, 2024 10:25 pm

Cox Engine of The Month

Warpy Balsa Woes

Page 1 of 1

Warpy Balsa Woes

Warpy Balsa Woes

I bought some 1/4" medium grained balsa sheets last week. The plan is to laminate two with epoxy to make a new 1/2" profile fuselage for the Yak-9 and also another one to make my speed plane. One was slightly bowed, so I chose it to laminate to another since the glue should fix it straight and stiff.

Monday evening I cleaned off my 3/8" glass worktop and collected my clamps. I cleaned both sheets with a paper towel and acetone and placed the first one on a strip of wax paper. Then I filled a mixing cup with an ounce of two part Loctite 60 minute epoxy, and squeegeed it evenly and very thin. I placed the other sheet on top, pinned it and applied 6 clamps, starting in the middle, across the 36" span of wood. I used the minimum pressure to hold it perfectly flat against the glass. A little glue oozed out of the edges, so I wiped it off and left it to harden. Later that night the remainder of glue in the cup was hard as a rock. It had cured nicely.

This afternoon, I took the clamps off and the damn board sprung free with a helluva bow. Not what I had expected. I soaked it with Windex and placed it back on the glass with a flat carpenter's pencil under each end and set a couple of weights on it to counter-bow it. I'll check it tomorrow to make sure I haven't bowed it back too much, and decide what to do. The humidity is high, so it may still be wet in the morning.

Meanwhile, I opened my new Skyray kit and of course the fuse is not only bowed to the inboard side, but twisted on the front end. It too dried under weights flat against the glass for 48 hours. Its bow is gone, but the twist is not, so I wet it again and weighted it down. I'll check it after another day or two.

Any tips on straightening and laminating would be welcome.

Rusty

Monday evening I cleaned off my 3/8" glass worktop and collected my clamps. I cleaned both sheets with a paper towel and acetone and placed the first one on a strip of wax paper. Then I filled a mixing cup with an ounce of two part Loctite 60 minute epoxy, and squeegeed it evenly and very thin. I placed the other sheet on top, pinned it and applied 6 clamps, starting in the middle, across the 36" span of wood. I used the minimum pressure to hold it perfectly flat against the glass. A little glue oozed out of the edges, so I wiped it off and left it to harden. Later that night the remainder of glue in the cup was hard as a rock. It had cured nicely.

This afternoon, I took the clamps off and the damn board sprung free with a helluva bow. Not what I had expected. I soaked it with Windex and placed it back on the glass with a flat carpenter's pencil under each end and set a couple of weights on it to counter-bow it. I'll check it tomorrow to make sure I haven't bowed it back too much, and decide what to do. The humidity is high, so it may still be wet in the morning.

Meanwhile, I opened my new Skyray kit and of course the fuse is not only bowed to the inboard side, but twisted on the front end. It too dried under weights flat against the glass for 48 hours. Its bow is gone, but the twist is not, so I wet it again and weighted it down. I'll check it after another day or two.

Any tips on straightening and laminating would be welcome.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Warpy Balsa Woes

Re: Warpy Balsa Woes

Rusty,

Sorry to hear of your troubles. I would think a nice steam bath followed by a sandwich should do it!

No man, not you the balsa!

Seriously if you steamed it then lay it between 2 2x4's or something similar it should straighten out. Are you using soft or hard balsa?

Ron

Sorry to hear of your troubles. I would think a nice steam bath followed by a sandwich should do it!

No man, not you the balsa!

Seriously if you steamed it then lay it between 2 2x4's or something similar it should straighten out. Are you using soft or hard balsa?

Ron

Cribbs74- Moderator

Posts : 11895

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Warpy Balsa Woes

Re: Warpy Balsa Woes

Yeah, what Ron said. I've never laminated anything that long but when I do laminate I sandwich between two melamine shelves and put 80 pounds of dumbells on top.

Jim

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 56

Location : Colorado

Re: Warpy Balsa Woes

Re: Warpy Balsa Woes

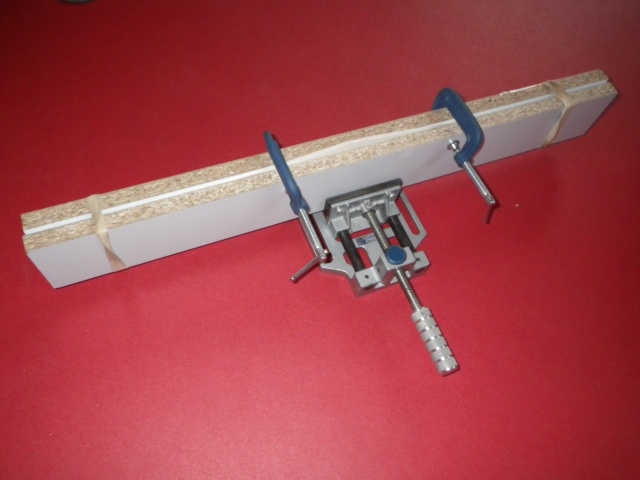

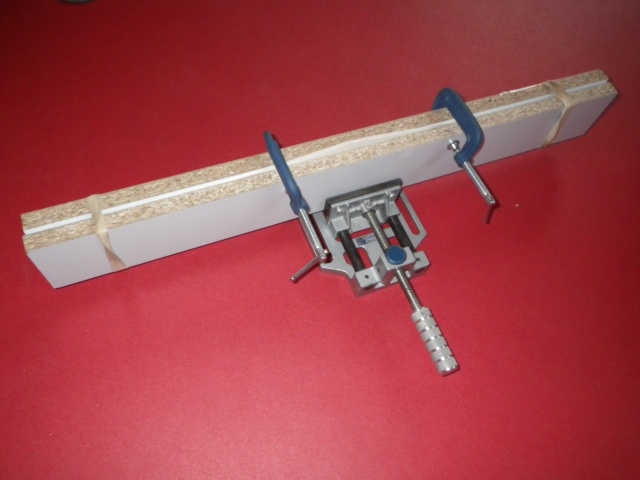

I'd call it medium balsa. The grain is not tiny and short as seen in the hard stiffest sheets, nor is is several inches long as in the lightest most flexible sheets. Here are some pictures. When I went out to the shop to take a picture, the laminated piece had bowed slightly back the other way, so it can apparently be coaxed into shape. When I get ready to use it, maybe I should cut it out and do all the sanding and shaping. Then straighten it immediately before sealing and priming. Maybe that will keep it straight permanently.Cribbs74 wrote:Rusty,

Sorry to hear of your troubles. I would think a nice steam bath followed by a sandwich should do it!

No man, not you the balsa!

Seriously if you steamed it then lay it between 2 2x4's or something similar it should straighten out. Are you using soft or hard balsa?

Ron

Here's a picture. Click the thumbnail for the full size. Hope you can get a good view on your phone.:

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Warpy Balsa Woes

Re: Warpy Balsa Woes

Holy cow, 80 pounds. I bet that does hold it straight. Maybe I did wrong by only clamping it only enough to hold it flat against the glass. Live and learn.JPvelo wrote:Yeah, what Ron said. I've never laminated anything that long but when I do laminate I sandwich between two melamine shelves and put 80 pounds of dumbells on top.

Jim

The wood for the racer is straight. I might cut it tomorrow night. Depends how whipped I am after flying. I'm taking the Clownlikething out for the first time. I rebuilt its OS fp40. It looks like it was stored with no oil, but I think I saved it.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Warpy Balsa Woes

Re: Warpy Balsa Woes

I used a couple books (all of Harry Potter, and some college literature texts) for my laminate fuses. I laid the two up with epoxy and put some Glad cling wrap above and below on a quite flat piece of 3/4 plywood. This worked out pretty good.

If your bows were not counter to each other then the wood will not stay straight. The wet and block should work. You can always block in a counter twist too.

If you choose to cook the wood (steam) be careful of crushing and bursting the fibers since they swell. White oak can become limp as cooked asparagus, so I don't even know how balsa will react. Padding before clamping or blocking is a must.

Phil

If your bows were not counter to each other then the wood will not stay straight. The wet and block should work. You can always block in a counter twist too.

If you choose to cook the wood (steam) be careful of crushing and bursting the fibers since they swell. White oak can become limp as cooked asparagus, so I don't even know how balsa will react. Padding before clamping or blocking is a must.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Warpy Balsa Woes

Re: Warpy Balsa Woes

Yeah,

It looks ok, reason I asked is because hard balsa would probably retain the shape better. Soft balsa is a PITA to keep straight not to mention hard to work with seeing as it's so brittle.

That's my take on it anyway. Instead of steam you could soak it in hot water and see how that goes. It would heat the wood evenly as opposed to steam.

If you have some warped scrap you could test it on that first.

Ron

It looks ok, reason I asked is because hard balsa would probably retain the shape better. Soft balsa is a PITA to keep straight not to mention hard to work with seeing as it's so brittle.

That's my take on it anyway. Instead of steam you could soak it in hot water and see how that goes. It would heat the wood evenly as opposed to steam.

If you have some warped scrap you could test it on that first.

Ron

Cribbs74- Moderator

Posts : 11895

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Warpy Balsa Woes

Re: Warpy Balsa Woes

I also had problems glueing the 2 ply wing for my Caudron. I mentioned it already in the CEF speed contest thread. I used wood glue that I put on 1 side. Due to the swell I ended up with a nice oblong fruit bowl. After sticking both halfs together, I thought all would go flat again but it turned out the other way. After drying, I wetted it the first time with water and clamped it up between to flat planks. After 1 night on the radiator, the wing came out flat but started twisting again in the next hour. I then repeated the procedure. It's drying now but I'm gonna wait a few more days before removing it.

Lieven

Lieven

OVERLORD- Diamond Member

- Posts : 1789

Join date : 2013-03-19

Age : 57

Location : Normandy, France

Similar topics

Similar topics» Pictures added Balsa balsa balsa

» "Molding Balsa"...NOT to be confused with "Moldy Balsa"!!!!! M.A.N 12-64

» PeeWee woes...

» OK Cub .049

» Cox Space Bug Woes

» "Molding Balsa"...NOT to be confused with "Moldy Balsa"!!!!! M.A.N 12-64

» PeeWee woes...

» OK Cub .049

» Cox Space Bug Woes

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules