Log in

Search

Latest topics

» Dodge Viper - What a waste but brilliant marketingby roddie Today at 6:46 pm

» COX .020 POWERED SPEEDSTER

by TD ABUSER Today at 6:32 pm

» **VOTE-ON-THE-NEXT-COX-ENGINE-OF-THE-MONTH** (November 2024)

by roddie Today at 6:13 pm

» Brushless motors?

by rsv1cox Today at 4:53 pm

» Free Flight Radio Assist

by rdw777 Today at 4:28 pm

» Cox 020 PeeWee rebuild questions

by balogh Today at 4:15 pm

» L4 Grasshopper

by latole Today at 3:43 pm

» PAW 80 and possible use

by fit90 Today at 8:36 am

» Music-wire bending tools (DIY video)

by 1975 control line guy Today at 8:32 am

» Ultrasonic Cleaners??

by sosam117 Yesterday at 11:26 am

» My CA or CyA (super glue) allergy

by rsv1cox Yesterday at 9:52 am

» My Pseudo killerbee.

by rsv1cox Yesterday at 7:04 am

messing around with flywheels

Page 1 of 3

Page 1 of 3 • 1, 2, 3

messing around with flywheels

messing around with flywheels

I've been wanting to run a Cox .049 engine in a "boat" (with a water-prop/flex-cable drive) for a LONG time. One of the biggest challenges is starting the engine. A flywheel is required to "load" the engine sufficiently.. along with the proper pitch/diameter water-prop. Sterling and Dumas used to make .049 running-hardware kits for this purpose; which included a properly weighted flywheel. The flywheels were "knurled" on their O.D. and also had a "V"-groove to engage a belt or "pull-cord". You can imagine the challenges associated with starting an engine this way.

I thought about the Cox "spring-starters".. and if they could somehow be utilized. The "zero-drag" type was specifically designed to engage an "air-prop".. but the "cam-style" had possibilities. How to "wind the spring" enough.. in the space of a tiny boat hull, became the challenge.

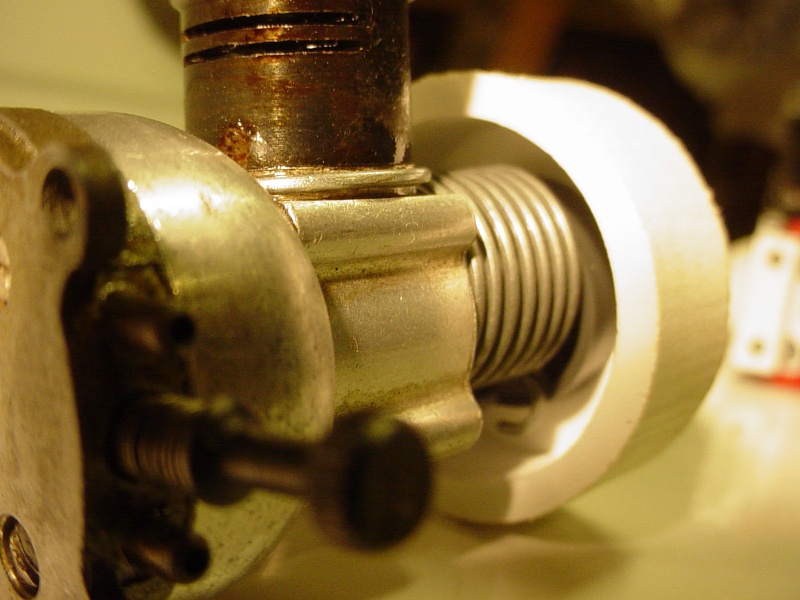

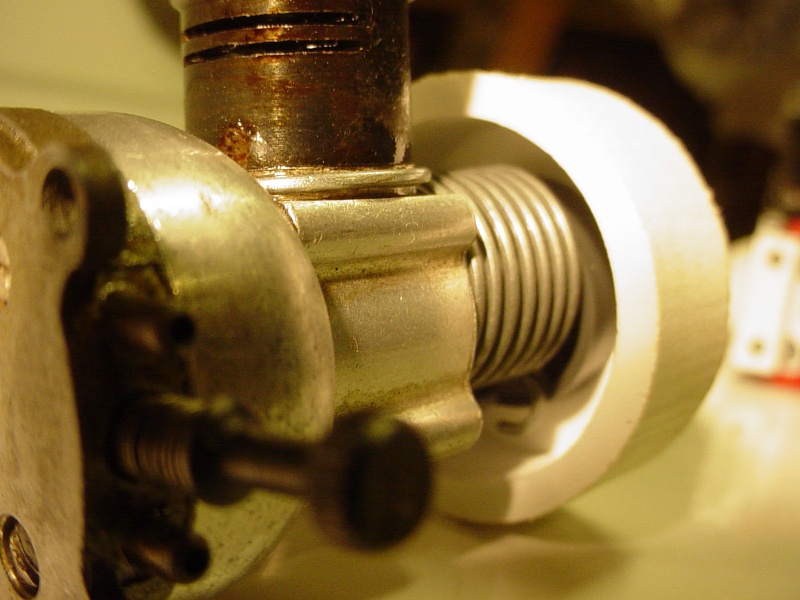

I am experimenting with a "bell-housing" shaped PVC part that bears on a hex-style drive-plate; encircling the cam-style starter assembly. It would permit the addition of weighted flywheel discs needed to keep the engine running.

Here's some pics of what I've been working on.

Dumas still makes this prop for the Cox .049.. as far as I know.

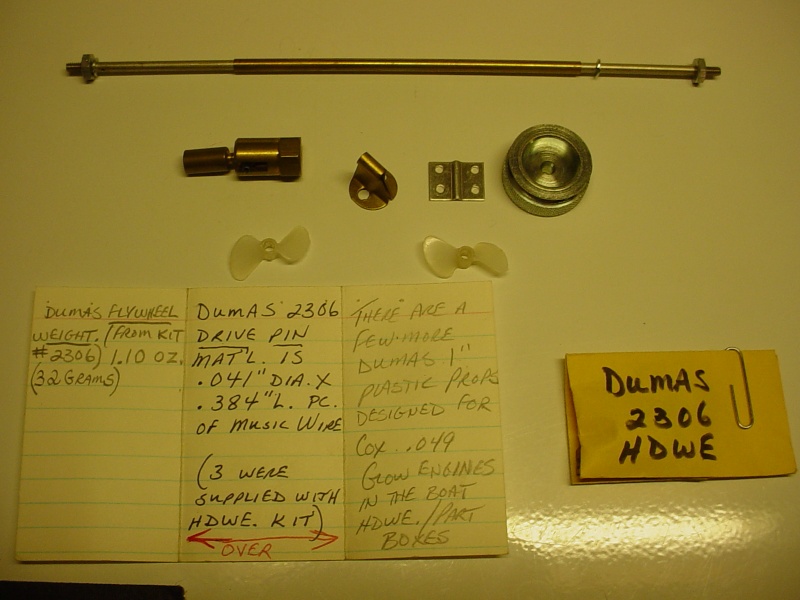

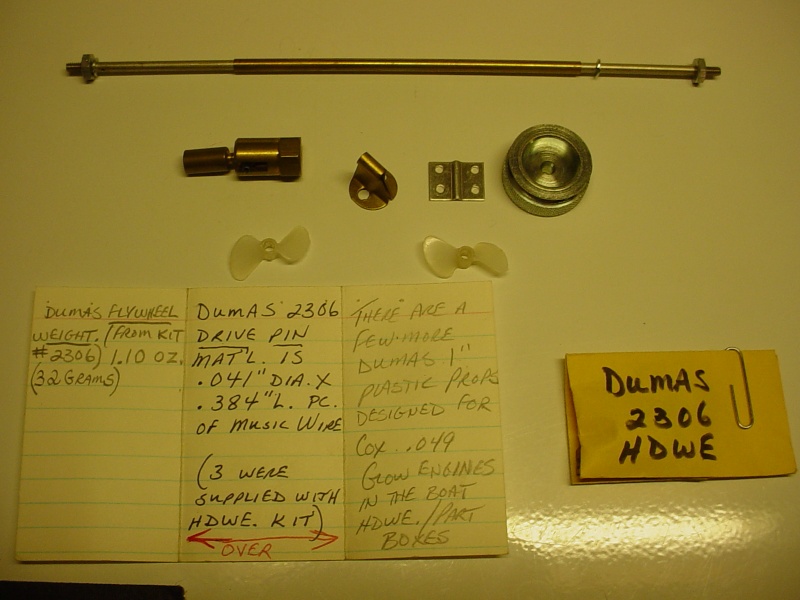

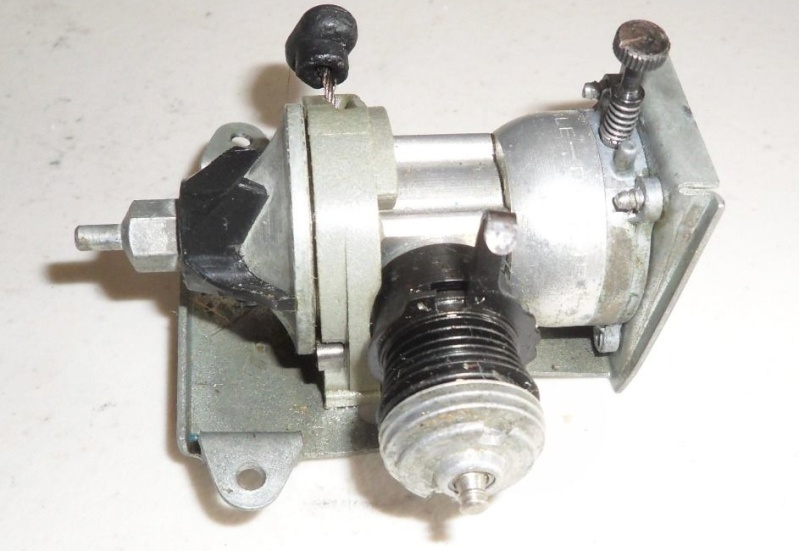

Here's the running hardware kit that I have.. not sure if it's still available.

some parts are not shown in this pic.. like the rudder assembly and the prop drive-pins. (my written notes on the index card, are from a few years ago)

I thought about the Cox "spring-starters".. and if they could somehow be utilized. The "zero-drag" type was specifically designed to engage an "air-prop".. but the "cam-style" had possibilities. How to "wind the spring" enough.. in the space of a tiny boat hull, became the challenge.

I am experimenting with a "bell-housing" shaped PVC part that bears on a hex-style drive-plate; encircling the cam-style starter assembly. It would permit the addition of weighted flywheel discs needed to keep the engine running.

Here's some pics of what I've been working on.

Dumas still makes this prop for the Cox .049.. as far as I know.

Here's the running hardware kit that I have.. not sure if it's still available.

some parts are not shown in this pic.. like the rudder assembly and the prop drive-pins. (my written notes on the index card, are from a few years ago)

Re: messing around with flywheels

Re: messing around with flywheels

Roddie, Dumas still sells .049 running hardware that comes with a flywheel. I've had my eye on it for quite a while. Check out this link:

http://www.dumasproducts.com/product_info.php?products_id=444

You also might want to try one of the pull starters. I believe they can be fitted with a cox flywheel.

Andy

http://www.dumasproducts.com/product_info.php?products_id=444

You also might want to try one of the pull starters. I believe they can be fitted with a cox flywheel.

Andy

anm2- Gold Member

- Posts : 293

Join date : 2013-03-30

Re: messing around with flywheels

Re: messing around with flywheels

anm2 wrote:Roddie, Dumas still sells .049 running hardware that comes with a flywheel. I've had my eye on it for quite a while. Check out this link:

http://www.dumasproducts.com/product_info.php?products_id=444

You also might want to try one of the pull starters. I believe they can be fitted with a cox flywheel.

Andy

Thanks Andy, That's good to know about the Dumas running hardware. It has a different part# than mine.. and also appears to have some different parts too.

I'm curious as to whether I can get an engine to run "properly".. without having to use that heavy metal flywheel. A "pull-starter" is even more added weight.. and requires having an overbuilt (and thus "heavy") engine mounting.. to prevent accidentally yanking a flooded engine out of the hull. I have the same concerns with using a starter-belt.. stressing the engine mounting in order to engage it.

The PVC flywheel that I made, would allow winding the cam-style starter-spring by gripping the model in both hands around the hull and using both thumbs to "hold and wind" the spring.

If the PVC flywheel doesn't have enough rotational-mass.. (weight) to keep the engine running in the proper rpm-range.. I can always add steel "fender-style" washers.

The Dumas flywheel in kit# 2306 weighs 32g (1.10 oz.) but was likely engineered along with the u-joint, drive-shaft and prop size/pitch.. to optimize the power from an .049 engine. The thing is.. there's a lot of difference between the output of a reedie vs. a Tee Dee.. so: did Dumas tune their drive set-up to perform well; somewhere in between the two different engine designs"? They only specify engine size.. and not the type.

Over-revving any engine is always a concern.. but a lighter flywheel, along with the "remaining" parts of the Dumas drive parts.. may allow a reed-valve engine to achieve higher rpm's.. allowing the boat model to "plane-out" quicker?

I plan on running a "throttled" reedie.. which will either "complicate" matters.. or possibly "prevent" prop-cavitation before the model can get up to speed. Thin (bendable) aluminum trim-tabs attached to the bottom of the transom are a "must" for tuning the hull.

I'm always looking for ways to "home-brew" parts for better or more reliable performance. Sometimes it's necessary to make a part that doesn't already exist.. or when an OEM part is no longer in production or unobtainable.

Are you looking to build a tethered-hydro Andy... or an RC open water model? I would be very interested in hearing about it, either way.

Re: messing around with flywheels

Re: messing around with flywheels

Another problem to consider is cooling.

Although the Bee doesn't run for long - the cylinder design (small fins) does rely on quite an air flow.

I have only ever experienced diesel engines in boats with water jackets. I think that, even then, the smallest was 1.5cc.

Any way, there I was pondering the possibilities of a glow .049 boat engine and I remembered I had one.

An O&R Mariner

On my list of restores - well in this instance a good clean. The bronze parts need a good clean and the storage oil has festered.

The flywheel is steel.

For a closer look

https://www.coxengineforum.com/t7157-1955-or-mariner-049

Although the Bee doesn't run for long - the cylinder design (small fins) does rely on quite an air flow.

I have only ever experienced diesel engines in boats with water jackets. I think that, even then, the smallest was 1.5cc.

Any way, there I was pondering the possibilities of a glow .049 boat engine and I remembered I had one.

An O&R Mariner

On my list of restores - well in this instance a good clean. The bronze parts need a good clean and the storage oil has festered.

The flywheel is steel.

For a closer look

https://www.coxengineforum.com/t7157-1955-or-mariner-049

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: messing around with flywheels

Re: messing around with flywheels

ian1954 wrote:Another problem to consider is cooling.

Although the Bee doesn't run for long - the cylinder design (small fins) does rely on quite an air flow.

I have only ever experienced diesel engines in boats with water jackets. I think that, even then, the smallest was 1.5cc.

I have cooling options that I will explore. Here are two.

I'll also be running 25% minimum nitro (more than likely, Sig Champion 35) which should run cooler than a sport fuel with only 15% nitro.

Re: messing around with flywheels

Re: messing around with flywheels

ian1954 wrote:Another problem to consider is cooling.

Although the Bee doesn't run for long - the cylinder design (small fins) does rely on quite an air flow.

I have only ever experienced diesel engines in boats with water jackets. I think that, even then, the smallest was 1.5cc.

Any way, there I was pondering the possibilities of a glow .049 boat engine and I remembered I had one.

An O&R Mariner

On my list of restores - well in this instance a good clean. The bronze parts need a good clean and the storage oil has festered.

The flywheel is steel.

For a closer look

https://www.coxengineforum.com/t7157-1955-or-mariner-049

What a nice kit that is!! The Dumas flywheel is Steel too, and weighs a whopping 32g. What's your opinion on the inertial-mass/weight of the flywheel.. in regards to it's function? An aero-prop for the same size engine displacement doesn't weigh nearly as much. A Cox grey-competition 6 x 3 weighs 6g. Blade-pitch is also a factor in engine-loading. Does the flywheel on a marine engine guard against over-revving? In a no-load condition (starting.. or boat flips over) having too little flywheel weight could cause the engine to exceed it's design rpm.. right?

Re: messing around with flywheels

Re: messing around with flywheels

It is the mass in the flywheel that has to counteract the resistance of the blade meeting air to keep the revs down and the engine spinning at a constant speed.

Some older engines with lightweight props used to have a flywheel fitted as well as the propeller to keep the revs within an acceptable limit.

It does get complicated though - a flywheel of the same weight but a larger diameter will run slower.

It is trial and error.

I like the Dumas water jacket - I didn't know things like that existed!

What I can warn you about is that starting with string can be fraught. I once did it on a 2.5 cc diesel and the string got caught up after it fired. I am glad I didn't have it wrapped around my fingers.

Some older engines with lightweight props used to have a flywheel fitted as well as the propeller to keep the revs within an acceptable limit.

It does get complicated though - a flywheel of the same weight but a larger diameter will run slower.

It is trial and error.

I like the Dumas water jacket - I didn't know things like that existed!

What I can warn you about is that starting with string can be fraught. I once did it on a 2.5 cc diesel and the string got caught up after it fired. I am glad I didn't have it wrapped around my fingers.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: messing around with flywheels

Re: messing around with flywheels

You seem to be missing a point: A flywheel provides rotational inertia to allow the engine to coast through to the next compression and power stroke.

If your mass is too light the engine will stall as soon as it is in the water, even if it runs pretty good in air.

Phil

If your mass is too light the engine will stall as soon as it is in the water, even if it runs pretty good in air.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: messing around with flywheels

Re: messing around with flywheels

ian1954 wrote:It is the mass in the flywheel that has to counteract the resistance of the blade meeting air to keep the revs down and the engine spinning at a constant speed.

Some older engines with lightweight props used to have a flywheel fitted as well as the propeller to keep the revs within an acceptable limit.

It does get complicated though - a flywheel of the same weight but a larger diameter will run slower.

It is trial and error.

I like the Dumas water jacket - I didn't know things like that existed!

What I can warn you about is that starting with string can be fraught. I once did it on a 2.5 cc diesel and the string got caught up after it fired. I am glad I didn't have it wrapped around my fingers.

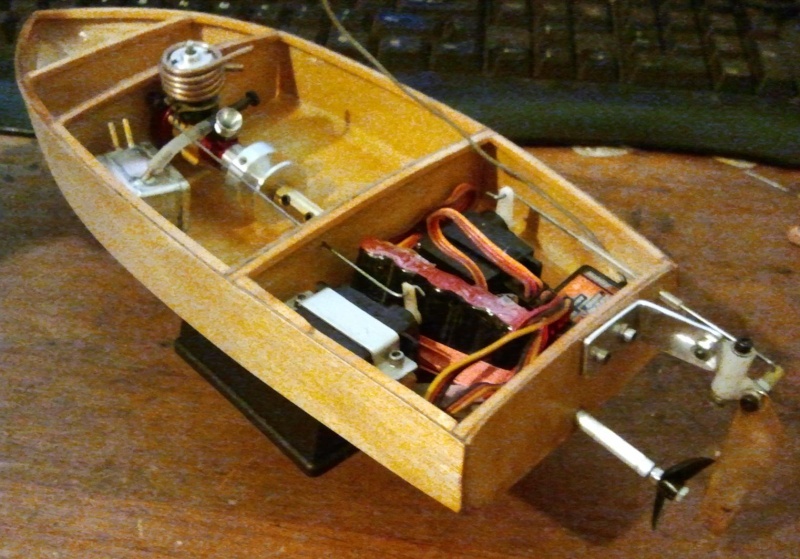

Yes.. that would make sense. I actually used a small (insignificant really) aluminum disc between the prop and drive-plate of the Babe Bee that I used to test the "Ace" RC venturi throttle. This is ultimately the set-up I hope to use in a two-channel RC marine version, using a tiny LiFe receiver pack and x2 nano-servos for rudder/throttle control.

You remember this vid..

https://www.coxengineforum.com/t5486-049-reed-valve-venturi-throttle?highlight=049+venturi

I think I answered a few questions that you asked about it. The glow-driver was on during the vid.. but I have achieved the same results after removing the battery clip.

It's questionable.. whether I even need a heat-sink/water-jacket.. because the Ace throttle directions actually recommend the use of a "muffler" to hold heat to the head at lower rpm's. That "Dumas" water-jacket I bought about 25 years ago.. and I've never seen another one. The Cox heat-sink is specifically designed for the .049 reed-valve engine.. and is probably what I'll use if I have trouble with over heating.

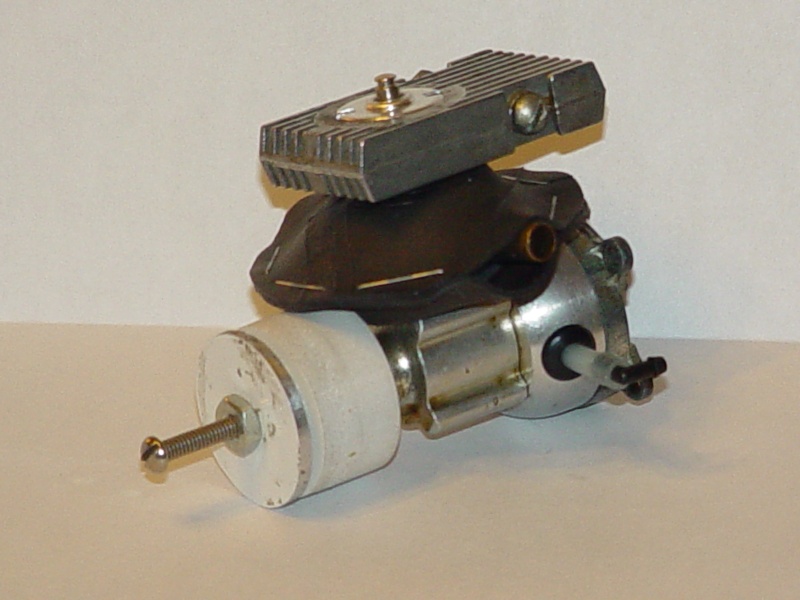

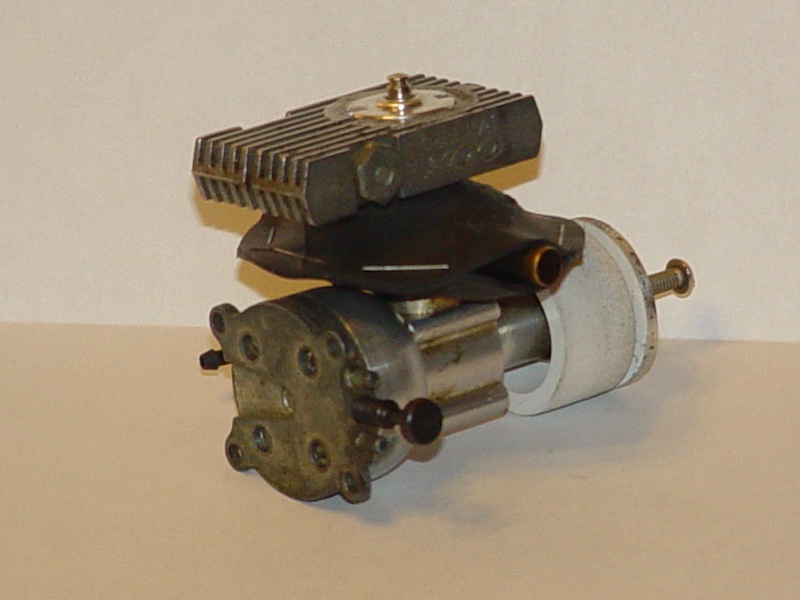

The Babe Bee's are the best engines I have, to try to produce a throttled .049 powered boat. I have modified two 5cc fuel tanks by drilling a 1/4" dia. hole through the wall.. and installing a rubber grommet for feeding an extended fuel pick-up line through.. for running a larger external fuel-cell. The bee's backplate greatly simplifies this type of "plunger-needle" throttle installation.

Incidentally.. "with" throttle control; I'll have more wiggle-room with flywheel weight.. because I can limit the "no-load" rpm's on shore.. and in the case that the boat flips over during a run. There "is" that possibility with the hull that I've designed. It's an out-rigger hydro.

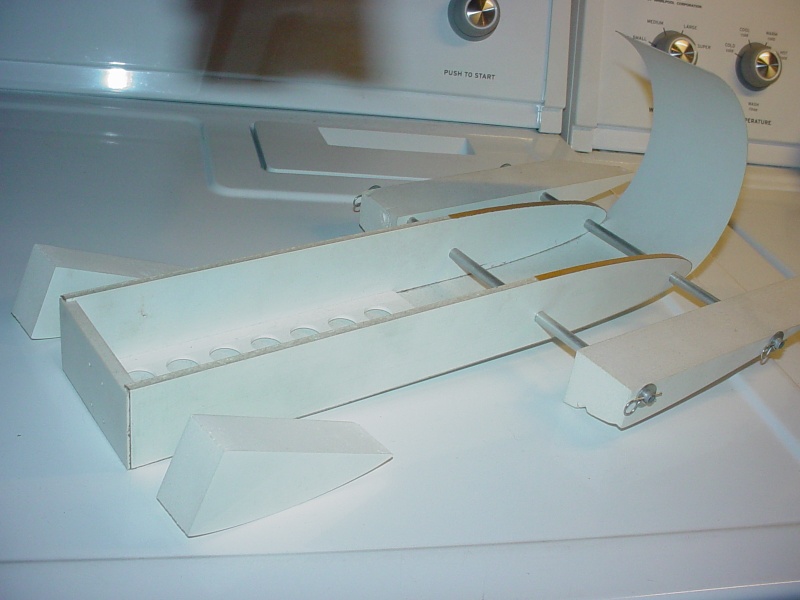

here's the hull.. .030" sheet-styrene "bottom", foam-board hull-sides/sponsons and 1/4" aluminum booms. The floor has a lightened 3mm sheet-PVC insert-plate to support the engine mount. Lightweight, "buoyant".. CNC designed and router-cut, about 8 years ago.

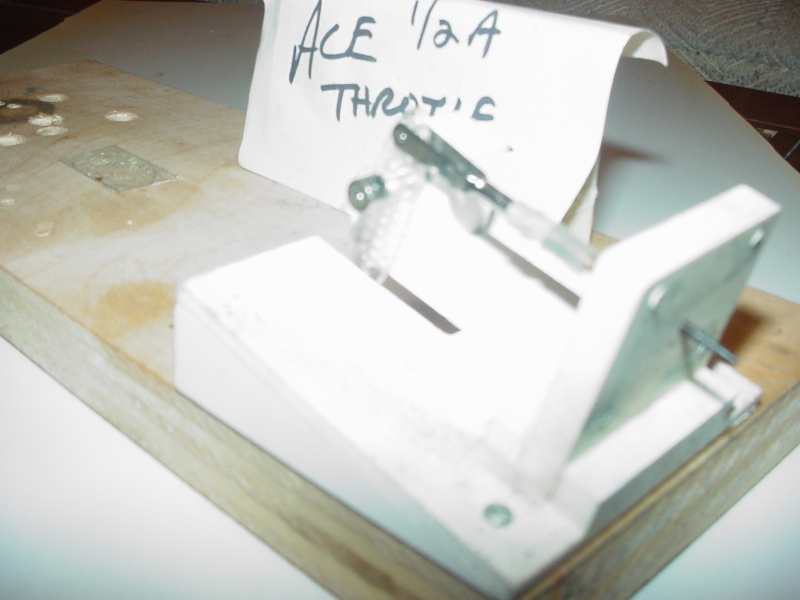

Here is the engine mount. It is sheet-PVC with a standard Cox "Bee" mounting pattern drilled.. a guide for the "Ace"-style plunger/needle, and provisions for an adjustable-throw throttle horn/linkage.

Here's a modified Babe-Bee for this set-up.

Posting these photos along with your interest, may "spur me on" to actually finishing this boat model. Being as "analytical" as I am.. the next phase will be the "static" testing of a throttled-engine/propped-drive, in a small test tank with water. I plan to run the stuffing-tube/prop-shaft through a rubber grommet in the wall of the water tank (small clear-plastic shoe-box with lid) and run a "throttled-engine" with the stock "Dumas" running hardware/flywheel to try and establish a "medium". This will be an engine test. Trimming the "hull" is a whole different matter.. but not too much different than an airplane. There is a C/G.. and a balance-point.. especially with a 3-point hydroplane hull! "Trim-tabs" on the transom, "turn-fins" on the sponson(s) and adjustable "drive-height" are the fine-tuning for running a fast boat that will turn on a dime! Model boat racing-drives are fascinating examples of miniature hydroplane performance hardware!

Here are a few examples of some nice running-hdwe.

Re: messing around with flywheels

Re: messing around with flywheels

Just what I was thinking Phil, as I was reading through the flywheel will help to keep a constant so overloading to stall or lean will be less possible,, But FIT is everthing !!! (meaning all components must be withend a =) ///Getback After Ian !pkrankow wrote:You seem to be missing a point: A flywheel provides rotational inertia to allow the engine to coast through to the next compression and power stroke.

If your mass is too light the engine will stall as soon as it is in the water, even if it runs pretty good in air.

Phil

getback- Top Poster

Posts : 10415

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: messing around with flywheels

Re: messing around with flywheels

The engine setup Cox had in there Sea Bee, pull start and exhaust throttle. Nothing for overheating but Cox did detune some of their cars with a large spacer under the cylinder to help with running hot. This engine might have that spacer too.

Last edited by crankbndr on Mon Sep 01, 2014 8:19 pm; edited 1 time in total

crankbndr- Top Poster

- Posts : 3108

Join date : 2011-12-10

Location : Homestead FL

Re: messing around with flywheels

Re: messing around with flywheels

pkrankow wrote:You seem to be missing a point: A flywheel provides rotational inertia to allow the engine to coast through to the next compression and power stroke.

If your mass is too light the engine will stall as soon as it is in the water, even if it runs pretty good in air.

Phil

Yes.. you're correct Phil. Extensive testing will need to be done. There "needs" to be a flywheel in a marine IC engine/"submerged-drive" set-up; exactly for the reasons you mentioned.

There are many variables.. just as there are in aero-modeling.

The nice thing about a model boat.. is that it doesn't "re-kit" itself when something goes wrong. If it "flips" and breaks-apart on the water.. you've at least built it fast enough to know that the engine/drive performs well!

Re: messing around with flywheels

Re: messing around with flywheels

crankbndr wrote:The engine setup Cox had in there Sea Bee, pull start and exhaust throttle. Nothing for overheating but Cox did detune some of there cars with a large spacer under the cylinder to help with running hot. This engine might have that spacer too.

Yep, there it is, I never knew about that, thanks.

Bob

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Re: messing around with flywheels

Re: messing around with flywheels

crankbndr wrote:The engine setup Cox had in there Sea Bee, pull start and exhaust throttle. Nothing for overheating but Cox did detune some of there cars with a large spacer under the cylinder to help with running hot. This engine might have that spacer too.

Man.. look at how thin the engine-mounting bulkhead is on the Sea-Bee.

Last edited by roddie on Mon Sep 01, 2014 7:34 pm; edited 1 time in total

Re: messing around with flywheels

Re: messing around with flywheels

Yeoww. Reminds me when I worked on office copiers and we started taking on the big high speed machines. All the techs were required to wear neckties. The first time I opened up the backside of one and ran it, I leaned over into some air currents that picked my tie up and pulled it toward the machine before I grabbed it. Running 120 copies a minute, that sucker would have reeled me in and ate my face before I could have reacted. I went straight to my desk and wrote a memo, "All techs must wear clip-on ties from now on."ian1954 wrote:What I can warn you about is that starting with string can be fraught. I once did it on a 2.5 cc diesel and the string got caught up after it fired. I am glad I didn't have it wrapped around my fingers.

In my youth, I worked at a machine shop and was tasked with drilling 2" holes in some 1/2" flat iron plates with a big slow moving automatically driven drill press. My hair was almost down to my belt at the time, and those old mechanics used to tell me I was going to get that hair caught in the drill press. Naaaah, no I'm not...It had an exposed ball bearing in the shaft above the chuck. Then one day I snoozed on it and next thing I knew I was being slowly pulled in. Holy crap! my head was starting to reel around the shaft when I was just able to reach the switch lever and shut it off. Now what. With the tips of my fingers I threw it in reverse and backed out. That was luck! I pulled a big wad of hair out of the bearing and stuffed it into a Big Mac box from a nearby trash can, looked around to see if anyone was watching. It didn't look like they were, but it was soon obvious that everyone had seen it. I was the subject of furtive snorking and snickering for a long time. Luckily I was the owner's son and so the razzing could've been worse. The worst part was the huge swollen bald spot on the top right back of my head.

Okay, sorry for the threadjack, I just got inspired by Ian cranking the Diesel.

[/hijack]

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: messing around with flywheels

Re: messing around with flywheels

Wow Rusty sounds like you were very lucky, must have 9 lives. Once I was drilling with a large drill motor, hand held with a 2' auger bit.

I was drilling between my legs and the bit snagged my Levis pant leg and started rolling it up, it was a slow speed high torque motor.

Even though I killed power it keep turning and almost broke my leg, I was badly bruised and chewed up. Another time I saw a guy running

a large belt sander with the trigger locked on, it got tangled in his shirt and ate a large hole in his belly before someone pulled the plug.

I never lock trigger on any tool anymore!

I was drilling between my legs and the bit snagged my Levis pant leg and started rolling it up, it was a slow speed high torque motor.

Even though I killed power it keep turning and almost broke my leg, I was badly bruised and chewed up. Another time I saw a guy running

a large belt sander with the trigger locked on, it got tangled in his shirt and ate a large hole in his belly before someone pulled the plug.

I never lock trigger on any tool anymore!

crankbndr- Top Poster

- Posts : 3108

Join date : 2011-12-10

Location : Homestead FL

Re: messing around with flywheels

Re: messing around with flywheels

RknRusty wrote:Yeoww. Reminds me when I worked on office copiers and we started taking on the big high speed machines. All the techs were required to wear neckties. The first time I opened up the backside of one and ran it, I leaned over into some air currents that picked my tie up and pulled it toward the machine before I grabbed it. Running 120 copies a minute, that sucker would have reeled me in and ate my face before I could have reacted. I went straight to my desk and wrote a memo, "All techs must wear clip-on ties from now on."ian1954 wrote:What I can warn you about is that starting with string can be fraught. I once did it on a 2.5 cc diesel and the string got caught up after it fired. I am glad I didn't have it wrapped around my fingers.

In my youth, I worked at a machine shop and was tasked with drilling 2" holes in some 1/2" flat iron plates with a big slow moving automatically driven drill press. My hair was almost down to my belt at the time, and those old mechanics used to tell me I was going to get that hair caught in the drill press. Naaaah, no I'm not...It had an exposed ball bearing in the shaft above the chuck. Then one day I snoozed on it and next thing I knew I was being slowly pulled in. Holy crap! my head was starting to reel around the shaft when I was just able to reach the switch lever and shut it off. Now what. With the tips of my fingers I threw it in reverse and backed out. That was luck! I pulled a big wad of hair out of the bearing and stuffed it into a Big Mac box from a nearby trash can, looked around to see if anyone was watching. It didn't look like they were, but it was soon obvious that everyone had seen it. I was the subject of furtive snorking and snickering for a long time. Luckily I was the owner's son and so the razzing could've been worse. The worst part was the huge swollen bald spot on the top right back of my head.

Okay, sorry for the threadjack, I just got inspired by Ian cranking the Diesel.

[/hijack]

Oh Man... you were LUCKY! I'm sure that you know what "could've" happened..

Oh Man... you were LUCKY! I'm sure that you know what "could've" happened..

BTW Rusty.. My first job after I graduated high school in 1978 was working at a company that my dad worked at. "Crosby Valve and Gage Co. in Wrentham, MA. They had an "N" stamp for manufacturing high-pressure steam relief valves in nuclear power generation plants here in the U.S... as well as several U.S. Navy "Buships" contracts. I settled in the Quality Assurance department.. where everything was about "documentation". Serialization records, specs. on material.. from where it had been forged.. casted.. bar-stock annealing.. oil/rapid-water quenching, NDE tests.. welding radio-graphs... magnetic particle tests, ultrasonic tests, liquid-penetrant tests..... There was TONS of paperwork for documentation packages associated with Boiler and Pressure Vessel Code Section III Nuclear compliance. Inspectors from Westinghouse, G.E., Bechtel, Deleval Turbine.. and many others, were on-site "daily" to oversee operations.. and make sure that we were manufacturing within the "code"...

Your reply reminded me of the "copy machine" that we had in the Q.A. department. Even by "today's" standards.. it wasn't your everyday copy machine. It was a "Van Dyke". There was one in our department.. and one upstairs in the "Specifications" dept. Do you recall the brand? It used LARGE "rolls" of paper; 11" wide.. and had a "knife" that would cut the paper to a specified "letter" or "legal" length. The "platen" was concaved.. with a "mat" that would hold the original "flat" against the glass.. and also shield your eyes from the bright-green Xenon (?) lamps. While copying; it would make a "kerplunk" sound as the knife cut the paper. It was typical for the machine to produce "thousands" of copies per day. The Van Dyke tech's name was "George Berry". He lived locally.. and would perform routine-maintenance and be on-call if there was an issue with either machine. (I can hack my own thread.... right?)

Re: messing around with flywheels

Re: messing around with flywheels

Yeah, I think van dyke was an old process pre-dating Xerography, but i couldn't fathom a guess as to who may have made such a machine like yours. Were the copies brown? It was probably really old, even back then.

A lot of machines had green illumination in their image formation systems because the early photoreceptors were sensitive to that wavelength in the 500nm range. It could have been xenon strobe, but no telling for sure. I've green seen fluorescents too in continuous exposure systems. The curved platen made it easy to form an undistorted 1:1 image on a giant drum or curved belt. There have been all sorts of crazy systems for copying over the years. Copiers are interesting beasts.

Rusty

A lot of machines had green illumination in their image formation systems because the early photoreceptors were sensitive to that wavelength in the 500nm range. It could have been xenon strobe, but no telling for sure. I've green seen fluorescents too in continuous exposure systems. The curved platen made it easy to form an undistorted 1:1 image on a giant drum or curved belt. There have been all sorts of crazy systems for copying over the years. Copiers are interesting beasts.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: messing around with flywheels

Re: messing around with flywheels

RknRusty wrote:Yeah, I think van dyke was an old process pre-dating Xerography, but i couldn't fathom a guess as to who may have made such a machine like yours. Were the copies brown? It was probably really old, even back then.

A lot of machines had green illumination in their image formation systems because the early photoreceptors were sensitive to that wavelength in the 500nm range. It could have been xenon strobe, but no telling for sure. I've green seen fluorescents too in continuous exposure systems. The curved platen made it easy to form an undistorted 1:1 image on a giant drum or curved belt. There have been all sorts of crazy systems for copying over the years. Copiers are interesting beasts.

Rusty

Hey Rusty, The copies from the Van Dyke machine were perfect grey-scale B & W copies. The documentation-packages that we assembled, were part of the valve's "History" and had to comply with the U.S. NRC's regulations. The valves that we were producing were "classified" pressure-retaining components for the super-heated steam plumbing, associated with nuclear energy production.

TD .020 Cracker Box

TD .020 Cracker Box

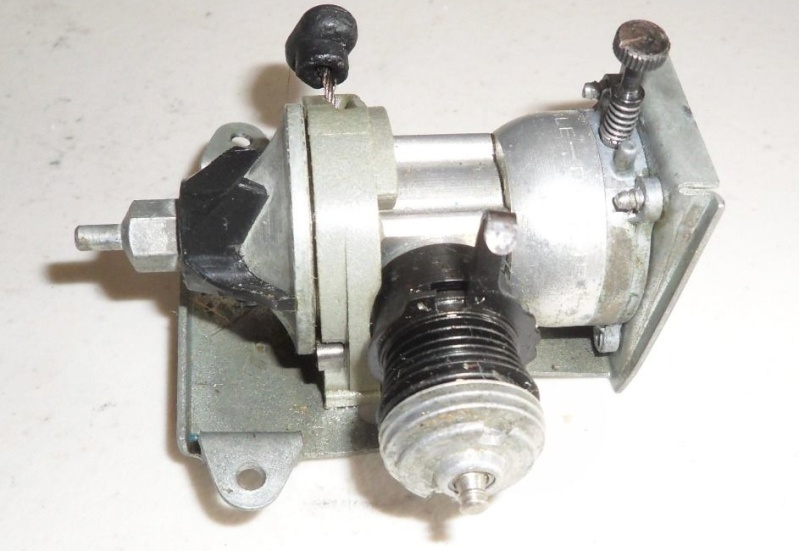

Here is my 2ch Cracker Box

2mm drive line

20mm surface prop

1/2oz fuel tank

Water cooled engine

Exhaust throttled TD .020

Skeg to hold stable flat fast turns

Hand fabricated kick back rudder assembly

Ready to fun weight 194.2g / 6.85oz

Wood hull 9.25in long

1/2A Nut- Top Poster

- Posts : 3526

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: messing around with flywheels

Re: messing around with flywheels

1/2A Nut wrote:

Here is my 2ch Cracker Box

2mm drive line

20mm surface prop

1/2oz fuel tank

Water cooled engine

Exhaust throttled TD .020

Skeg to hold stable flat fast turns

Hand fabricated kick back rudder assembly

Ready to fun weight 194.2g / 6.85oz

Wood hull 9.25in long

Now "that's" WICKED cool!!!!

Re: messing around with flywheels

Re: messing around with flywheels

If anyone's interested.

http://www.ebay.com/itm/Vintage-Cox-Flywheel-350-4-350-8-191-4-191-1-Engine-Airplane-Part-2663-NOS-IB-/161266487561?pt=Radio_Control_Parts_Accessories&hash=item258c3b5109&_uhb=1

Rod.

http://www.ebay.com/itm/Vintage-Cox-Flywheel-350-4-350-8-191-4-191-1-Engine-Airplane-Part-2663-NOS-IB-/161266487561?pt=Radio_Control_Parts_Accessories&hash=item258c3b5109&_uhb=1

Rod.

Oldenginerod- Top Poster

- Posts : 4017

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: messing around with flywheels

Re: messing around with flywheels

What happened to the pictures in this thread? They seem to have disappeared. Any chance to get them back?

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: messing around with flywheels

Re: messing around with flywheels

Only the post with the seabee pics are gone I was able to view every pic. Could have been a glitch at the time you viewed.

1/2A Nut- Top Poster

- Posts : 3526

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: messing around with flywheels

Re: messing around with flywheels

Does it fly/float?

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Page 1 of 3 • 1, 2, 3

Similar topics

Similar topics» Messing with Sasquach

» Cox needle-valve seals

» Testors/McCoy .049 smoked...

» flywheels.. weighting your crankshaft

» Cox needle-valve seals

» Testors/McCoy .049 smoked...

» flywheels.. weighting your crankshaft

Page 1 of 3

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules