Log in

Search

Latest topics

» Dodge Viper - What a waste but brilliant marketingby roddie Today at 6:46 pm

» COX .020 POWERED SPEEDSTER

by TD ABUSER Today at 6:32 pm

» **VOTE-ON-THE-NEXT-COX-ENGINE-OF-THE-MONTH** (November 2024)

by roddie Today at 6:13 pm

» Brushless motors?

by rsv1cox Today at 4:53 pm

» Free Flight Radio Assist

by rdw777 Today at 4:28 pm

» Cox 020 PeeWee rebuild questions

by balogh Today at 4:15 pm

» L4 Grasshopper

by latole Today at 3:43 pm

» PAW 80 and possible use

by fit90 Today at 8:36 am

» Music-wire bending tools (DIY video)

by 1975 control line guy Today at 8:32 am

» Ultrasonic Cleaners??

by sosam117 Yesterday at 11:26 am

» My CA or CyA (super glue) allergy

by rsv1cox Yesterday at 9:52 am

» My Pseudo killerbee.

by rsv1cox Yesterday at 7:04 am

messing around with flywheels

Page 3 of 3

Page 3 of 3 •  1, 2, 3

1, 2, 3

Re: messing around with flywheels

Re: messing around with flywheels

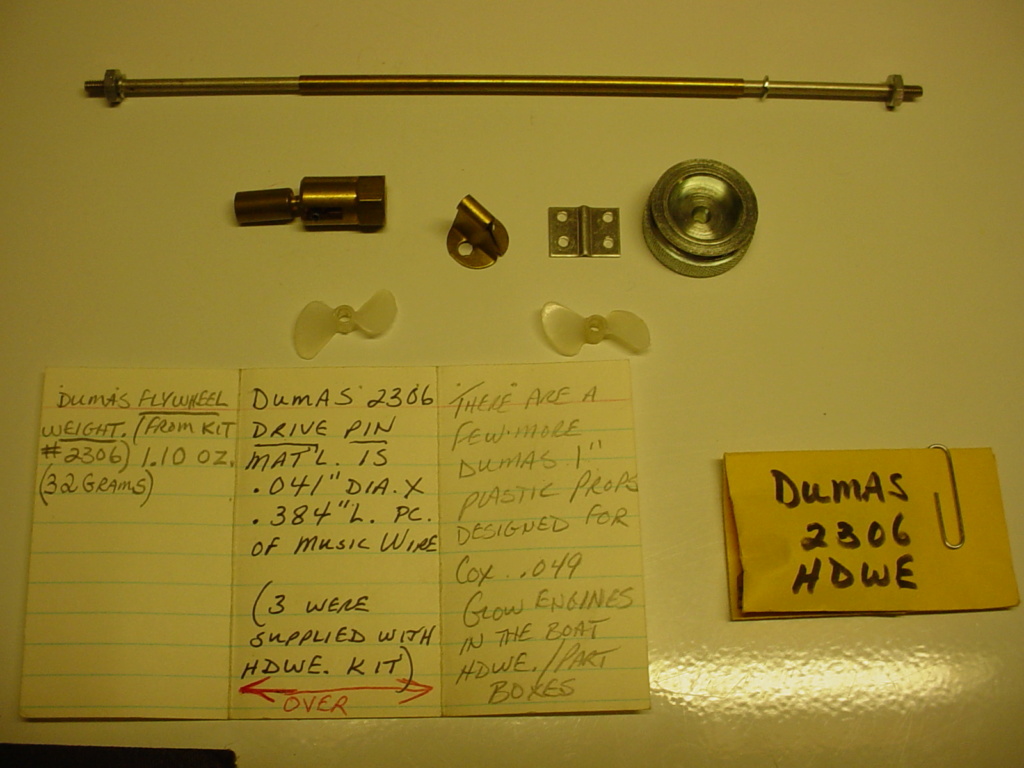

Here's a 3rd test running the 1 oz. "Dumas" flywheel designed for the Cox .049 engine for use in their model boats. This test really proves what CEF member "Kari" explained in his post..

Last edited by roddie on Sun Jan 20, 2019 11:52 am; edited 3 times in total (Reason for editing : trying to fix vid-link)

Re: messing around with flywheels

Re: messing around with flywheels

Way to go! Very nice rrrrrrun! I gotta make one of those throttles. Too Cool! Thanks !

PS: only video 1 opens and plays, #2 & #3 say they are unavailable.

SNL is on, see ya tomorrow.

PS: only video 1 opens and plays, #2 & #3 say they are unavailable.

SNL is on, see ya tomorrow.

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 71

Location : Grand Rapids, MI

Re: messing around with flywheels

Re: messing around with flywheels

Marleysky wrote:Way to go! Very nice rrrrrrun! I gotta make one of those throttles. Too Cool! Thanks !

PS: only video 1 opens and plays, #2 & #3 say they are unavailable.

SNL is on, see ya tomorrow.

I don't know why vids 2 & 3 won't play..

I experienced the same.. then the issue seemed to subside? Let me know if there's still trouble viewing them.

I experienced the same.. then the issue seemed to subside? Let me know if there's still trouble viewing them. Thanks VERY MUCH for watching!!!

Re: messing around with flywheels

Re: messing around with flywheels

I am only getting the first video as well. The engine ran well though. Wish you would have let it run on peak a little longer!

Ron

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: messing around with flywheels

Re: messing around with flywheels

Cool Run Man !! That is not what i would have thought it was going to do DUH but it is a boat /car motor now , Good to hear your voice

getback- Top Poster

Posts : 10415

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: messing around with flywheels

Re: messing around with flywheels

Man, that sounds like one very angry Bee  Love the throttle response the light flywheel gives.

Love the throttle response the light flywheel gives.

I just remembered, I have a couple of NOS Thimble Drome boat flywheels, cat#330:

The flywheel has knurled outer surface probably to help turning the engine by hand and also a groove for a starter belt. The nut has a stub axle where a plastic ”joint” can be slid on to provide a flexible connection to propeller shaft.

The plastic is obviously hard as rock after half a century of storage. The flywheel is white metal I think, and it weighs 1.2oz. The nut is aluminum.

.

I just remembered, I have a couple of NOS Thimble Drome boat flywheels, cat#330:

The flywheel has knurled outer surface probably to help turning the engine by hand and also a groove for a starter belt. The nut has a stub axle where a plastic ”joint” can be slid on to provide a flexible connection to propeller shaft.

The plastic is obviously hard as rock after half a century of storage. The flywheel is white metal I think, and it weighs 1.2oz. The nut is aluminum.

.

KariFS- Diamond Member

- Posts : 2041

Join date : 2014-10-10

Age : 53

Re: messing around with flywheels

Re: messing around with flywheels

Roddie, that was pretty cool. Now, do you have boat plans? I have the shaft, the universal and the prop.I would need to fabricate the stuffing box for the hull. I'm not certain if Dumas offered that. I would love to put my parts into use.

Ken Cook- Top Poster

- Posts : 5627

Join date : 2012-03-27

Location : pennsylvania

Re: messing around with flywheels

Re: messing around with flywheels

Ken Cook wrote: Roddie, that was pretty cool. Now, do you have boat plans? I have the shaft, the universal and the prop.I would need to fabricate the stuffing box for the hull. I'm not certain if Dumas offered that. I would love to put my parts into use.

Thanks Ken, It was a fun little indoor project for a cold Winter's day.

CEF member halfAnut (Brad) is the man to ask about anything related to running a Cox engine in a model boat. He's given me lots of helpful tips.

Regarding Dumas running-hardware; they used to produce complete kits designed for Cox engines, for running in their 1/2A size boats.

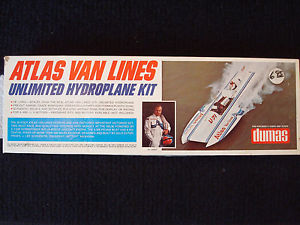

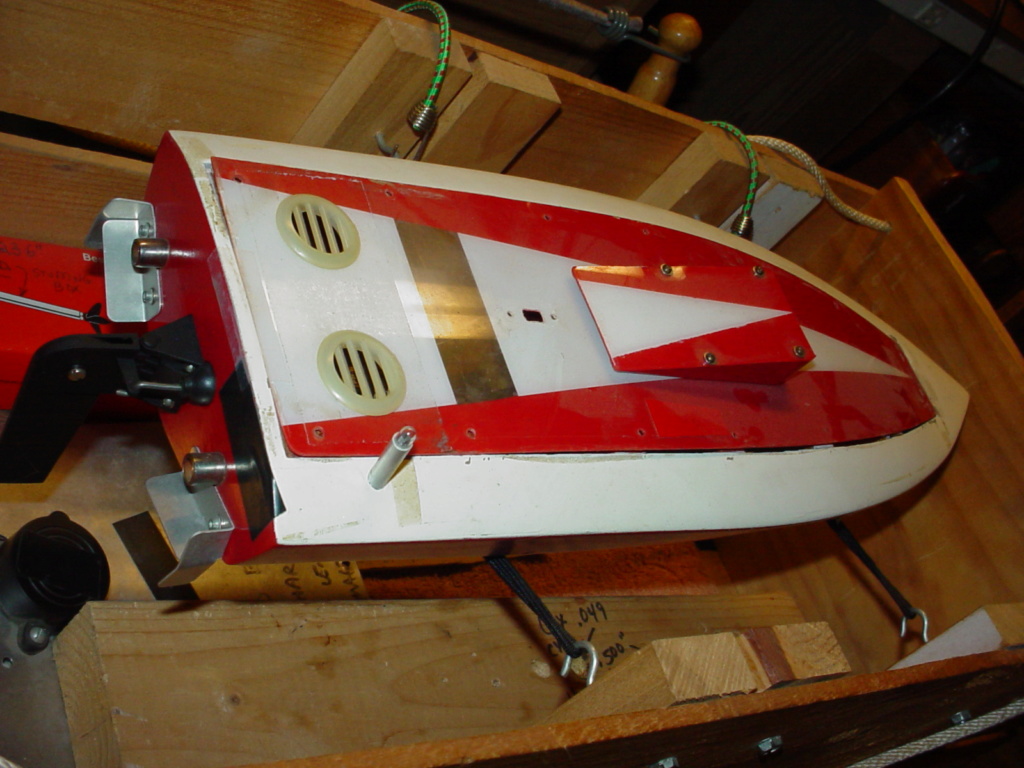

I have the Dumas hardware kit #2306 which is designed for running a Cox .049 engine in their Atlas Van Lines hydroplane. I also have the AVL hydroplane kit.

shown below is Dumas kit #2306

not shown (in the sm. envelope) are prop-drive pins and a 5-40 fully-threaded stub-shaft which connects the engines' crankshaft to the kits' U-joint.

The AVL kit is long-since out of production.. and quite collectable.

I got mine through Tower Hobbies back in the early 1990's. I started building it.. but stopped when I had trouble understanding the instructions.

I did build the Dumas "Short Stuff" (aka DV-10 or Deep Vee 10) but powered it with a Graupner electric motor/hardware kit.

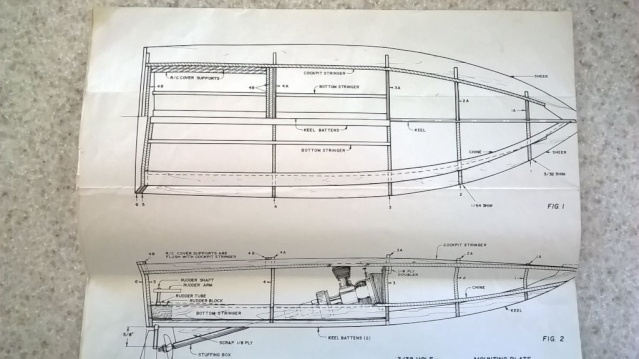

I don't know if those drawings will help.. but I'm sure that there's a myriad of model boat plans available for download.. or maybe "Brad" has some that he'd be willing to share. My AVL kit-box/plan is buried.. so I don't know (and can't remember) if it's a full-size plan. I doubt it though.

A few years ago I bought some small replacement model-boat props and drive-shaft set produced by "Aquacraft" for their little "Reef Racer" model. I figured that they might be adaptable for Cox engine power.

The Aquacraft props and hardware are metric.. but they utilize a "drive-dog" type prop-coupling.. which is superior to what Dumas offers/offered. The Aquacraft props are also suitable for a "surface-drive" application.. which is likely what you'd want to run in a high-performance hull.

Re: messing around with flywheels

Re: messing around with flywheels

Here's another configuration and test-vid for running an ultra-lightweight (.15oz./4gr. my lightest thus far) flywheel on the same engine.

Just to reiterate; the glow-fuel being used is a blend of Sig "Champion" brand 25 and 35, which is decades-old. Keep that in mind.. if you ever decide to throw-away your old/aged glow-fuel. It may still have some "kick" left in it...

If you watch this video, please be patient... because it was a "cold-start" condition. It took me a few minutes to realize that the engine wasn't getting any fuel.. and the use of my muffler prevents priming the cylinder through an exhaust-port.

because it was a "cold-start" condition. It took me a few minutes to realize that the engine wasn't getting any fuel.. and the use of my muffler prevents priming the cylinder through an exhaust-port.

I found it interesting; how "little" fuel was required to support combustion this time. The mixture-needle was only open 1/2 to 3/4 of a turn. Any "richer" was too much "drag" on combustion with such a light-load. (at least that's my synopsis.. )

)

Just to reiterate; the glow-fuel being used is a blend of Sig "Champion" brand 25 and 35, which is decades-old. Keep that in mind.. if you ever decide to throw-away your old/aged glow-fuel. It may still have some "kick" left in it...

If you watch this video, please be patient...

I found it interesting; how "little" fuel was required to support combustion this time. The mixture-needle was only open 1/2 to 3/4 of a turn. Any "richer" was too much "drag" on combustion with such a light-load. (at least that's my synopsis..

Re: messing around with flywheels

Re: messing around with flywheels

This one's for Ron Cribbs..  The same engine.. with the last tests' .15 oz./4gr. flywheel.. except an extended high-speed run to possibly obtain an audio-tach reading.

The same engine.. with the last tests' .15 oz./4gr. flywheel.. except an extended high-speed run to possibly obtain an audio-tach reading.

For those who don't know; Ron CD'd the 2017 CEF "Tach-Race".. which not only proves that he's a great guy.. but also a bona-fide "speed-junkie" (just kidding..)

(just kidding..)

For those who don't know; Ron CD'd the 2017 CEF "Tach-Race".. which not only proves that he's a great guy.. but also a bona-fide "speed-junkie"

(just kidding..)

(just kidding..) Re: messing around with flywheels

Re: messing around with flywheels

Thanks Roddie, pretty cool, that’s as probably as light as you can go and still have it run. That testing couldn’t have come at a better time! Seeing as we are gearing up for a Tether event.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: messing around with flywheels

Re: messing around with flywheels

Hey Ron, It bummed me out that your tether-car's drive-wheel came-apart during testing.. and took the TD .020 with it..

Please accept my apologies if you already know the following information. The Cox .020 engines' crankshafts are threaded for a 3-48 UNC size machine-screw. This screw happens to fit nicely "snug" into the "I.D." of 1/8" standard-wall alloy tubing. Any wheel having a "hub" to accept a 1/8" (.125") axle could easily be fitted to your engine.

I have a supply of 1" length 3-48 black-oxide cap-screws.. and also some standard-wall 1/8" alloy tubing, in either aluminum, brass or copper. I also have 3-48 nylon-insert style lock-nuts.. and various assorted-diameter model-wheels having a 1/8" hub..

Let me know if you can use any of these items to make repairs to your tether-car. Can you use that engine-mount.. or is it for a Tee Dee .010?

Please accept my apologies if you already know the following information. The Cox .020 engines' crankshafts are threaded for a 3-48 UNC size machine-screw. This screw happens to fit nicely "snug" into the "I.D." of 1/8" standard-wall alloy tubing. Any wheel having a "hub" to accept a 1/8" (.125") axle could easily be fitted to your engine.

I have a supply of 1" length 3-48 black-oxide cap-screws.. and also some standard-wall 1/8" alloy tubing, in either aluminum, brass or copper. I also have 3-48 nylon-insert style lock-nuts.. and various assorted-diameter model-wheels having a 1/8" hub..

Let me know if you can use any of these items to make repairs to your tether-car. Can you use that engine-mount.. or is it for a Tee Dee .010?

Re: messing around with flywheels

Re: messing around with flywheels

I’ll send you a PM

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: messing around with flywheels

Re: messing around with flywheels

That last run was cranking out some rpm's wish you could have got a tach reading , maybe Brad or Andras will chim in and ck. it . Good testing Roddie !!

getback- Top Poster

Posts : 10415

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: messing around with flywheels

Re: messing around with flywheels

getback wrote:That last run was cranking out some rpm's wish you could have got a tach reading , maybe Brad or Andras will chim in and ck. it . Good testing Roddie !!

Hey bro! Yea.. that little mill was screaming...

Not sure if you caught-it in my dialogue.. but the mixture-needle ended-up being "leaned-out" to within one-turn open, to achieve combustion on every stroke.

Not sure if you caught-it in my dialogue.. but the mixture-needle ended-up being "leaned-out" to within one-turn open, to achieve combustion on every stroke. These no-load/flywheel-tests weren't intended to prove much.. but let's examine a few variables..

The test-engine was configured using a crankcase and cylinder assembly that I had "on-hand". The crankshaft was not removed for de-varnishing. I concentrated more on the induction-side; making sure that fuel was reaching the venturi.

The .049 Bees' crankcase was fitted with an original copper/star reed-valve. Some modelers claim that the copper reed will "float" at higher-rpm's. .............

I'd put "this test-engine" in any model..

Page 3 of 3 •  1, 2, 3

1, 2, 3

Similar topics

Similar topics» Messing with Sasquach

» Cox needle-valve seals

» Testors/McCoy .049 smoked...

» flywheels.. weighting your crankshaft

» Cox needle-valve seals

» Testors/McCoy .049 smoked...

» flywheels.. weighting your crankshaft

Page 3 of 3

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules