Log in

Search

Latest topics

» Dodge Viper - What a waste but brilliant marketingby roddie Today at 6:46 pm

» COX .020 POWERED SPEEDSTER

by TD ABUSER Today at 6:32 pm

» **VOTE-ON-THE-NEXT-COX-ENGINE-OF-THE-MONTH** (November 2024)

by roddie Today at 6:13 pm

» Brushless motors?

by rsv1cox Today at 4:53 pm

» Free Flight Radio Assist

by rdw777 Today at 4:28 pm

» Cox 020 PeeWee rebuild questions

by balogh Today at 4:15 pm

» L4 Grasshopper

by latole Today at 3:43 pm

» PAW 80 and possible use

by fit90 Today at 8:36 am

» Music-wire bending tools (DIY video)

by 1975 control line guy Today at 8:32 am

» Ultrasonic Cleaners??

by sosam117 Yesterday at 11:26 am

» My CA or CyA (super glue) allergy

by rsv1cox Yesterday at 9:52 am

» My Pseudo killerbee.

by rsv1cox Yesterday at 7:04 am

Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Page 30 of 30

Page 30 of 30 •  1 ... 16 ... 28, 29, 30

1 ... 16 ... 28, 29, 30

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Nice work Brad,… You put a lot of research and thought into your projects….I really enjoy the videos of the well tuned screamers

rdw777- Diamond Member

Posts : 1672

Join date : 2021-03-11

Location : West Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Thank you RDW777,

The fun is making the most out of the engine power on hand per plane type designed, the building of and testing.

The results confirm efforts made and open the door to the next level of extreme performance.

The fun is making the most out of the engine power on hand per plane type designed, the building of and testing.

The results confirm efforts made and open the door to the next level of extreme performance.

1/2A Nut- Top Poster

- Posts : 3526

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

It is important to adjust this exhaust collector Yes your assumption is correct the cylinder is not able to screw complete in certain cases Depending on the cylinder used, the only one that is direct fit is the cylinder model found on a simple surstart with rc exaust ring or those designed for The different collectors almost all use a machined cylinder for rc ringbalogh wrote:Thanks, Brad,

yes, exactly as you advised, I chamfered the header entry.

Why do we use 140 for the timing here, instead of the 160 used in the earlier formula? Even if SPI, the exhaust timing remains the same as in a non-SPI cylinder??

I also noted, that the Kyosho muffler may not allow the cylinder thread to fully bottom out in the crankcase, and it may slightly reduce the compression ratio to some extent, albeit not so much that would justify the limping of the engine well below 20k. I did not want to force the cylinder to fully screw in against the Kyosho muffler, but will see if repeated spanning of the cylinder will cause the aluminum header to yield/wear some and the components will finally settle..

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Brad, can you please remind me about the all-up weight of your Nano 010? I am planning to build something similar to this concept of yours with only a square carbon rod serving as the fuselage between the wing and tail section. I will have a SIG 10mm x 100mm wing profile for a full balsa board wing at around 18" span, and want to calculate the necessary taper from wing center to tip.

Thank you.

balogh- Top Poster

Posts : 4940

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

HalfaDave- Platinum Member

- Posts : 615

Join date : 2022-12-06

Location : Oakville, Ontario

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Thank you Dave!

1/2A Nut- Top Poster

- Posts : 3526

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Hello Brad,

please see my questions 3 post up regarding the weight of the Nano 010..thank you.

please see my questions 3 post up regarding the weight of the Nano 010..thank you.

balogh- Top Poster

Posts : 4940

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Nano .010 2ch.

3oz RTF - 1st version green fuselage

2.2oz RTF - 2nd version neon pink fuselage

3oz RTF - 1st version green fuselage

2.2oz RTF - 2nd version neon pink fuselage

1/2A Nut- Top Poster

- Posts : 3526

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Thanks a lot, Brad...I assume mine will be near 3 oz (thanks to my NiMh battery that weighs almost 1 oz alone) and will try to set the wing surface to around 30....35 sq.inch

balogh- Top Poster

Posts : 4940

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

1/2A Nut- Top Poster

- Posts : 3526

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

VaRooooom Nice run Brad it was really moving out And I could see it much better in 1440p HD . Whats the range on your trans. you look a 1/2 mile away in the clouds

getback- Top Poster

Posts : 10415

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Great video, Brad,

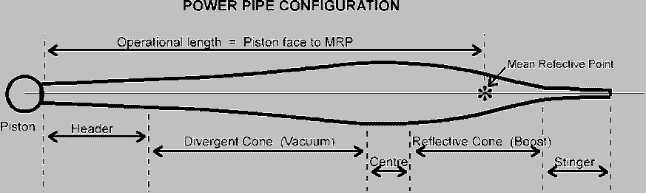

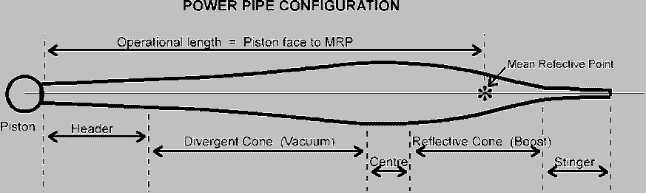

I see that your tuned pipe connects direct to the exhaust manifold, and your pipe really steps in at the resonance frequency to boost the engine rpm..Though I use a bit larger prop like the 5x4 COX, I think my silicone exhaust extender between the exhaust manifold and the pipe is excessive...(In fact my tuned pipe has never stepped in to boost engine speed up to the resonance frequency). I use the formula I inherited from you, whereas the TeeDee049 resonance speed in rpm, N=234,500/L where L is the distance in inches between the piston face and the MRP point of the pipe just behind the stinger..

I may be doing something wrong. The distance in the photo below is about 10.0 inches, including the silicone bend, so in principle the tuned pipe should pull the rpm up to near 24k...but it does not...

I see that your tuned pipe connects direct to the exhaust manifold, and your pipe really steps in at the resonance frequency to boost the engine rpm..Though I use a bit larger prop like the 5x4 COX, I think my silicone exhaust extender between the exhaust manifold and the pipe is excessive...(In fact my tuned pipe has never stepped in to boost engine speed up to the resonance frequency). I use the formula I inherited from you, whereas the TeeDee049 resonance speed in rpm, N=234,500/L where L is the distance in inches between the piston face and the MRP point of the pipe just behind the stinger..

I may be doing something wrong. The distance in the photo below is about 10.0 inches, including the silicone bend, so in principle the tuned pipe should pull the rpm up to near 24k...but it does not...

balogh- Top Poster

Posts : 4940

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Thank you Eric, fast n fun!

At 100 mph / 147 ft. per second makes for a small plane fast.

The black scheme profiles best for the eyes to keep it in control.

Best to avoid no sky blending colors or those that fade and blend.

Within a few seconds it can get far out given the abnormal speeds.

Vertical stab blend pasts 150 ft. neon yellow pops in the passes.

25" span 75 sq. in. wing / 8oz - 226g RTF

Thank you Andras,

Your "a bit larger prop" has a impactful difference - thicker airfoil, wider blades, weighs more, flexes and is not balanced for top rpm.

Post the vid - lets see what the Cox 5x4 prop unloads to in flight not what it benches - we can listen for the pipe to step up the rpm.

Per our previous discussions your set up is more for eye candy / exhaust note / goo control given

the flex tube losses, spinner mass, larger prop and size / weight of plane. Long flex tube soft walls

change in volume percentage and temp - loss of potential better function with tuned pipe pressure.

Coupler at pipe needs matching pipe ID for smooth flow with the flex tube. Insert curved inner aluminum

tube for heat stability / diameter control under exhaust pulses.

Based on project viewed and setup - recommend trying for pipe function flight unloaded low weight thin blade: APC 4.7 x 4.2E

MRP - Mean Reflective Point * is well in front of the base of the stinger.

The RC engine tuned pipe formula should always be referenced correctly for on lookers to understand if referencing. :

(Wave Speed - hot gas vapor 1650 ft. per second to 1675) x (engine timing) ÷ (MRP) = Function RPM

Always measure the engine timing of the engine to be used with the formula for best results.

Example:

1650 x (Typical Cox .049 timing - 140) ÷ 10 will sync at 23,100 rpm with a clean flow / sealed tuned pipe exhaust system.

1675 is good for hot / thin air, dry weather with exposed aluminum pipes.

At 100 mph / 147 ft. per second makes for a small plane fast.

The black scheme profiles best for the eyes to keep it in control.

Best to avoid no sky blending colors or those that fade and blend.

Within a few seconds it can get far out given the abnormal speeds.

Vertical stab blend pasts 150 ft. neon yellow pops in the passes.

25" span 75 sq. in. wing / 8oz - 226g RTF

Thank you Andras,

Your "a bit larger prop" has a impactful difference - thicker airfoil, wider blades, weighs more, flexes and is not balanced for top rpm.

Post the vid - lets see what the Cox 5x4 prop unloads to in flight not what it benches - we can listen for the pipe to step up the rpm.

Per our previous discussions your set up is more for eye candy / exhaust note / goo control given

the flex tube losses, spinner mass, larger prop and size / weight of plane. Long flex tube soft walls

change in volume percentage and temp - loss of potential better function with tuned pipe pressure.

Coupler at pipe needs matching pipe ID for smooth flow with the flex tube. Insert curved inner aluminum

tube for heat stability / diameter control under exhaust pulses.

Based on project viewed and setup - recommend trying for pipe function flight unloaded low weight thin blade: APC 4.7 x 4.2E

MRP - Mean Reflective Point * is well in front of the base of the stinger.

The RC engine tuned pipe formula should always be referenced correctly for on lookers to understand if referencing. :

(Wave Speed - hot gas vapor 1650 ft. per second to 1675) x (engine timing) ÷ (MRP) = Function RPM

Always measure the engine timing of the engine to be used with the formula for best results.

Example:

1650 x (Typical Cox .049 timing - 140) ÷ 10 will sync at 23,100 rpm with a clean flow / sealed tuned pipe exhaust system.

1675 is good for hot / thin air, dry weather with exposed aluminum pipes.

1/2A Nut- Top Poster

- Posts : 3526

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Thanks a lot, Brad, for your explanation...yes, I had my doubts with he silicone extender, especially with the bend in it ,that I read somewhere in itself would not hinder the propagation of sound waves...but the flexibility of the silicone extender, i.e. its expansion due to the pressure waves, was indeed overlooked by me...so I will look for a non-flexible extension, and a more sporty propeller than what I currently have on hand..

balogh- Top Poster

Posts : 4940

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

1/2A Nut- Top Poster

- Posts : 3526

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Page 30 of 30 •  1 ... 16 ... 28, 29, 30

1 ... 16 ... 28, 29, 30

Similar topics

Similar topics» CG on Speed Contest Planes

» Anyone here into Giant Scale R/C Planes? Post Pics of your Planes.

» Fellow speed freaks, help me build a pair of speed Bees.

» 1/2a rc planes

» Looking for: Easy to build basic RC airplane plans

» Anyone here into Giant Scale R/C Planes? Post Pics of your Planes.

» Fellow speed freaks, help me build a pair of speed Bees.

» 1/2a rc planes

» Looking for: Easy to build basic RC airplane plans

Page 30 of 30

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules