Log in

Search

Latest topics

» Fox .35 Modifications by Onelife Today at 6:47 pm

» Happy Anzac Day!

by 706jim Today at 6:44 pm

» Project Cox .049 r/c & Citabrian Champion

by MauricioB Today at 4:08 pm

» Jim Walkers FireBee - This is going to be fun

by rsv1cox Today at 3:56 pm

» Revivng Some Childhood Classics

by rsv1cox Today at 7:17 am

» Introducing our Cox .049 TD Engines

by getback Today at 6:20 am

» Roddie's flat-bottomed boat..

by Levent Suberk Today at 12:23 am

» Cox powered jet-pump for model Sprint Boat

by roddie Yesterday at 10:25 pm

» Micro Draco Gets to Fly on a Beautiful Morning.

by rdw777 Yesterday at 8:15 pm

» Jim Walker Firebaby

by rdw777 Yesterday at 8:06 pm

» Hydro-bat by Vic Smeed: engine probs

by GallopingGhostler Yesterday at 5:12 pm

» Roddie-Rigger.. a 2005 original design

by roddie Yesterday at 3:39 pm

Cox Engine of The Month

K&B 3.5 question

Page 1 of 1

K&B 3.5 question

K&B 3.5 question

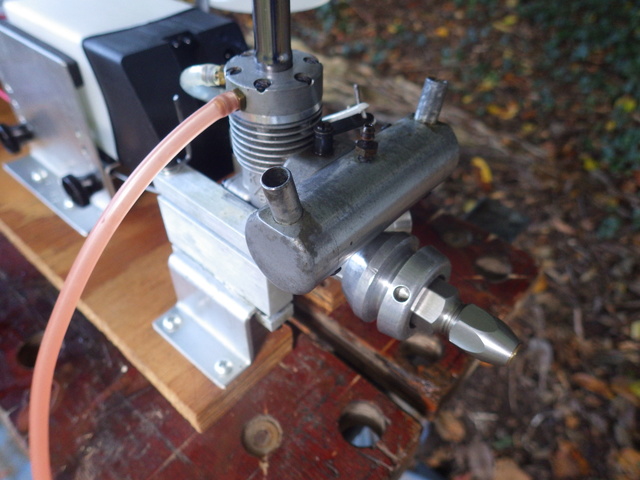

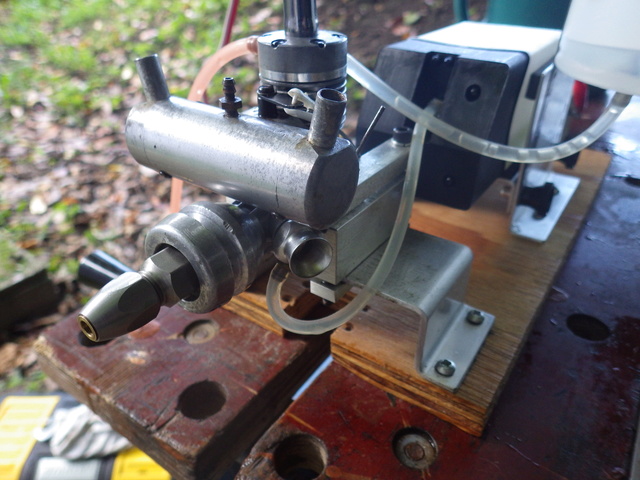

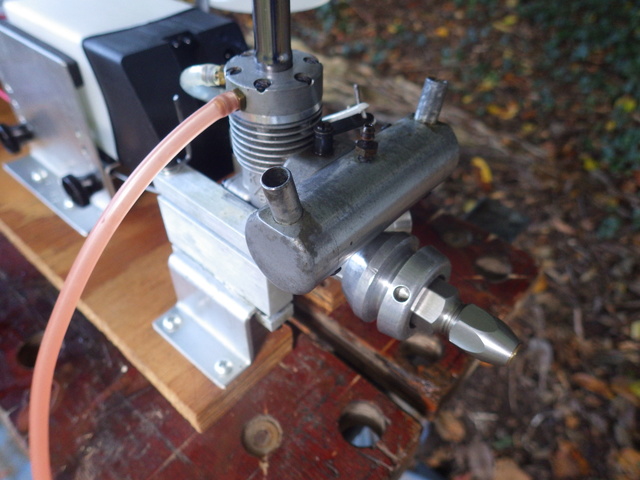

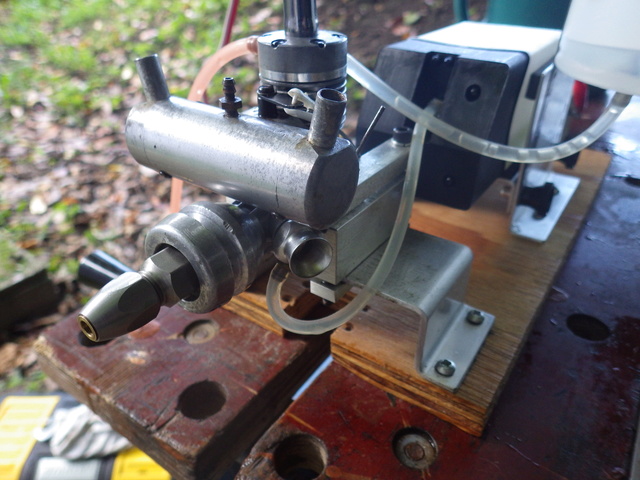

I just rebuilt a K&B 3.5 engine. When I got it, turning the crankshaft was like turning a pepper mill. I replaced both ball bearings and gave it a good clean. After assembly, the crankshaft is still a bit hard to turn. This is due to a tight fit between the crankshaft and the housing. When I heat up the housing with a torch, the crankshaft turns free.

Is this tight fit normal with K&B engines?

Is this tight fit normal with K&B engines?

OVERLORD- Diamond Member

- Posts : 1786

Join date : 2013-03-19

Age : 57

Location : Normandy, France

Re: K&B 3.5 question

Re: K&B 3.5 question

Tighten the prop really tight, whack the side of the case with a solid block of wood. Hit the case repeatedly with the block of wood offering a nice square rap on the bearing housing of the case. This will seat the bearings and all should be smooth.

Ken Cook- Top Poster

- Posts : 5449

Join date : 2012-03-27

Location : pennsylvania

Re: K&B 3.5 question

Re: K&B 3.5 question

Thanks for your quick reply Ken, I haven't tried that yet. I knocked the crankshaft both ways a bit but that didn't do anything, also, I thought heating the housing would set the bearings.

Is it better to remove the bearing housing from the engine when doing this?

Is it better to remove the bearing housing from the engine when doing this?

OVERLORD- Diamond Member

- Posts : 1786

Join date : 2013-03-19

Age : 57

Location : Normandy, France

Re: K&B 3.5 question

Re: K&B 3.5 question

Ken's advice is sound but 2 cautions

Some cases are easy to damage if you do not slam square! That said the K&B is pretty stout

In my case (pun) I ruined a older Fox MK VI by not hitting/slamming square on my hard wood helper trying to remove a front bearing

yes different place to slam/hit, but just the same, it is possible to damage some cases when being (Needed) Brutal

Do not do this over torque with a light old Rev up 8x8 wood prop or similar.... I did and then forgot I did

The Fox MK IV roared to life and when high rpm and the hub disintegrated.... shaft run on the bench freaked me a but as I was afraid to pinch off the fuel

Use a USED, not going to run, strong big hub like APC, prop and then consider it no good.... Well depending on what you think was deliberate over torque to help seat the bearing

I had to use a combination of over torque, heat, and smacking to seat one bugger front bearing....

Some cases are easy to damage if you do not slam square! That said the K&B is pretty stout

In my case (pun) I ruined a older Fox MK VI by not hitting/slamming square on my hard wood helper trying to remove a front bearing

yes different place to slam/hit, but just the same, it is possible to damage some cases when being (Needed) Brutal

Do not do this over torque with a light old Rev up 8x8 wood prop or similar.... I did and then forgot I did

The Fox MK IV roared to life and when high rpm and the hub disintegrated.... shaft run on the bench freaked me a but as I was afraid to pinch off the fuel

Use a USED, not going to run, strong big hub like APC, prop and then consider it no good.... Well depending on what you think was deliberate over torque to help seat the bearing

I had to use a combination of over torque, heat, and smacking to seat one bugger front bearing....

fredvon4- Top Poster

Posts : 4001

Join date : 2011-08-26

Age : 68

Location : Lampasas Texas

Re: K&B 3.5 question

Re: K&B 3.5 question

Everything remains assembled, you don't take it apart. This seats the bearings. If you ever replaced U-joints on a driveshaft, it's the same procedure. You don't hit with enough force to do damage to the engine, your just shocking the case. I have replaced dozens of bearings and never had an issue.

Ken Cook- Top Poster

- Posts : 5449

Join date : 2012-03-27

Location : pennsylvania

Re: K&B 3.5 question

Re: K&B 3.5 question

I knocked the engine several times with the handle of a hammer all the way around and that was indeed better but still not turning smooth. I then heated the engine first and knocked it some more. That improved things but the crankshaft was still rubbing a bit on the inside of the bearing housing. I left the engine alone for a few days and this afternoon, I gave it a spin. After a few pulls, it became alive and that shook everything into place. Now the engine turns as smooth as it can be.

The head doesn't leak, the engine runs well and is a real screamer at full throttle. Due to the aluminium flywheel that gives almost no load and inertia, it was difficult to keep a reasonable idle speed with just the cable connected. I have to change my set up to keep the exhaust throttle more steady and also I have to review the cooling water bottle. I hope to make a video after the changes to add to my marine engine thread.

The head doesn't leak, the engine runs well and is a real screamer at full throttle. Due to the aluminium flywheel that gives almost no load and inertia, it was difficult to keep a reasonable idle speed with just the cable connected. I have to change my set up to keep the exhaust throttle more steady and also I have to review the cooling water bottle. I hope to make a video after the changes to add to my marine engine thread.

OVERLORD- Diamond Member

- Posts : 1786

Join date : 2013-03-19

Age : 57

Location : Normandy, France

Re: K&B 3.5 question

Re: K&B 3.5 question

The heat more than likely did it some good. Running it like that which most of the time won't even allow you to flip it properly will not do it any good. They always run real smooth with new bearings. Ken

Ken Cook- Top Poster

- Posts : 5449

Join date : 2012-03-27

Location : pennsylvania

Similar topics

Similar topics» Another Question?.

» A question

» Please, need some help to identify a Baby Bee ?

» Medallion needle

» Tee Dee .09 question

» A question

» Please, need some help to identify a Baby Bee ?

» Medallion needle

» Tee Dee .09 question

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules