Log in

Search

Latest topics

» Golden Bee basic running problemby roddie Today at 22:51

» Simple Gliders

by rdw777 Today at 18:25

» Foam hand kids glider converted to 0.049 CL

by rdw777 Today at 18:11

» Weird search for a single comic from an old Mad Magazine

by Kim Today at 13:44

» Scientific "Zipper" Build...Zipper Flys!.

by getback Today at 7:27

» Cox .049 Tee Dee engines back in stock (limited availablility)

by GallopingGhostler Today at 1:05

» Very off-topic.........Time passes and not always for the best......

by rsv1cox Yesterday at 14:47

» Roddie-Rigger.. a 2005 original design

by roddie Wed 24 Jul 2024 - 23:48

» Jim Walker Bonanza etc.

by rsv1cox Wed 24 Jul 2024 - 18:30

» Throttles for Cox Tee Dee .049 / .020 / .010 engines --- videos

by sosam117 Wed 24 Jul 2024 - 8:54

» Introducing our Cox .049 TD Engines

by Admin Tue 23 Jul 2024 - 2:00

» Project Cox .049 r/c & Citabrian Champion

by getback Mon 22 Jul 2024 - 16:14

Cox Engine of The Month

July-2024

robot797's

"ULTIMITE COX 010: it has a clutch, E starter, throttle, exhaust, aluminum tank, aluminum venturi, gearbox with forward and reverse, and now its on a custom drawn and printed stand"

PAST WINNERS

robot797's

"ULTIMITE COX 010: it has a clutch, E starter, throttle, exhaust, aluminum tank, aluminum venturi, gearbox with forward and reverse, and now its on a custom drawn and printed stand"

PAST WINNERS

Troubleshooting a 0.061 norvel ame

Page 1 of 2

Page 1 of 2 • 1, 2

Troubleshooting a 0.061 norvel ame

Troubleshooting a 0.061 norvel ame

Hey everyone, looking for some advice on a engine of mine that I cant seem to keep running. I picked it up used, has some top end pinch like it's not fully broken in. It's an rc version with the glued in carb. I have it wired open for control line, maybe that's part of the issue. I have sunk a fair number of hours into it so far... I dont like getting beat. It's been disassembled, inspected and cleaned. Nothing obvious, looks real good. Running 15% nitro at 3400ft 5x3 Cox prop.

Here is the symptoms;

-wont start unless the needle setting is dead on, one click either way it just wont run. About 1 and 3/4 turns out

-only runs for 25 seconds ish then dies. Holy smookes does it run though. Seems like it heats up, the piston maybe sticks and it dies.

- cant seem to adjust the needle when running just dies when I touch it

- I noticed the carb barrel has a little wobble/play against the carb body. If I wiggle a little it effects tune slightly.

-heat gun helped a bit with loosing up the fit for starting.

-get a bit of a grey oily mess so something is "breaking in"

I was thinking of sandwiching a fuel tube o ring inbetween the throttle arm and carb body to take up the wobble incase it's both not broken in and has an air leak. Thoughts, anyone have similar issues? Maybe a heavier prop for more flywheel effect?

Here is the symptoms;

-wont start unless the needle setting is dead on, one click either way it just wont run. About 1 and 3/4 turns out

-only runs for 25 seconds ish then dies. Holy smookes does it run though. Seems like it heats up, the piston maybe sticks and it dies.

- cant seem to adjust the needle when running just dies when I touch it

- I noticed the carb barrel has a little wobble/play against the carb body. If I wiggle a little it effects tune slightly.

-heat gun helped a bit with loosing up the fit for starting.

-get a bit of a grey oily mess so something is "breaking in"

I was thinking of sandwiching a fuel tube o ring inbetween the throttle arm and carb body to take up the wobble incase it's both not broken in and has an air leak. Thoughts, anyone have similar issues? Maybe a heavier prop for more flywheel effect?

layback209- Gold Member

- Posts : 282

Join date : 2017-10-13

Age : 38

Location : Okotoks

Re: Troubleshooting a 0.061 norvel ame

Re: Troubleshooting a 0.061 norvel ame

What brand and fuel mix are you using?

How much castor and nitro?

How old is the fuel?

How much castor and nitro?

How old is the fuel?

1/2A Nut- Top Poster

- Posts : 3464

Join date : 2013-10-20

Age : 60

Location : Brad in Texas

Re: Troubleshooting a 0.061 norvel ame

Re: Troubleshooting a 0.061 norvel ame

Originaly started 25% sig half a fuel, 50/50 synthetic and castor, probably 1 yrs old. My other big mig runs awesome on it. Was flying it today actualy. Same symptoms but could tune a little more.

The 15% nitro is sig all castor 20%. I have no idea how old it is. Bought it at a hobby shop a few years ago. Basically a full gallon jug. Stored indoors. But it's old.

The 15% nitro is sig all castor 20%. I have no idea how old it is. Bought it at a hobby shop a few years ago. Basically a full gallon jug. Stored indoors. But it's old.

layback209- Gold Member

- Posts : 282

Join date : 2017-10-13

Age : 38

Location : Okotoks

layback209- Gold Member

- Posts : 282

Join date : 2017-10-13

Age : 38

Location : Okotoks

Re: Troubleshooting a 0.061 norvel ame

Re: Troubleshooting a 0.061 norvel ame

That grey oily mess is the coating that makes this engine so special. As the engine completes break in, it should stop sloughing off.

Your altitude may be fighting you!

The AME needs pressure...and.consistant fuel flow. You mentioned 15% nitro...what is the oil type and content? The original instructions recommended castor in the fuel for break-in. Do you have original instructions? I may someplace.. if you want a copy.

Contact NVEngines.com to get a venturi for it. Skip fighting the carb for now. I will admit I'm a CL guy, so the RC carb is useless to me.

As an alternative, wire the carb 1/2-2/3 open to give the engine more vacuum for pulling fuel through the carb...this may make it easier to needle for best running before running wide open. Check the NVA for obstructions. Use a different sized fuel line. I notice a difference at the needle between small fuel line and medium fuel line. You may want to rig a friction-held throttle to play with different throttle settings as you run the engine in. I know my Norvel Big Mig .074s have quite a range on the needle...a lot more than a Cox engine.

Ensure you are running muffler pressure on a one ounce tank with the tank center level with the NVA. Don't try to pump fuel far or uphill. Don't let fuel flow downhill and flood the engine.

Or ship the thing to me...I'll get it running as long as it isn't DOA. I'll shoot video and send it back. I'm in MS, at a few hundred feel ASL.

Your altitude may be fighting you!

The AME needs pressure...and.consistant fuel flow. You mentioned 15% nitro...what is the oil type and content? The original instructions recommended castor in the fuel for break-in. Do you have original instructions? I may someplace.. if you want a copy.

Contact NVEngines.com to get a venturi for it. Skip fighting the carb for now. I will admit I'm a CL guy, so the RC carb is useless to me.

As an alternative, wire the carb 1/2-2/3 open to give the engine more vacuum for pulling fuel through the carb...this may make it easier to needle for best running before running wide open. Check the NVA for obstructions. Use a different sized fuel line. I notice a difference at the needle between small fuel line and medium fuel line. You may want to rig a friction-held throttle to play with different throttle settings as you run the engine in. I know my Norvel Big Mig .074s have quite a range on the needle...a lot more than a Cox engine.

Ensure you are running muffler pressure on a one ounce tank with the tank center level with the NVA. Don't try to pump fuel far or uphill. Don't let fuel flow downhill and flood the engine.

Or ship the thing to me...I'll get it running as long as it isn't DOA. I'll shoot video and send it back. I'm in MS, at a few hundred feel ASL.

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2000

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: Troubleshooting a 0.061 norvel ame

Re: Troubleshooting a 0.061 norvel ame

Make sure the backplate is tight. Remove it check the O ring oil it and the threads and

put it back on there always oil all threads when assembling the engine. Helps with leaks

with cleanings and improves longevity.

Is this for CL project or RC?

Buy some real 1/2A fuel from Fitz

High castor content for break in to avoid heat build up and sag.

Good for break in time 1 quart will be enough then 1 quart of

24% nitro sport fuel with 20% oil.

http://fitzfuels.com/index.php?id_category=12&controller=category

Mercury 15 Vintage Engine Fuel (Quart)

Reference: M15

Condition: New product

15% Nitro, 25% Castor (high quality Klotz oil).

put it back on there always oil all threads when assembling the engine. Helps with leaks

with cleanings and improves longevity.

Is this for CL project or RC?

Buy some real 1/2A fuel from Fitz

High castor content for break in to avoid heat build up and sag.

Good for break in time 1 quart will be enough then 1 quart of

24% nitro sport fuel with 20% oil.

http://fitzfuels.com/index.php?id_category=12&controller=category

Mercury 15 Vintage Engine Fuel (Quart)

Reference: M15

Condition: New product

15% Nitro, 25% Castor (high quality Klotz oil).

1/2A Nut- Top Poster

- Posts : 3464

Join date : 2013-10-20

Age : 60

Location : Brad in Texas

Re: Troubleshooting a 0.061 norvel ame

Re: Troubleshooting a 0.061 norvel ame

Thanks for the feedback Jim and 1/2a nut.

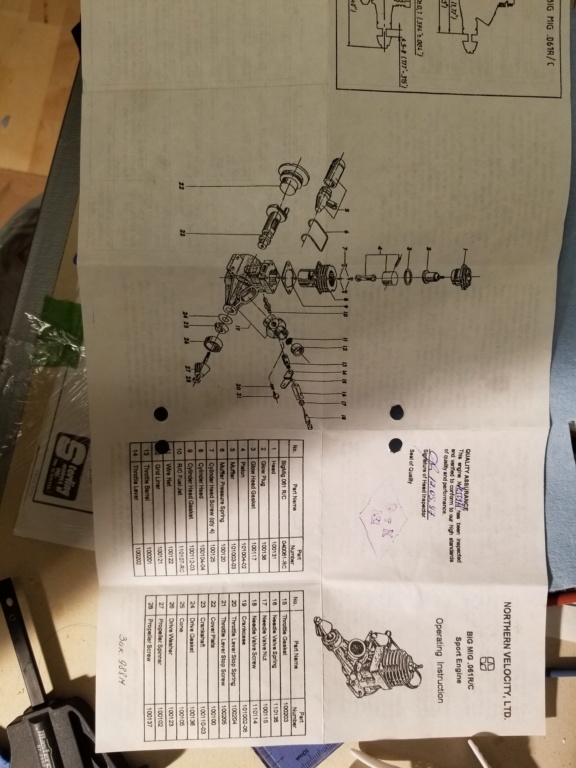

Interesting this engine has space for a backplate o ring but does not have one or show one in the parts list (see below).. i should also note I was using muffler pressure and med fuel line. Since I was able to find the manual some new revelations from reading instructions. Calls for 3 head gaskets durring break in, I'm only using one, probably did not help. The fuel had 20% castor.

This is for controlline, I was thinking of ordering a venturi but was hoping to get it running with the carb. Good thought with closing the throttle a bit. Been a while since I had to break a motor in. The instructions were super vague here.

Thanks for the fuel link, I'll see what shipping is like to Canada. If that's even an option. The only stuff I can get is sig 1/2a fuel and that's a challenge too.

Should I put an oring on the back plate? I may have something close from a metric oring kit i have.

Thanks for the offer Jim, i would take you up on it and send some beer money but shipping would be more than the value. I also feel like i should be able to figure it out. Maybe my kids will give me more than 5mins to tinker next weekend lol.

Interesting this engine has space for a backplate o ring but does not have one or show one in the parts list (see below).. i should also note I was using muffler pressure and med fuel line. Since I was able to find the manual some new revelations from reading instructions. Calls for 3 head gaskets durring break in, I'm only using one, probably did not help. The fuel had 20% castor.

This is for controlline, I was thinking of ordering a venturi but was hoping to get it running with the carb. Good thought with closing the throttle a bit. Been a while since I had to break a motor in. The instructions were super vague here.

Thanks for the fuel link, I'll see what shipping is like to Canada. If that's even an option. The only stuff I can get is sig 1/2a fuel and that's a challenge too.

Should I put an oring on the back plate? I may have something close from a metric oring kit i have.

Thanks for the offer Jim, i would take you up on it and send some beer money but shipping would be more than the value. I also feel like i should be able to figure it out. Maybe my kids will give me more than 5mins to tinker next weekend lol.

layback209- Gold Member

- Posts : 282

Join date : 2017-10-13

Age : 38

Location : Okotoks

layback209- Gold Member

- Posts : 282

Join date : 2017-10-13

Age : 38

Location : Okotoks

1/2A Nut- Top Poster

- Posts : 3464

Join date : 2013-10-20

Age : 60

Location : Brad in Texas

Re: Troubleshooting a 0.061 norvel ame

Re: Troubleshooting a 0.061 norvel ame

It looks like you have one of the early versions and there are/were a few issues with those:

- The glow plug/insert is too cold (easily recognised by the flat top of the center electrode, the later warmer ones end in a round ball) => swap to a the later ones or get one of the Merlin inserts, or even better the Galbreath Nelson heads. You can also get a head for Turbo plugs from: https://kamtechnik.com/product-category/cox-aft/

- The crank to crankcase fit is too tight and that makes the engine over heat. => lap the crank to the crankcase lightly with a rubbing compound or toothpaste. Wash carefully and check the fit, it doesn't take much but it is faster to do it manually than during a very long run-in of the engine.

Below is a short "timeline" of these engines from left too the right. Your engine would come in second from the left I guess. You can see the rounded end on the glow plug electrode on these engines.

- The glow plug/insert is too cold (easily recognised by the flat top of the center electrode, the later warmer ones end in a round ball) => swap to a the later ones or get one of the Merlin inserts, or even better the Galbreath Nelson heads. You can also get a head for Turbo plugs from: https://kamtechnik.com/product-category/cox-aft/

- The crank to crankcase fit is too tight and that makes the engine over heat. => lap the crank to the crankcase lightly with a rubbing compound or toothpaste. Wash carefully and check the fit, it doesn't take much but it is faster to do it manually than during a very long run-in of the engine.

Below is a short "timeline" of these engines from left too the right. Your engine would come in second from the left I guess. You can see the rounded end on the glow plug electrode on these engines.

Surfer_kris- Diamond Member

- Posts : 1909

Join date : 2010-11-20

Location : Sweden

Re: Troubleshooting a 0.061 norvel ame

Re: Troubleshooting a 0.061 norvel ame

After Ken, Rusty and I determined that crank shafts were frequently the source of heat and galing when new....all NVs got shaft polish before breakin.

Drill motor/ drill press....High speed not needed

strip of any tough cloth 1/4 inch wide by 5~6 long

this or similar set of diamond polishing pastes..... work the small drop of polish up and down while medium speed rotation

mirror finish in under 5 minutes. test fit clean and dry no oil, should spin free for several revolutions with no discernable drag spots

please do not hand lap with paste in the crank case... leave as much factory coating in the nose bearing for a longer lasting crank case

https://smile.amazon.com/Diamond-Lapping-Paste-Polishing-Compound/dp/B015HLK31W/ref=sr_1_1_sspa?crid=R1067QJURU03&keywords=diamond+polishing+paste&qid=1571578841&sprefix=diamond+pol%2Caps%2C266&sr=8-1-spons&psc=1&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUExSkNGVFA2WDBJT1VMJmVuY3J5cHRlZElkPUEwNjIzMTQxNjgxUVRMMDM5U0RSJmVuY3J5cHRlZEFkSWQ9QTA3NzEyMjIyOUhPMUxBV0pNNFUyJndpZGdldE5hbWU9c3BfYXRmJmFjdGlvbj1jbGlja1JlZGlyZWN0JmRvTm90TG9nQ2xpY2s9dHJ1ZQ==

Drill motor/ drill press....High speed not needed

strip of any tough cloth 1/4 inch wide by 5~6 long

this or similar set of diamond polishing pastes..... work the small drop of polish up and down while medium speed rotation

mirror finish in under 5 minutes. test fit clean and dry no oil, should spin free for several revolutions with no discernable drag spots

please do not hand lap with paste in the crank case... leave as much factory coating in the nose bearing for a longer lasting crank case

https://smile.amazon.com/Diamond-Lapping-Paste-Polishing-Compound/dp/B015HLK31W/ref=sr_1_1_sspa?crid=R1067QJURU03&keywords=diamond+polishing+paste&qid=1571578841&sprefix=diamond+pol%2Caps%2C266&sr=8-1-spons&psc=1&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUExSkNGVFA2WDBJT1VMJmVuY3J5cHRlZElkPUEwNjIzMTQxNjgxUVRMMDM5U0RSJmVuY3J5cHRlZEFkSWQ9QTA3NzEyMjIyOUhPMUxBV0pNNFUyJndpZGdldE5hbWU9c3BfYXRmJmFjdGlvbj1jbGlja1JlZGlyZWN0JmRvTm90TG9nQ2xpY2s9dHJ1ZQ==

fredvon4- Top Poster

Posts : 4004

Join date : 2011-08-26

Age : 68

Location : Lampasas Texas

Re: Troubleshooting a 0.061 norvel ame

Re: Troubleshooting a 0.061 norvel ame

Good point, one can even make an extra relief on the crank in the right place, like on the Cox .049 TD engine.

Don't bring out the "Fox Lustrox" paste...

Don't bring out the "Fox Lustrox" paste...

Surfer_kris- Diamond Member

- Posts : 1909

Join date : 2010-11-20

Location : Sweden

Re: Troubleshooting a 0.061 norvel ame

Re: Troubleshooting a 0.061 norvel ame

Y'all beat me to the punch on the crank polishing. That's what it sounds like - running 25 seconds and then slowing to a stop. Oddly enough, two of my Big Migs did it after being flown for about 20 flights and a couple of crashes. So far my AME is okay, but it only has 8 flights on it. It really hauls ass for a sport engine. All of them are .061s.

Kris, good catch on the glow plug heat range. I learned something new from that, I've never seen a flat topped electrode.

Rusty

Kris, good catch on the glow plug heat range. I learned something new from that, I've never seen a flat topped electrode.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Troubleshooting a 0.061 norvel ame

Re: Troubleshooting a 0.061 norvel ame

"Don't bring out the "Fox Lustrox" paste..".

I still have one or two packs of Duke Fox's Majik Dust

fredvon4- Top Poster

Posts : 4004

Join date : 2011-08-26

Age : 68

Location : Lampasas Texas

Re: Troubleshooting a 0.061 norvel ame

Re: Troubleshooting a 0.061 norvel ame

Interesting thanks for the feedback, I never would of thought of the crank fit being a challenge either. Learning lots. When I had it apart I didnt really notice anything but wasn't sure what to look for. Here is a pick you have to zoom in to see the crank. Looks pretty clean but there is some hints of rubbing.

I have used a light/soft scotch bright pad in the past to clean the crank on a different motor. If the next test and tune session goes poorly I'll try and polish it up.

I have used a light/soft scotch bright pad in the past to clean the crank on a different motor. If the next test and tune session goes poorly I'll try and polish it up.

layback209- Gold Member

- Posts : 282

Join date : 2017-10-13

Age : 38

Location : Okotoks

Re: Troubleshooting a 0.061 norvel ame

Re: Troubleshooting a 0.061 norvel ame

.

Last edited by layback209 on Mon 28 Oct 2019 - 17:11; edited 1 time in total

layback209- Gold Member

- Posts : 282

Join date : 2017-10-13

Age : 38

Location : Okotoks

Re: Troubleshooting a 0.061 norvel ame

Re: Troubleshooting a 0.061 norvel ame

Update, had a hour to tinker today. Very successful, thanks for all the advice really appreciate it.

-added 2 head shims and changed the glow plug to an os 8 with a plug insert style head I had laying around. Wow does it start better now. Had no idea that the older flat top inserts were different, heck I didnt even notice it was different until mentioned.

-also made a little silicone fuel tube gasket and sandwiched it between the carb arm and body. Turned out that this was one source of a major fuel leak. Got lots of needle adjustment now.

-also used a 1/2a tank and tubing.

-starting at half throttle helped keep the heat down enough that I got through 3 ozs. After each 1 oz tank run and it sounded better and better. Can not wait to keep going with it.

Still needs a heat gun to get the top end loosened up enough to start. I'm very convinced it's a tight crank to bearing fit that was causing the 25s runs earlier. I tried to lean it out a bit through the second tank and it died, was tight to turn over too. Quick cool down and it fired right up.

I'm hoping that after 7 more oz of running I dont need to pull the crank and polish, but if that's what it takes I'll do it.

-added 2 head shims and changed the glow plug to an os 8 with a plug insert style head I had laying around. Wow does it start better now. Had no idea that the older flat top inserts were different, heck I didnt even notice it was different until mentioned.

-also made a little silicone fuel tube gasket and sandwiched it between the carb arm and body. Turned out that this was one source of a major fuel leak. Got lots of needle adjustment now.

-also used a 1/2a tank and tubing.

-starting at half throttle helped keep the heat down enough that I got through 3 ozs. After each 1 oz tank run and it sounded better and better. Can not wait to keep going with it.

Still needs a heat gun to get the top end loosened up enough to start. I'm very convinced it's a tight crank to bearing fit that was causing the 25s runs earlier. I tried to lean it out a bit through the second tank and it died, was tight to turn over too. Quick cool down and it fired right up.

I'm hoping that after 7 more oz of running I dont need to pull the crank and polish, but if that's what it takes I'll do it.

Last edited by layback209 on Mon 28 Oct 2019 - 17:09; edited 2 times in total

layback209- Gold Member

- Posts : 282

Join date : 2017-10-13

Age : 38

Location : Okotoks

Re: Troubleshooting a 0.061 norvel ame

Re: Troubleshooting a 0.061 norvel ame

Good to hear things are coming together , thats strange were the air /fuel leak was detected . I have a few of the NV engines that i have not ran so this tutual is good

getback- Top Poster

Posts : 10276

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: Troubleshooting a 0.061 norvel ame

Re: Troubleshooting a 0.061 norvel ame

One thing that concerns me is when you say the engine is getting hard to turn over after it was run. A tight crank would've revealed burnished aluminum onto the shaft when you took it apart. You would typically see this on the front portion of the shaft. I've witnessed a lot worse than your picture. Are you certain the prop driver assembly isn't being forced too far back into the front of the case? You mentioned blackish gray oil in your post and this type of issue is one that could cause that. Blackish oil is a result of aluminum and fuel residue. This could come from the muffler rubbing on the case, loose engine mounting, the prop driver or thrust washer or the rod rubbing on the backplate.

While your picture shows us the back of your backplate, was there any rubbing of the rod onto the backplate? With the plug removed is there any kind of bind through the rotation of the crank? A rod that's slightly out of square or bent could cause binding on the crank pin or wrist pin. Another area of concern would be the inside face of the crank web where it mates against the inside of the case.

Are you certain this is a AME version cylinder? This would be 3 large ports within the cylinder vs 5 small ones as in the Big Mig. The reason I ask this is due to the alignment of the wrist pin with the very front hole in the AME cylinder liner. In the travel of the piston if the wrist pin is moving front to back, the pin can snag the port causing a tight spot. The wrist pins are staked on these engines and the staking can also protrude out beyond the circumference of the piston causing friction and drag. This is very critical with the AME engine.

Not that this is a cause of your issues, but the standard plug inserts generally lower your compression due to the cavity within the plug around the element. In addition, you added more head shims further lowering the compression. The plug that was mentioned by Kris was the early plug and they typically require slightly more voltage than 1.5 volts. Seeing you changed to a standard plug, your now achieving the proper glow to enhance the starting making it easier to start. The Norvel's generally only require one head shim once broken in unless the engine is taking out plugs when run.

How is the fit of the r/c carb to the case? Is it loose? If this joint is leaking air at all it was cause havoc. Using a small adjustable, check it for any wiggle whatsoever. This can be removed and sealed back using JB weld. A good cleaning and a little JB weld placed onto the carb body will provide a fillet around the case insuring a leak free fit.

While your picture shows us the back of your backplate, was there any rubbing of the rod onto the backplate? With the plug removed is there any kind of bind through the rotation of the crank? A rod that's slightly out of square or bent could cause binding on the crank pin or wrist pin. Another area of concern would be the inside face of the crank web where it mates against the inside of the case.

Are you certain this is a AME version cylinder? This would be 3 large ports within the cylinder vs 5 small ones as in the Big Mig. The reason I ask this is due to the alignment of the wrist pin with the very front hole in the AME cylinder liner. In the travel of the piston if the wrist pin is moving front to back, the pin can snag the port causing a tight spot. The wrist pins are staked on these engines and the staking can also protrude out beyond the circumference of the piston causing friction and drag. This is very critical with the AME engine.

Not that this is a cause of your issues, but the standard plug inserts generally lower your compression due to the cavity within the plug around the element. In addition, you added more head shims further lowering the compression. The plug that was mentioned by Kris was the early plug and they typically require slightly more voltage than 1.5 volts. Seeing you changed to a standard plug, your now achieving the proper glow to enhance the starting making it easier to start. The Norvel's generally only require one head shim once broken in unless the engine is taking out plugs when run.

How is the fit of the r/c carb to the case? Is it loose? If this joint is leaking air at all it was cause havoc. Using a small adjustable, check it for any wiggle whatsoever. This can be removed and sealed back using JB weld. A good cleaning and a little JB weld placed onto the carb body will provide a fillet around the case insuring a leak free fit.

Ken Cook- Top Poster

- Posts : 5542

Join date : 2012-03-27

Location : pennsylvania

Re: Troubleshooting a 0.061 norvel ame

Re: Troubleshooting a 0.061 norvel ame

Hi Ken thanks for the reply. I think you nailed my current issue.

I had some time to tinker today. Got a few more ozs through, but could not get the engine to rev up, seemed stuck in 4 stroke revs, like its being dragged by something thats causing undo friction.

I was very conscious when I reassembled the engine to not overtighten the prop thrust plate as it's a different friction fit thing. Has a ring that fits over a split ring conical spacer that grabs onto the crank when the prop is installed. I think it got over tightened and was rubbing on the crank case. There is also some ware on the back plate. I tore the motor down again BC the top end broke in but there is still drag. Doesnt seem like the crank is spaced properly... and its difficult do to the friction fit thrust plate. Super duper fiddly I dont like this older design at all. I roughed the friction fit surfaces with some sand paper in Hope's that it will grab on before taking up to much of the float that it needs so there is no drag.

Ran out of time to get it back together. I really like the next generation that has the machined flat spot in the crank that the thrust/ prop plate fits to.

It also has 5 ports. Had a peak at the wrist pin it's where it should be inside of the piston not protruding.

I had some time to tinker today. Got a few more ozs through, but could not get the engine to rev up, seemed stuck in 4 stroke revs, like its being dragged by something thats causing undo friction.

I was very conscious when I reassembled the engine to not overtighten the prop thrust plate as it's a different friction fit thing. Has a ring that fits over a split ring conical spacer that grabs onto the crank when the prop is installed. I think it got over tightened and was rubbing on the crank case. There is also some ware on the back plate. I tore the motor down again BC the top end broke in but there is still drag. Doesnt seem like the crank is spaced properly... and its difficult do to the friction fit thrust plate. Super duper fiddly I dont like this older design at all. I roughed the friction fit surfaces with some sand paper in Hope's that it will grab on before taking up to much of the float that it needs so there is no drag.

Ran out of time to get it back together. I really like the next generation that has the machined flat spot in the crank that the thrust/ prop plate fits to.

It also has 5 ports. Had a peak at the wrist pin it's where it should be inside of the piston not protruding.

layback209- Gold Member

- Posts : 282

Join date : 2017-10-13

Age : 38

Location : Okotoks

Re: Troubleshooting a 0.061 norvel ame

Re: Troubleshooting a 0.061 norvel ame

The 5 ports make it a Big Mig therefore fuel delivery shouldn't be a issue. You asked earlier about a o-ring for the backplate. Typically, there's plenty of room between the rod face and the backplate face preventing the rubbing you pictured. This is also one purpose of the thrust washer. The rub marks are continuous in a centrifugal pattern. That tells me that the crank is running true and the rod to pin isn't causing the rod to jump through it's travel. There were versions with o-rings on the backplate. If the rod isn't causing substantial binding against the backplate then I wouldn't be overly concerned of this rubbing. If the rubbing taking place is causing a bind you could sand it a bit. The backplate does have anodizing on it, seeing that it's now worn off, I wouldn't hesitate to sand that face by placing a piece of 400 grit on a piece of glass and smoothing out the backplate removing that swirl. This can be polished further using aluminum polish like Mother's mag wheel polish or similar and washed in hot water.

I'm very familiar with the old prop driver assembly and these are generally maintenance free until the need comes to take them apart. During assembly, tighten the prop driver fully with cylinder removed and the backplate off. Inspect the outer ring for any cracks. Check for binding and address the nose of the case if needed. The thrust washer can also be distorted from heat and wear which may need to be flipped over if it's cupped.If the prop driver assembly isn't bottoming out like it should due to the front of the crankcase being too long, the case itself can be cleaned up like the backplate. You can stand the case right on it's nose and allow it to square itself to the glass and carefully sand it in this position just removing a little material to allow for some clearance.

While the newer driver washer is simple, it can be easily lost during a prop change or even storage without the prop screw. I have seen many of these damaged where those that use starters improperly and damage the drive washer as it becomes jammed onto the shaft. I do agree in terms of simplicity, it's easy to install.

I'm very familiar with the old prop driver assembly and these are generally maintenance free until the need comes to take them apart. During assembly, tighten the prop driver fully with cylinder removed and the backplate off. Inspect the outer ring for any cracks. Check for binding and address the nose of the case if needed. The thrust washer can also be distorted from heat and wear which may need to be flipped over if it's cupped.If the prop driver assembly isn't bottoming out like it should due to the front of the crankcase being too long, the case itself can be cleaned up like the backplate. You can stand the case right on it's nose and allow it to square itself to the glass and carefully sand it in this position just removing a little material to allow for some clearance.

While the newer driver washer is simple, it can be easily lost during a prop change or even storage without the prop screw. I have seen many of these damaged where those that use starters improperly and damage the drive washer as it becomes jammed onto the shaft. I do agree in terms of simplicity, it's easy to install.

Ken Cook- Top Poster

- Posts : 5542

Join date : 2012-03-27

Location : pennsylvania

Re: Troubleshooting a 0.061 norvel ame

Re: Troubleshooting a 0.061 norvel ame

The wear on the backplate looks to me like it is from the crankpin touching the backplate. You can check this with the cylinder and piston off, then compare the movement of the crank with and without the backplate tightened. You can also peak down into the crankcase while doing this and use a feeler gage to measure the distance to the backplate. I usually set things up to have about 0.1mm between the crankpin and the backplate when the crank is pushed completely backwards. The crank itself should also be able to move back and forth with the prop fully tightened. Too little play here can make the crank bind to the crankcase, there should be at least 0.1-0.2mm of play back and forth.

Surfer_kris- Diamond Member

- Posts : 1909

Join date : 2010-11-20

Location : Sweden

Re: Troubleshooting a 0.061 norvel ame

Re: Troubleshooting a 0.061 norvel ame

Thanks Ken and Kris, I had bagged the motor up and put it aside for the moment as it had me beat.

That's a good procedure for setting the crank up, I'll give it a shot. May need to take a little off the front of the crank case.

That's a good procedure for setting the crank up, I'll give it a shot. May need to take a little off the front of the crank case.

layback209- Gold Member

- Posts : 282

Join date : 2017-10-13

Age : 38

Location : Okotoks

Video Update: YouTube link enclosed

Video Update: YouTube link enclosed

hey everyone wanted to thank everyone for the awesome input. After countless hours this engine is destined for parts. Made a quick video of one of the tare downs, inspection, component clean up and run test.

Turned out that the connector rod is contacting the crank. I'm fairly confident the bushing is out of alignment as the back plate clearance is with in specifications.

https://youtu.be/2IxUH6X00Ts

P.s. I strapped a different big mig on the lil Satan this winter, if it runs good, flight video will be posted.

Turned out that the connector rod is contacting the crank. I'm fairly confident the bushing is out of alignment as the back plate clearance is with in specifications.

https://youtu.be/2IxUH6X00Ts

P.s. I strapped a different big mig on the lil Satan this winter, if it runs good, flight video will be posted.

layback209- Gold Member

- Posts : 282

Join date : 2017-10-13

Age : 38

Location : Okotoks

short story

short story

it hapen du to not used 3 head gasket norvel piston is so tight new u just bind it wrong now crank pin on crank shaft is of set down very litle now con rod fal of it pin try wit engine redy to run move cap of crank turn it like u want to start him piston con rod wil no longer stay in to crank pin is cose of engine binding crank chaft is ded of

davidll1984- Diamond Member

- Posts : 2303

Join date : 2020-02-12

Age : 39

Location : shawinigan

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Glow Plug Norvel .074 / Turbo Head Norvel .074

» 020 troubleshooting

» So I got a norvel

» Need help troubleshooting a Cox .049 engine

» Can we get some help designing our Cox Engine Troubleshooting Chart?

» 020 troubleshooting

» So I got a norvel

» Need help troubleshooting a Cox .049 engine

» Can we get some help designing our Cox Engine Troubleshooting Chart?

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules