Log in

Search

Latest topics

» Foam hand kids glider converted to 0.049 CLby roddie Today at 4:33 am

» Cox PT-19 Wing

by latole Today at 4:28 am

» Roddie-Rigger.. a 2005 original design

by roddie Today at 2:54 am

» Golden Bee basic running problem

by roddie Yesterday at 10:51 pm

» Simple Gliders

by rdw777 Yesterday at 6:25 pm

» Weird search for a single comic from an old Mad Magazine

by Kim Yesterday at 1:44 pm

» Scientific "Zipper" Build...Zipper Flys!.

by getback Yesterday at 7:27 am

» Cox .049 Tee Dee engines back in stock (limited availablility)

by GallopingGhostler Yesterday at 1:05 am

» Very off-topic.........Time passes and not always for the best......

by rsv1cox Thu Jul 25, 2024 2:47 pm

» Jim Walker Bonanza etc.

by rsv1cox Wed Jul 24, 2024 6:30 pm

» Throttles for Cox Tee Dee .049 / .020 / .010 engines --- videos

by sosam117 Wed Jul 24, 2024 8:54 am

» Introducing our Cox .049 TD Engines

by Admin Tue Jul 23, 2024 2:00 am

Cox Engine of The Month

July-2024

robot797's

"ULTIMITE COX 010: it has a clutch, E starter, throttle, exhaust, aluminum tank, aluminum venturi, gearbox with forward and reverse, and now its on a custom drawn and printed stand"

PAST WINNERS

robot797's

"ULTIMITE COX 010: it has a clutch, E starter, throttle, exhaust, aluminum tank, aluminum venturi, gearbox with forward and reverse, and now its on a custom drawn and printed stand"

PAST WINNERS

cleaning w ultrasonic

Page 1 of 2

Page 1 of 2 • 1, 2

cleaning w ultrasonic

cleaning w ultrasonic

i finally broke down and bought the Harbor Freight ultrasonic cleaner. (my holiday gift to myself)

yes, i spend the extra $13 for a warranty. which chaps my hide, but every other forum says to doo it for when the unit breaks in 6 months

used some safety wire to make handles to lift the tray (but will make a basket soon)

the PLAN(tm) is to clean up disassembelled motors, as well as carbs for vintage motorcycles, firearm bits - and anything else I can fit

using water and ZEP degreaser (purple) at the moment, have not yet tested. Will keep ya'll informed

https://www.harborfreight.com/25-liter-ultrasonic-cleaner-63256.html

yes, i spend the extra $13 for a warranty. which chaps my hide, but every other forum says to doo it for when the unit breaks in 6 months

used some safety wire to make handles to lift the tray (but will make a basket soon)

the PLAN(tm) is to clean up disassembelled motors, as well as carbs for vintage motorcycles, firearm bits - and anything else I can fit

using water and ZEP degreaser (purple) at the moment, have not yet tested. Will keep ya'll informed

https://www.harborfreight.com/25-liter-ultrasonic-cleaner-63256.html

cstatman- Platinum Member

Posts : 551

Join date : 2021-02-17

Age : 60

Location : San Jose, CA

Re: cleaning w ultrasonic

Re: cleaning w ultrasonic

Please do NOT submerse an entire engine with all parts complete in your sonic cleaner...especially if they are needle or ball bearing engines

You do want heat if HF sonic cleaner has this mode

Use Only non caustic solutions that do not darken or change aluminum

I am personally a big fan of heat and very very dilute solution of water and Dawn dish soap as the Ph doesnt adversly impact aluminum parts

Others will say Dawn power, Simple Green, or other degrease solutions are fine..and they are....IF you don't leave overnight in the solution

Lazily I have been known to chunk an entire Cox .049~.15 engine in the sonic pre heated for fairly short 15 to 30 min degrease and loosen.... BUT every time I forgot and engine cooked for overn night got ugly discoloration

As much as I like my el cheapo HF sonic cleaner, MY china $129 E-Bay 2.5 liter cleaner with heat and timer control has the HF one gathering dust...that said, the HF cleaner is a good unit....just don't ignorantly destroy bearing races or discolor4 your beloved engines

PS a hand full of nastily greasy tools can NOT be hurt and shiny clean tools is a good thing

You do want heat if HF sonic cleaner has this mode

Use Only non caustic solutions that do not darken or change aluminum

I am personally a big fan of heat and very very dilute solution of water and Dawn dish soap as the Ph doesnt adversly impact aluminum parts

Others will say Dawn power, Simple Green, or other degrease solutions are fine..and they are....IF you don't leave overnight in the solution

Lazily I have been known to chunk an entire Cox .049~.15 engine in the sonic pre heated for fairly short 15 to 30 min degrease and loosen.... BUT every time I forgot and engine cooked for overn night got ugly discoloration

As much as I like my el cheapo HF sonic cleaner, MY china $129 E-Bay 2.5 liter cleaner with heat and timer control has the HF one gathering dust...that said, the HF cleaner is a good unit....just don't ignorantly destroy bearing races or discolor4 your beloved engines

PS a hand full of nastily greasy tools can NOT be hurt and shiny clean tools is a good thing

fredvon4- Top Poster

Posts : 4004

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: cleaning w ultrasonic

Re: cleaning w ultrasonic

Not to down play the attributes of an Ultrasonic cleaner, my wife used one to clean her jewelry but I have recently become an advocate for Berryman's parts cleaner fluid as some here might recall. Label says "No agitation required."

I have used it for years to clean auto parts, mostly carburetors. A few months ago I cleaned a rather castor locked Cox Babe Bee with it. Left it in an hour, came out sparkling clean after a dump in Simple Green, then a warm water rinse. Naturally, disassembly and lubrication followed.

Impressed enough, about five other engines followed with soak times reduced to as little as 15 minutes with the same result. I can find no fault with it after cleaning a couple hundred engines using other methods. My work/wait times have been reduced from hours to minutes with much less stress on me and the engines.

Nasty engines - Hour soak

Not so nasty engines - 15 minutes

I have used it for years to clean auto parts, mostly carburetors. A few months ago I cleaned a rather castor locked Cox Babe Bee with it. Left it in an hour, came out sparkling clean after a dump in Simple Green, then a warm water rinse. Naturally, disassembly and lubrication followed.

Impressed enough, about five other engines followed with soak times reduced to as little as 15 minutes with the same result. I can find no fault with it after cleaning a couple hundred engines using other methods. My work/wait times have been reduced from hours to minutes with much less stress on me and the engines.

Nasty engines - Hour soak

Not so nasty engines - 15 minutes

rsv1cox- Top Poster

Posts : 10851

Join date : 2014-08-18

Location : West Virginia

Re: cleaning w ultrasonic

Re: cleaning w ultrasonic

fredvon4 wrote:just don't ignorantly destroy bearing races

So, just how does an ultrasonic cleaner destroy bearing races? Not a debate by any means, but am just curious as I have not used one, but have honestly wanted one, but after reading this, I am curious. Most of my engines are bushed and not have any bearings, but a couple that I do want to eventually clean do have bearings. Thank you.

NEW222- Top Poster

- Posts : 3895

Join date : 2011-08-13

Age : 45

Location : oakbank, mb

Re: cleaning w ultrasonic

Re: cleaning w ultrasonic

Bearings and races are very hard often brittle metals. Ultra sonic 4to5 kilohertz waves slam these parts together very violently often destroying the ball, roller, or race

Similar to Every bearing mfg on earth telling customers to NEVER SPIN DRY WITH COMPRESSED AIR, ONE-- IT CAN DESTROY THE BEARING AND-- TWO CAN CAUSE SERIOUS INJURY

BIT OF TRIVIA a turbine engine after idle then run up has engineered bearings that at operating temp and pressure flowing oil bath see 100,000 to over 600,000 RPM.

the SAME BEARING SOLVENT CLEANED AND AIR DRIED THEN SPUN BY COMPRESSED AIR will explode violently as low as 50,000 RPM

I was exposed to this in my turbine engine school...demonstrated for every class in side a engine test cell as an object lesson for us

Similar to Every bearing mfg on earth telling customers to NEVER SPIN DRY WITH COMPRESSED AIR, ONE-- IT CAN DESTROY THE BEARING AND-- TWO CAN CAUSE SERIOUS INJURY

BIT OF TRIVIA a turbine engine after idle then run up has engineered bearings that at operating temp and pressure flowing oil bath see 100,000 to over 600,000 RPM.

the SAME BEARING SOLVENT CLEANED AND AIR DRIED THEN SPUN BY COMPRESSED AIR will explode violently as low as 50,000 RPM

I was exposed to this in my turbine engine school...demonstrated for every class in side a engine test cell as an object lesson for us

fredvon4- Top Poster

Posts : 4004

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: cleaning w ultrasonic

Re: cleaning w ultrasonic

Yep, I have learned my lesson too on using my Ultrasonic cleaner on ball bearing engines and anodized parts.

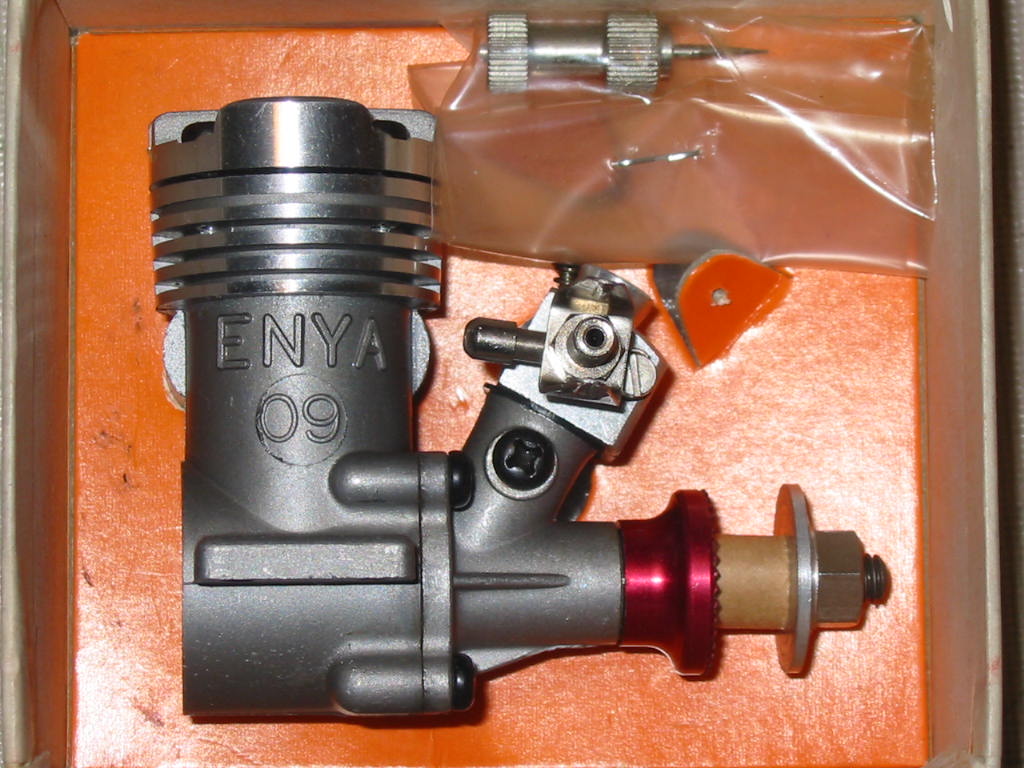

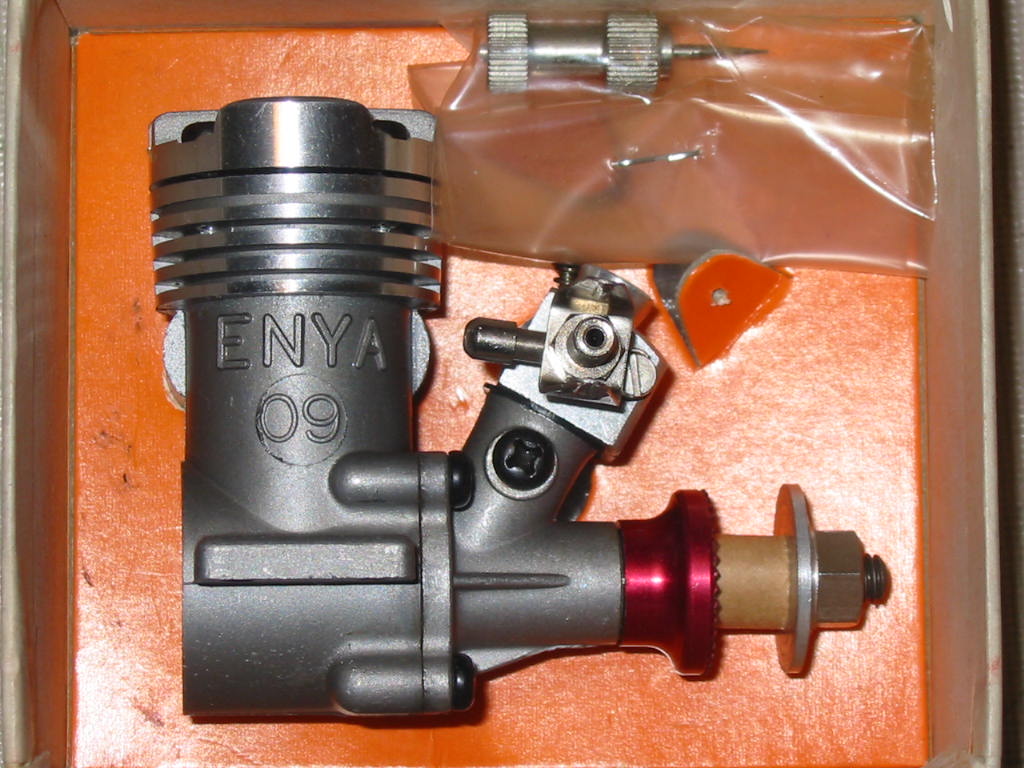

After disassembling my Enya .09 with ball bearing (in the front housing).

I placed everything into my wire basket (mine came with a fine and course screen baskets).

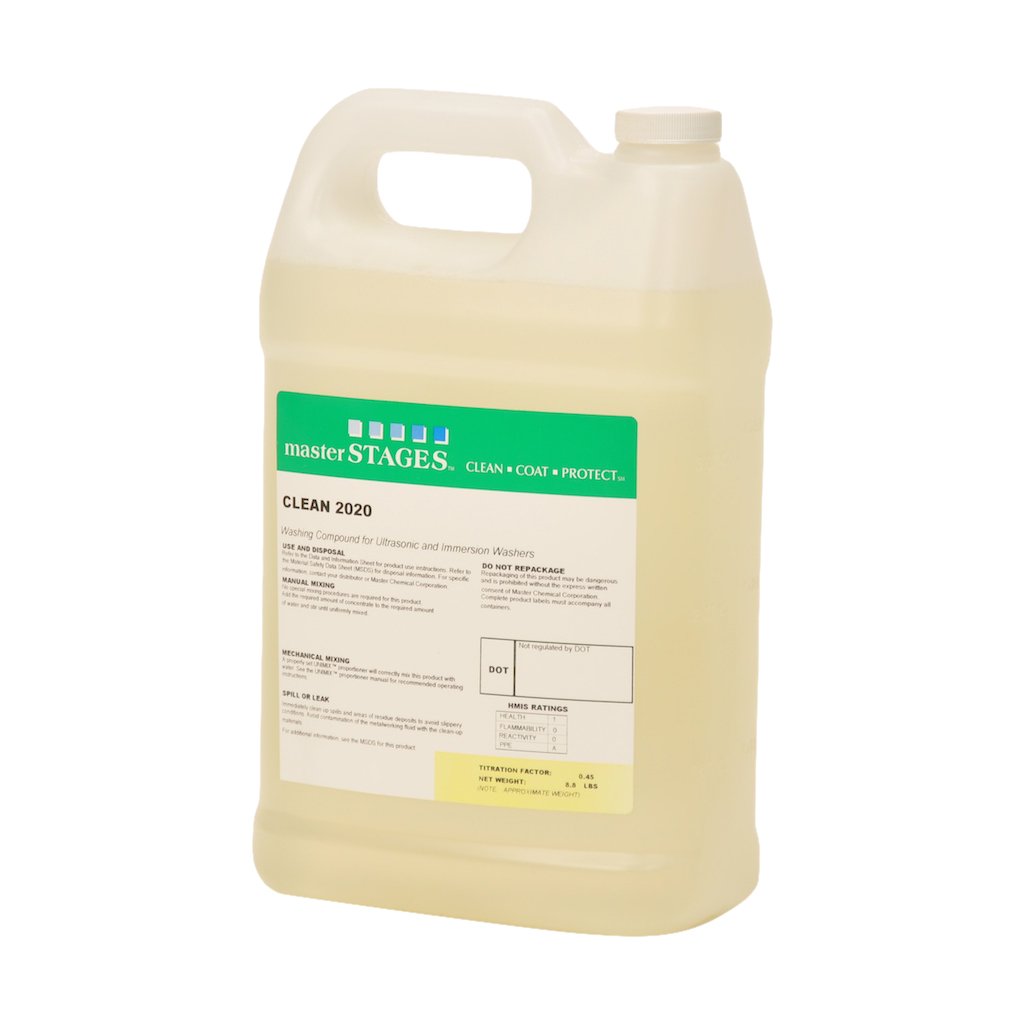

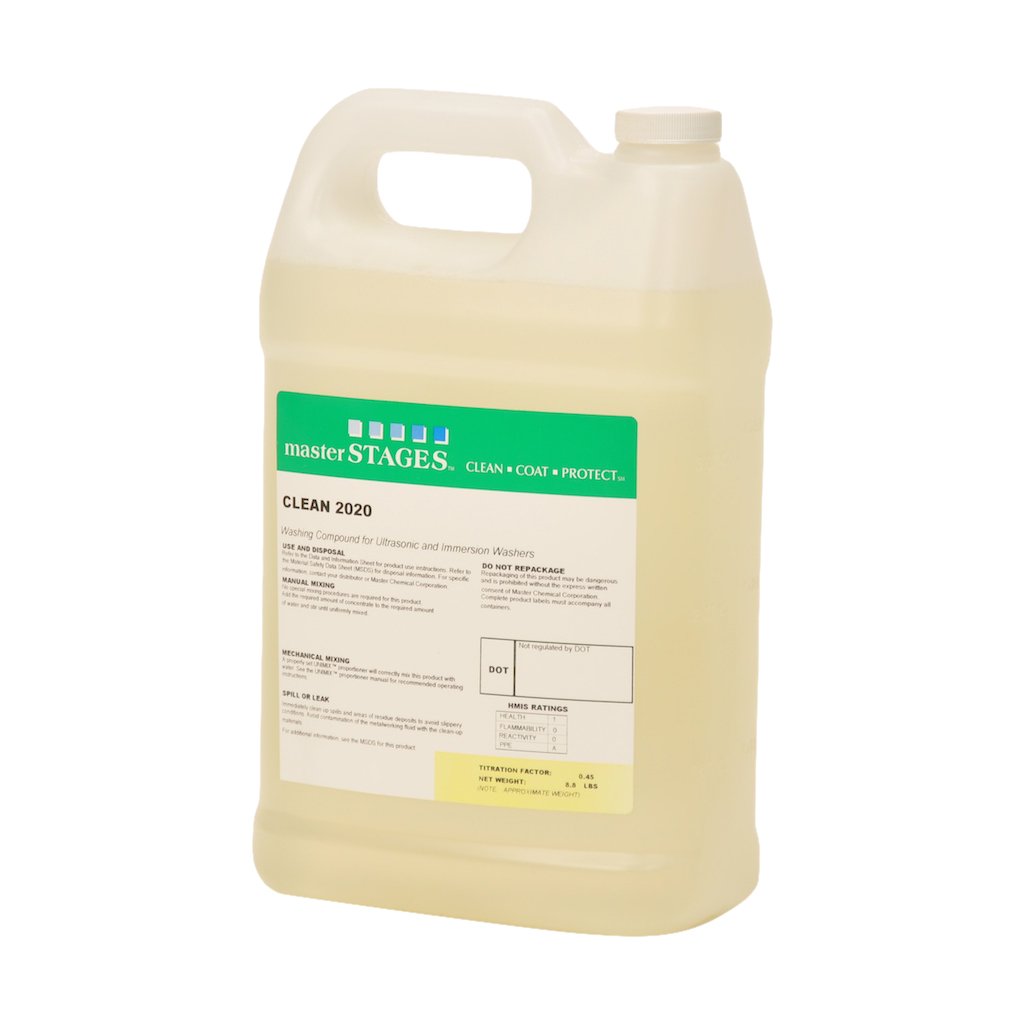

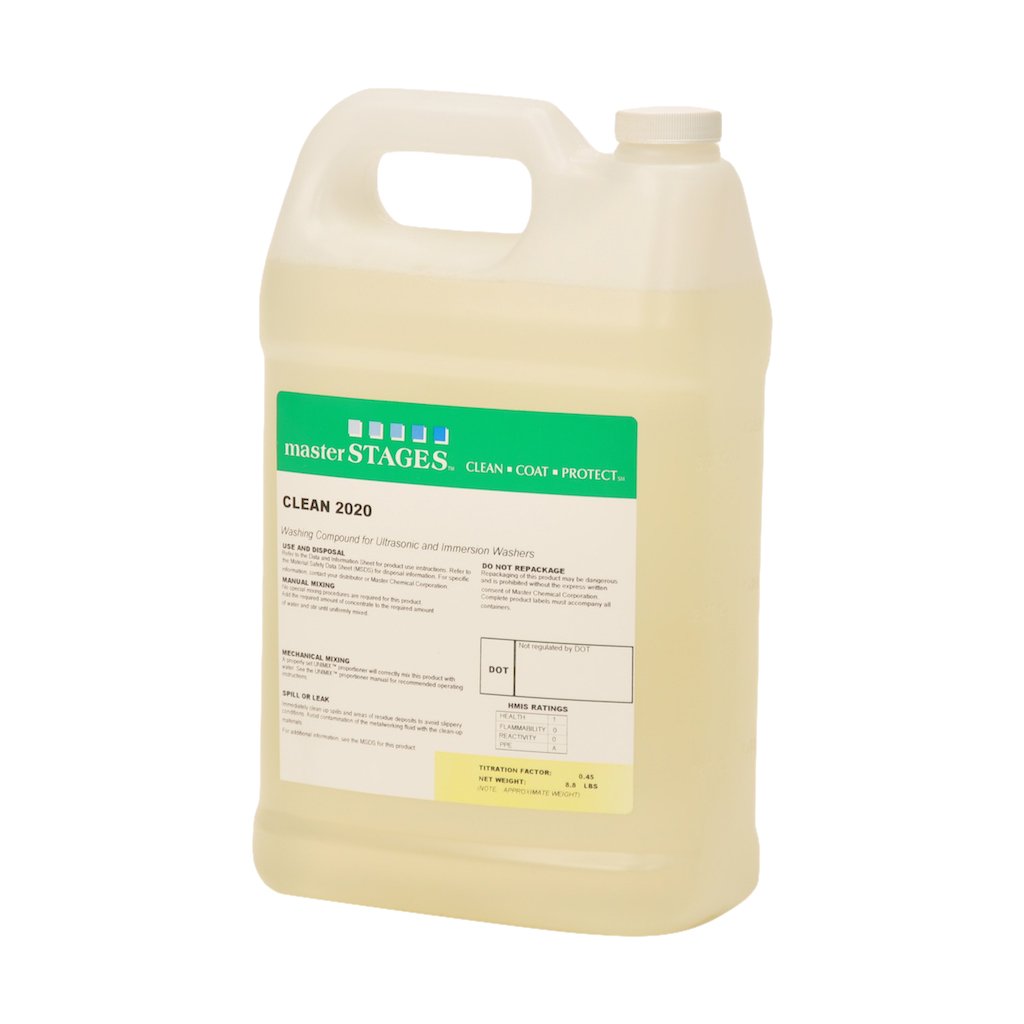

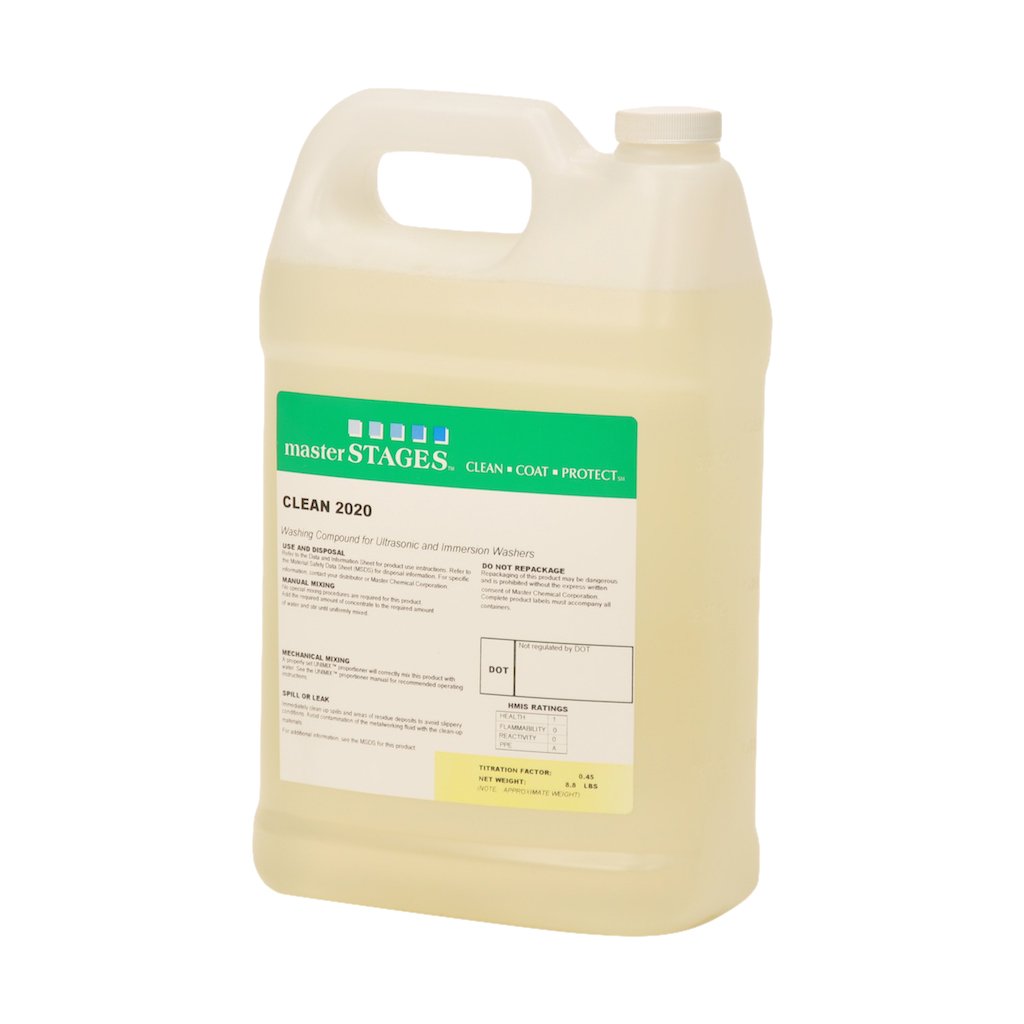

The solution I use is Master Stages CLEAN2020/1G Clean 2020 Washing Compound for Ultrasonic Washers.

It is safe for aluminum and rubber parts, but it is a concentrated, so you have to dilute it to no more than 10%.

Mine is at 8% and does a nice job of cleaning dirty engines. it also leaves a fine coating to stop rust/oxidation.

The solution is heated to 120 degrees.

Where I worked (at Caterpillar's fuel system) that is the solution to clean our fuel injector parts.

So, if it's good for those critical parts, it should do well on my model engines?

Anyway, back to the cleaning of the bearings and anodized parts.

DON'T PUT THEM INTO THE SONIC TANK FOR CLEANING!

After 20 minutes in the sonic tank, the bearing in the front housing no longer was able to turn and the red anodized prop washer(driver) was now a very light pink instead of the dark red it originally it was.

But the engine parts were very clean! See the photo below of the gunk that came off the engine, along with the red anodizing from the prop drive washer.

So, what I have learned is, "if" I can remove the bearing easily enough, I remove them before sonic cleaning.

If I can't, then the part with the bearings gets a good tooth bush cleaning in hot dawn (with grease cutter) solution then dry the part using air from my heat gun to dry them.

I ordered from Ken Enya the Enya .09 rebuild kit (Enya part #MK094) which has in it eight new screws for the engine, carb gasket, new screws for the carb, front housing gasket, thrust washer (behind the prop washer/driver), new "red" prop driver, prop washer and nut, for a cost of $19.89, plus purchase a new ball bearing as well to replace the messed up one (I did).

By the way, I looked under a microscope that I have at the ball bearing and noticed that the balls looked like they were shot peened, and the balls were no longer nice and smooth but looked like the surface of the moon?

So, the sonic vibration hammered the balls in their race and roughened up the ball surfaces.

Well, here is the finished (rebuilt) Enya .09-III, looking as good as new!

And a lesson learned.

All of the other engines that I have been cleaning this year didn't have bearings in them. No problem.

1st engine with a bearing in it and I should have known about the anodizing.

Had the anodizing disappear on a Cox engine that I cleaned as well. (Should have remembered that mistake?)

After disassembling my Enya .09 with ball bearing (in the front housing).

I placed everything into my wire basket (mine came with a fine and course screen baskets).

The solution I use is Master Stages CLEAN2020/1G Clean 2020 Washing Compound for Ultrasonic Washers.

It is safe for aluminum and rubber parts, but it is a concentrated, so you have to dilute it to no more than 10%.

Mine is at 8% and does a nice job of cleaning dirty engines. it also leaves a fine coating to stop rust/oxidation.

The solution is heated to 120 degrees.

Where I worked (at Caterpillar's fuel system) that is the solution to clean our fuel injector parts.

So, if it's good for those critical parts, it should do well on my model engines?

Anyway, back to the cleaning of the bearings and anodized parts.

DON'T PUT THEM INTO THE SONIC TANK FOR CLEANING!

After 20 minutes in the sonic tank, the bearing in the front housing no longer was able to turn and the red anodized prop washer(driver) was now a very light pink instead of the dark red it originally it was.

But the engine parts were very clean! See the photo below of the gunk that came off the engine, along with the red anodizing from the prop drive washer.

So, what I have learned is, "if" I can remove the bearing easily enough, I remove them before sonic cleaning.

If I can't, then the part with the bearings gets a good tooth bush cleaning in hot dawn (with grease cutter) solution then dry the part using air from my heat gun to dry them.

I ordered from Ken Enya the Enya .09 rebuild kit (Enya part #MK094) which has in it eight new screws for the engine, carb gasket, new screws for the carb, front housing gasket, thrust washer (behind the prop washer/driver), new "red" prop driver, prop washer and nut, for a cost of $19.89, plus purchase a new ball bearing as well to replace the messed up one (I did).

By the way, I looked under a microscope that I have at the ball bearing and noticed that the balls looked like they were shot peened, and the balls were no longer nice and smooth but looked like the surface of the moon?

So, the sonic vibration hammered the balls in their race and roughened up the ball surfaces.

Well, here is the finished (rebuilt) Enya .09-III, looking as good as new!

And a lesson learned.

All of the other engines that I have been cleaning this year didn't have bearings in them. No problem.

1st engine with a bearing in it and I should have known about the anodizing.

Had the anodizing disappear on a Cox engine that I cleaned as well. (Should have remembered that mistake?)

sosam117- Diamond Member

- Posts : 1310

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: cleaning w ultrasonic

Re: cleaning w ultrasonic

I have a different method but which works well enough for the carburetor and another object a pot with lid on which is to fix an orbital sander for body I never use it for the mini motor, I prefer to do it manually

Itink It is preferable to only use for single pieces more than one risk of damage. I believe that the sonic cleaner is a good tool to clean the parts well, especially if the parts have corner holes nooks and crannies

Some parts must be cleaned by hand

Itink It is preferable to only use for single pieces more than one risk of damage. I believe that the sonic cleaner is a good tool to clean the parts well, especially if the parts have corner holes nooks and crannies

Some parts must be cleaned by hand

davidll1984- Diamond Member

- Posts : 2303

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: cleaning w ultrasonic

Re: cleaning w ultrasonic

Congratulations on getting you a ultra sonic cleaner ,these are very handy https://www.ebay.com/itm/190645122981?hash=item2c6355b7a5:g:DeoAAOSwXc9cB0Qo

Last edited by getback on Thu Dec 16, 2021 6:28 am; edited 1 time in total (Reason for editing : add on)

getback- Top Poster

Posts : 10276

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: cleaning w ultrasonic

Re: cleaning w ultrasonic

People. I don't understand the resistance to using or even trying Berrymans parts cleaner. $21 at Walmart. Simple, effective and cheap. Fifteen minutes to an hour and you move on to the fun part.

If I'm doing something wrong list it here, because I would like to know.

If I'm doing something wrong list it here, because I would like to know.

rsv1cox- Top Poster

Posts : 10851

Join date : 2014-08-18

Location : West Virginia

Re: cleaning w ultrasonic

Re: cleaning w ultrasonic

Hey Hey hey I Vote for the use of it > I don't have any right now < And don't clean as many parts? as I use too , we used this stuff at ALL the mechanics jobs i have had and i love the stuff and was at awl when you posted your results . The plastic thing got me to thinking cause i have a few that need it ! Stored in boxes don't do much for showing off your goodies

getback- Top Poster

Posts : 10276

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: cleaning w ultrasonic

Re: cleaning w ultrasonic

thank you all for good advice.

the HF has heat option

i'm using Zep degreaser mixed ~50/50 with water - similar to simple green purple

I don't have any ball-bearing motors, but understand the issue

i won't put a fully assembelled motor in, everything gets disassembelled first

no anodized parts - good call - i hadn't thought about that

won't leave in longer than cleaning cycle, and will rinse first with water, then with Ballistol

I DO use berrymans, Aero-Kroil and Ballistol for initial cleaning and separation of gunky parts

I like the mini-ball basket idea - looks just like a tea strainer. (mini ball, not to be comfused with minie ball)

https://www.amazon.com/Strainer-Mulling-Stainless-Perfect-ARTIST/dp/B07FZP5YFB/

my main hope for it? cleaning the weee tiny small passageways, between fins, small cracks and crevices...

will see what happens. my latest "box of junk engines" find from flEbay should be here friday....

I NEED .020s, but i keep buying .049s

the HF has heat option

i'm using Zep degreaser mixed ~50/50 with water - similar to simple green purple

I don't have any ball-bearing motors, but understand the issue

i won't put a fully assembelled motor in, everything gets disassembelled first

no anodized parts - good call - i hadn't thought about that

won't leave in longer than cleaning cycle, and will rinse first with water, then with Ballistol

I DO use berrymans, Aero-Kroil and Ballistol for initial cleaning and separation of gunky parts

I like the mini-ball basket idea - looks just like a tea strainer. (mini ball, not to be comfused with minie ball)

https://www.amazon.com/Strainer-Mulling-Stainless-Perfect-ARTIST/dp/B07FZP5YFB/

my main hope for it? cleaning the weee tiny small passageways, between fins, small cracks and crevices...

will see what happens. my latest "box of junk engines" find from flEbay should be here friday....

I NEED .020s, but i keep buying .049s

cstatman- Platinum Member

Posts : 551

Join date : 2021-02-17

Age : 60

Location : San Jose, CA

Re: cleaning w ultrasonic

Re: cleaning w ultrasonic

Thanks Guys, It came to me on my way to Lowes this morning. No one here is as crazy as I am buying these old abused castor locked lumps of engines that require deep cleaning.

Someone here months ago asked about the cylinder index and how many engines people here had. I was the only one to own up with a total then or around 600+. Since then I have added many more the majority needed deep cleaning. I only wish I had discovered parts cleaner first. Would have saved me time and had been far easier on the engines.

Someone here months ago asked about the cylinder index and how many engines people here had. I was the only one to own up with a total then or around 600+. Since then I have added many more the majority needed deep cleaning. I only wish I had discovered parts cleaner first. Would have saved me time and had been far easier on the engines.

rsv1cox- Top Poster

Posts : 10851

Join date : 2014-08-18

Location : West Virginia

Re: cleaning w ultrasonic

Re: cleaning w ultrasonic

Awesome nice choice! The ultrasonic is nothing short of a life saver in my books. I use a cheepy jewelry one lol. One day I will upgrade lol

I love it for cleaning dirty oily nitro rc car plastic my cleaning solution is powdered dish detergent, just mix in hot water from the kettle and let er chooch. So awesome because you can let it clean and progress other things while it works.

For cleaning off say gear grease, I float a container with gasoline with a smidge of 2-stroke oil. That way the ultrasonic stays clean.

For nitro engines I tend to float a jar of old questionable nitro fuel for cleaning. Then transfer to a jar of 99% rubbing alcohol to finish it off. Works well enough for me.

Happy cleaning. Works great on dirt bike carbs too. No more 24hr pinsol baths lol.

I love it for cleaning dirty oily nitro rc car plastic my cleaning solution is powdered dish detergent, just mix in hot water from the kettle and let er chooch. So awesome because you can let it clean and progress other things while it works.

For cleaning off say gear grease, I float a container with gasoline with a smidge of 2-stroke oil. That way the ultrasonic stays clean.

For nitro engines I tend to float a jar of old questionable nitro fuel for cleaning. Then transfer to a jar of 99% rubbing alcohol to finish it off. Works well enough for me.

Happy cleaning. Works great on dirt bike carbs too. No more 24hr pinsol baths lol.

layback209- Gold Member

- Posts : 282

Join date : 2017-10-13

Age : 38

Location : Okotoks

Re: cleaning w ultrasonic

Re: cleaning w ultrasonic

I am a fan of B12 Chem tool AND the $0.97c store brand Aerosol carb cleaners

IMO ultra sonic shouldn't be first choice for heavy degreasing or trying to free up castor locked

I am also a big fan of EVAPORUST BUT it should only be used on ferrous metals and not on Anodized Aluminum

I am a big fan of small $9.99 crock pot and full strength Engine coolants for aluminum engine and radiators

I love the smell of SIMPLE GREEN

IMO ultra sonic shouldn't be first choice for heavy degreasing or trying to free up castor locked

I am also a big fan of EVAPORUST BUT it should only be used on ferrous metals and not on Anodized Aluminum

I am a big fan of small $9.99 crock pot and full strength Engine coolants for aluminum engine and radiators

I love the smell of SIMPLE GREEN

fredvon4- Top Poster

Posts : 4004

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: cleaning w ultrasonic

Re: cleaning w ultrasonic

I too use an ultrasonic. I soak gummed-up engines in hot bath, about 140-150 deg F. I use the glass jar trick described above, with denatured ethanol as a detergent. Windshield washer fluid, or camping stove fuel. No ultrasonic at this point, just the heat. This usually makes the engines easy to disassemble.

After disassembly I clean the more stubborn residues with a toothpick, Q-tip etc. I usually polish the aluminium parts lightly, and after polish back to hot bath, this time with ultrasonic, changing the fluid and repeating as necessary until all the polishing paste residue is gone. The cylinder and piston go only once, as they are not polished.

A prolonged ultrasonic treatment may cause some light discolouration to the cylinder blueing, and possibly on colour anodizing. Delrin does not fare well in hot ethanol either, so it is best to remove all the plastic parts you are going to re-use. Dishwashing detergent and toothbrush works well with the plastic.

My method is a bit more labor-intensive. I don’t think any of the good old detergents are available any more, at least for consumer use. Carb cleaners, brake cleaners etc seem to have lost their power lately. But this is more like therapy to me anyway, cleaning up one or two engines in an evening is enough for me

After disassembly I clean the more stubborn residues with a toothpick, Q-tip etc. I usually polish the aluminium parts lightly, and after polish back to hot bath, this time with ultrasonic, changing the fluid and repeating as necessary until all the polishing paste residue is gone. The cylinder and piston go only once, as they are not polished.

A prolonged ultrasonic treatment may cause some light discolouration to the cylinder blueing, and possibly on colour anodizing. Delrin does not fare well in hot ethanol either, so it is best to remove all the plastic parts you are going to re-use. Dishwashing detergent and toothbrush works well with the plastic.

My method is a bit more labor-intensive. I don’t think any of the good old detergents are available any more, at least for consumer use. Carb cleaners, brake cleaners etc seem to have lost their power lately. But this is more like therapy to me anyway, cleaning up one or two engines in an evening is enough for me

KariFS- Diamond Member

- Posts : 2019

Join date : 2014-10-10

Age : 52

Re: cleaning w ultrasonic

Re: cleaning w ultrasonic

well it didn't work worth a darn.

i watched some videos, to discover? my unit was defective, not ultrasonic-ing , just heating

so I took it back and the kind young lady at Harbor Freight said "it happens, its Chinese junk" and let me swap it.

(IF I was 20 years younger? I would totally have asked her out on a date, she was BIG time cute, lovely smile, and good attitude. "do your best work, but remember its just a job" and she dint mind chatting with old farts at harbor frieght)

stopped at Home Despot on the way back, picked up some Simple Green Purple (yes, green purple, whatever)

25/75 purple to water, got the heat going, loaded the basket, let the disassembelled parts soak in the heat for about 5 mins, then gave it 480 seconds of ultrasonic.

removed everything, rinsed with cool clear water, wiped down with shop cloth, let sit in the sun.

it works GREAT on starter springs.

okay on backplates and other areas with wee little nooks and crannies.

AND! I managed to instantly oxidize about 5 crankcases.

black and UUUGLY.

little brushing, little mother's(tm) aluminium mag wheel polish, little elbow grease, they are shiney and pretty. Yes I used q-tips to get the insides

SO - the REST of the crankcases are going into a berrymans dip for ~ 15 mins, then water rinse and elbow greasing.

I'm not adventurous enough to try berrymans in the ultrasonic bath, I see it only as a fire hazard/inhalation hazard, and probably burn the dang garage down around me

hybrid, combine lots of methods, clean it all up.

the ultrasonic did GREAT on some grimy old hand tools.....

we now return you to your regularly scheduled programming.

i watched some videos, to discover? my unit was defective, not ultrasonic-ing , just heating

so I took it back and the kind young lady at Harbor Freight said "it happens, its Chinese junk" and let me swap it.

(IF I was 20 years younger? I would totally have asked her out on a date, she was BIG time cute, lovely smile, and good attitude. "do your best work, but remember its just a job" and she dint mind chatting with old farts at harbor frieght)

stopped at Home Despot on the way back, picked up some Simple Green Purple (yes, green purple, whatever)

25/75 purple to water, got the heat going, loaded the basket, let the disassembelled parts soak in the heat for about 5 mins, then gave it 480 seconds of ultrasonic.

removed everything, rinsed with cool clear water, wiped down with shop cloth, let sit in the sun.

it works GREAT on starter springs.

okay on backplates and other areas with wee little nooks and crannies.

AND! I managed to instantly oxidize about 5 crankcases.

black and UUUGLY.

little brushing, little mother's(tm) aluminium mag wheel polish, little elbow grease, they are shiney and pretty. Yes I used q-tips to get the insides

SO - the REST of the crankcases are going into a berrymans dip for ~ 15 mins, then water rinse and elbow greasing.

I'm not adventurous enough to try berrymans in the ultrasonic bath, I see it only as a fire hazard/inhalation hazard, and probably burn the dang garage down around me

hybrid, combine lots of methods, clean it all up.

the ultrasonic did GREAT on some grimy old hand tools.....

we now return you to your regularly scheduled programming.

cstatman- Platinum Member

Posts : 551

Join date : 2021-02-17

Age : 60

Location : San Jose, CA

Re: cleaning w ultrasonic

Re: cleaning w ultrasonic

Glad that it worked for you Charles. Yes, SG will discolor cases a lesson I learned early.

Harbor Freight does sell some really sorry stuff, but my HF air compressor just keeps on keeping on along with a lot of my other HF items. I once bought a very upscale Lyman digital caliper, lasted months while my el-cheepo HF digital caliper serves me almost every day and has for years.

Harbor Freight does sell some really sorry stuff, but my HF air compressor just keeps on keeping on along with a lot of my other HF items. I once bought a very upscale Lyman digital caliper, lasted months while my el-cheepo HF digital caliper serves me almost every day and has for years.

rsv1cox- Top Poster

Posts : 10851

Join date : 2014-08-18

Location : West Virginia

Re: cleaning w ultrasonic

Re: cleaning w ultrasonic

I think I'll stick to my Master STAGES CLEANER 2020

This is what it does:

Master STAGES CLEAN 2020 is a concentrated, very high-performance cleaner made for washing all metals including brass, copper alloy, and aluminum in ultrasonic or immersion washers. Its cleaning ability is extraordinary, which often leads to shorter cleaning cycles or elimination of cleaning steps. CLEAN 2020's oil rejecting properties mean longer bath life and economical operation.

CLEAN 2020 is a concentrated, very high-performance cleaner made for washing all metals including brass, copper alloy, and aluminum in ultrasonic or immersion washers. Its cleaning ability is extraordinary, which often leads to shorter cleaning cycles or elimination of cleaning steps. CLEAN 2020's oil rejecting properties mean longer bath life and economical operation.

Excellent cleaning in immersion and ultrasonic tanks

Long life because oils split rapidly to the surface of your cleaner tank where they can be skimmed off

An excellent choice where one product is used for multiple purposes, such as washing mixed batches of ferrous, aluminum, and copper alloy parts

Will provide extended in-process tarnish resistance on copper and copper alloy parts

Safe on aluminum, aluminum alloy, and magnesium

Will remove coolant residues as well as straight oils

This is what it does:

Master STAGES

Excellent cleaning in immersion and ultrasonic tanks

Long life because oils split rapidly to the surface of your cleaner tank where they can be skimmed off

An excellent choice where one product is used for multiple purposes, such as washing mixed batches of ferrous, aluminum, and copper alloy parts

Will provide extended in-process tarnish resistance on copper and copper alloy parts

Safe on aluminum, aluminum alloy, and magnesium

Will remove coolant residues as well as straight oils

sosam117- Diamond Member

- Posts : 1310

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: cleaning w ultrasonic

Re: cleaning w ultrasonic

HF - I think its all about which tool, who made it, and what its being used for.

If I need something 2 or 3 times? I will use the HF that is often 1/10th the price of name brand

If I need it daily, for my job? I will consider very carefully.

I have had some really great luck with HF vernier calipers, ratchets, mallets, and manual tools. I also have one of their electric pole saws that I've used reliably for the past 6 years. sometimes ya get a lemon (like ultra #1) sometimes, ya can just LOOK and tell, "that ain't the right tool for the application I need" --- but $$$? If I can buy 3 or 4 HF wrenches and bust them up over 5 years? and its STILL cheaper by 1/10th than a name brand? yeah, I will take that gamble

Sosam - hmmm - i like it, I will have to look at the product.

Ya'll have a great rest of the weekend

If I need something 2 or 3 times? I will use the HF that is often 1/10th the price of name brand

If I need it daily, for my job? I will consider very carefully.

I have had some really great luck with HF vernier calipers, ratchets, mallets, and manual tools. I also have one of their electric pole saws that I've used reliably for the past 6 years. sometimes ya get a lemon (like ultra #1) sometimes, ya can just LOOK and tell, "that ain't the right tool for the application I need" --- but $$$? If I can buy 3 or 4 HF wrenches and bust them up over 5 years? and its STILL cheaper by 1/10th than a name brand? yeah, I will take that gamble

Sosam - hmmm - i like it, I will have to look at the product.

Ya'll have a great rest of the weekend

cstatman- Platinum Member

Posts : 551

Join date : 2021-02-17

Age : 60

Location : San Jose, CA

Re: cleaning w ultrasonic

Re: cleaning w ultrasonic

Charles, you mentioned motorcycle carbs and the HF Ultrasonic cleaner (USC). I have one just for that. A quick and cheap degreaser is Fantastic 409. The beauty of it is it doesn't attack plastic and rubber like Berryman's does. In fact, I've tossed completely assembled bike carbs into USC just to get them clean enough to begin disassembly...complete with float jet needles, diaphragms, and orings!

Ensure you use the unit completely full of solvent/parts. If you are doing very small batches, then use glass jars to hold your solvent and part, and full the rest of the tub with straight water. The "buzz" gets through the glass, and the.jar keeps you from using more cleaner than needed. Short-tanking the tub is a guaranteed way to kill the USC.

I also took mine apart, and sealed the tank to the upper body with RTV glue. This is to prevent fluids from seeping between the seam of tank/body and protects the electrical parts.

Between the soaps and use, it didn't take long for the plastic mat to melt/ruin. I replace the mat with anything I don't care about. A side of plastic milk jug will work, but I use a rubber mat. Just don't let your items wait on the bare tank floor...another way to kill one of these tools!

Ensure you use the unit completely full of solvent/parts. If you are doing very small batches, then use glass jars to hold your solvent and part, and full the rest of the tub with straight water. The "buzz" gets through the glass, and the.jar keeps you from using more cleaner than needed. Short-tanking the tub is a guaranteed way to kill the USC.

I also took mine apart, and sealed the tank to the upper body with RTV glue. This is to prevent fluids from seeping between the seam of tank/body and protects the electrical parts.

Between the soaps and use, it didn't take long for the plastic mat to melt/ruin. I replace the mat with anything I don't care about. A side of plastic milk jug will work, but I use a rubber mat. Just don't let your items wait on the bare tank floor...another way to kill one of these tools!

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2000

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: cleaning w ultrasonic

Re: cleaning w ultrasonic

cstatman wrote:HF - I think its all about which tool, who made it, and what its being used for.

If I need something 2 or 3 times? I will use the HF that is often 1/10th the price of name brand

If I need it daily, for my job? I will consider very carefully.

I have had some really great luck with HF vernier calipers, ratchets, mallets, and manual tools. I also have one of their electric pole saws that I've used reliably for the past 6 years. sometimes ya get a lemon (like ultra #1) sometimes, ya can just LOOK and tell, "that ain't the right tool for the application I need" --- but $$$? If I can buy 3 or 4 HF wrenches and bust them up over 5 years? and its STILL cheaper by 1/10th than a name brand? yeah, I will take that gamble

Sosam - hmmm - i like it, I will have to look at the product.

Ya'll have a great rest of the weekend

Working for Caterpillar in their Fuel Systems Division, I learned a lot about cleanliness.

We have sophisticated wash tanks that does a primary wash (remove the heavy crud) with some light agitation.

Next was the high-power spray wash (it has spray nozzles like what your home power washer uses).

Next was the Ultra Sonic wash to remove the small fine particles.

After that it was a high-power blower to remove most of the water. (like a blower at your local car wash)

Last was the high heat drier to remove any moisture that was left on the parts.

And then the parts exit the washer on a conveyor system.

My job (when I was working for Cat -- I'm retired now) was to take parts that came out of the "parts" washer and do cleanliness checks. The quantity of parts selected was by the surface volume of the parts. Big parts less parts. Small parts more pieces.

Anyway, I would sonic clean the parts while the parts were in a glass beaker. After 10 minutes I would take the parts out of the beaker after 10 minutes of the parts resting in the beaker. Then take the solution that was in the beaker and go over to my cleanliness station and check for dirty/particles on a patch that the solution had to strain through (like an extra super fine filter.)

The filters felt like what a wing of a moth feels like (if you ever felt a moth's wing).

So, under a microscope I would look for metal particles and they could not exceed 5 microns in size and count the quantity of metal particles that could not exceed 14 parts.

After that I would have to weigh the patch to see how much "dirt" was not washed away from the washer operation.

The patch could not weight over certain amount. The weight was on a chart in the cleanliness station. Each weight was different for different part numbers.

And last part of my job was to check the solution of the washing agents in each tank. I used a something like a sight glass that would give me the solution concentration.

I would open up the section where I would smear the tank solution on look thru the other end and it should tell me what % I currently had in that specific tank. If it was low, I would pour more of the Masters Stages Cleaner 2020 into that tank. If it was high, I would add D.I. (deionized water) water to the wash tank.

I had to check the tanks at the start of the shift, right after lunch, then near the end of my shift.

And record the PH, tank solution %, temperatures of each tank (each one was heated to around 140°)

The five washers I took care of (each the size of two semi-trailers long) washed 1/2 the plants critical fuel system components.

Part that went thru it was everything from rubber and tygon O-rings, plastic parts (injected parts) epoxy molded parts to aluminum (cast and injected molded), steel, cast iron, nut and bolts of every kind (chrome plated too), brass and copper parts.

So, I figured if Cat used it for years (while I worked there - 37 yrs.) with no adverse effects on the fuel system parts, it should be ok for my little engine parts.

Over the time working there I started at the washers. This was the lowest inspection job at the time when I had it and it was called Quality Control Manufacturing's Final Inspector. from there all the critical washed parts that went through those washers went into the Assembly "Clean" room to be assembled into Cat's fuel system's injectors.

From the washers, I moved up through inspection from a final inspector to line inspector, to gaging inspector, to Quality Assurance processor (purchasing, repairing, setting up gages) to Quality Technician (got my degree in engineering at Illinois State) and as Q.T. I was team leader of the gaging inspectors, and I was able to travel to Japan, Germany, England, Sweden, and Norway to access new gaging equipment to see if they were capable of Cat requirements for gaging. If it was, I made a recommendation to either pass on it or purchase it. I liked where I got to at the end. Trips to other countries on Cat dime. If I was there over the weekend, The weekend was my own time (for site seeing). Japan was great. I went through the building where Enya engines were at. England, I went through many different castles (on castle tours). Germany, I saw and took a photo of check point Charlie.

Still have the old company card. Though it has expired two years ago now. Lots of different stamp marks in my passport book.

sosam117- Diamond Member

- Posts : 1310

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

rsv1cox- Top Poster

Posts : 10851

Join date : 2014-08-18

Location : West Virginia

Re: cleaning w ultrasonic

Re: cleaning w ultrasonic

RSV Bob,

Yup!

I learned of this "cheat" a couple of years back. The thread was started by a guy that was as frugal as I am. He actually used boiling water and 409 in a 5 gallon pail. I tried it on several bike carbs and found it is a great way to get the grime off.

My big fail with this was on downdraft Webers. I chucked two in the bucket (it IS bigger than my HF USC, after all). As they came out cleaner, I stripped them down and checked them back in. Then, grabbing the handle and lifting the bucket, I "agitated" the whole mess. On close inspection, I discovered I had busted off one of the float bosses at it's base. That screw-up cost me $100 to have fixed by a "micro-welder" outside of Atlanta, GA. I have used him for delicate aluminum welding several times since with much success and satisfaction.

Carb jets have awfully small holes and passageways. The same "system" is used for brake/clutch hydraulics. I still pre-soak in the same 5 gallon pail, and still use the USC for bulk parts cleaning before hand cleaning/inspection. However, I will never "agitate" multiple items (with delicate structures sticking out) at once...like stripped carbs sets.

I do want to try the stuff mentioned up a few threads. 409 just happens to be stocked at my local Lowe's...and that convenience is hard to beat.

Yup!

I learned of this "cheat" a couple of years back. The thread was started by a guy that was as frugal as I am. He actually used boiling water and 409 in a 5 gallon pail. I tried it on several bike carbs and found it is a great way to get the grime off.

My big fail with this was on downdraft Webers. I chucked two in the bucket (it IS bigger than my HF USC, after all). As they came out cleaner, I stripped them down and checked them back in. Then, grabbing the handle and lifting the bucket, I "agitated" the whole mess. On close inspection, I discovered I had busted off one of the float bosses at it's base. That screw-up cost me $100 to have fixed by a "micro-welder" outside of Atlanta, GA. I have used him for delicate aluminum welding several times since with much success and satisfaction.

Carb jets have awfully small holes and passageways. The same "system" is used for brake/clutch hydraulics. I still pre-soak in the same 5 gallon pail, and still use the USC for bulk parts cleaning before hand cleaning/inspection. However, I will never "agitate" multiple items (with delicate structures sticking out) at once...like stripped carbs sets.

I do want to try the stuff mentioned up a few threads. 409 just happens to be stocked at my local Lowe's...and that convenience is hard to beat.

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2000

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: cleaning w ultrasonic

Re: cleaning w ultrasonic

rsv1cox wrote:People. I don't understand the resistance to using or even trying Berrymans parts cleaner. $21 at Walmart. Simple, effective and cheap. Fifteen minutes to an hour and you move on to the fun part.

If I'm doing something wrong list it here, because I would like to know.

No, you're not doing anything wrong. I just received my shipment of Berrymans from WalMart ( fulfilled by Auto Zone) delivered to my front door for $27 and change. Just finished reading ( Scanned thru) the SDS and Berrymans "can you handle it" guide for safe usage and clean-up.

Going to dump in a handfull of cruddy engines just to see how much fun it'll be.

There is some interesting notes on handling and using the stuff. It's a "two Part" liquid, the top layer keeps the bottom layer from evaporation.

https://www.berrymanproducts.com/assets/CD-A-Int-0996-0996C-SDS-R02-W.pdf

https://www.berrymanproducts.com/chem-dip/

https://www.berrymanproducts.com/question/ok-to-use-chem-dip-in-an-ultrasonic-cleaner/

Last edited by Marleysky on Sun Dec 19, 2021 1:12 pm; edited 1 time in total (Reason for editing : added ultra sonic notes)

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 71

Location : Grand Rapids, MI

Re: cleaning w ultrasonic

Re: cleaning w ultrasonic

cstatman wrote:

it works GREAT on starter springs.

okay on backplates and other areas with wee little nooks and crannies.

AND! I managed to instantly oxidize about 5 crankcases.

black and UUUGLY.

little brushing, little mother's(tm) aluminium mag wheel polish, little elbow grease, they are shiney and pretty. Yes I used q-tips to get the insides

SO - the REST of the crankcases are going into a berrymans dip for ~ 15 mins, then water rinse and elbow greasing.

I'm not adventurous enough to try berrymans in the ultrasonic bath, I see it only as a fire hazard/inhalation hazard, and probably burn the dang garage down around me

hybrid, combine lots of methods, clean it all up.

the ultrasonic did GREAT on some grimy old hand tools.....

we now return you to your regularly scheduled programming.

I learnt this aluminum part lesson as well. If your using a water blended/base cleaning solution it seems to oxidize pretty good. You can reduce thd amount it oxidizes by reducing the ultrasonic cleaning time. At 480 it will cause it I found 180 and below was ok on that end. I tent to fill a jar with a non water base cleaner (such as glow fuel), drop the aluminum parts in and float it in the ultrasonic water bath. Doest seem to oxidize with that approach.

Good job polishing it up. Happy cleaning lots of good advice on this thread. Cheers.

layback209- Gold Member

- Posts : 282

Join date : 2017-10-13

Age : 38

Location : Okotoks

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Ultrasonic cleaning of a cox engine

» Cleaning Solution Used in Ultrasonic Cleaner?

» Wanted..recommendation on ultra sonic cleaner

» after run cleaning?

» Bore cleaning .049's

» Cleaning Solution Used in Ultrasonic Cleaner?

» Wanted..recommendation on ultra sonic cleaner

» after run cleaning?

» Bore cleaning .049's

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules