Log in

Search

Latest topics

» Does anyone know what this contraption is???by Levent Suberk Today at 4:17 am

» Cox Corsair - No guts no glory

by latole Today at 3:43 am

» COX .020 POWERED SPEEDSTER

by GallopingGhostler Yesterday at 10:11 pm

» Sunday Morning Comin' Down

by roddie Yesterday at 6:58 pm

» My N-1R build log

by roddie Yesterday at 6:13 pm

» It's a "Flash-Back Friday"

by Kim Fri Oct 25, 2024 1:02 pm

» Billy's Scientific "Sizzlin Liz" Mustang

by Jerry Fri Oct 25, 2024 10:13 am

» The Wood Shovel

by rsv1cox Thu Oct 24, 2024 3:01 pm

» Cox Icon RC TRansmitter and servo

by Cox International Thu Oct 24, 2024 11:55 am

» Cox 020 PeeWee rebuild questions

by LooseSpinner99 Thu Oct 24, 2024 8:42 am

» Cox p39 Airacobra

by 1975 control line guy Wed Oct 23, 2024 1:17 pm

» OK Cub .024

by GallopingGhostler Wed Oct 23, 2024 12:16 pm

OK Cub .039

Page 1 of 1

OK Cub .039

OK Cub .039

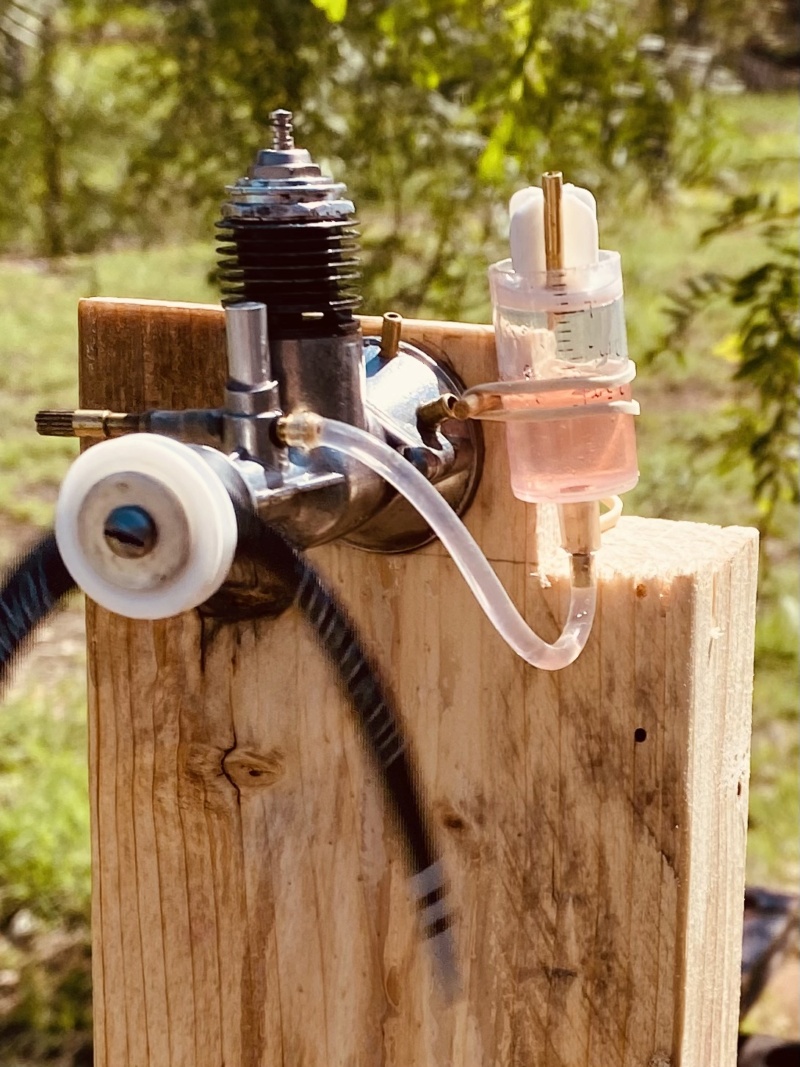

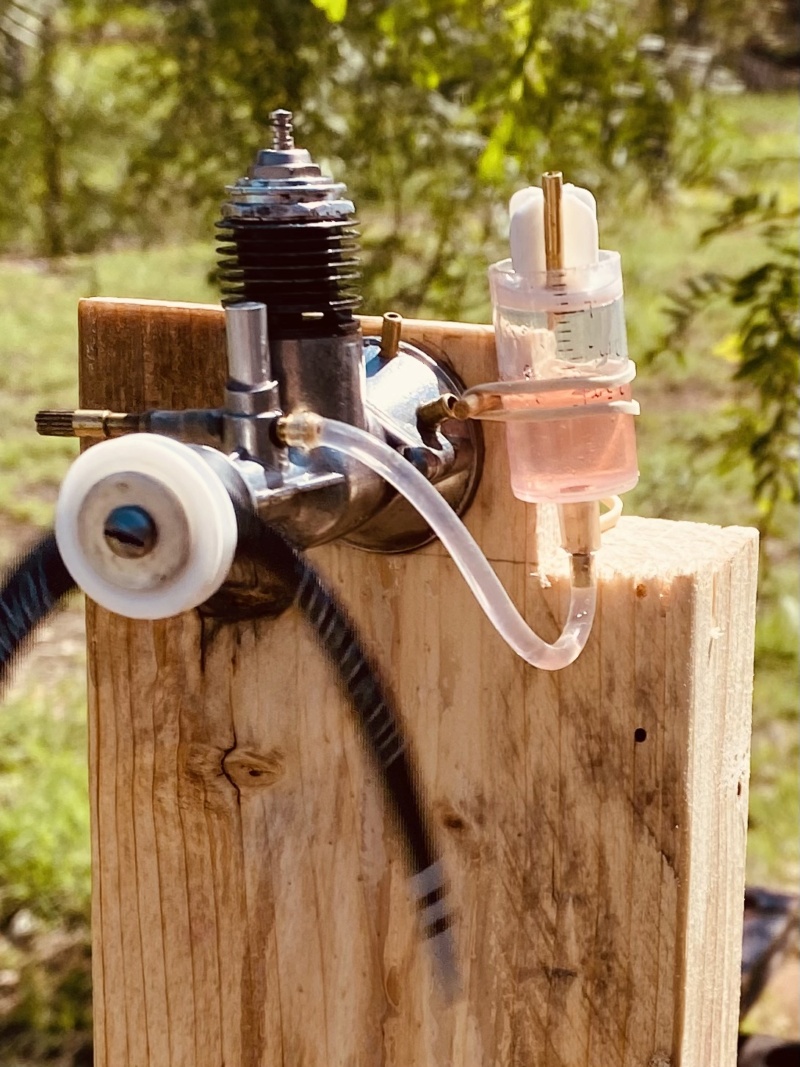

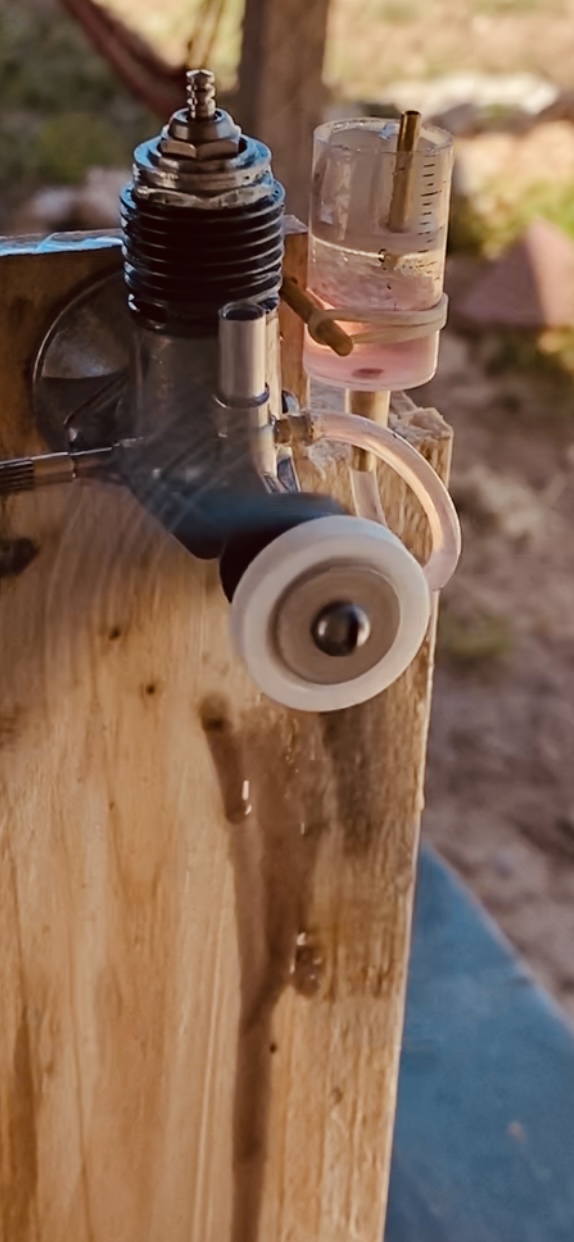

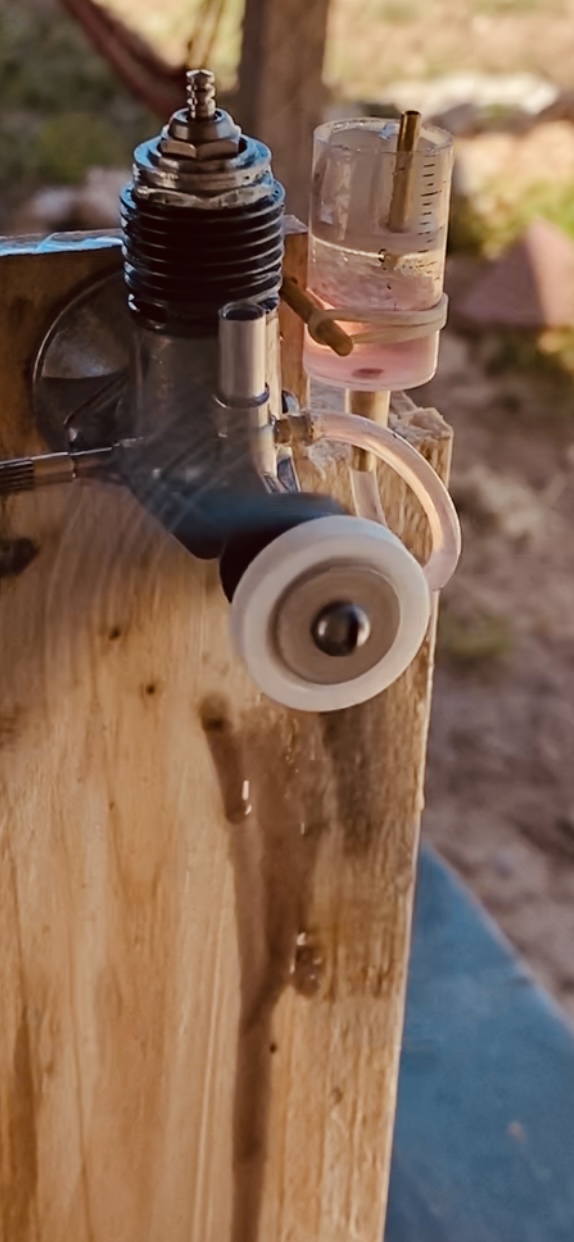

Me and this Cub’s been going round and round the last several shop sessions but I finally convinced it to run or it was going to get the hammer!!…. I’ve owned it for about five years but was never able to start it…. Only a pop or two from a very healthy prime…..One of the things suggested to me was take two of the three head gaskets out …. Did that but still no go….

I took a hint from some of the old Cub advertisements and found a little pulley in my junk box to try and start it with a pull string…. Better, A little promise, But needle and spray bar was still causing problems….. Fuel draw was terrible so I installed an aluminum tube in the venturi that was a good press fit and then another tube that telescopes into the outer one ending up with a .125” venturi…. Original is .187…. Would nearly try but to get the needle open enough to flow at all was on the ragged edge to cause it to flood….. To complicate the matter the spray bar has two holes in it and was somewhat loose…. I tried with the holes parallel with the crank and also one up, one down straight into the crank port…. No bueno!!…… The only thing I did not do was to try and taper the needle some more….

So an orphaned Cox 290 backplate donated its fine needle assembly and was installed with a little JB Weld for seal and it finally behaves like a real engine …. Starts easy (still with the string so far) and needles well…..I don’t think it ever ran with the needle and venturi like it was before…. It turns a Grish Tornado 5-3 prop 11.5 K on 24% fuel….Just a little lower than the engine reviews gave it…. It might run in and get just a little better, I think its running condition is still relatively new….Anyway, Having fun getting a 70 yo engine to run

I took a hint from some of the old Cub advertisements and found a little pulley in my junk box to try and start it with a pull string…. Better, A little promise, But needle and spray bar was still causing problems….. Fuel draw was terrible so I installed an aluminum tube in the venturi that was a good press fit and then another tube that telescopes into the outer one ending up with a .125” venturi…. Original is .187…. Would nearly try but to get the needle open enough to flow at all was on the ragged edge to cause it to flood….. To complicate the matter the spray bar has two holes in it and was somewhat loose…. I tried with the holes parallel with the crank and also one up, one down straight into the crank port…. No bueno!!…… The only thing I did not do was to try and taper the needle some more….

So an orphaned Cox 290 backplate donated its fine needle assembly and was installed with a little JB Weld for seal and it finally behaves like a real engine …. Starts easy (still with the string so far) and needles well…..I don’t think it ever ran with the needle and venturi like it was before…. It turns a Grish Tornado 5-3 prop 11.5 K on 24% fuel….Just a little lower than the engine reviews gave it…. It might run in and get just a little better, I think its running condition is still relatively new….Anyway, Having fun getting a 70 yo engine to run

rdw777- Diamond Member

Posts : 1634

Join date : 2021-03-11

Location : West Texas

akjgardner- Diamond Member

Posts : 1587

Join date : 2014-12-28

Age : 65

Location : Greensberg Indiana

Re: OK Cub .039

Re: OK Cub .039

Last edited by GallopingGhostler on Wed May 31, 2023 10:46 am; edited 1 time in total (Reason for editing : Duplicate message.)

GallopingGhostler- Top Poster

Posts : 5653

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: OK Cub .039

Re: OK Cub .039

Robert, you fixed a nagging problem that I did not like with the OK's. Their NVA system is probably the worst in the world, they used a weird split collar needle valve system that I couldn't get a piece of silicon fuel tubing on to stop needle seal leaks. The was true on both my .049-A and .049-B. Your combination of the venturi extension, which helped provide better suction by streamlining the incoming air, plus the more reliable Cox NVA was the trick.

I later may replace my NVA's with a Cox like you did. I could get them to run, yes, but needling them was another issue. If I could have honed in a setting, they would have been reliable runners. Run they did, but did not run optimally because it was difficult to adjust.

I later may replace my NVA's with a Cox like you did. I could get them to run, yes, but needling them was another issue. If I could have honed in a setting, they would have been reliable runners. Run they did, but did not run optimally because it was difficult to adjust.

Last edited by GallopingGhostler on Wed May 31, 2023 10:46 am; edited 1 time in total (Reason for editing : See previous message.)

GallopingGhostler- Top Poster

Posts : 5653

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: OK Cub .039

Re: OK Cub .039

Greenie for you for Not given in to hammer  I think i have one of those here somewhere !? Got to get things straightened out around here .... Is the tank on the engine no good or just easier to use your setup ? Got planes for it now ?

I think i have one of those here somewhere !? Got to get things straightened out around here .... Is the tank on the engine no good or just easier to use your setup ? Got planes for it now ?

I think i have one of those here somewhere !? Got to get things straightened out around here .... Is the tank on the engine no good or just easier to use your setup ? Got planes for it now ?

I think i have one of those here somewhere !? Got to get things straightened out around here .... Is the tank on the engine no good or just easier to use your setup ? Got planes for it now ?

getback- Top Poster

Posts : 10398

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: OK Cub .039

Re: OK Cub .039

I bought a bunch of those when they were selling out their inventory. Looks like I’ve got some mods to do

akjgardner- Diamond Member

Posts : 1587

Join date : 2014-12-28

Age : 65

Location : Greensberg Indiana

Re: OK Cub .039

Re: OK Cub .039

Actually, when OK came out with their reed valve version, the .06 (.059) "R" version, that corrected the needling problem, plus properly propped (max power RPM 11,500, say perhaps a 6x4 or 6x5?, got my tach, next chance will test) is a decent engine, IMO.

Sometimes, I think people try to prop these like they were a Cox .049 with smaller props for higher RPM. They won't take advantage of that lower RPM band. Think 1960's Enya, not Cox.

Sometimes, I think people try to prop these like they were a Cox .049 with smaller props for higher RPM. They won't take advantage of that lower RPM band. Think 1960's Enya, not Cox.

GallopingGhostler- Top Poster

Posts : 5653

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: OK Cub .039

Re: OK Cub .039

Thanks fellas….It’s too bad that the OK needle assembly were as poor as the were on some of their engines…. Otherwise they’re sort of “OK” little motors  …. I have an .049 A that works OK with its own needle but it also came with a venturi stack about the same length as the one in the photo ….. I think they really need that help minimally to get flows up a little better….,

…. I have an .049 A that works OK with its own needle but it also came with a venturi stack about the same length as the one in the photo ….. I think they really need that help minimally to get flows up a little better….,

Agree with you George they are nowhere near power output of a Cox…. But that’s OK if we just give them what they are and not expect rocket performance…. Just a neat piece of 1/2A history…. I would guess the .039 and Cub .049 are similar to a Cox .020 in power….

I don’t have anything at the moment for it to fly on Eric but thinking something freeflight-ish with R/C assist to bring it back… That’s why I was fiddling with the FF style small capacity tank in the photo…. Looks like 3cc’s will run it 30-40 seconds…

Agree with you George they are nowhere near power output of a Cox…. But that’s OK if we just give them what they are and not expect rocket performance…. Just a neat piece of 1/2A history…. I would guess the .039 and Cub .049 are similar to a Cox .020 in power….

I don’t have anything at the moment for it to fly on Eric but thinking something freeflight-ish with R/C assist to bring it back… That’s why I was fiddling with the FF style small capacity tank in the photo…. Looks like 3cc’s will run it 30-40 seconds…

rdw777- Diamond Member

Posts : 1634

Join date : 2021-03-11

Location : West Texas

Re: OK Cub .039

Re: OK Cub .039

Robert, the later .059-R was a bit more powerful, and from what I gather, a decent engine. I have one example now. Been thinking about testing it out on my son's Ace R/C Grasshopper. Since it attains its peak HP at a lower RPM, trick is to use a slightly greater pitch or greater diameter prop, to extract its full usefulness.

My comment about the Enya's were from my earlier experiences. I found that the Enya .15-III TV with throttle wired wide open and an 8x6 Masters prop did the same lap speeds as my OS Max .15FP-S plain bearing sport Schneurle with an 8x4 Masters on my Junior Ringmaster. Also I found it interesting that the Enya could do a wet-2 to lean-2 in stunts, returning to a wet-2. With the OS as configured, I could not get it to do that.

My Enya .09-III TV with Tatone 09-19 Peace Pipe muffler and 7x3 APC prop flew very .049 like on my Sure Flite Cessna 180 foamie ARF, but turned it into a nice sport plane with a 7x6 wood prop. Didn't have a wood 8x4 prop at the time, would have probably done even better putting the wind past the fuselage.

A good discussion was initiated by the late George "Willie" Fox on Jan. 10, 2018:

https://www.coxengineforum.com/t11473-the-ok-cub-060-059

The others, "A" and "B", I think they do decently if one is not expecting Pedal to the Metal (old saying amongst sports car fans, gas pedal all the way depressed to the floor). As @Kim expressed, just about all the Scientific half-A C/L planes were overpowered even with the Cox Babe Bee. The earlier OK's suited them well.

As @Kim expressed, just about all the Scientific half-A C/L planes were overpowered even with the Cox Babe Bee. The earlier OK's suited them well.

A downside to the earlier front venturi OK half-A engines was their oddly manufactured needle assembly. The consistency and quality of Cox engines even from Leroy's onset plus his ability to lower costs but not quality put him ahead of the half-A market early on. I find even the pre-1956 Cox .049 Thermal Hopper impressive. I remember all my early experiences with Cox reed valve engines, and I never had any problems starting them, and this is in consideration that I had no one to teach me. They were the best plug and play engines ever.

I remember all my early experiences with Cox reed valve engines, and I never had any problems starting them, and this is in consideration that I had no one to teach me. They were the best plug and play engines ever.

My comment about the Enya's were from my earlier experiences. I found that the Enya .15-III TV with throttle wired wide open and an 8x6 Masters prop did the same lap speeds as my OS Max .15FP-S plain bearing sport Schneurle with an 8x4 Masters on my Junior Ringmaster. Also I found it interesting that the Enya could do a wet-2 to lean-2 in stunts, returning to a wet-2. With the OS as configured, I could not get it to do that.

My Enya .09-III TV with Tatone 09-19 Peace Pipe muffler and 7x3 APC prop flew very .049 like on my Sure Flite Cessna 180 foamie ARF, but turned it into a nice sport plane with a 7x6 wood prop. Didn't have a wood 8x4 prop at the time, would have probably done even better putting the wind past the fuselage.

A good discussion was initiated by the late George "Willie" Fox on Jan. 10, 2018:

https://www.coxengineforum.com/t11473-the-ok-cub-060-059

The others, "A" and "B", I think they do decently if one is not expecting Pedal to the Metal (old saying amongst sports car fans, gas pedal all the way depressed to the floor).

A downside to the earlier front venturi OK half-A engines was their oddly manufactured needle assembly. The consistency and quality of Cox engines even from Leroy's onset plus his ability to lower costs but not quality put him ahead of the half-A market early on. I find even the pre-1956 Cox .049 Thermal Hopper impressive.

GallopingGhostler- Top Poster

Posts : 5653

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: OK Cub .039

Re: OK Cub .039

Grasshopper would be a fine test bed for your engine George….. I had one once and flew it mostly with Babe Bee’s..,.Wouldn’t win a beauty contest but tuff as nails..,, Good ruff field flyer …

I did some more running yesterday and it’s getting easier to start… At first the spent oil was fairly dark (below) but is clearing up the more I run it..

It will turn the 5-3 at 11.9K now,

A Top Flight White Nylon 6-3 at 9.4K - Steady

Cox Black 6-3 at 8.2K - Really too much for it, Not steady

Interesting to note they would give these engines up to one hour break in time before conducting tests….From sceptreflight on this engine:

I guess we got spoiled to Cox running peak right out of the box..,Still is interesting to fiddle with older technology

I did some more running yesterday and it’s getting easier to start… At first the spent oil was fairly dark (below) but is clearing up the more I run it..

It will turn the 5-3 at 11.9K now,

A Top Flight White Nylon 6-3 at 9.4K - Steady

Cox Black 6-3 at 8.2K - Really too much for it, Not steady

Interesting to note they would give these engines up to one hour break in time before conducting tests….From sceptreflight on this engine:

I guess we got spoiled to Cox running peak right out of the box..,Still is interesting to fiddle with older technology

rdw777- Diamond Member

Posts : 1634

Join date : 2021-03-11

Location : West Texas

Re: OK Cub .039

Re: OK Cub .039

Most OK engines are far from being OK. The .039 suited small models but it's pretty anemic . Yours seem down on rpm's. I've seen these many times with burrs at the bottom of the cylinder where the radial ports are . I've seen metal burrs completely bed themselves into the cylinder generating unnecessary heat and low rpm numbers. This doesn't break in, it wears out. A tell tale sign is the black oil you've mentioned. This can also be a result of the wrist pin where it contacts the cylinder walls at the exhaust ports.

Choking down the venturi no matter how small you feel that is could also cause low rpm numbers. The Cox spraybar might also be larger than the OK version choking it off even more which could also be a result of the low rpm numbers. I've had a few OK engines offer Cox like rpm numbers. They're not afraid of nitro. However, things like to break when introduced to high nitro contents. This engine works terrific for school yard free flight models.

Choking down the venturi no matter how small you feel that is could also cause low rpm numbers. The Cox spraybar might also be larger than the OK version choking it off even more which could also be a result of the low rpm numbers. I've had a few OK engines offer Cox like rpm numbers. They're not afraid of nitro. However, things like to break when introduced to high nitro contents. This engine works terrific for school yard free flight models.

Ken Cook- Top Poster

- Posts : 5616

Join date : 2012-03-27

Location : pennsylvania

Re: OK Cub .039

Re: OK Cub .039

Robert, you got that correct about it being a good runner.rdw777 wrote:Grasshopper would be a fine test bed for your engine George….. I had one once and flew it mostly with Babe Bee’s..., Wouldn’t win a beauty contest but tuff as nails..., Good ruff field flyer …

Those OK's were using machining techniques common in the 1940's. Leroy Cox modernized his factory using later and more precise equipment of the 1950's. I remember breaking in the Cox reedies, the Pee Wee and .049's, first run would reveal tiny metal flecks in the unburnt Castor ooze outside the cylinder, it resembled the tiny metal flakes in metallic spray paint. By the 2nd or 3rd tankful, it would be all gone.rdw777 wrote:I did some more running yesterday and it’s getting easier to start… At first the spent oil was fairly dark (below) but is clearing up the more I run it..

It will turn the 5-3 at 11.9K now, A Top Flight White Nylon 6-3 at 9.4K - Steady, Cox Black 6-3 at 8.2K - Really too much for it, Not steady.

Interesting to note they would give these engines up to one hour break in time before conducting tests….From sceptreflight on this engine:

Sceptre Flight Engine Tests: Model Engine Tests - OK Cub .039 (2)Air Trails wrote:During the break-in period, starting was found easy with a heavy prime in the exhaust (3 to 4 drops) and one drop in the intake. The engine appears to be rather wet, but kicks off quickly. After one hour of running the engine would continue to run on a lean needle valve setting, indicating it was thoroughly broken in, so the rpm tests were started.

I guess we got spoiled to Cox running peak right out of the box..,Still is interesting to fiddle with older technology

Honing techniques earlier on were coarser on the OK's, but one would expect that predating the Coxes. The late Joe Wagner had an explanation of what was happening with the iron piston in a soft steel sleeve process. The tiny chips from the honing marks broke off and embedded themselves in the iron piston surface, which after accumulation, would act to harden the iron surface for longer wear.

With the cylinder being polished by the piston's motion and piston surface hardening, the RPM's would increase and stabilize, indicating that the engine was sufficiently broke in when engine could maintain consistent RPM.

Regarding large chips, I'm thinking that with any new engine, doesn't hurt to partially disassemble to ensure there is no swarf (loose chips from machining operations) inside the crankcase. I'm wondering if that may be the chips that Ken is referring to. Also, I am thinking that if breaking of edges were not included in the machining operations, then it may be beneficial that one using a fine file break edges (may be with exception of the exhaust port) so that a slight chamfer is created.

Anyway, just some

thoughts.

thoughts.

GallopingGhostler- Top Poster

Posts : 5653

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: OK Cub .039

Re: OK Cub .039

To remove a cylinder on a OK engine, OK provided a split collar which clamped the cylinder and it had a handle to turn it. These cylinders are very soft and they're also susceptible to distortion when tightened to the case. If possible, insure that the cylinder isn't too tight on the case, just enough to hold it. Otherwise, this causes a lot of low end drag on the piston at the bottom end. I've experienced this with many .049 B's. Never stick any wrenches in a OK exhaust port, it will guarantee a destroyed cylinder. Don't remove a cylinder on a stuck OK engine, insure the piston is going up and down and then remove cylinder. If one removes it prior to freeing it, the rod will twist and snap off. I prefer not to take these engines apart unless absolutely necessary. A good polish on the shaft also tends to yield a bit more rpm's. Insure that the shaft is loose when spun in the case.

Ken Cook- Top Poster

- Posts : 5616

Join date : 2012-03-27

Location : pennsylvania

Re: OK Cub .039

Re: OK Cub .039

Thank you for the cautions and tips Gentlemen, I pulled the cylinder off one more time for a close inspection of possibilities you have shared…. I don’t see any glaring problems but good to err on the side of caution….

When I first disassembled the engine it wasn’t the cylinder that was hard to get off but the cyl/head joint, …. I don’t have the OK ring tool but a wrap of fine emery cloth bedded with leather, heat, The right size pliers, and a light touch finally got it apart…. 9/16 box end on the head…. I probably would have left that joint alone but needed to address the multiple gaskets…. I always orient the rod the same if I take it apart that far….. The shaft spin seems pretty good and the drive plate is being a little fussy to press off so I’ll leave that joint alone…,From here we’ll just run it and keep an eye on the oil….

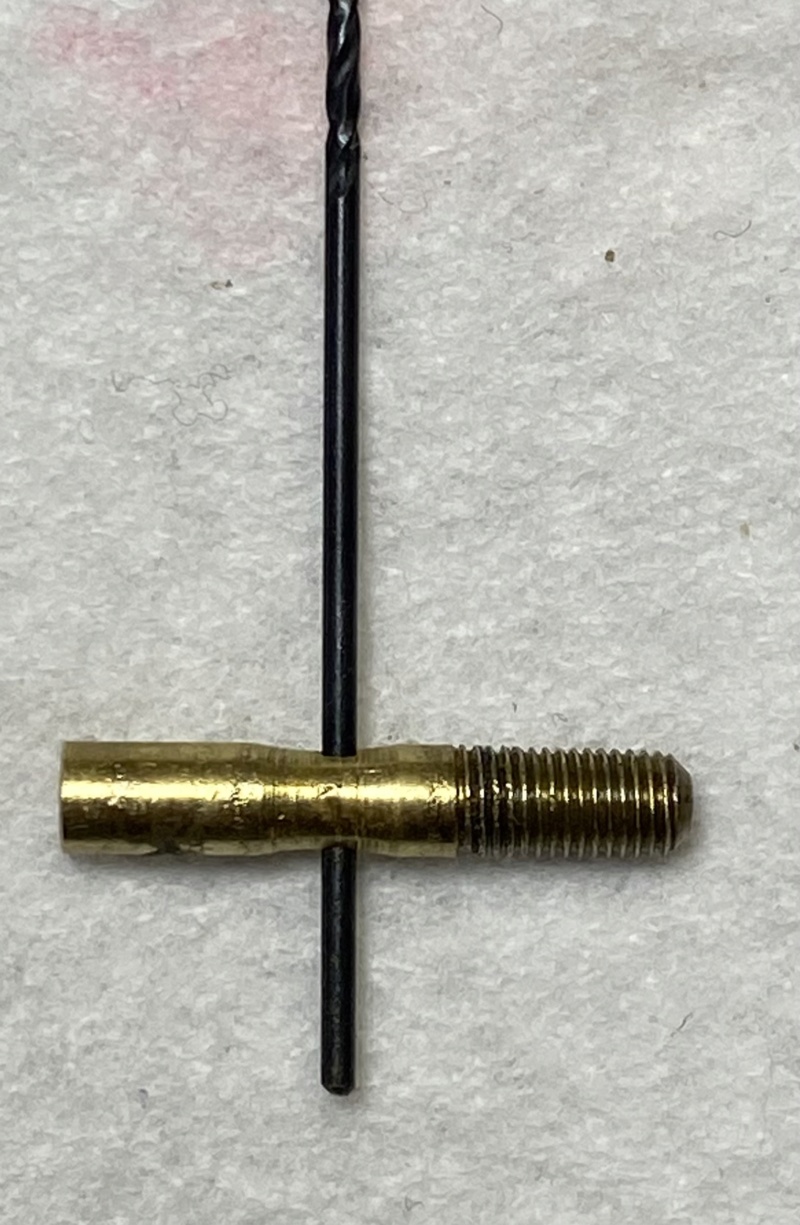

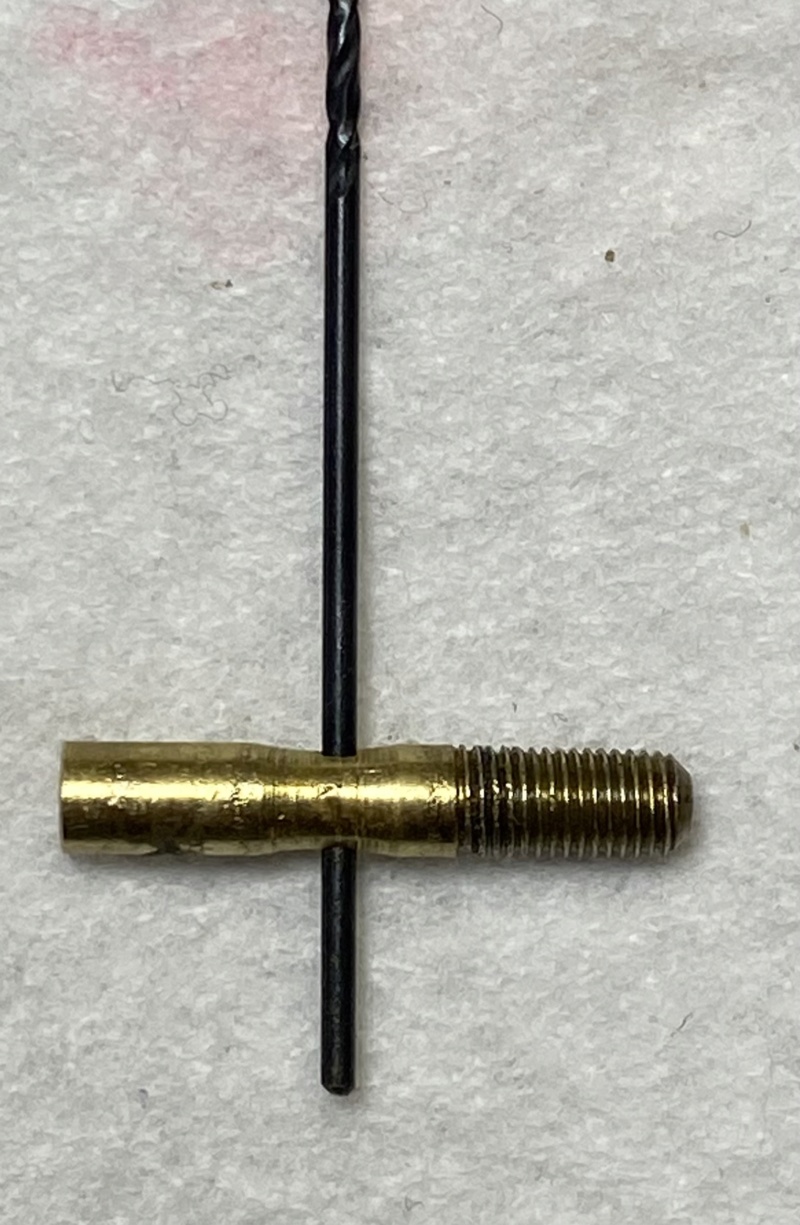

Good catch on spray bar diameter Ken, The photo below shows that it was indeed necked down a little in the center…. The Cox bar is more the diameter of the widest part of the Cub’s….If I would have thought I would of filed the center of the Cox down a little as well….Also a .037 drill thru the Cub’s two ports to show just for grins….The single Cox port is about the same size….

It’s OK if this engine’s not a barn burner….If I build something for it will be just as you mentioned Ken, A schoolyard FF type….. Short runs, Easy life….I also have an anemic

Cub .049 A that runs good…. Also an Atwood Wasp .049 that is next for rehab too…. Some vintage FF type that all these could work on….

When I first disassembled the engine it wasn’t the cylinder that was hard to get off but the cyl/head joint, …. I don’t have the OK ring tool but a wrap of fine emery cloth bedded with leather, heat, The right size pliers, and a light touch finally got it apart…. 9/16 box end on the head…. I probably would have left that joint alone but needed to address the multiple gaskets…. I always orient the rod the same if I take it apart that far….. The shaft spin seems pretty good and the drive plate is being a little fussy to press off so I’ll leave that joint alone…,From here we’ll just run it and keep an eye on the oil….

Good catch on spray bar diameter Ken, The photo below shows that it was indeed necked down a little in the center…. The Cox bar is more the diameter of the widest part of the Cub’s….If I would have thought I would of filed the center of the Cox down a little as well….Also a .037 drill thru the Cub’s two ports to show just for grins….The single Cox port is about the same size….

It’s OK if this engine’s not a barn burner….If I build something for it will be just as you mentioned Ken, A schoolyard FF type….. Short runs, Easy life….I also have an anemic

Cub .049 A that runs good…. Also an Atwood Wasp .049 that is next for rehab too…. Some vintage FF type that all these could work on….

rdw777- Diamond Member

Posts : 1634

Join date : 2021-03-11

Location : West Texas

Re: OK Cub .039

Re: OK Cub .039

Ken, some good pointers about these engines, their ease in being damaged by mishandling, thanks. Even with the Cox tank engines, in my youth, I damaged a number of those by my lack of understanding in repairing them. Only difference was parts then were readily available and cheap.Ken Cook wrote: To remove a cylinder on a OK engine, OK provided a split collar which clamped the cylinder and it had a handle to turn it. These cylinders are very soft and they're also susceptible to distortion when tightened to the case. If possible, insure that the cylinder isn't too tight on the case, just enough to hold it. Otherwise, this causes a lot of low end drag on the piston at the bottom end. I've experienced this with many .049 B's. Never stick any wrenches in a OK exhaust port, it will guarantee a destroyed cylinder. Don't remove a cylinder on a stuck OK engine, insure the piston is going up and down and then remove cylinder. If one removes it prior to freeing it, the rod will twist and snap off. I prefer not to take these engines apart unless absolutely necessary. A good polish on the shaft also tends to yield a bit more rpm's. Insure that the shaft is loose when spun in the case.

I think it may have been @sosam117 that mentioned use of the Enya .049 / .06 NVA as it was narrower and a better fit for some of the other small engines, but those now seem to be as rare as hen's teeth. Those engines are a work of art. The Coxes are more readily available.

I can't help but notice the blunt point on these OK needles. The threaded split collars on those leaked bad, difficult to hold a setting. For this reason is why I liked the Cox NVA's, all of them on Cox engines. You could tweak them one way or the other, and they'd perform, all of them, or at least the ones I have / had.

GallopingGhostler- Top Poster

Posts : 5653

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: OK Cub .039

Re: OK Cub .039

Interesting thread Robert. I read through the whole thing.

Building a plane that fits the engine swaps convention but in this case makes a lot of sense. You have a lot invested in the engine and building a plane to meet it's capabilities would be a fun project.

Building a plane that fits the engine swaps convention but in this case makes a lot of sense. You have a lot invested in the engine and building a plane to meet it's capabilities would be a fun project.

rsv1cox- Top Poster

Posts : 11142

Join date : 2014-08-18

Location : West Virginia

Re: OK Cub .039

Re: OK Cub .039

Thanks Bob, I’ve enjoyed the challenge of getting it to run, And to own and use a little piece of 1/2A history…. Pretty close kin to getting a once popular old car up and running again

Building a plane that fits the engine swaps convention but in this case makes a lot of sense.

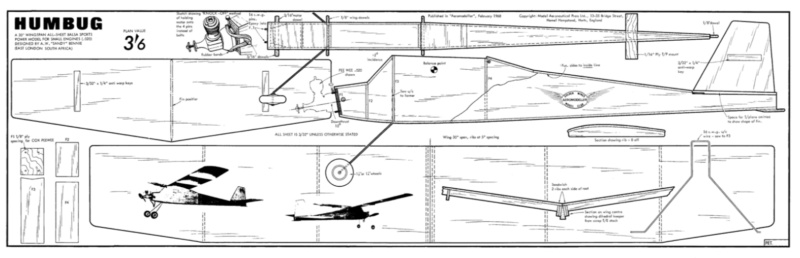

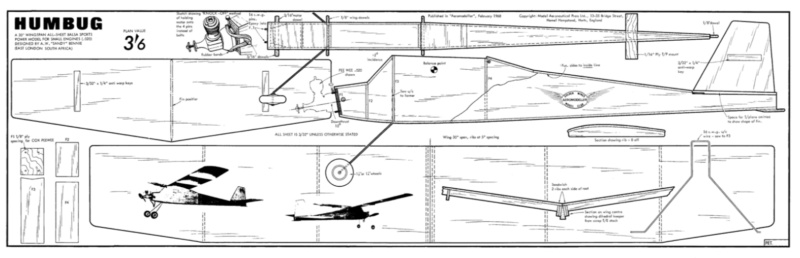

Cutting out parts for “Humbug “ now….I like its all sheet construction (tuff) and simple build…. It has about the same wing area typical to 1950’s sport FF designs ….. Can always use a PeeWee .020 if the Cub rares up LOL!!!

Building a plane that fits the engine swaps convention but in this case makes a lot of sense.

Cutting out parts for “Humbug “ now….I like its all sheet construction (tuff) and simple build…. It has about the same wing area typical to 1950’s sport FF designs ….. Can always use a PeeWee .020 if the Cub rares up LOL!!!

rdw777- Diamond Member

Posts : 1634

Join date : 2021-03-11

Location : West Texas

Re: OK Cub .039

Re: OK Cub .039

I also have an ok it is like new super compression because I have little use because of this problem maybe I should give another chance to serve I found it unfortunate to have such a difficult engine to adjust when it is adjusted it runs well but when I tilt the engine forward it becomes very rich and stall I will modify it I think it could be worth the time to improve this engine

davidll1984- Diamond Member

- Posts : 2322

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: OK Cub .039

Re: OK Cub .039

Thanks for sharing David  …. Hopefully you can get it running well enough to put it too work!…. Just don’t expect a lot of power from it…. Fun to tinker with though

…. Hopefully you can get it running well enough to put it too work!…. Just don’t expect a lot of power from it…. Fun to tinker with though

rdw777- Diamond Member

Posts : 1634

Join date : 2021-03-11

Location : West Texas

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules