Log in

Search

Latest topics

» Fox .35 Modifications by Onelife Today at 8:12 pm

» Jim Walkers FireBee - This is going to be fun

by roddie Today at 6:51 pm

» *Cox Engine of The Month* Submit your pictures! -May 2024-

by Admin Today at 6:46 pm

» Post your Older ignition books

by lla Today at 6:34 pm

» S1 Ringmaster

by Onelife Today at 8:40 am

» Speed plane - Crispy but not too crispy

by rsv1cox Today at 7:54 am

» O&R 23 & Brown Jr

by getback Today at 7:47 am

» Introducing our Cox .049 TD Engines

by MauricioB Today at 2:31 am

» Jim Walker Firebaby

by rdw777 Yesterday at 4:16 pm

» Hemostat clamp/smooth-jaws

by roddie Yesterday at 3:48 pm

» Black Widow Run time

by Ken Cook Yesterday at 3:44 pm

» 1:64 scale Diecast (Hot Wheels)

by roddie Yesterday at 3:33 pm

Cox Engine of The Month

Line Connectors and Lead-Outs

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

Re: Line Connectors and Lead-Outs

Re: Line Connectors and Lead-Outs

Yea I know as soon as I get another order up I am going to get some of the good clips , but I have been using them for a while and not had a failure yet (knock on wood ) I talk to Rog about 2 week ago and he has been very busy and still wanting to get out and fly some more I think I am going to pull some planes off the wall today and start them//may be get in the field tomorrow kindy Hottt today ...... Where is the best place to get the clip ends for 1/2a at anyway since were on the subject ??

getback- Top Poster

Posts : 10127

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: Line Connectors and Lead-Outs

Re: Line Connectors and Lead-Outs

getback wrote:Yea I know as soon as I get another order up I am going to get some of the good clips , but I have been using them for a while and not had a failure yet (knock on wood ) I talk to Rog about 2 week ago and he has been very busy and still wanting to get out and fly some more I think I am going to pull some planes off the wall today and start them//may be get in the field tomorrow kindy Hottt today ...... Where is the best place to get the clip ends for 1/2a at anyway since were on the subject ??

I've had my stock of clips for years.. so I couldn't tell you where to find them. I'd start with Brodak though.

Ken Cook- Top Poster

- Posts : 5461

Join date : 2012-03-27

Location : pennsylvania

Re: Line Connectors and Lead-Outs

Re: Line Connectors and Lead-Outs

Tagged it Thanks Ken , good prices if you don't mine buying in bulk witch I don't . wish they had pics. but that's ok I think I can figure it out when the time comes . Eric

getback- Top Poster

Posts : 10127

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: Line Connectors and Lead-Outs

Re: Line Connectors and Lead-Outs

Eric, the knots taught to Scouts have the characteristics of...easy to tie, easy to untie, and does the job. The easy to untie part makes them not good for leadouts. I have been teaching scouts those knots for 34 years (so far).

Most use the Palomar knot on leaouts. There are many drawings and videos on the Palomar knot. Easy to learn...good luck.

George

Most use the Palomar knot on leaouts. There are many drawings and videos on the Palomar knot. Easy to learn...good luck.

George

gcb- Platinum Member

- Posts : 908

Join date : 2011-08-11

Location : Port Ewen, NY

Re: Line Connectors and Lead-Outs

Re: Line Connectors and Lead-Outs

getback wrote:Tagged it Thanks Ken , good prices if you don't mine buying in bulk witch I don't . wish they had pics. but that's ok I think I can figure it out when the time comes . Eric

I'm wondering how small a clip can be made with the tool that Rusty posted a pic of. Is there a demo-vid on it somewhere? One of Windy U.'s maybe?

My smallest "Luxon" clips are made from larger diameter wire than I would have thought.

Here's a package that I bought from a vendor at the 92 Nat's in Springfield, MA.

Who knows.. maybe they're still in business..

Here's some knot photos that might help.

Re: Line Connectors and Lead-Outs

Re: Line Connectors and Lead-Outs

Well that's a lot better than the uni-knot I have been tieing , I found this , Thanks George I can work with that should put the mark dead on when finished . Ericgcb wrote:Eric, the knots taught to Scouts have the characteristics of...easy to tie, easy to untie, and does the job. The easy to untie part makes them not good for leadouts. I have been teaching scouts those knots for 34 years (so far).

Most use the Palomar knot on leaouts. There are many drawings and videos on the Palomar knot. Easy to learn...good luck.

George

getback- Top Poster

Posts : 10127

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: Line Connectors and Lead-Outs

Re: Line Connectors and Lead-Outs

Unless Rusty will tell us I guess if you want one that bad you will have to make itRknRusty wrote:Roddie, it's not unusual for 1/2A builders to stagger leadouts, and it doesn't appear to induce any flyability issues. It's a good idea for keeping them from hooking each other. I personally don't do it because I have never had a snagging problem with proper clips. I like the Luxon type. I hate the squeeze type on the right because I have trouble hooking them up to lines with thimbles. I like the bent steel type that work like the squeeze clips but are shaped more like paper clips.

They can be made with a simple bending tool. This one is for 1/16" length adjustments that the expert stunters use with the hard point handles. Easy to make out of a .75"-16tpi bolt

Eric

Eric

getback- Top Poster

Posts : 10127

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: Line Connectors and Lead-Outs

Re: Line Connectors and Lead-Outs

getback wrote:Unless Rusty will tell us I guess if you want one that bad you will have to make itRknRusty wrote:Roddie, it's not unusual for 1/2A builders to stagger leadouts, and it doesn't appear to induce any flyability issues. It's a good idea for keeping them from hooking each other. I personally don't do it because I have never had a snagging problem with proper clips. I like the Luxon type. I hate the squeeze type on the right because I have trouble hooking them up to lines with thimbles. I like the bent steel type that work like the squeeze clips but are shaped more like paper clips.

They can be made with a simple bending tool. This one is for 1/16" length adjustments that the expert stunters use with the hard point handles. Easy to make out of a .75"-16tpi boltI cant find it any were other than images and if you visit the page it bring you back here

Eric

Lee Machine Shop. There's a link to his email here:

http://stunthanger.com/smf/index.php/topic,6425.0.html

I bought mine from Jim Lee at the last VSC. I haven't used it yet but I have a bunch of clips a friend of mine bent up on his.

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 56

Location : Colorado

Re: Line Connectors and Lead-Outs

Re: Line Connectors and Lead-Outs

Oh, sorry, I left out that part. Jim Lee makes and sells all sorts of cool tools.

I've seen the clip bender work. If I recall correctly, you lay the steel wire across the two posts on the bolt ends, slip the bending bar onto one of them and pull the wire around to shape it. I'd have to fiddle with it to get it. But to make clips in 1/16" increments, one turn of the 16 tpi bolt = you guessed it, 1/16".

Rusty

I've seen the clip bender work. If I recall correctly, you lay the steel wire across the two posts on the bolt ends, slip the bending bar onto one of them and pull the wire around to shape it. I'd have to fiddle with it to get it. But to make clips in 1/16" increments, one turn of the 16 tpi bolt = you guessed it, 1/16".

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Line Connectors and Lead-Outs

Re: Line Connectors and Lead-Outs

RknRusty wrote:Oh, sorry, I left out that part. Jim Lee makes and sells all sorts of cool tools.

I've seen the clip bender work. If I recall correctly, you lay the steel wire across the two posts on the bolt ends, slip the bending bar onto one of them and pull the wire around to shape it. I'd have to fiddle with it to get it. But to make clips in 1/16" increments, one turn of the 16 tpi bolt = you guessed it, 1/16".

Rusty

So I guess you could make small clips by turning-in the nut to the length required? Can multiple size wire be used? I'm thinking there must be a hole to receive an "L-bend" to keep the wire from slipping? Sorry for the questions..

Re: Line Connectors and Lead-Outs

Re: Line Connectors and Lead-Outs

WOW Nice but pricy !! I am like roddie would like to try it but would have to make my own /// I can buy a lot of clips for that price and don't use the hard tail handle ( not saying it s not worth it but not to me ) am sure it is of good quality . Thanks Guys . Eric

getback- Top Poster

Posts : 10127

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: Line Connectors and Lead-Outs

Re: Line Connectors and Lead-Outs

Next time I'm at Wayne's, I'll get some detail pictures. Or in H'ville next month if Jim is there.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Line Connectors and Lead-Outs

Re: Line Connectors and Lead-Outs

The Bear model products is gone. Owner was Bob Bearden and he has left us for the circle up in the sky. In the last year of his life he sent me some nice stuff and would not let me pay him. I said that after he was gone I would pay his wife. He threatened to come back and haunt me if I did that. I sent her some money and told her the story and hoped that he would actually haunt me but alas he never showed up. Real nice man that left us too soon!

faif2d- Bronze Member

- Posts : 30

Join date : 2014-09-08

Location : texas

Re: Line Connectors and Lead-Outs

Re: Line Connectors and Lead-Outs

Thanks for bringing that to our attention faif2d , Its always a shame to hear a fellow modeler leave us , its a good thing we have new / young blood getting into the hobby  gatback

gatback

gatback

gatback

getback- Top Poster

Posts : 10127

Join date : 2013-01-18

Age : 66

Location : julian , NC

solid-wire lead-outs

solid-wire lead-outs

faif2d wrote:The Bear model products is gone. Owner was Bob Bearden and he has left us for the circle up in the sky. In the last year of his life he sent me some nice stuff and would not let me pay him. I said that after he was gone I would pay his wife. He threatened to come back and haunt me if I did that. I sent her some money and told her the story and hoped that he would actually haunt me but alas he never showed up. Real nice man that left us too soon!

I wanted to bump this thread.. especially after reading this post. R.I.P. Mr. Bearden.

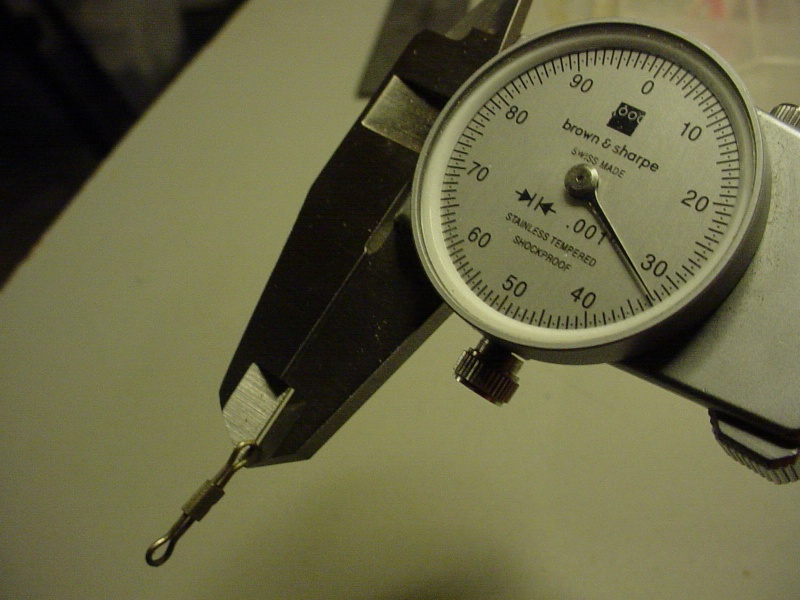

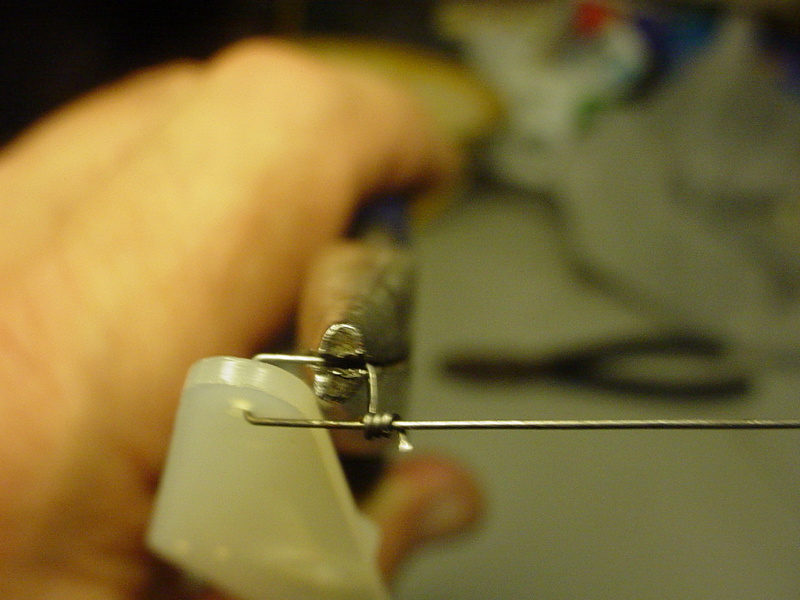

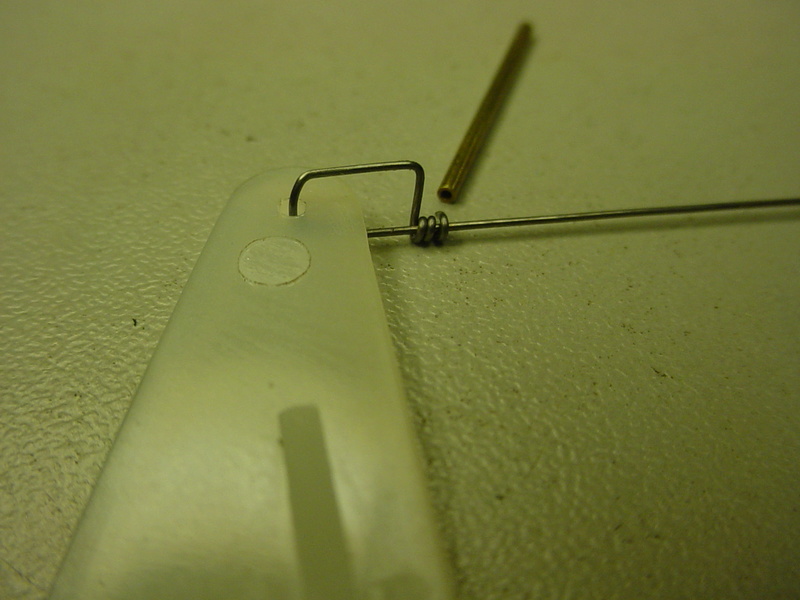

This afternoon I decided to make-up some .015" solid-wire lead-outs for a Sig 1/2A nylon bell-crank to be installed in a little flying wing powered by a Cox .049 product-engine..

I bought this tube of K & S .015" wire many years ago.. knowing that I would use some of it to make solid lead-outs for small airplanes.

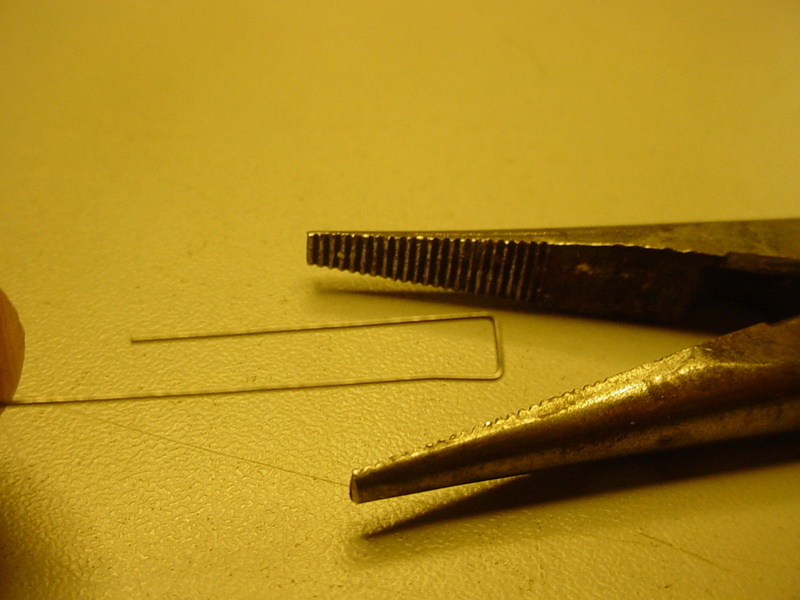

This requires having the wire, good-quality needle-nose pliers and a little patience.. (be careful with your eyes.. safety-glasses prevent accidents..) ALSO.. be mindful of any exposed electrical-outlets nearby.. or you could inadvertently do some welding..

My Sig 1/2A Nylon bell-crank came molded with the bearing and elevator-horn parts attached.. needing to be trimmed-off. A #11 blade/handle makes short-work of that.

Start your first 90-degree bend about 1" (25mm) from the end of the wire.. and make the 2nd bend with the "tip" of your pliers.. to form a tight "U"-bend..

... then thread the wire through your bell-crank's lead-out-hole. Again.. using the nose of your pliers as a "spacer" between the bellcrank.. grab the short wire and hold it with the pliers. Using your "fingers".. bend the short wire 90 degrees to form a "box".. and wrap the wire two or three time around. (I'm sorry for the lack of photos showing this..) You want the "boxed-section" to have a non-binding clearance for the bell-crank arms when they move to their extreme positions.

The below photo shows a piece of very small brass tubing that can help to wind the wire tightly against itself for a nice tight coil.. and is easier on the fingers.

If you don't get it quite right the 1st few times.. the .015" wire can be easily snipped-off with standard wire-cutters for giving it another try.

"Solids" are old-school cool

Page 2 of 2 •  1, 2

1, 2

Similar topics

Similar topics» Ebay Ringmaster Resto (finishing pics!)

» Another proposed design by Roddie

» P-38 Lightning-Roddie style..

» Wingtip lead-outs...should have done this sooner.

» Making lines...not lead outs. Bring in your favorite methods!

» Another proposed design by Roddie

» P-38 Lightning-Roddie style..

» Wingtip lead-outs...should have done this sooner.

» Making lines...not lead outs. Bring in your favorite methods!

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules