Log in

Search

Latest topics

» Project Cox .049 r/c & Citabrian Championby MauricioB Today at 4:08 pm

» Fox .35 Modifications

by GallopingGhostler Today at 3:58 pm

» Jim Walkers FireBee - This is going to be fun

by rsv1cox Today at 3:56 pm

» Happy Anzac Day!

by GallopingGhostler Today at 12:44 pm

» Revivng Some Childhood Classics

by rsv1cox Today at 7:17 am

» Introducing our Cox .049 TD Engines

by getback Today at 6:20 am

» Roddie's flat-bottomed boat..

by Levent Suberk Today at 12:23 am

» Cox powered jet-pump for model Sprint Boat

by roddie Yesterday at 10:25 pm

» Micro Draco Gets to Fly on a Beautiful Morning.

by rdw777 Yesterday at 8:15 pm

» Jim Walker Firebaby

by rdw777 Yesterday at 8:06 pm

» Hydro-bat by Vic Smeed: engine probs

by GallopingGhostler Yesterday at 5:12 pm

» Roddie-Rigger.. a 2005 original design

by roddie Yesterday at 3:39 pm

Cox Engine of The Month

still spinning my wheels..

Page 1 of 1

still spinning my wheels..

still spinning my wheels..

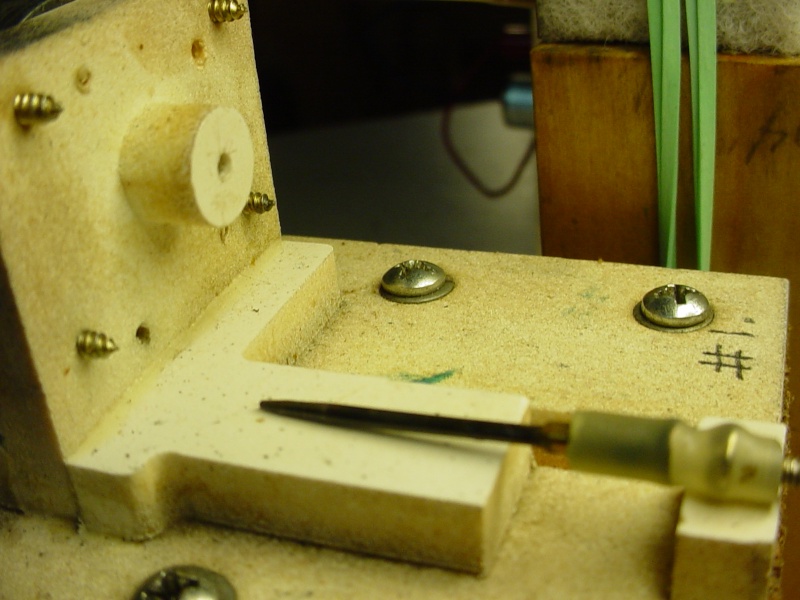

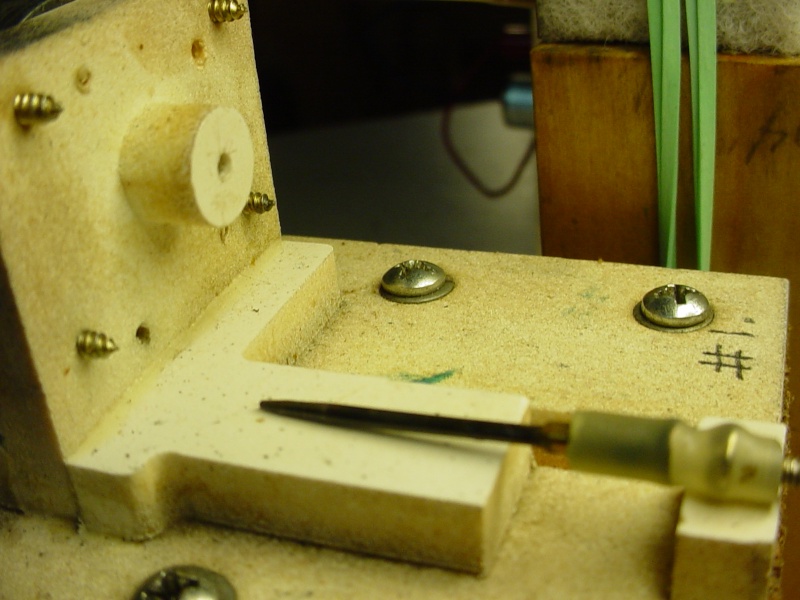

Literally and figuratively. I actually tried to bench-run an engine today in my workshop. It was an experiment that I could have prepared better for.. but I didn't want to tear down a Babe Bee. I had one RTR with a needed hex drive-plate for my "flywheel encased cam-style starter-spring" test . The back-plate screen already removed for testing the Ace venturi throttle with the flywheel. This arrangement is being tested for a marine application running a 1" surface-prop.

I mounted the starter-spring and cam then fitted the hollowed-out PVC custom-made flywheel using a 5-40 stud/spinner-hub and custom 3/4" x .080" thick aluminum washer-plate. Mounted the engine on a custom PVC fixture having a guide for the venturi-plunger/needle (Ace design.. the same one used in my throttle vid). Dug out a "Sandblaster" heat-sink (Cox P/N 1970) and tighten it on.

This Bee like a few others I have, has been fitted with an external fuel pick-up. I have used the little 1oz. Sullivan clunk-tanks with success on the bench.. but today I opted for one the small tin speed tanks that I built.

As usual.. I'm thinking way outside the box.. I fuel-up through the uniflow-vent with the needle open until fuel flowed through the line to the engine. Good.. maybe it will start without an exhaust prime? I connect my Cox glow-clip coming from the glow-driver in my power-panel. I proceed to wind-back the flywheel and release.. repeat.. repeat.. Nope.. exhaust-prime needed. Fires off the prime.. Good! Several repeats of this process until she started to draw fuel.. but wouldn't run long enough to get a decent needle-setting. Starting was hard.. and I found that the only way to get fuel out of the tank was to choke the venturi with the "Ace" needle.. which did work.. but I'd only get "pops" because of the lack of air.

I fuel-up through the uniflow-vent with the needle open until fuel flowed through the line to the engine. Good.. maybe it will start without an exhaust prime? I connect my Cox glow-clip coming from the glow-driver in my power-panel. I proceed to wind-back the flywheel and release.. repeat.. repeat.. Nope.. exhaust-prime needed. Fires off the prime.. Good! Several repeats of this process until she started to draw fuel.. but wouldn't run long enough to get a decent needle-setting. Starting was hard.. and I found that the only way to get fuel out of the tank was to choke the venturi with the "Ace" needle.. which did work.. but I'd only get "pops" because of the lack of air.

One thing that concerned me was over-revving the engine... so most of the cranking was done with a very rich needle.. and the Ace plunger inserted into the guide. The tank is suspect.. because it hasn't seen much testing. I didn't want to use a lot of fuel if I didn't have to.. being indoors. Just a "thimble's worth" basically. I tried uni-flow-only vent.. then opened-up the fill-vent which seemed to improve starting.. but not draw. I also didn't have much time before my wife got home..

I did confirm that the custom flywheel; wound-back using fingers-thumb isn't a great method for starting the engine.. (not a cold one anyway) It also requires mounting the engine a little higher in the hull for clearance.. as compared to a Dumas flywheel.

My intention was to avoid needing a belt to start the engine.. and possibly achieve a higher throttled rpm than I might when using the heavy Dumas-style flywheel which is designed for w.o.t. operation.

I made smaller PVC flywheels that fit back-over the round drive-plate, that could be used with a friction-wheel electric-starter.

These may need to be weighted for inertia.. but I may have that covered in the way of the alum. fender-washers that I made.

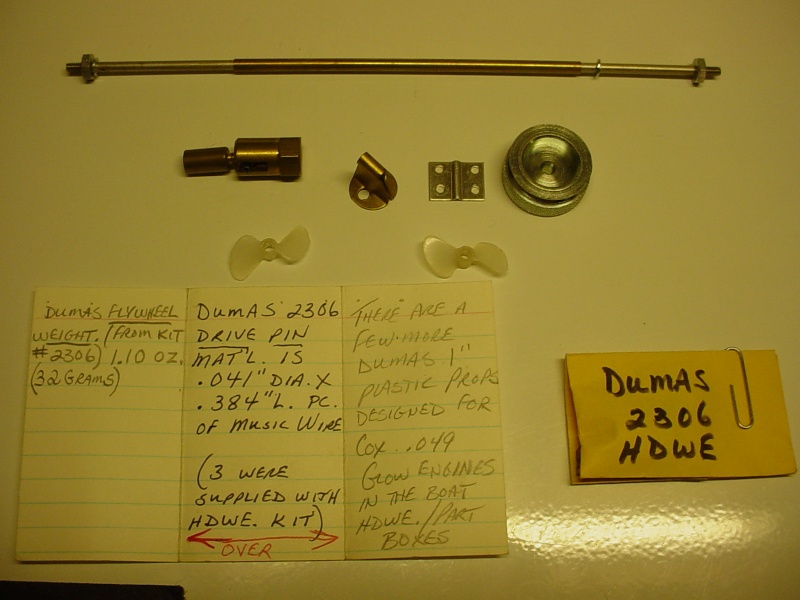

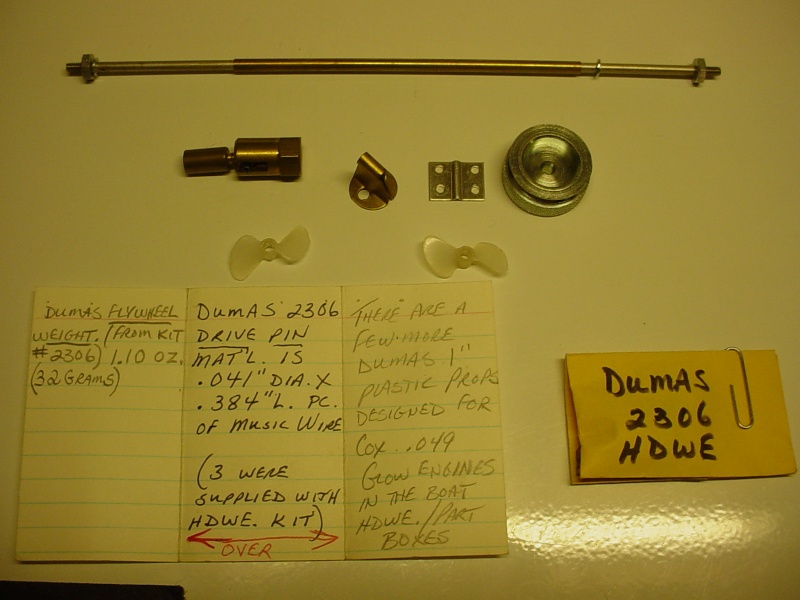

The Dumas boat kits designed for the Cox .049 recommend their 1" plastic "submerged-style" prop, flywheel and running hardware.

Some parts not shown here..

I did a search for 1" dia. "surface-drive" props.. and came up with replacement props and drive for the Aqua-craft "Reef-Racer" boat which is sold by Tower Hobbies. It's a 15"L. x 5.3" beam model.

The prop is a 1"D x 1.58"P nylon with drive-dog threaded for a 3mm solid-steel shaft.

Set of two replacement props.. $5.00

Shaft and stuffing-tube.. $10.00

I looked at a variety of couplers.. and should be able to make a surface drive for my rigger.. without needing to build a strut for the transom. I have a couple of Graupner rudders that should mount over the shaft exit-point.. and extend far enough back to clear the prop. If not I can make an extension-block.

This is that rudder. I like the design in that it will pivot "up" if it strikes an object floating in the water.. and also can be "tamed" as far as the authority in which it applies it's force in turning.

This boat (Dumas "Short Stuff") flipped on it's maiden with the rudder in the position shown. Tilting it back on subsequent tests prevented this. By tilting-back to around 45 degrees.. I could carve deep turns at full-throttle without flipping it. There will be a different turning dynamic with an out-rigger as compared to a Vee-hull though.

It's going to take more time than I put in today to get the engine running "out of the water"... but it's a start.

I mounted the starter-spring and cam then fitted the hollowed-out PVC custom-made flywheel using a 5-40 stud/spinner-hub and custom 3/4" x .080" thick aluminum washer-plate. Mounted the engine on a custom PVC fixture having a guide for the venturi-plunger/needle (Ace design.. the same one used in my throttle vid). Dug out a "Sandblaster" heat-sink (Cox P/N 1970) and tighten it on.

This Bee like a few others I have, has been fitted with an external fuel pick-up. I have used the little 1oz. Sullivan clunk-tanks with success on the bench.. but today I opted for one the small tin speed tanks that I built.

As usual.. I'm thinking way outside the box..

One thing that concerned me was over-revving the engine... so most of the cranking was done with a very rich needle.. and the Ace plunger inserted into the guide. The tank is suspect.. because it hasn't seen much testing. I didn't want to use a lot of fuel if I didn't have to.. being indoors. Just a "thimble's worth" basically. I tried uni-flow-only vent.. then opened-up the fill-vent which seemed to improve starting.. but not draw. I also didn't have much time before my wife got home..

I did confirm that the custom flywheel; wound-back using fingers-thumb isn't a great method for starting the engine.. (not a cold one anyway) It also requires mounting the engine a little higher in the hull for clearance.. as compared to a Dumas flywheel.

My intention was to avoid needing a belt to start the engine.. and possibly achieve a higher throttled rpm than I might when using the heavy Dumas-style flywheel which is designed for w.o.t. operation.

I made smaller PVC flywheels that fit back-over the round drive-plate, that could be used with a friction-wheel electric-starter.

These may need to be weighted for inertia.. but I may have that covered in the way of the alum. fender-washers that I made.

The Dumas boat kits designed for the Cox .049 recommend their 1" plastic "submerged-style" prop, flywheel and running hardware.

Some parts not shown here..

I did a search for 1" dia. "surface-drive" props.. and came up with replacement props and drive for the Aqua-craft "Reef-Racer" boat which is sold by Tower Hobbies. It's a 15"L. x 5.3" beam model.

The prop is a 1"D x 1.58"P nylon with drive-dog threaded for a 3mm solid-steel shaft.

Set of two replacement props.. $5.00

Shaft and stuffing-tube.. $10.00

I looked at a variety of couplers.. and should be able to make a surface drive for my rigger.. without needing to build a strut for the transom. I have a couple of Graupner rudders that should mount over the shaft exit-point.. and extend far enough back to clear the prop. If not I can make an extension-block.

This is that rudder. I like the design in that it will pivot "up" if it strikes an object floating in the water.. and also can be "tamed" as far as the authority in which it applies it's force in turning.

This boat (Dumas "Short Stuff") flipped on it's maiden with the rudder in the position shown. Tilting it back on subsequent tests prevented this. By tilting-back to around 45 degrees.. I could carve deep turns at full-throttle without flipping it. There will be a different turning dynamic with an out-rigger as compared to a Vee-hull though.

It's going to take more time than I put in today to get the engine running "out of the water"... but it's a start.

Re: still spinning my wheels..

Re: still spinning my wheels..

Wow...that is some process! Hope it works out for you!

Engineering-Challenged Kim

Engineering-Challenged Kim

Kim- Top Poster

Posts : 8528

Join date : 2011-09-06

Location : South East Missouri

1/2A Nut- Top Poster

- Posts : 3426

Join date : 2013-10-20

Age : 60

Location : Brad in Texas

Re: still spinning my wheels..

Re: still spinning my wheels..

Way cool, I understand very little about what you are doing, but the video at the end explains the direction you are going.

Hopefully it doesn't end with a German explative!

Hopefully it doesn't end with a German explative!

Cribbs74- Moderator

Posts : 11895

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: still spinning my wheels..

Re: still spinning my wheels..

Lol if you have learned anything you have at least learned a German word: Scheisse

1/2A Nut- Top Poster

- Posts : 3426

Join date : 2013-10-20

Age : 60

Location : Brad in Texas

Re: still spinning my wheels..

Re: still spinning my wheels..

Scheisse...Ha! ... German Ich verstehen! ( not sure I can spell it all well anymore though!?). A surface prop? Kinda inefficient aren't they? My boat experience is all full size stuff only though.

OhBee- Platinum Member

- Posts : 698

Join date : 2016-03-23

Age : 73

Location : Minnesota

Re: still spinning my wheels..

Re: still spinning my wheels..

I think it means "the experiment did not quite go accorcing to the plan".

KariFS- Diamond Member

- Posts : 2002

Join date : 2014-10-10

Age : 52

Re: still spinning my wheels..

Re: still spinning my wheels..

KariFS wrote:I think it means "the experiment did not quite go accorcing to the plan".

I thought it meant, "Aw shucks!".

George

gcb- Platinum Member

- Posts : 908

Join date : 2011-08-11

Location : Port Ewen, NY

Re: still spinning my wheels..

Re: still spinning my wheels..

Surface prop setups are the best for speed and helps keep the load off the engine.

I have built 5 different cox powered boats 3 of them outriggers so far many many runs, worn out two TD .049s

and 2 Queen Bee's by the 2nd Queen Bee the set up was pristine and there was no adverse wear

on the aluminum crank case. Centering the flywheel is very important, there is a bit of a over bore

in the Dumas steel wheel and requires shimming with CA glue on the axle to tighten the fit.

Water cooling the steel cylinder and head with aluminum tube works very well. Cooling is a must

with a good set up you will unload the prop and turn up some screaming rpm's.

The Dumas nylon props are meant for submerged drive there is no ramping on the trailing edge for

prop lift. Back in the day you could get the alternate Dumas 1/2A beryllium props and mod them for surface

drive. I talked to the owner of Dumas about 7 yrs ago they had the molds but had no plans to cast more props

in metal. Today you can take a Octura X427 reshape it down, cut the tonque's off or ears to increase

speed star tip or Texas cut and of course sharpen the blade for better performance. That prop will lift

and make a great surface prop. There are many replacement props made with glass/ plastic for the small

micro class boats that are setup for surface drive. I have some micro props from Horizon Hobby that

was meant for a 14" mono that works well.

I have built 5 different cox powered boats 3 of them outriggers so far many many runs, worn out two TD .049s

and 2 Queen Bee's by the 2nd Queen Bee the set up was pristine and there was no adverse wear

on the aluminum crank case. Centering the flywheel is very important, there is a bit of a over bore

in the Dumas steel wheel and requires shimming with CA glue on the axle to tighten the fit.

Water cooling the steel cylinder and head with aluminum tube works very well. Cooling is a must

with a good set up you will unload the prop and turn up some screaming rpm's.

The Dumas nylon props are meant for submerged drive there is no ramping on the trailing edge for

prop lift. Back in the day you could get the alternate Dumas 1/2A beryllium props and mod them for surface

drive. I talked to the owner of Dumas about 7 yrs ago they had the molds but had no plans to cast more props

in metal. Today you can take a Octura X427 reshape it down, cut the tonque's off or ears to increase

speed star tip or Texas cut and of course sharpen the blade for better performance. That prop will lift

and make a great surface prop. There are many replacement props made with glass/ plastic for the small

micro class boats that are setup for surface drive. I have some micro props from Horizon Hobby that

was meant for a 14" mono that works well.

1/2A Nut- Top Poster

- Posts : 3426

Join date : 2013-10-20

Age : 60

Location : Brad in Texas

Re: still spinning my wheels..

Re: still spinning my wheels..

Way to go Roddie !! if that's the same bee you did in the test of the Ace throttle it probably needs a cleaning ? I like the thought of using that in a boat of your own design I will bee watching and pushing you on to the pond ...Sorry the pull back starter didn't work out but am sure you can get it figured to do right, I had an engine with the brass pulley setup on it but sold it , may have another would have to look let me know if you need one! Eric

getback- Top Poster

Posts : 10114

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: still spinning my wheels..

Re: still spinning my wheels..

getback wrote:Way to go Roddie !! if that's the same bee you did in the test of the Ace throttle it probably needs a cleaning ? I like the thought of using that in a boat of your own design I will bee watching and pushing you on to the pond ...Sorry the pull back starter didn't work out but am sure you can get it figured to do right, I had an engine with the brass pulley setup on it but sold it , may have another would have to look let me know if you need one! Eric

Thanks for the offer Eric.. but I do have the Dumas flywheel that come with their hardware kit. I'm a little leery now from what Brad (1/2Anut) said about them being over-bored and needing to be centered. Being a curious person.. I checked the size of the hub-hole on my Dumas flywheel using my #size drills. The #30 (.1285") drill was the size that fit. A 5-40 machine-screw (Cox .049 prop-screw size) threaded-diameter measures between .120/.122" and the un-threaded portion of a stub-shaft is probably .125". If so; that would account for around .0015" of float inside the hub. This doesn't seem like much.. but apparently it may be enough to cause an imbalance.. along with any other possible imbalances in the flywheel overall. It is "knurled" for a friction-wheel's contact surface. It would be interesting to throw one on a precision prop-balancer. At 1+ ounce in weight.. it's not something that you want to have way-out of balance, spinning on the end of your crankshaft.. even if the stuffing-tube is well-supported close to it.

My PVC flywheels were completely machined using a .125" diameter end-mill on a CNC router.. so the hub-holes were "drilled-through" using that tool. I just don't know whether they're going to be too light in weight for tuning the throttled engine. I did get a short few seconds run in yesterday with throttle-response, so I'm feeling positive about it.

Re: still spinning my wheels..

Re: still spinning my wheels..

With a throttle the flywheel helps keep some load on the engine when putting back to the shore.

If submerged drive you can throttle about at all speed ranges, same for semi submerged.

A light toss on launch pops them up on plane fast if surface drive / outrigger. If the weight of the flywheel

has it sitting on the shaft when it is tighten down then you get the full gap on one side enough to scrub off peak rpm.

Also over time the aluminum crank case will waller out.

If submerged drive you can throttle about at all speed ranges, same for semi submerged.

A light toss on launch pops them up on plane fast if surface drive / outrigger. If the weight of the flywheel

has it sitting on the shaft when it is tighten down then you get the full gap on one side enough to scrub off peak rpm.

Also over time the aluminum crank case will waller out.

1/2A Nut- Top Poster

- Posts : 3426

Join date : 2013-10-20

Age : 60

Location : Brad in Texas

Re: still spinning my wheels..

Re: still spinning my wheels..

You think a piece of hose would square it up so to run true ?? The out of round .0015 is quite a bit for a 1 oz. weight, getback

getback- Top Poster

Posts : 10114

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: still spinning my wheels..

Re: still spinning my wheels..

getback wrote:You think a piece of hose would square it up so to run true ?? The out of round .0015 is quite a bit for a 1 oz. weight, getback

Actually Eric.. .0015" is quite small.. (one and a half thousandths) and no tubing that I know of would have a wall that thin. Possibly a piece of very thin plastic (mylar gage-stock) could be used in the assembly to assure it being on-center.

Again.. being who I am.. I thought about what "anyone" might have around the house for use as "gage-stock".. and peeled the window out of a mail envelope.

I wonder if fitting a rubber-ring to a flywheel would act as a harmonic-balancer?

Similar topics

Similar topics» Spinning an aluminum cowling

» Four .049 engine powered tether racer?

» Spinning nasty glowheads with sandpaper.

» Fashion model walks into spinning propellor

» (Wanted) Carl Goldberg 1/2A wheels

» Four .049 engine powered tether racer?

» Spinning nasty glowheads with sandpaper.

» Fashion model walks into spinning propellor

» (Wanted) Carl Goldberg 1/2A wheels

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules