Log in

Search

Latest topics

» Jim Walkers FireBee - This is going to be funby rsv1cox Today at 12:27 pm

» Three -- sold out (making two more) Cox .010 Carburetors with wrench

by balogh Today at 11:51 am

» Roddie's flat-bottomed boat..

by roddie Today at 10:11 am

» Project Cox .049 r/c & Citabrian Champion

by rdw777 Today at 8:14 am

» Revivng Some Childhood Classics

by getback Today at 7:31 am

» Fox .35 Modifications

by Ken Cook Today at 3:16 am

» Happy Anzac Day!

by Boats13 Yesterday at 11:03 pm

» Introducing our Cox .049 TD Engines

by getback Yesterday at 6:20 am

» Cox powered jet-pump for model Sprint Boat

by roddie Thu Apr 25, 2024 10:25 pm

» Micro Draco Gets to Fly on a Beautiful Morning.

by rdw777 Thu Apr 25, 2024 8:15 pm

» Jim Walker Firebaby

by rdw777 Thu Apr 25, 2024 8:06 pm

» Hydro-bat by Vic Smeed: engine probs

by GallopingGhostler Thu Apr 25, 2024 5:12 pm

Cox Engine of The Month

Making a Stunt Tank

Page 1 of 1

ebeneezer- Gold Member

- Posts : 282

Join date : 2012-05-22

Age : 66

Location : Banbury Oxfordshire England

Re: Making a Stunt Tank

Re: Making a Stunt Tank

Make one in paper or card stock first.

If you can have fewer pieces and a couple more bends you might have better results.

You need a small tool for bending careful bends. This can be made from common cold-roll steel and a couple nuts and bolts. I have been using a pair of sheet metal pliers.

Use a sharpened nail of the proper diameter to make the fuel line holes. The bend/flare of using a punch will provide more surface to solder too vs drilling.

You can use a clamp or vise to hold the ends tight to the tank body for soldering. Finer joints require less solder to become leak free.

Clean, sand and flux everything.

Tinplate is another good choice of material.

Good pics here

http://www.modelflying.co.uk/forums/postings.asp?th=66985&p=1

Another diagram near the bottom of the page

http://www.aeromaniacs.com/Tips.html

I have been experimenting with recycled tinplate from an olive oil can. My results have been less than stellar with less than half my tanks even sealing up.

Phil

If you can have fewer pieces and a couple more bends you might have better results.

You need a small tool for bending careful bends. This can be made from common cold-roll steel and a couple nuts and bolts. I have been using a pair of sheet metal pliers.

Use a sharpened nail of the proper diameter to make the fuel line holes. The bend/flare of using a punch will provide more surface to solder too vs drilling.

You can use a clamp or vise to hold the ends tight to the tank body for soldering. Finer joints require less solder to become leak free.

Clean, sand and flux everything.

Tinplate is another good choice of material.

Good pics here

http://www.modelflying.co.uk/forums/postings.asp?th=66985&p=1

Another diagram near the bottom of the page

http://www.aeromaniacs.com/Tips.html

I have been experimenting with recycled tinplate from an olive oil can. My results have been less than stellar with less than half my tanks even sealing up.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Making a Stunt Tank

Re: Making a Stunt Tank

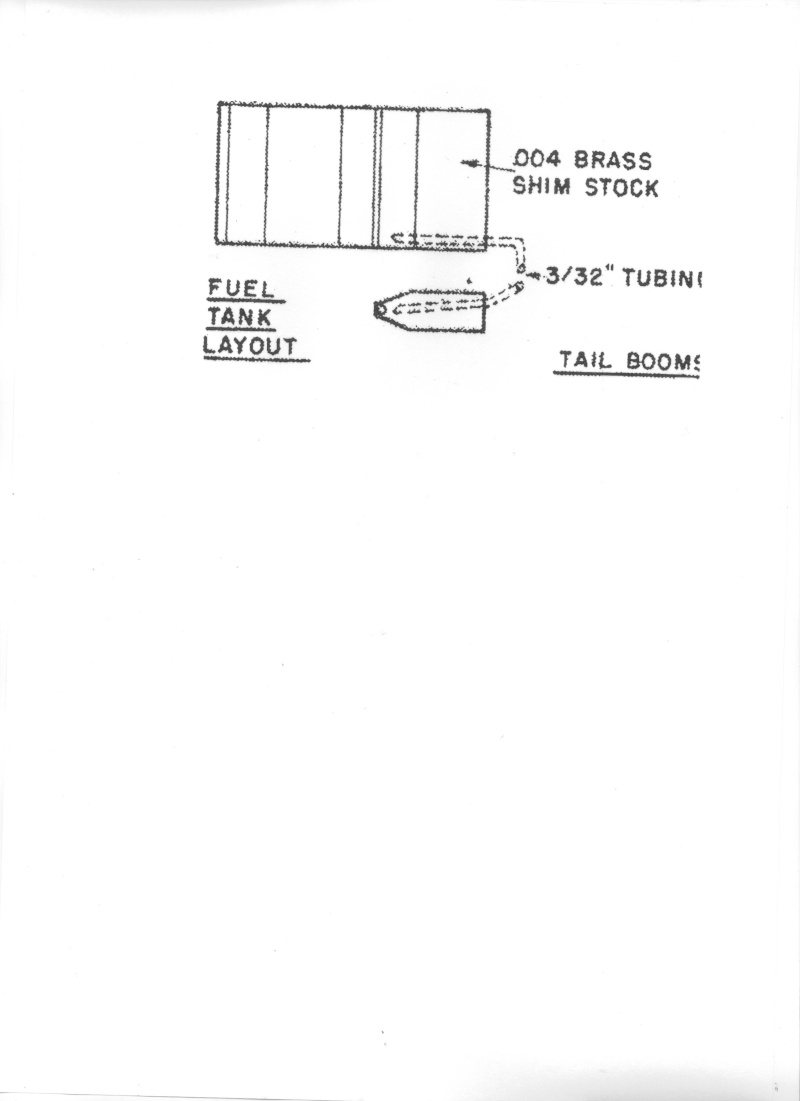

Your diagram shows brass shim stock. In my opinion, that would be a very poor choice of material to use. I wouldn't use brass tubing either. Brass and our fuel don't get along well and the green death will overcome. Brass work hardens and splits. Brass shim stock is strained one direction and will inherently split if bent improperly. Brass tubing isn't seamless and once again it will split. Copper tubing is not as prone to this problem. If you use clean tinplate, like the type that's found on a laquer thinner can, it will work far superior. In addition to that, I wouldn't sand tinplate with abrasives prior to soldering. Using a wire wheel or Scotch-Brite pads yield far better results and will also prevent the plating from being removed. The plating is your only defense in preventing corrosion which will readily happen unless you remove all of the flux. I do this with a laquer thinner followed by a soaking of high percentage castor fuel for at least 24 hours. I like to use 60/40 rosin core and Nokorode paste flux. Be certain to solder the pickup at the rear of the tank or it will act like a tuning fork inside and will once again fail. If possible, solder your filler pipes inside as well. When complete pressure test after cleaning all the flux off of the exterior of the tank and try and fill it up with a syringe like your trying to pop it. Ken

Ken Cook- Top Poster

- Posts : 5451

Join date : 2012-03-27

Location : pennsylvania

Re: Making a Stunt Tank

Re: Making a Stunt Tank

Thanks guys, after some research I've decided to buy a tank from Cox International. It's seems quite envolved to make a good stunt tank. Maybe oneday.

ebeneezer- Gold Member

- Posts : 282

Join date : 2012-05-22

Age : 66

Location : Banbury Oxfordshire England

Similar topics

Similar topics» Video: Making a pressureless bladder tank and using it to fuel my Medallion

» Tee Dee .049 w/stunt tank. New in box.

» Silver Stunt Tank

» Cox stunt tank

» Odd Stunt Tank?

» Tee Dee .049 w/stunt tank. New in box.

» Silver Stunt Tank

» Cox stunt tank

» Odd Stunt Tank?

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules