Log in

Search

Latest topics

» Here we go again... another Lawn-Boyby rsv1cox Today at 6:40 pm

» My Cox .049 Marine inboard engine

by roddie Today at 2:48 pm

» Help Pee Wee tank cap .020

by rdw777 Today at 12:38 pm

» **VOTE-ON-THE-NEXT-COX-ENGINE-OF-THE-MONTH** (May 2024)

by Admin Today at 10:31 am

» Revivng Some Childhood Classics

by GTO455 Today at 8:11 am

» Jim Walkers FireBee - This is going to be fun

by rsv1cox Today at 7:29 am

» Post your Older books

by rsv1cox Yesterday at 7:51 pm

» EXTREMELY RARE COX THIMBLE DROME PROTOTYPE "BLACK WIDOW" GAS MODEL AIRPLANE

by rsv1cox Yesterday at 6:58 pm

» I brake for Turtles....

by rsv1cox Yesterday at 6:38 pm

» Ball - Socket Joints

by Ken Cook Yesterday at 3:06 pm

» A little nostalgia…

by MauricioB Yesterday at 2:32 pm

» A new useful transport vehicle

by davidll1984 Yesterday at 10:32 am

Cox Engine of The Month

Engine build and dismantle ideas

Page 1 of 1

Engine build and dismantle ideas

Engine build and dismantle ideas

Hi All,

Some thoughts on building and dismantling Cox engines or any engine for that matter. I understand many of the methods and ideas on the forum are proven methods used and deloped against old, forgotten, and often abused engines, hence the need for methods such as heat and or my favorite which I havent seen mentioned so much "brute force and ignorance". Lol.

My ideas and suggestions come from racing two stroke yamaha TZ grand prix bikes. Where we had safety issues as well as the need to regularly do partial rebuilds. Piston rings every race meeting, pistons about every 3 race meetings and crankshaft rebuilds every 500 miles including practice miles. We worked with many different metals from chrome or nikasil lined barrels, Titanium con-rods, and many bolts were titanium, as well as the cast " Hiroshima wonder metal", and chrome molly.

Starting with new parts and maintaining them is a very different situation to that many in this forum find themselves in, but here are some things I learned from another sport where the parts and engines were generally new and less abused. Lol. Some of the ideas I got direct from the Japanese factory engine mechanics when asked to help out by doing laps on their bikes to test tires.

No Silicon. No Silicon near engines. Straight silicon tends to form into little balls inside your engine when used on various parts for various reasons, and those little balls always find a hole to block, generally an oil gallery or such. Blown crank or gearbox, etc... not so bad on a cox motor, less little holes to block. I have seen it suggested to use silicon to seal barrels all kinds of things. There are better ways I believe. Some products have silicon in them but have other chemicals in them and dont behave in this way. I tended to use permatex non hardening aviation gasket liquid sealant and yamabond to seal things up. Preferably perfect surfaces and new gaskets, and sometimes still a bit of permatex which meant definitely new gasket each time. But NO pure silicon

Bolts, studs, screws, nuts etc, all were dipped in the wonder oil 'trans fluid' before assembly and probably tightening with a torque wrench. The oil stopped the bolts etc. seizing up inside the dissimilar metals and seemed to do wonders for preserving threads that were being constantly undone and done up. Trans fluid was also used for storing parts. clean the part, wipe over with trans fluid, wrap in a rag, and its still good years later. No WD40. WD40 is nasty stuff, use when you must, but clean completely off after. As a side note, we used trans fluid in our straight cut six speed manual gearboxes, it handled heat and pressure better, got in everywhere, didnt foam up, less resistance to the gears turning, so better speed and came out cleaner, which tells its own story. We ran dry clutches so that wasnt an issue in doing it.

Lock-wire. fantastic method. stops things undoing, coming loose and falling off, like you gearbox drain undoing during a race or your break caliper bolts coming loose etc. it was checked heavily in scrutineering where they checked certain items were lock-wired.

I have read in forum topics where people have had issues with things like cylinders, heads,.... coming loose. lock-wire them with really really thin lockwire. you need to be able to drill two very small holes close together if possible and on different parts and then lock-wire them together. Permatex non hardening aviation gasket liquid sealant used very sparingly will stop a cylinder rotating but will dismantle without heat.

JB-Weld can be a great product it seems very similar to a Yamaha product we used to use mostly when very heavily modifying barrels. I cant remember its name now, but it was like aluminum in a paste that was mixed with other stuff and wonders could be performed. We could machine off the cast metal inlets that held the carbys and build brand new new really big inlets by machining it when it was set. we also went to the extend where we wanted transfer ports that would be wider than the barrel so we could use this stuff and then machine it as part of the barrel once it was set. I assume it is much like JB weld which I have not yet used. One really serious problem we found with this stuff was that if it wasnt mixed, set and cured to perfection in the correct conditions, nice dry non humid days, it could look perfect, machine perfect, and seem to run perfect, untill you got up into very high sustained revs say down a long straight and it would start sucking air and you would blow an engine to pieces. The stuff might be a bit porous but only when the pressures were high was it noticeable. This was not the standard result of using the stuff, but it certainly happened to some unlucky teams.

So to me and my ways. new or newish engine. Pull apart, inspect, clean every part, cleaning is when you find little things you otherwise miss. thats why I cleaned my race bike. clean the part, check the lock-wire, check the bolt, nut is done up. cleaning is great for reliability! use lock-wire on things that might come loose or tend to spin, this is better than doing them up super tight, which just stretches the thread and next time you need to do even more super tight..... Lock-wire or use a lightweight sealant as suggested above, stops spinning, stops air leaks. use trans fluid on threads, pull apart and clean thoroughly now and then, and then re-assemble. Use new gaskets!!!! yes, use new gaskets or just dont bother pulling apart and cleaning. Lol. get the leftover fuel out of your engine, tank and lines at the end of the day. Its not nice stuff for anything but burning in a combustion chamber. Run your engine as recommended by the manufacturer and it will be reliable and do what you want. If your going to mod an engine, dont be half hearted, your already outside of recommended specs for reliable known running, so build a bloody hand-grenade motor you can be really proud of Lol. :-)

My rambling personal thoughts that may be utter rubbish.

If they help you out at all that is great, if not, no harm done. :-)

Take it easy.

Cheers,

Gary

Some thoughts on building and dismantling Cox engines or any engine for that matter. I understand many of the methods and ideas on the forum are proven methods used and deloped against old, forgotten, and often abused engines, hence the need for methods such as heat and or my favorite which I havent seen mentioned so much "brute force and ignorance". Lol.

My ideas and suggestions come from racing two stroke yamaha TZ grand prix bikes. Where we had safety issues as well as the need to regularly do partial rebuilds. Piston rings every race meeting, pistons about every 3 race meetings and crankshaft rebuilds every 500 miles including practice miles. We worked with many different metals from chrome or nikasil lined barrels, Titanium con-rods, and many bolts were titanium, as well as the cast " Hiroshima wonder metal", and chrome molly.

Starting with new parts and maintaining them is a very different situation to that many in this forum find themselves in, but here are some things I learned from another sport where the parts and engines were generally new and less abused. Lol. Some of the ideas I got direct from the Japanese factory engine mechanics when asked to help out by doing laps on their bikes to test tires.

No Silicon. No Silicon near engines. Straight silicon tends to form into little balls inside your engine when used on various parts for various reasons, and those little balls always find a hole to block, generally an oil gallery or such. Blown crank or gearbox, etc... not so bad on a cox motor, less little holes to block. I have seen it suggested to use silicon to seal barrels all kinds of things. There are better ways I believe. Some products have silicon in them but have other chemicals in them and dont behave in this way. I tended to use permatex non hardening aviation gasket liquid sealant and yamabond to seal things up. Preferably perfect surfaces and new gaskets, and sometimes still a bit of permatex which meant definitely new gasket each time. But NO pure silicon

Bolts, studs, screws, nuts etc, all were dipped in the wonder oil 'trans fluid' before assembly and probably tightening with a torque wrench. The oil stopped the bolts etc. seizing up inside the dissimilar metals and seemed to do wonders for preserving threads that were being constantly undone and done up. Trans fluid was also used for storing parts. clean the part, wipe over with trans fluid, wrap in a rag, and its still good years later. No WD40. WD40 is nasty stuff, use when you must, but clean completely off after. As a side note, we used trans fluid in our straight cut six speed manual gearboxes, it handled heat and pressure better, got in everywhere, didnt foam up, less resistance to the gears turning, so better speed and came out cleaner, which tells its own story. We ran dry clutches so that wasnt an issue in doing it.

Lock-wire. fantastic method. stops things undoing, coming loose and falling off, like you gearbox drain undoing during a race or your break caliper bolts coming loose etc. it was checked heavily in scrutineering where they checked certain items were lock-wired.

I have read in forum topics where people have had issues with things like cylinders, heads,.... coming loose. lock-wire them with really really thin lockwire. you need to be able to drill two very small holes close together if possible and on different parts and then lock-wire them together. Permatex non hardening aviation gasket liquid sealant used very sparingly will stop a cylinder rotating but will dismantle without heat.

JB-Weld can be a great product it seems very similar to a Yamaha product we used to use mostly when very heavily modifying barrels. I cant remember its name now, but it was like aluminum in a paste that was mixed with other stuff and wonders could be performed. We could machine off the cast metal inlets that held the carbys and build brand new new really big inlets by machining it when it was set. we also went to the extend where we wanted transfer ports that would be wider than the barrel so we could use this stuff and then machine it as part of the barrel once it was set. I assume it is much like JB weld which I have not yet used. One really serious problem we found with this stuff was that if it wasnt mixed, set and cured to perfection in the correct conditions, nice dry non humid days, it could look perfect, machine perfect, and seem to run perfect, untill you got up into very high sustained revs say down a long straight and it would start sucking air and you would blow an engine to pieces. The stuff might be a bit porous but only when the pressures were high was it noticeable. This was not the standard result of using the stuff, but it certainly happened to some unlucky teams.

So to me and my ways. new or newish engine. Pull apart, inspect, clean every part, cleaning is when you find little things you otherwise miss. thats why I cleaned my race bike. clean the part, check the lock-wire, check the bolt, nut is done up. cleaning is great for reliability! use lock-wire on things that might come loose or tend to spin, this is better than doing them up super tight, which just stretches the thread and next time you need to do even more super tight..... Lock-wire or use a lightweight sealant as suggested above, stops spinning, stops air leaks. use trans fluid on threads, pull apart and clean thoroughly now and then, and then re-assemble. Use new gaskets!!!! yes, use new gaskets or just dont bother pulling apart and cleaning. Lol. get the leftover fuel out of your engine, tank and lines at the end of the day. Its not nice stuff for anything but burning in a combustion chamber. Run your engine as recommended by the manufacturer and it will be reliable and do what you want. If your going to mod an engine, dont be half hearted, your already outside of recommended specs for reliable known running, so build a bloody hand-grenade motor you can be really proud of Lol. :-)

My rambling personal thoughts that may be utter rubbish.

If they help you out at all that is great, if not, no harm done. :-)

Take it easy.

Cheers,

Gary

bakergw- Account Deactivated by Owner

- Posts : 76

Join date : 2020-09-20

Re: Engine build and dismantle ideas

Re: Engine build and dismantle ideas

Whilst your ideas are all valid-I think you may have overlooked the issue of scale here....things like lockwires may work very well on a 10mm bolt....but when you're dealing with a 2-56 screw for example-cross drilling for a lockwire becomes a nonsense-let alone finding castellated nuts in our sizes!....and in the Cox engine range we are dealing with that sort of size for assembly screws. Some form of antiseize compound may be appropriate in some uses, thread lockers in others. mountings and propeller balance tend to be overlooked as sources of vibration-and a good amount of attention paid to these two aspects yield dividends. that and using the correct tools correctly....FWIW I use metal bearers on my larger FF models-as do many control line racing type designs such as team race and rat race class models-and of course CL speed models use full length metal pans-but that sort of thing is not really practical in the 1/2A engine and smaller regimes

ChrisM

'ffkiwi'

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 362

Join date : 2018-07-10

Location : Wellington, NZ

Re: Engine build and dismantle ideas

Re: Engine build and dismantle ideas

Good points Gary, and a page right out of my do and don't do book.

Silicone, I have seen engines (mostly British) clogged with the stuff. WD40 number one on my don't use list. ATF is marvelous and has uses outside automatic transmissions.

Good info. - Bob

Silicone, I have seen engines (mostly British) clogged with the stuff. WD40 number one on my don't use list. ATF is marvelous and has uses outside automatic transmissions.

Good info. - Bob

rsv1cox- Top Poster

Posts : 10603

Join date : 2014-08-18

Location : West Virginia

Re: Engine build and dismantle ideas

Re: Engine build and dismantle ideas

WD 40 is the crappyist crap in a can I have ever seen. Stopped using it 30 years ago. I don’t know how they can sell that stuff. Must be a lot of Karens but it grocery stores.

Bob no more Remoil you got stash?

Bob no more Remoil you got stash?

crankbndr- Top Poster

- Posts : 3073

Join date : 2011-12-10

Location : Homestead FL

Re: Engine build and dismantle ideas

Re: Engine build and dismantle ideas

I agree wholeheartedly Gary, I also agree with Crank concerning WD-40.

Cribbs74- Moderator

Posts : 11895

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Engine build and dismantle ideas

Re: Engine build and dismantle ideas

M'y self have expérience in larger hi performance engine from dirt bike To cars wit turbo nitrous oxide 2 stroke engine modification after big accident crash wit 450 Yamaha atv left al of that pétrole gear head behind me can feel m'y back vertébrale spine painful if bad weather coming tank god y am ok Not paralised and can work afer 7 years stil Feel the damage now y drive cars drift m'y 91Nissan skyline som time out land just for the fun and blast of Good memory wen y was younger in Perfect chape tink basic tunig aply To Most type of engine but in the Word of smal engines can achive very hi reving Monster machine like 30 000 rpm range plus and cox is one of them and use wd40 no Not inside my engine y do use for plastiques flexnes y tink its best Not use oil wit détergent in or enykind of dissolvant in engines

davidll1984- Diamond Member

- Posts : 2293

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Engine build and dismantle ideas

Re: Engine build and dismantle ideas

crankbndr wrote:WD 40 is the crappyist crap in a can I have ever seen. Stopped using it 30 years ago. I don’t know how they can sell that stuff. Must be a lot of Karens but it grocery stores.

Bob no more Remoil you got stash?

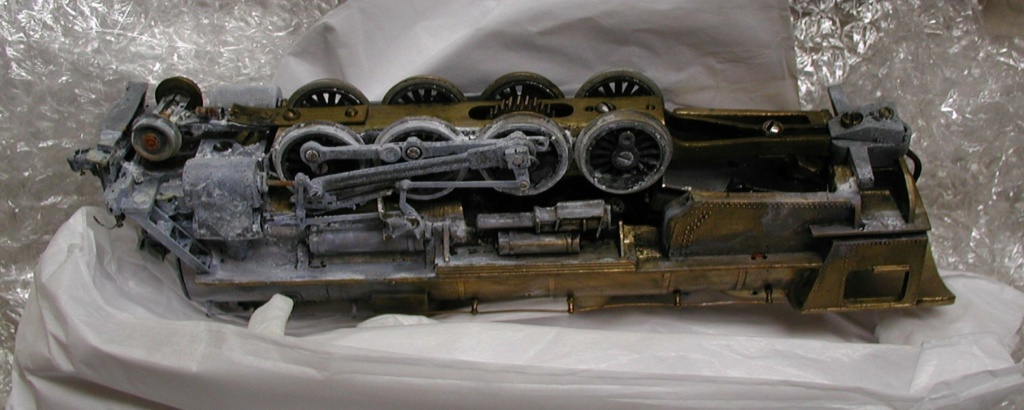

This one was as bad, but I don't have a "before" picture. Saturated with Remoil, wrapped and left to cure for a few days before I take it apart.

But to repeat my WD40 story. Many, many, years ago I thought it a good idea to spray my stored glow engines with the stuff. Months later (summertime) I got them out to use and they were all gummed up. Had to disassemble and clean again before I could use them. Switched to Remoil and no more problems. But, I usually also put a drop of after run oil in the cylinder too and flip it over a few times.

And, David you are a wild and crazy guy.

rsv1cox- Top Poster

Posts : 10603

Join date : 2014-08-18

Location : West Virginia

Re: Engine build and dismantle ideas

Re: Engine build and dismantle ideas

Remington has been broken up and parts sold off in bankruptcy, Ruger bought Marlin, Vista (Federal) bought the ammo. Palmetto State Armory bought Storm Lake Barrels and some other brands. Some unknown entity bought Remington firearms. One of my go to oils Remoil is not available here anymore. Trying a new spray oil from Seafoam now.

crankbndr- Top Poster

- Posts : 3073

Join date : 2011-12-10

Location : Homestead FL

Re: Engine build and dismantle ideas

Re: Engine build and dismantle ideas

Gary, please excuse the topic drift.

Hadn't thought of that. Will be looking for Remoil spray my next visit to Walmart. Remington went to a new spray can some time ago that I don't like as much. Difficult to modulate the spray head. I gave up buying the little plastic flip tops, too expensive. So now I just fill it with air tool oil. A little heavier but acceptable.

I did find a sellers picture of the locomotive above.

After a couple of days wrapped in Remoil and with a little CRC contact cleaner on the commutator it took right off on the test track. Remoil - miracle stuff. Still have to take it apart.

Still have to take it apart.

Ya got me started.....

Hadn't thought of that. Will be looking for Remoil spray my next visit to Walmart. Remington went to a new spray can some time ago that I don't like as much. Difficult to modulate the spray head. I gave up buying the little plastic flip tops, too expensive. So now I just fill it with air tool oil. A little heavier but acceptable.

I did find a sellers picture of the locomotive above.

After a couple of days wrapped in Remoil and with a little CRC contact cleaner on the commutator it took right off on the test track. Remoil - miracle stuff.

Ya got me started.....

rsv1cox- Top Poster

Posts : 10603

Join date : 2014-08-18

Location : West Virginia

Re: Engine build and dismantle ideas

Re: Engine build and dismantle ideas

Just carful if use remington oil dont swap cans is one for cleaning the bore of canon very bad for coper Reed valve y se two cox killer oil can  never use hope nitro for engine Not same stuf use only nitrometane never use such crap in m'y engine guns and fire arm use Most of the time solvant for lead coper y use cliper oil if chort of blue oil after run wd40 To disolve rust crap on part y dont like gun brusch for canon in cylinder y use plastiques brush Nice train by the way rsv1cox

never use hope nitro for engine Not same stuf use only nitrometane never use such crap in m'y engine guns and fire arm use Most of the time solvant for lead coper y use cliper oil if chort of blue oil after run wd40 To disolve rust crap on part y dont like gun brusch for canon in cylinder y use plastiques brush Nice train by the way rsv1cox

never use hope nitro for engine Not same stuf use only nitrometane never use such crap in m'y engine guns and fire arm use Most of the time solvant for lead coper y use cliper oil if chort of blue oil after run wd40 To disolve rust crap on part y dont like gun brusch for canon in cylinder y use plastiques brush Nice train by the way rsv1cox

never use hope nitro for engine Not same stuf use only nitrometane never use such crap in m'y engine guns and fire arm use Most of the time solvant for lead coper y use cliper oil if chort of blue oil after run wd40 To disolve rust crap on part y dont like gun brusch for canon in cylinder y use plastiques brush Nice train by the way rsv1cox

davidll1984- Diamond Member

- Posts : 2293

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Engine build and dismantle ideas

Re: Engine build and dismantle ideas

davidll1984 wrote:Just carful if use remington oil dont swap cans is one for cleaning the bore of canon very bad for coper Reed valve y se two cox killer oil cannever use hope nitro for engine Not same stuf use only nitrometane never use such crap in m'y engine guns and fire arm use Most of the time solvant for lead coper y use cliper oil if chort of blue oil after run wd40 To disolve rust crap on part y dont like gun brusch for canon in cylinder y use plastiques brush Nice train by the way rsv1cox

Hi David, Thanks - yes, not the same, Hoppees Nitro bore cleaning solvent is much different than Remoil. Two different things and applications.

Bob

rsv1cox- Top Poster

Posts : 10603

Join date : 2014-08-18

Location : West Virginia

Re: Engine build and dismantle ideas

Re: Engine build and dismantle ideas

Post a reply Empty by rsv1cox on Sat Nov 28, 2020 2:49 am

Gary, please excuse the topic drift.

Lol, thats what forums are for! :-) people read stuff have ideas and the discussion heads where it does. Lol

I have chronic ADHD and very extreme formally diagnosed dyslexia and as a chief engineer at an aerospace company I drive people mental with my topic drift when talking, and starting conversations in the middle and forgetting the first part. Lol.

Its all good stuff :-) I better go do the forum tutorial to learn how to reply properly to an individual post.

Take it easy.

Gary

Gary, please excuse the topic drift.

Lol, thats what forums are for! :-) people read stuff have ideas and the discussion heads where it does. Lol

I have chronic ADHD and very extreme formally diagnosed dyslexia and as a chief engineer at an aerospace company I drive people mental with my topic drift when talking, and starting conversations in the middle and forgetting the first part. Lol.

Its all good stuff :-) I better go do the forum tutorial to learn how to reply properly to an individual post.

Take it easy.

Gary

bakergw- Account Deactivated by Owner

- Posts : 76

Join date : 2020-09-20

Re: Engine build and dismantle ideas

Re: Engine build and dismantle ideas

Thanks for understanding Gary, topic drift happens here and most accept it as a matter of course. I'm a frequent perpetrator and usually (but not always) forgiven.

I had a person in my section that was dyslexic. Every now and then she would get something upside down or backwards but that was rare. She was special and one of the most competent and dependable people that I had.

I had a person in my section that was dyslexic. Every now and then she would get something upside down or backwards but that was rare. She was special and one of the most competent and dependable people that I had.

rsv1cox- Top Poster

Posts : 10603

Join date : 2014-08-18

Location : West Virginia

Re: Engine build and dismantle ideas

Re: Engine build and dismantle ideas

Hey Gary, I didn't see ya come in.

WELCOME TO THE FORUM!!

Good group here, friendliest forum on the net.

Bob

WELCOME TO THE FORUM!!

Good group here, friendliest forum on the net.

Bob

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Re: Engine build and dismantle ideas

Re: Engine build and dismantle ideas

Thanks Bob and all,

Yes I agree the forum is very friendly. unusual for a net forum these days. I usually almost make a point of not being involved in forums for the usual forum reason problems. The cox model engines and flying them has really given me a great interest again. I had been reading the forum and was surprised that people were discussing the engines and associated things with such enthusiasm but there seemed to be room for different ideas/experiences circumstances of things working, not working, etc. under different conditions, mixed with a wealth of experience and knowledge built up by many over many years. So I thought I would join and try posting and glad I did. I thought I might take some flak and or hits for some of my ideas and thoughts, but there seems to be room for ideas here. Hmmmm sounds like a great engineering approach, like I try to teach engineering Grads and Interns when they come into my team at work. Lol.

Thanks!

Take it easy.

Gary

Yes I agree the forum is very friendly. unusual for a net forum these days. I usually almost make a point of not being involved in forums for the usual forum reason problems. The cox model engines and flying them has really given me a great interest again. I had been reading the forum and was surprised that people were discussing the engines and associated things with such enthusiasm but there seemed to be room for different ideas/experiences circumstances of things working, not working, etc. under different conditions, mixed with a wealth of experience and knowledge built up by many over many years. So I thought I would join and try posting and glad I did. I thought I might take some flak and or hits for some of my ideas and thoughts, but there seems to be room for ideas here. Hmmmm sounds like a great engineering approach, like I try to teach engineering Grads and Interns when they come into my team at work. Lol.

Thanks!

Take it easy.

Gary

bakergw- Account Deactivated by Owner

- Posts : 76

Join date : 2020-09-20

Similar topics

Similar topics» How to build an electric starter, using a Cox. 010 engine :)

» New User - Engine Build

» Dismantle the Cox conrod from the piston. Help

» Build centrifugal clutch for Cox engine myself?

» How to build a high-performance Cox .049 Engine

» New User - Engine Build

» Dismantle the Cox conrod from the piston. Help

» Build centrifugal clutch for Cox engine myself?

» How to build a high-performance Cox .049 Engine

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules