Log in

Search

Latest topics

» **VOTE-ON-THE-NEXT-COX-ENGINE-OF-THE-MONTH** (May 2024)by Admin Today at 10:31 am

» Revivng Some Childhood Classics

by GTO455 Today at 8:11 am

» My Cox .049 Marine inboard engine

by rsv1cox Today at 7:41 am

» Jim Walkers FireBee - This is going to be fun

by rsv1cox Today at 7:29 am

» Help Pee Wee tank cap .020

by MauricioB Yesterday at 10:11 pm

» Post your Older books

by rsv1cox Yesterday at 7:51 pm

» EXTREMELY RARE COX THIMBLE DROME PROTOTYPE "BLACK WIDOW" GAS MODEL AIRPLANE

by rsv1cox Yesterday at 6:58 pm

» I brake for Turtles....

by rsv1cox Yesterday at 6:38 pm

» Ball - Socket Joints

by Ken Cook Yesterday at 3:06 pm

» A little nostalgia…

by MauricioB Yesterday at 2:32 pm

» A new useful transport vehicle

by davidll1984 Yesterday at 10:32 am

» TAPLIN TWIN 7ccm

by grant.symes Yesterday at 3:29 am

Cox Engine of The Month

Back to the Yak - Yak-9 Build, Part II

Page 5 of 9

Page 5 of 9 •  1, 2, 3, 4, 5, 6, 7, 8, 9

1, 2, 3, 4, 5, 6, 7, 8, 9

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

Rusty, when you use spackle is it the Home Depot patch a hole in the wall stuff? Is it an overall grain filler or just for larger dents?

Jim

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 56

Location : Colorado

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

It's the super light weight stuff for patching holes in the wall or leveling where an area of paint has peeled, like when you fix water damage on the ceiling. I only use it to level dents and dings on the plane. It looks like the builder of my Shoestring used it all over to fill in the weave on whatever fabric he covered the balsa with. It weighs next to nothing. I made fillets on a model with it once and brushed it with CA and it was instantly rock hard... and no longer sandable.JPvelo wrote:Rusty, when you use spackle is it the Home Depot patch a hole in the wall stuff? Is it an overall grain filler or just for larger dents?

Jim

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

I asked the same question at Stunthangar; whether I should use flat color(white on mine) for the under coats for greater adhesion and less weight, and also whether gloss was even necessary on the final coat for a glassy finish if it's going to be covered with clear.roddie wrote:... I was also curious about the weight of "gloss" vs. using a flat finish.. only to be top-coated by several thin coats of clear (Lustre-Kote)...

I got one reply from Doc Holiday, but it was only a vague guess. So I suppose I'll have to buy some flat paint and try both on some test pieces, top it with clear and see what it looks like. I already have white gloss paint. That will answer the appearance question, but not the weight/adhesion question.

I was going to Monokote the wing tonight but it got too late. I'll get it done this weekend.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

Since Jim said he was thinking of spackle, Polycrylic, and tissue for the Acromaster I figured I'd post pics of the Yak after that treatment. While sanding, I made a couple of small dents and a scratch that need filling, but it's ready for primer. The weather has prevented me from painting, so over the last week I made some brass strap hinges for the flap coupler and did some detail sanding, but not much.

The doublers aren't covered with anything yet. It looks like like there's a sharp angle where it meets the fuse, but it's really a gradual taper. I'm going to smooth it further with some microballoons.

The paper still covers the stab slot which will stay until after painting. You can see some of the tissue overlap along the bottom but can't feel it.

There was a bad dent in the top right behind the doublers, but the spackle and tissue hid it nicely. And the spackling can be seen through the tissue on the front of the canopy, but it's smooth as glass.

I hope to cover the wing and glue it on today. Still haven't done anything to the tail feathers since spackling the rough edges. Later, I'll Monokote the Stab and paint the fin and rudder.

The doublers aren't covered with anything yet. It looks like like there's a sharp angle where it meets the fuse, but it's really a gradual taper. I'm going to smooth it further with some microballoons.

The paper still covers the stab slot which will stay until after painting. You can see some of the tissue overlap along the bottom but can't feel it.

There was a bad dent in the top right behind the doublers, but the spackle and tissue hid it nicely. And the spackling can be seen through the tissue on the front of the canopy, but it's smooth as glass.

I hope to cover the wing and glue it on today. Still haven't done anything to the tail feathers since spackling the rough edges. Later, I'll Monokote the Stab and paint the fin and rudder.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

Yeah man! It is looking good.

Cribbs74- Moderator

Posts : 11895

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

It better be, I've been fiddling with it since June.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

RknRusty wrote:It better be, I've been fiddling with it since June.

Well, I didn't want to say anything, but since your brought it up...

Cribbs74- Moderator

Posts : 11895

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

I rescued the Yak skeleton from the wet shop and worked on Monokoting it while watching football.

First I checked the wing for any twist. I used a method Ken taught me; took two straight edges and placed one on each end of the wing against the last rib. Look down the length of the wing and eyeball the straight edges and if they're aligned with each other the wing is straight. If they're crisscrossed the wing is twisted and it tells you which way to untwist it. There was a very slight misalignment so I twisted and held the wing and re-checked. After a couple of tries it was straight. A couple of hours later it was still straight, so I started applying the Kote. I got the bottom panels done and will do the top ones tomorrow while watching the Panthers & 49ers.

The Yak has simple curves at the tip and the film went on without much trouble. All one piece without having to cut any botches out or make separate sheets for the wingtips. I got it on really tight and it looks like I already shrunk it, but I have not because I want the whole thing covered before I tighten it up. I don't ever use a gun any more, just the iron with no sock. That's how I did the Shoestring and my last 1/2A, which believe it or not was the Refried Bean.

I'm going to add some aluminum colored strips next to the fuse on top of the center sheeting. Then the red stars.

Here's what it looks like so far.

First I checked the wing for any twist. I used a method Ken taught me; took two straight edges and placed one on each end of the wing against the last rib. Look down the length of the wing and eyeball the straight edges and if they're aligned with each other the wing is straight. If they're crisscrossed the wing is twisted and it tells you which way to untwist it. There was a very slight misalignment so I twisted and held the wing and re-checked. After a couple of tries it was straight. A couple of hours later it was still straight, so I started applying the Kote. I got the bottom panels done and will do the top ones tomorrow while watching the Panthers & 49ers.

The Yak has simple curves at the tip and the film went on without much trouble. All one piece without having to cut any botches out or make separate sheets for the wingtips. I got it on really tight and it looks like I already shrunk it, but I have not because I want the whole thing covered before I tighten it up. I don't ever use a gun any more, just the iron with no sock. That's how I did the Shoestring and my last 1/2A, which believe it or not was the Refried Bean.

I'm going to add some aluminum colored strips next to the fuse on top of the center sheeting. Then the red stars.

Here's what it looks like so far.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

I had a good night in the shop. After talking to Jim about his Akromaster, I decided to put another coat of Polycrylic on my fuselage.

Some minor twist had returned to the wing so I used a hair dryer to heat the LE center joint, which is epoxied and glassed, and gently twisted it and held it until it cooled. It came out perfect. I used the steel rods from my wing jig as straight edges to check for any criss-cross between the ends and it came out perfect and stayed straight all day.

I finished covering the wing and shrunk the film and it looks great. Since tomorrow's flying has been cancelled, I'll sand and prime the fuse and get that wing glued on. One nice thing about a low winger is it's easy to paint with the wing in place. When it finally starts to look like an airplane I'll take some pictures. That'll be pretty soon.

Rusty

Some minor twist had returned to the wing so I used a hair dryer to heat the LE center joint, which is epoxied and glassed, and gently twisted it and held it until it cooled. It came out perfect. I used the steel rods from my wing jig as straight edges to check for any criss-cross between the ends and it came out perfect and stayed straight all day.

I finished covering the wing and shrunk the film and it looks great. Since tomorrow's flying has been cancelled, I'll sand and prime the fuse and get that wing glued on. One nice thing about a low winger is it's easy to paint with the wing in place. When it finally starts to look like an airplane I'll take some pictures. That'll be pretty soon.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Cribbs74- Moderator

Posts : 11895

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

Okay, Cribbs, hope you haven't been eating that popcorn too fast.Cribbs74 wrote:

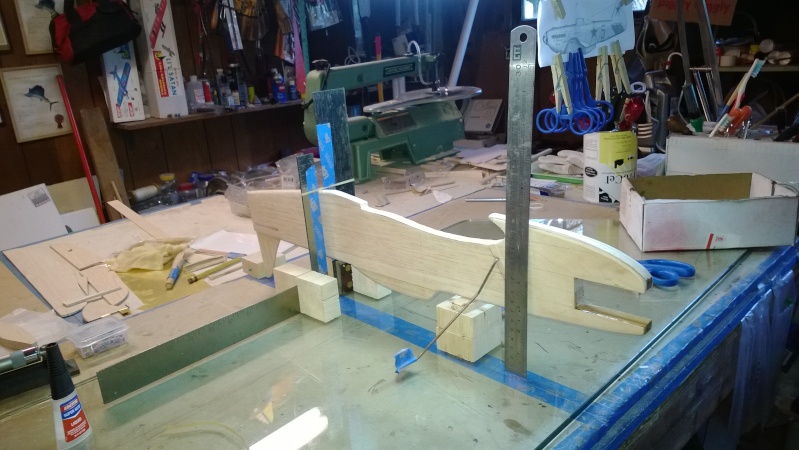

Time to glue the wing. I've been out of commission with a blown elbow since my last installment. That gave me time to think too much about jigging it up and getting the wing in perfectly straight. I came up with all kinds of fancy ideas, but when I went out to the shop, I said the hell with it and improvised. I have the fuse locked in with the lead and trailing incidence lines exactly 144mm off the glass, and all alignment blocks are superglued to the glass. After a quick break I'll lay the wing in and shim it up square and mix some 60 minute epoxy with sawdust to fill the gaps and glue that mother in place... hopefully not upside down.

I have Microballoons I bought for the filets, but I thought that wouldn't be as strong as sawdust for filling gaps in the wing seat. If anyone has an opinion on that, let me know. It'll be an hour or two before I start gluing. I can go with the balloons if y'all think it's structurally sound.

Here's my fancy fuse jig:

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

Well I did have a bowl of popcorn two nights this weekend. The real stuff, not the micro bag fluff.

I think a lot would depend on how much gap you have to fill. If you have 80-90% wood to wood contact I wouldn't think you could go wrong either way.

I think a lot would depend on how much gap you have to fill. If you have 80-90% wood to wood contact I wouldn't think you could go wrong either way.

Cribbs74- Moderator

Posts : 11895

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

Rusty, the most problematic area of the Yak is the little section of the fuse that wraps around the leading edge. That area will crack and will always crack. I don't know how much experience you've had with microballoons. The more you use, the weaker the fillet will be. All will be fine and you will have no worries. My first Yak was built 35 years ago and is still going strong with yellow glue and Ambroid. Seeing that your using epoxy on the wing to fuse joint, that's light years ahead of what everyone else used back in the day. If you have gaps, I would lay the fuse on it's side, mix more epoxy and hit it with a heat gun and let it run into the gap. Put the microballoons and epoxy mix and "Get er Dun"!!

Ken Cook- Top Poster

- Posts : 5476

Join date : 2012-03-27

Location : pennsylvania

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

Ken, I installed one shim made from tapered 1/16" balsa and slid it all the way around the LE joint where you mentioned, and that's about all the gap there was. I had previously built up the whole saddle with thin shaped strips glued on with Titebond. I mixed the 60 minute epoxy with some fine dust from my tabletop belt sander and painted the whole strip. And when I got to the wrapped LE, I thickened it with more sawdust for that area. As far as I can tell, it looks like a tight fit all the way around. Of course the whole bottom is held on by mostly nothing unless the air scoop provides some support. I'll decide if it needs any additional strengthening when I glue it on.

I put some sharpie dots all the way around the wing's edges and checked about 10 times with a square and it's all the same height off the glass. I think I have the best wing I've ever made, mated as straight as I ever have before. This is my first full build of a big plane and I've taken "meticulous" to ridiculous lengths. No way the Skyray will take this much work. So I'm down to attaching control surfaces, tank mount, engine placement, cheek(with cool aluminum exhaust pipes), paint and... well I'm getting there.

Rusty

I put some sharpie dots all the way around the wing's edges and checked about 10 times with a square and it's all the same height off the glass. I think I have the best wing I've ever made, mated as straight as I ever have before. This is my first full build of a big plane and I've taken "meticulous" to ridiculous lengths. No way the Skyray will take this much work. So I'm down to attaching control surfaces, tank mount, engine placement, cheek(with cool aluminum exhaust pipes), paint and... well I'm getting there.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

That does look good man!

I hope it's a ton of fun. Bout time to do some break in runs on that .35

I hope it's a ton of fun. Bout time to do some break in runs on that .35

Cribbs74- Moderator

Posts : 11895

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

Wood against wood, no gaps. Just a little masking tape left over but the filet will hide it. The white patch is CA hardened spackling.

This was the only gap and this tapered shim filled it and forced the wing into alignment. I'll leave the tab in case I want to run a strip under the belly. I'll sand it off after that.

I worked on finishing the flap coupling today and it got too cold to paint. Here she is now.

This was the only gap and this tapered shim filled it and forced the wing into alignment. I'll leave the tab in case I want to run a strip under the belly. I'll sand it off after that.

I worked on finishing the flap coupling today and it got too cold to paint. Here she is now.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

Looking good!

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 56

Location : Colorado

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

Man Rusty, this may be your prettiest build yet!

Good idea on thin shims, it's something I may do in the future.

Ron

Good idea on thin shims, it's something I may do in the future.

Ron

Cribbs74- Moderator

Posts : 11895

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

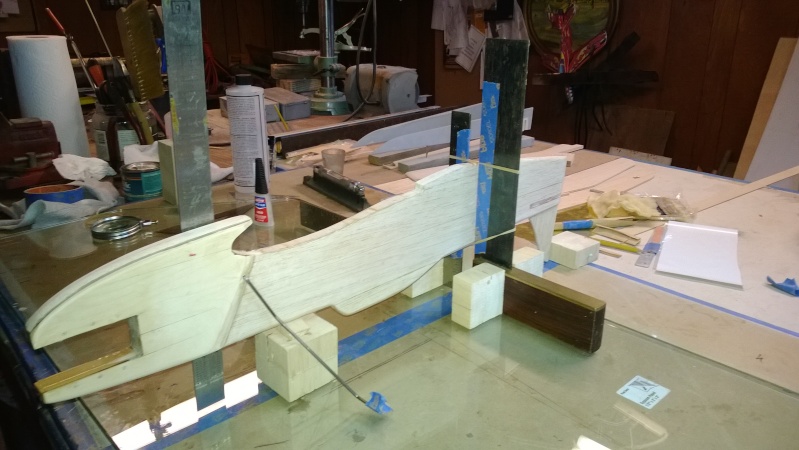

My Lucky Boxes work!

Academically, I knew they would, but it was a relief to actually see it demonstrated on the table. I shaped them and squared them up from what they look like in the picture below. I capped them top and bottom today. The outboard caps extend to accept the flap horn stress. When I put the coupler wire in them to test, they have more than enough back and forth swing, and Zero up and down slop. It won't look like something Al Rabe built, but when it's painted I think it'll still look pretty professional. Tonight the white paint goes on and the ten hinges will be installed.

Academically, I knew they would, but it was a relief to actually see it demonstrated on the table. I shaped them and squared them up from what they look like in the picture below. I capped them top and bottom today. The outboard caps extend to accept the flap horn stress. When I put the coupler wire in them to test, they have more than enough back and forth swing, and Zero up and down slop. It won't look like something Al Rabe built, but when it's painted I think it'll still look pretty professional. Tonight the white paint goes on and the ten hinges will be installed.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

I am having a bit of trouble understanding what exactly lucky boxes are. From your picture it appears that the flap control arm cutouts are cut out a little larger which I assume is to allow movement in all directions to keep the flaps from binding.

So my question is how is the control arm locked in place once installed? What keeps them from just falling free or pulling out?

Ron

So my question is how is the control arm locked in place once installed? What keeps them from just falling free or pulling out?

Ron

Cribbs74- Moderator

Posts : 11895

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

Oh, I never saw your reply, Ron. I was about to post about today's work and found it. Since the coupler wire is not glued in place, I made brass hinges that will be fixed to the trail edge of the main wing. Here's what they look like.Cribbs74 wrote:I am having a bit of trouble understanding what exactly lucky boxes are. From your picture it appears that the flap control arm cutouts are cut out a little larger which I assume is to allow movement in all directions to keep the flaps from binding.

So my question is how is the control arm locked in place once installed? What keeps them from just falling free or pulling out?

Ron

There's the hole the coupler is inserted into.

Here it is starting to look like a plane.

Earlier I had it with the flaps on it too, it looks good. I was getting measurements for the control horn placement. Tonight I'll make a ply reinforcement fot the elevator horn and minwax it. Fter it dries, tomorrow, another snow day for me to play, I'll Monokote the tail feathers, glue them and maybe even hook up the linkages. That's a little ambitious, but I'm on a roll now.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

Looks fantastic Rusty,

Thanks for the explaination, I see how they function now.

Thanks for the explaination, I see how they function now.

Cribbs74- Moderator

Posts : 11895

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

I want to glue the hinges into the flaps tonight. I also want to pin them as reinforcement. What do you guys use for that? Music wire, straight pins, toothpicks...? I'm leaning toward straight pins with a plain head. I think it would look the best.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

One thing I learned was how to install them with epoxy properly. This completely did away with pinning. The hinge must be scarified and I have a carbide riff that does a good job for that. I then use a toothpick and dip one end in Vaseline. I apply the Vaseline to the barrel of the hinge and heat with a heat gun and this makes it completely flow into the barrel. The hinges are now cleaned vigorously with acetone or lacquer thinner and a acid brush just on the glue areas and not the barrel that was just lubricated. I use 1/64th ply and make a biscuit like tool to apply 30 min epoxy into the hinge slots. Prior to installing the hinge, I make sure no residual epoxy is left on the flap, elevator, trailing edge. Insert the hinge and align it properly. This sounds very tedious but when your doing several it's not so bad. I never had a hinge fail doing this. I've also drilled additional holes in the hinge leaf when I saw fit to do so as some manufacturers didn't always provide enough holes. Ken

Ken Cook- Top Poster

- Posts : 5476

Join date : 2012-03-27

Location : pennsylvania

Page 5 of 9 •  1, 2, 3, 4, 5, 6, 7, 8, 9

1, 2, 3, 4, 5, 6, 7, 8, 9

Similar topics

Similar topics» Yak-9 Build, part one

» Part ID: Back Plate Extension?

» Custom 1963 Cox PT-19 and HELLO!

» Shoestring flights - I brought it home! Now, can I do it again?

» Guillows Cessna 150 build circa 1970 (Build Log)

» Part ID: Back Plate Extension?

» Custom 1963 Cox PT-19 and HELLO!

» Shoestring flights - I brought it home! Now, can I do it again?

» Guillows Cessna 150 build circa 1970 (Build Log)

Page 5 of 9

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules