Log in

Search

Latest topics

» Fox .35 Modifications by Onelife Today at 6:47 pm

» Happy Anzac Day!

by 706jim Today at 6:44 pm

» Project Cox .049 r/c & Citabrian Champion

by MauricioB Today at 4:08 pm

» Jim Walkers FireBee - This is going to be fun

by rsv1cox Today at 3:56 pm

» Revivng Some Childhood Classics

by rsv1cox Today at 7:17 am

» Introducing our Cox .049 TD Engines

by getback Today at 6:20 am

» Roddie's flat-bottomed boat..

by Levent Suberk Today at 12:23 am

» Cox powered jet-pump for model Sprint Boat

by roddie Yesterday at 10:25 pm

» Micro Draco Gets to Fly on a Beautiful Morning.

by rdw777 Yesterday at 8:15 pm

» Jim Walker Firebaby

by rdw777 Yesterday at 8:06 pm

» Hydro-bat by Vic Smeed: engine probs

by GallopingGhostler Yesterday at 5:12 pm

» Roddie-Rigger.. a 2005 original design

by roddie Yesterday at 3:39 pm

Cox Engine of The Month

3D Printing

Page 1 of 4

Page 1 of 4 • 1, 2, 3, 4

3D Printing

3D Printing

I have been looking at 3D printers for some time and they always seemed to be very expensive. Especially "shop bought" or pre assembled jobs.

Why? There are quite a few custom parts that can be made - servo holders, bell cranks, engine mounts ............(more ideas welcome).

Some only use PLA - this seems to be a delicate plastic while quite a few can handle ABS (higher temperature to melt, heated bed required).

After many seconds of research there appeared to be a few problems selecting a printer - apart from cost!

A lot of the pre contructed printers have parts that are not easily available making repairs and maintenance a trifle expensive and modifications (different sized printing head) not possible.

So I perused the various forums (none a patch on this one - creep, crawl!) and realised that you can easily build your own for a fraction of the cost.

Chicken and egg - the self build machines use brackets made by 3D printing. These can be found though - there are many entrepenurial 3D enthusiasts around.

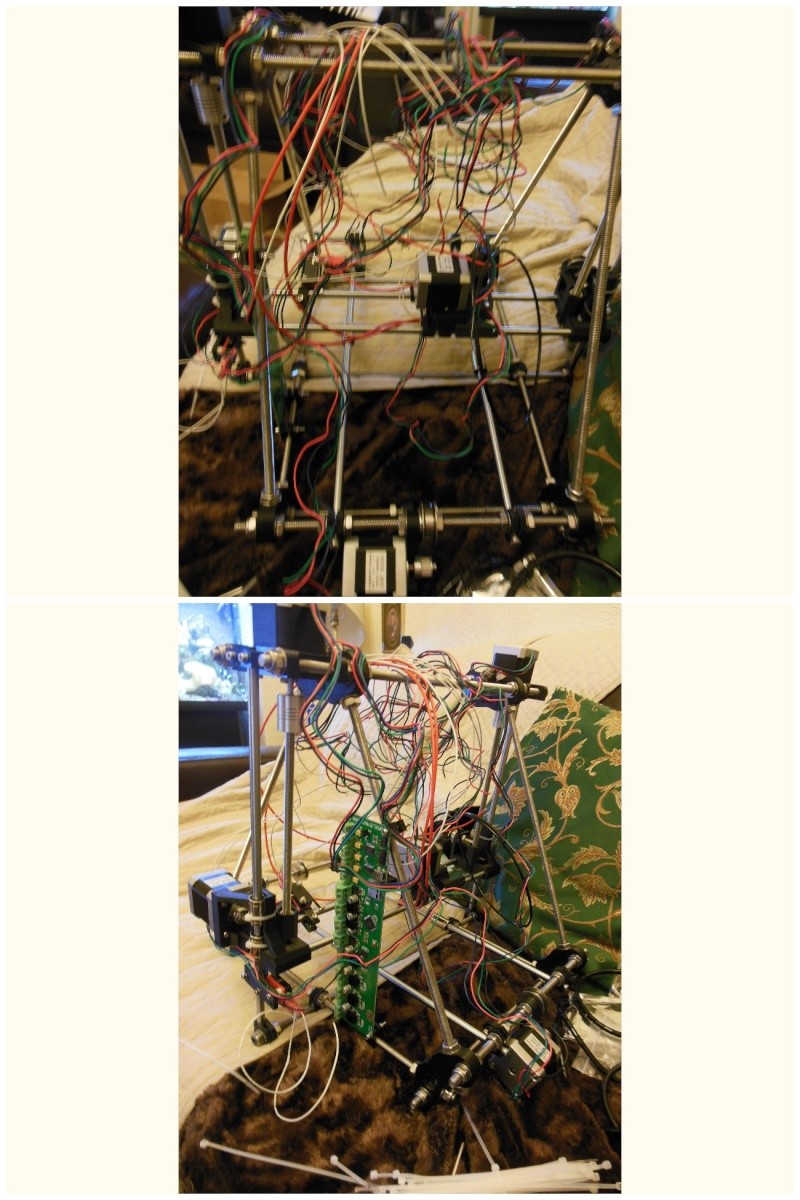

The frames are simple threaded rods and the sliding parts mounted on smooth aluminium rods.

Stepper motors, wiring, control boards are all easily found from a multitude of sources on the interweb and fleabay.

There are many, many build manuals on the interweb - they have material checklistss and are very detailed.

http://garyhodgson.com/reprap/prusa-mendel-visual-instructions/

However, there are many different variations of mounting brackets.

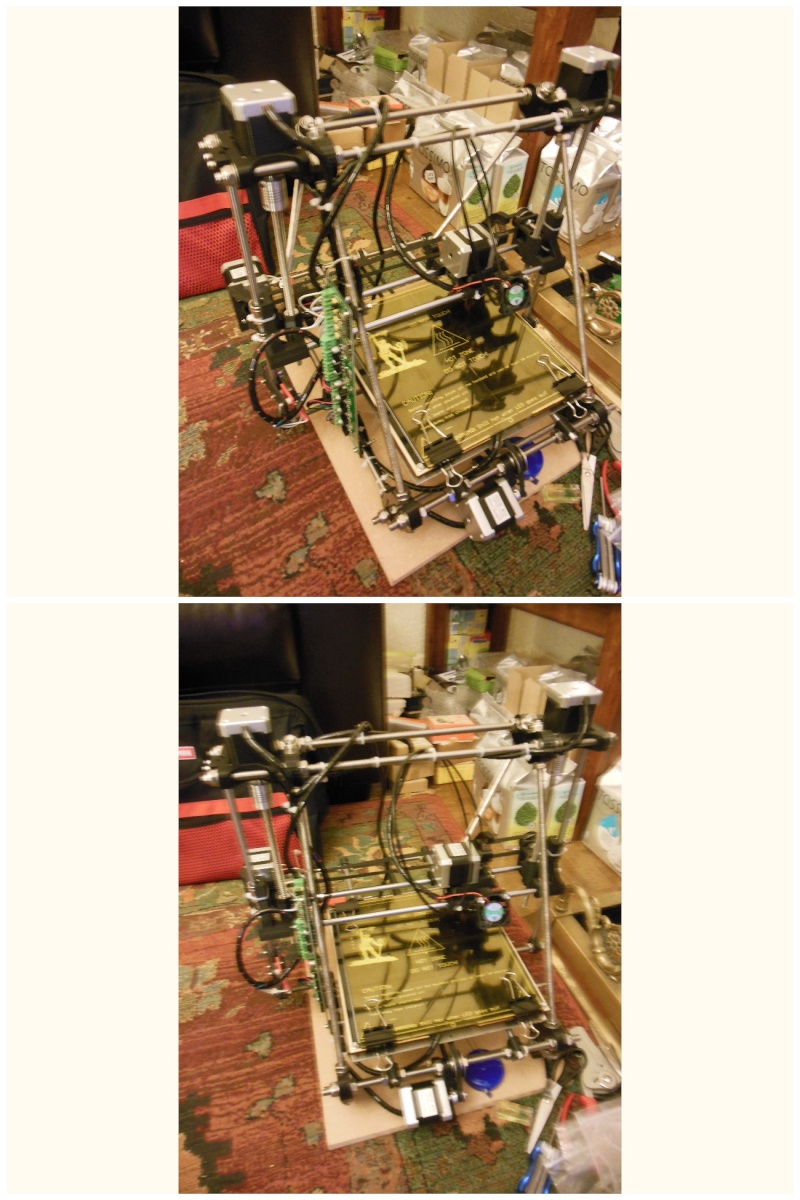

Afeter a few more seconds thinking about it - I decided to build the Prusa Mendel Iteration 2.

Why? It looks easy and is better than Iteration 1. There is an Iteration 3 but it doesn't have the "skeletal" look of the previous versions.

Also, I watched a derogatory U tube video with some chap criticising it and I decided that I didn't like him.

https://www.youtube.com/watch?v=IQuUqd9ldUU

This "printer" is not perfect but as an introduction and buildable for well under £200 ($300) - I made another of my milli second impulse decisions and decided to source parts and give it a whirl. There are also numerous hints, tips and improvements on U tube and enthusiasts web sites.

All my parts arrived and I started building yesterday. The mechanical and framework is 90% complete and I now am ready to embark on the electrickery.

If anyone is interested - I will update the post. It is likely to be slow though (I have spent 4 hours on it so far) as I have just had both eyes operated on. Day after returning from Chicago - holes laser drilled!!!!!!

Why? There are quite a few custom parts that can be made - servo holders, bell cranks, engine mounts ............(more ideas welcome).

Some only use PLA - this seems to be a delicate plastic while quite a few can handle ABS (higher temperature to melt, heated bed required).

After many seconds of research there appeared to be a few problems selecting a printer - apart from cost!

A lot of the pre contructed printers have parts that are not easily available making repairs and maintenance a trifle expensive and modifications (different sized printing head) not possible.

So I perused the various forums (none a patch on this one - creep, crawl!) and realised that you can easily build your own for a fraction of the cost.

Chicken and egg - the self build machines use brackets made by 3D printing. These can be found though - there are many entrepenurial 3D enthusiasts around.

The frames are simple threaded rods and the sliding parts mounted on smooth aluminium rods.

Stepper motors, wiring, control boards are all easily found from a multitude of sources on the interweb and fleabay.

There are many, many build manuals on the interweb - they have material checklistss and are very detailed.

http://garyhodgson.com/reprap/prusa-mendel-visual-instructions/

However, there are many different variations of mounting brackets.

Afeter a few more seconds thinking about it - I decided to build the Prusa Mendel Iteration 2.

Why? It looks easy and is better than Iteration 1. There is an Iteration 3 but it doesn't have the "skeletal" look of the previous versions.

Also, I watched a derogatory U tube video with some chap criticising it and I decided that I didn't like him.

https://www.youtube.com/watch?v=IQuUqd9ldUU

This "printer" is not perfect but as an introduction and buildable for well under £200 ($300) - I made another of my milli second impulse decisions and decided to source parts and give it a whirl. There are also numerous hints, tips and improvements on U tube and enthusiasts web sites.

All my parts arrived and I started building yesterday. The mechanical and framework is 90% complete and I now am ready to embark on the electrickery.

If anyone is interested - I will update the post. It is likely to be slow though (I have spent 4 hours on it so far) as I have just had both eyes operated on. Day after returning from Chicago - holes laser drilled!!!!!!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 69

Location : England

Re: 3D Printing

Re: 3D Printing

I too looked long and hard at the 3D printers that are made of rods and printed parts.

I decided on a sturdier design. Although the cost was greater I feel the added rigidity of the frame will yield better prints.

http://store.makerstoolworks.com/printer-kits/mendelmax-2-0-standard-kit/

There will be lots of tweaking to get things right and I am still printing upgrades and tweaking after 3 months.

I decided on a sturdier design. Although the cost was greater I feel the added rigidity of the frame will yield better prints.

http://store.makerstoolworks.com/printer-kits/mendelmax-2-0-standard-kit/

There will be lots of tweaking to get things right and I am still printing upgrades and tweaking after 3 months.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 48

Location : Neenah, WI

Re: 3D Printing

Re: 3D Printing

That looks like a very tidy printer. Do you know what controller board it uses and what software are you running?

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 69

Location : England

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 69

Location : England

Re: 3D Printing

Re: 3D Printing

It has a rambo controller board in it along with a GLCD kit in it. I use Ponterface and Slic3r for the software. With the GLCD kit I can run the printer standalone with the SD card interface in it.

Looks to be coming along nicely. The wiring is one of the most difficult things to keep tidy and still be able to work on the machine.

Looks to be coming along nicely. The wiring is one of the most difficult things to keep tidy and still be able to work on the machine.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 48

Location : Neenah, WI

Re: 3D Printing

Re: 3D Printing

I have finished the build now. The controller board is a Melzi.

I have downloaded Pronterface and Repetier (along with the driver software) and once I have fine tuned the printer, I will try both.

The Rambo board is more feature packed than the Melzi but, if this follows my CNC builds, I will be chopping and changing.

Thanks for the info Jason

I have downloaded Pronterface and Repetier (along with the driver software) and once I have fine tuned the printer, I will try both.

The Rambo board is more feature packed than the Melzi but, if this follows my CNC builds, I will be chopping and changing.

Thanks for the info Jason

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 69

Location : England

Re: 3D Printing

Re: 3D Printing

What material are you using?

It might be stronger to do the layering in the other direction...some testing might be in order.

Phil

It might be stronger to do the layering in the other direction...some testing might be in order.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: 3D Printing

Re: 3D Printing

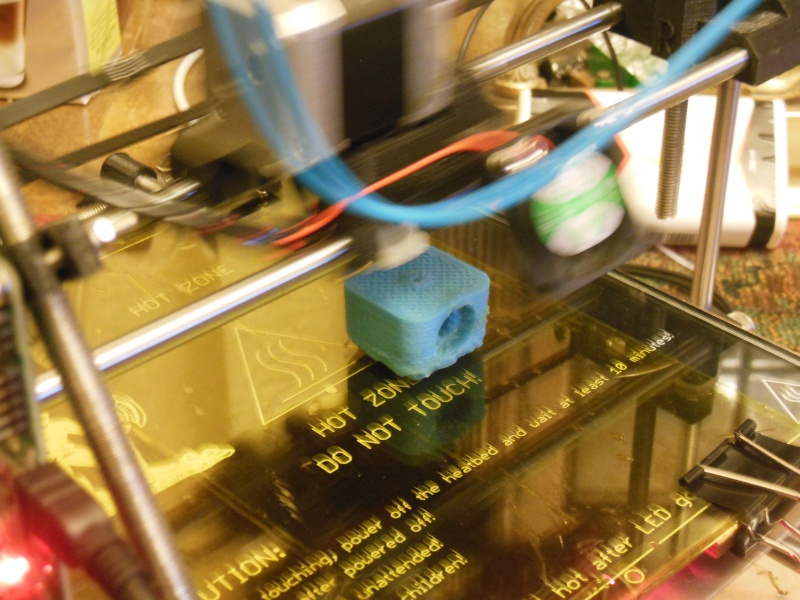

It is ABS plastic. The mounts are also very strong - I cannot snap them. Don't be fooled by the "ridges" they aren't like the grain in wood. The plastic is all melted together.pkrankow wrote:What material are you using?

It might be stronger to do the layering in the other direction...some testing might be in order.

Phil

The ridges are a product of using too large a diameter melt (0.5mm) on a small area with sharp turns and too thick a layering.

There are a lot of adjustments to do. It is like piping icing decoration on a cake. It is not possible the form a sharp corner easily. The smaller the print the harder it is.

I sawed through one of the bearers and it was solid. I couldn't cut it with a knife.

They would all look better if produced with a smaller nozzle and a thinner layer.

I have made a few as test pieces and am going to machine them. Some "smooth" them out using acetone.

It would also be difficult to build the bearers any other way. The plastic is molten when being laid - if not supported the arms would end up as a pile of goo on the table.

You also need quite a large area for the part to remain "stck" to the table and not move.

Ian

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 69

Location : England

Re: 3D Printing

Re: 3D Printing

Looking good. ABS is the most difficult to learn with. I had issues with my ABS filament as it had water in it. ABS will absorb water out of the air. I had to bake mine in the oven for 8 hours on the lowest oven setting to bake the moisture out of it. I was getting steam pockets and plastic bubbles.

What temperature where you running at? I run ABS at 230 to 235C. The hot plate I have set to 100C. PLA at 180C with the plate at 80C. I print on Kapton but there is ABS glue that can be used to prig right on the glass. I haven't tried that yet.

PLA is a lot easier to work with but it's not rated for outdoor stuff.

What temperature where you running at? I run ABS at 230 to 235C. The hot plate I have set to 100C. PLA at 180C with the plate at 80C. I print on Kapton but there is ABS glue that can be used to prig right on the glass. I haven't tried that yet.

PLA is a lot easier to work with but it's not rated for outdoor stuff.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 48

Location : Neenah, WI

Re: 3D Printing

Re: 3D Printing

I have the bed set at 110c and the first layers at 235c, the rest at 230c. No fan for the first few layers.Jason_WI wrote:Looking good. ABS is the most difficult to learn with. I had issues with my ABS filament as it had water in it. ABS will absorb water out of the air. I had to bake mine in the oven for 8 hours on the lowest oven setting to bake the moisture out of it. I was getting steam pockets and plastic bubbles.

What temperature where you running at? I run ABS at 230 to 235C. The hot plate I have set to 100C. PLA at 180C with the plate at 80C. I print on Kapton but there is ABS glue that can be used to prig right on the glass. I haven't tried that yet.

PLA is a lot easier to work with but it's not rated for outdoor stuff.

Kapton tape and I was advised to use ABS slurry - ABS dissolve in acetone. I am currently dissolving ABS scrap in acetone to make this.

However, "hairspray" was also recommended and so when the SWTSMB isn't looking I "borrow" the aerosol for a quick squirt. It works a treat and she hasn't noticed the smell yet! Just thinks melting ABS smells nice.

I use the hairspray on Kapton tape and will do the same with the slurry.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 69

Location : England

Re: 3D Printing

Re: 3D Printing

Where did you find the .stl files for the engine mounts?

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 48

Location : Neenah, WI

Re: 3D Printing

Re: 3D Printing

The engine mounts that Jason produced are much crisper than mine. I need to spend more time on my printer setup and practice.

The crankcase is a mighty fine effort - the ones I produced (I didn't post any pictures) looked saggy. Still, I was pleased for first efforts.

Jason's are very neat.

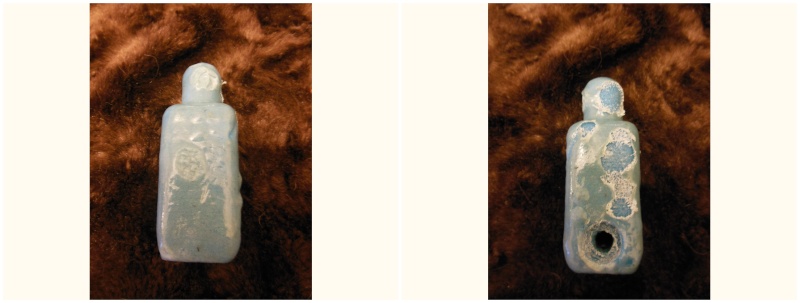

I will be working on a few more designs - but for now, here is the Cox hybrid progress. It is a cross between an Enya and a Keil crankcase modded for Cox components.

For "prototyping" the 3D printer is a marvel. A physical 3D object like the crankcase Jason produced makes visualisation of a build much easier than a diagram or picture. They can even be used to produce moulds for castings.

Thank you Jason for posting your prints. It is a spur for me to improve mine.

The crankcase is a mighty fine effort - the ones I produced (I didn't post any pictures) looked saggy. Still, I was pleased for first efforts.

Jason's are very neat.

I will be working on a few more designs - but for now, here is the Cox hybrid progress. It is a cross between an Enya and a Keil crankcase modded for Cox components.

For "prototyping" the 3D printer is a marvel. A physical 3D object like the crankcase Jason produced makes visualisation of a build much easier than a diagram or picture. They can even be used to produce moulds for castings.

Thank you Jason for posting your prints. It is a spur for me to improve mine.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 69

Location : England

Re: 3D Printing

Re: 3D Printing

great job Ian , out of my league for sure ! are you and Jason I think it was going to hook su up with some plastic engines that are quieter . LOL

nice job Eric

nice job Eric

nice job Eric

nice job Eric

getback- Top Poster

Posts : 10114

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: 3D Printing

Re: 3D Printing

Prints are looking alot better. Is this PLA or ABS?

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 48

Location : Neenah, WI

Re: 3D Printing

Re: 3D Printing

This is ABS. I am going to have to print it again though.Jason_WI wrote:Prints are looking alot better. Is this PLA or ABS?

I decided that I wanted to smooth it. Read about using acetone --- dipped it ......... not a good result!

will post pictures tonight.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 69

Location : England

Re: 3D Printing

Re: 3D Printing

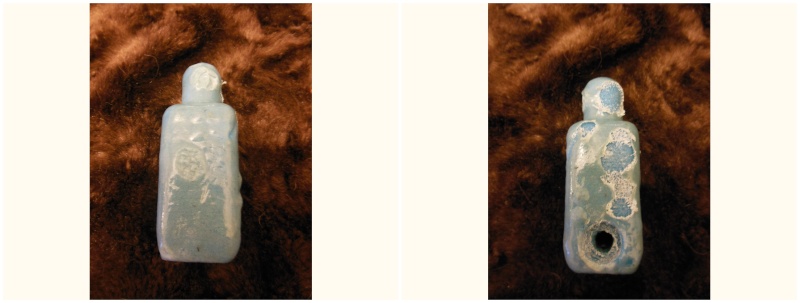

How not to smooth an ABS print - I dipped the part in acetone. I was really pleased it went smooth and shiny --- then as it dried the newly formed skin bubbled and blistered!

Anyway, I took the opportunity for a slight redesign - smaller with less curved edges and I am ready to continue

Any ideas what it is going to be? It is something to do with model aeroplanes!

Anyway, I took the opportunity for a slight redesign - smaller with less curved edges and I am ready to continue

Any ideas what it is going to be? It is something to do with model aeroplanes!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 69

Location : England

Re: 3D Printing

Re: 3D Printing

Dang! I thought it was an arrow shaft linkage connector in the 12/5 post. No Idea now though.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: 3D Printing

Re: 3D Printing

Drive for a car?

Phil

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Page 1 of 4 • 1, 2, 3, 4

Similar topics

Similar topics» PT-19 3D printing

» Printing out .pdf plans to scale

» Printing on Tissue

» Printing in tile program

» Todays Cox 3D Printing Adventures....

» Printing out .pdf plans to scale

» Printing on Tissue

» Printing in tile program

» Todays Cox 3D Printing Adventures....

Page 1 of 4

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules