Log in

Search

Latest topics

» **VOTE-ON-THE-NEXT-COX-ENGINE-OF-THE-MONTH** (May 2024)by akjgardner Today at 6:10 am

» Jim Walkers FireBee - This is going to be fun

by rdw777 Today at 5:42 am

» My Cox .049 Marine inboard engine

by MauricioB Today at 4:50 am

» Help Pee Wee tank cap .020

by MauricioB Yesterday at 10:11 pm

» Post your Older books

by rsv1cox Yesterday at 7:51 pm

» EXTREMELY RARE COX THIMBLE DROME PROTOTYPE "BLACK WIDOW" GAS MODEL AIRPLANE

by rsv1cox Yesterday at 6:58 pm

» I break for Turtles....

by rsv1cox Yesterday at 6:38 pm

» Revivng Some Childhood Classics

by Ken Cook Yesterday at 6:27 pm

» Ball - Socket Joints

by Ken Cook Yesterday at 3:06 pm

» A little nostalgia…

by MauricioB Yesterday at 2:32 pm

» A new useful transport vehicle

by davidll1984 Yesterday at 10:32 am

» TAPLIN TWIN 7ccm

by grant.symes Yesterday at 3:29 am

Cox Engine of The Month

tailwheel idea for 1/2 A

Page 1 of 1

tailwheel idea for 1/2 A

tailwheel idea for 1/2 A

I wanted a "Beefy" tail-wheel for my CEF Speed Contest model, so I thought about what I had available in the shop, that was small and round... I also needed a tire. I came up with a small rubber grommet and O-ring combo. I bushed the hub with brass tubing pcs.; reduced to fit the tail-gear axle. The "right size" O-ring will seat firmly in the rubber grommets' channel, with a little twisting.

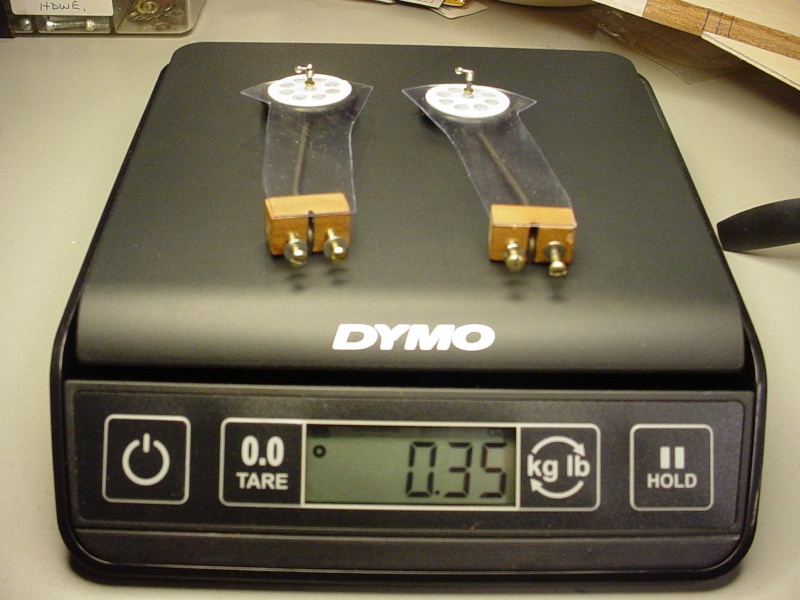

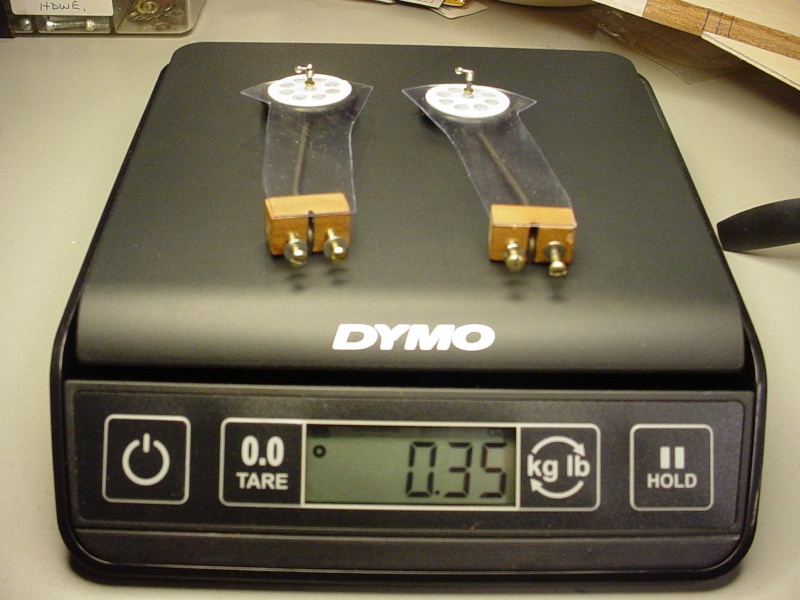

Where 1/2A landing gear commonly consists of 1/16" dia. music wire, I like to use the "spring" retainers that were once available from Goldberg and Sig. (you can wind your own coil/spring using .015" music-wire around a .047" music-wire pin held in a vise/fixture) When you have "bushed hubs" on your wheels, you should make hubcaps... This can be done with thin plastic sheet (trim color.. possibly) Drill 1/16" dia. holes along one edge of the sheet, spaced about 5/16" apart.. then center a hand-held hole-punch with ea. drill-hole, and punch-out your hubcaps. They're durable, lightweight, act as washers... and look nicer (using a spring-retainer)... than a wheel collar or solder blob. The hubcap fits snug over the 1/16" dia. music-wire axle, and hides/covers axle bushing sleeves up to 1/4" dia.

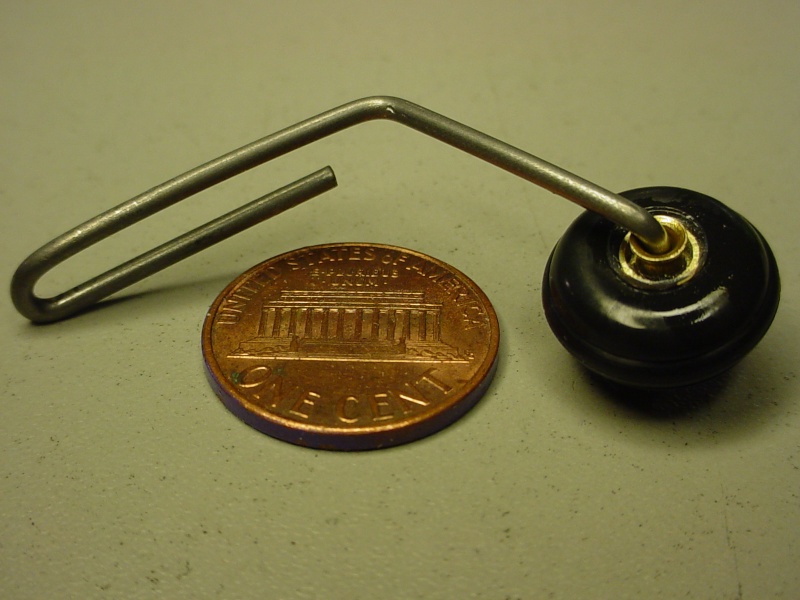

This tail-wheel is just over 1/2" dia. (.570") with the O-ring tire seated in the rubber grommets' channel. The hub-reduction is a series of brass tubing sleeves down to .065" i.d. for the .062" music-wire axle. The hubcaps are thin aluminum discs I had kicking around.

Below are the "spring style" wheel retainers that were once available... (Sig PN SH-121-sadly discontinued)

It's easy to make wheels from stuff you may already have in the shop.

Roddie

Where 1/2A landing gear commonly consists of 1/16" dia. music wire, I like to use the "spring" retainers that were once available from Goldberg and Sig. (you can wind your own coil/spring using .015" music-wire around a .047" music-wire pin held in a vise/fixture) When you have "bushed hubs" on your wheels, you should make hubcaps... This can be done with thin plastic sheet (trim color.. possibly) Drill 1/16" dia. holes along one edge of the sheet, spaced about 5/16" apart.. then center a hand-held hole-punch with ea. drill-hole, and punch-out your hubcaps. They're durable, lightweight, act as washers... and look nicer (using a spring-retainer)... than a wheel collar or solder blob. The hubcap fits snug over the 1/16" dia. music-wire axle, and hides/covers axle bushing sleeves up to 1/4" dia.

This tail-wheel is just over 1/2" dia. (.570") with the O-ring tire seated in the rubber grommets' channel. The hub-reduction is a series of brass tubing sleeves down to .065" i.d. for the .062" music-wire axle. The hubcaps are thin aluminum discs I had kicking around.

Below are the "spring style" wheel retainers that were once available... (Sig PN SH-121-sadly discontinued)

It's easy to make wheels from stuff you may already have in the shop.

Roddie

Re: tailwheel idea for 1/2 A

Re: tailwheel idea for 1/2 A

Perfect used to make those retainers as well. Good job on that tail wheel.

Ron

Ron

Cribbs74- Moderator

Posts : 11895

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: tailwheel idea for 1/2 A

Re: tailwheel idea for 1/2 A

Cribbs74 wrote:Perfect used to make those retainers as well. Good job on that tail wheel.

Ron

"used to" being the key word.. Thanks Ron. I do have a bunch of them. They're .017" dia. wire. I'll bet that the springs that are used in Cox Tanked engines' fuel pick-up tubes could be cut into sm. pcs. and used for even smaller axles. Bend "one coil" out 180 degrees using a pin and tweezers, and you have the same design.

Here's the finished tail-wheel for my Rare-Bear Speed Contest entry. The hubcaps are drilled and hole punched from clear plastic sheet, and the inner axle is a small shortened lead-out guide. The bracket will be pinned into the fuse with 2 round toothpicks; cut-off flush with the wire and reinforced with a strip of fiberglass window screen and brushed with epoxy. I tack the screen 1st with CA.. then I use a flux brush with bristles cut short, to brush the epoxy into the screen. This makes for a very strong, lightweight and neat patch.

oh.. and the O-ring tire can be changed if it ever wears out.

Roddie

Similar topics

Similar topics» Anyone knows this design?

» Is this ae Bad idea?

» Any idea what kit this is?

» Name our new engine!

» CEF site help needed

» Is this ae Bad idea?

» Any idea what kit this is?

» Name our new engine!

» CEF site help needed

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules